Documente Academic

Documente Profesional

Documente Cultură

Fenner 471 Friction Belt Installation Guide by CBC Australia

Încărcat de

Fanir ZTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fenner 471 Friction Belt Installation Guide by CBC Australia

Încărcat de

Fanir ZDrepturi de autor:

Formate disponibile

3

V & Wedge belt Installation Instructions

Friction Belts

“ONE SHOT” TENSIONING

Fenner Belts are built to ensure precise inher- BELT TENSION INDICATOR APPLIES

ent length and to stay matched during storage

and on the drive. Over many years , the principle SETTING FORCE AT MID-CENTRE DISTANCE

of “one-shot” tensioning has been verified by

successful drives the world over.

■ Install the belts to be a snug fit around the

pulleys. 16

pe mm

■ Spin the pulleys 3-4 revolutions to bed belts ce r 1 m defl

into the pulley grooves. nt

re etr ecti

dis e o on

(Note: if done manually, beware of finger tan f

ce The setting forces opposite are

entrapment between belts and pulleys)

designed to cover a wide range

■ Tension the belts to the 1.25x setting forces

from the table.

of drives. A precise setting

force for individual applications

■ Run the drive under load for 15-20 minutes.

can be calculated. Please con-

■ Stop the drive, check tension & reset to the

basic value (standard vee and wedge belts) if sult your local distributor or use

necessary. the ‘Fenner Select’ design soft-

CRE Plus & Quattro Plus belts should be reset ware at www.fptgroup.com.

to the 1.25x value. SETTING FORCES

With a drive that is properly designed for the

application there should be no need for further

attention during the life of the belts. Setting force to deflect belt

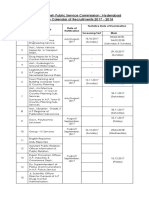

Belt 16 mm per metre of span

For short centre distance drives where the deflec- Section

tion of the belt is too small to measure accurately

it is recommended that both deflection and set- Small pulley Basic setting forces 1.25 x setting forces

diameter (mm) Newtons (N) kilograms (kgf) Newtons (N) kilograms (kgf)

ting force be doubled.

56 to 71 16 1.6 20 2.0

SPZ 75 to 90 18 1.8 22 2.2

Method of belt tensioning using 95 to 125 20 2.0 25 2.5

Fenner Belt Tension Indicator XPZ & QXPZ over 125 22 2.2 28 2.8

80 to 100 22 2.2 28 2.8

■ Calculate the deflection in mm on a basis of 16mm

per metre of centre distance. Centre distance SPA 106 to 140 30 3.0 38 3.9

(metres) x 16 = deflection (mm). 150 to 200 36 3.7 45 4.6

XPA & QXPA over 200 40 4.0 50 5.1

■ Set the lower marker ring at the deflection dis- 112 to 160 40 4.0 50 5.1

tance required in mm on the lower scale. SPB 170 to 224 50 5.1 62 6.3

■ Set the upper marker ring against the bottom edge 236 to 355 62 6.3 77 7.9

of the top tube. XPB& QXPB over 355 65 6.6 81 8.3

■ Place the belt tension indicator on top of the belt 224 to 250 70 7.1 87 8.9

at the centre of span, and apply a force at right SPC 265 to 355 92 9.4 115 12.0.0

angles to the belt, deflecting it to the point where & QXPC over 375 115 12.0.0 144 15.0.0

the lower marker ring is level with the top of an 8V 335 & above 150 15.0. 190 19.0.0

adjacent belt. Z 56 to 100 5 to 7.5 0.5 to 0.8

90

■ Read off the setting force value indicated by the A (& HA banded) 80 to 140 70 80

10 to 15 1.0 to 1.5 8 10 12 14

top edge of the upper marker ring. B 125 to 200 20 to 30 2.0 to 3.1

C 200 to 400 40 to 60 4.1 to 6.1

■ Compare this force to the kgf value shown in

D 355 to 600 70 to 105 7.1 to 10.7

the table.

■ If a Fenner Belt Tension Indicator is not avail-

able, a spring balance and rule will suffice. FENNER BELT TENSION INDICATOR

■ With banded belts use a bar across the band

width to ensure even distribution of the force

and divide the force measured by the number

70 80 90

of belts in the band for comparison with the 8 10 12 14

values in the table above.

NOTES: Deflection in mm Setting force in kgf

For single belt drives a straight edge should be placed

across the two pulleys to act as a datum for measuring

the amount of deflection. TROUBLE SHOOTING

If the measured force falls within the values given, Small radial cracks on belt side and base Whip during running

the drive should be satisfactory. A measured

force below the basic value indicates under- Generally caused by slippage due to insufficient Often caused by incorrect tensioning, particularly

tensioning. belt tension, but excessive heat and/or chemical on long centre drives. If a slightly higher (or lower)

fumes can also cause the same problem. tension does not cure the problem there may be

A new drive should be tensioned to the 1.25x a critical vibration frequency in the system which

Belt swelling or softening requires re-design or use of banded belts. Consult

value to allow for the normal drop in tension dur-

ing the running-in period. Caused by excessive contamination by oil, cer- FPT Technical Services.

tain cutting fluids, water or rubber solvent. Pulleys

After the drive has been running for 15–20 min-

utes, under load the tension should be checked Pulley groove wear can cause rapid belt failure.

and re-adjusted, if necessary. Check grooves for wear with a Fenner groove

gauge.

Registered Trade Mark of ERIKS Industrial Services

www.fptgroup.com

®

Fenner is a registered Trade Mark of Fenner PLC

All dimensions are in millimetres unless otherwise stated

www.fptgroup.com

Head Office: Amber Way, Halesowen, West Midlands. B62 8WG

3

Vee & Wedge belt Installation Instructions

Friction Belts

Although comparatively old in principle today’s ■ TENSIONING PULLEYS Tensioning pulley movemement must al-

belt drive is an extremely efficient method low for passing the belts over the outside

of transmitting power between prime mover If tensioning (jockey) pulleys are to be

diameter of one of the drive pulleys on

and machinery. used on wedge belt drives, they must be

installation, and should also allow for belt

It owes its present high performance stand- grooved pulleys working on the inside of

stretch/bedding in.

ards to many years of research and develop- the drive, preferably on the slack side. The

ment by engineers and technologists, leading pulley should be positioned as close as

to significant refinements in materials and possible to the large pulley. Flat tensioning

processes. The modern wedge belt drive is a

pulleys, bearing on the outside of the drive highly efficient power transmission

To derive maximum benefit from such ad- are permissible only with vee and not with

vances it is important that the simple instal- medium, but optimum perform-

lation and operation procedures set out here wedge belts. They should be positioned ance will not be achieved without

are closely followed. Making these routines within one third of the centre distance from correct tension and alignment.

standard practice will ensure optimum per- the small pulley.

formance and long, trouble-free life from

The tensioning pulley must have at least

Fenner belt drives.

the same diameter as the small pulley of

TAPER LOCK

the drive. All Fenner vee and wedge belt pulleys use Ta-

INSTALLATION per Lock shaft fixing. Detailed instructions for

■ PULLEYS fitting and dismounting Taper Lock products

Before assembling the drive, check the pul- are included with Taper Lock bushes.

ley grooves are free from scores or sharp

edges, and all dimensions conform to the 1 2 3 4

relevant standard. Angular Composite Axial Correct installation

Drive installation is straightforward with misalignment misalignment misalignment -both shafts and pul-

Taper Lock – but follow all steps on the leys are parallel and in

installation leaflet provided with every alignment.

Taper Lock bush.

■ ALIGNMENT

Good alignment of pulleys is important to

avoid belt flank wear. The diagrams oppo-

site show some of the common alignment

faults.

Pulley misalignment should not exceed 1/2

0

angular and 10mm / metre drive centre

distance, axial.

A laser alignment device is available, which

facilitates quick, easy and accurate pulley align-

ment - consult your authorised distributor.

■ BELT INSTALLATION

When the pulleys have been correctly

positioned on the shafts, the belts can be

installed to complete the drive. INSTALLATION AND

The drive centre distance should be re- TAKE-UP ALLOWANCE

duced prior to the installation of the belts

so that they may be fitted without the use Belt Installation Allowances Take

of force. Under no circumstances must Pitch Length -up

belts be prised into the grooves. Belts and

pulley grooves can easily be damaged by (mm) SPZ SPA SPB SPC 8V (mm)

using sharp tools to stretch the belts over Z A B C D

the pulley rim. 410 to 12530 5

The installation allowance given in the table 530 to 12840 10

opposite is the minimum recommended

reduction in centre distance for the vari- 850 to 11160 15

ous belt sections and lengths to allow for

correct fitting. 1170 to 11500 20

The take-up allowance given in the same 1510 to 11830 20 25

table should be added on to the calculated

centre distance to allow for belt stretch/ 1840 to 12170 30

bedding in.

2180 to 12830 25 40

■ GUARDS 2840 to 13500 30 50

Where guards are necessary it is desirable 3520 to 14160 50 60

to use mesh materials to permit adequate

ventilation. 4170 to 15140 65 70

Guards should be generously sized to allow 5220 to 16150 85

for incidental belt flap.

6180 to 17500 105

7600 to 18500 125

8880 to 10170 145

10600 to 12500 175

Registered Trade Mark of ERIKS Industrial Services

www.fptgroup.com

®

Fenner is a registered Trade Mark of Fenner PLC

All dimensions are in millimetres unless otherwise stated

www.fptgroup.com

Head Office: Amber Way, Halesowen, West Midlands. B62 8WG

S-ar putea să vă placă și

- T Verter n2 Series User Manual PDFDocument4 paginiT Verter n2 Series User Manual PDFرفيفان النشمي0% (1)

- 2017-02-22 - Application Installation of GeneratorsDocument60 pagini2017-02-22 - Application Installation of GeneratorsSelva Kumar CÎncă nu există evaluări

- Screw CompressorsDocument12 paginiScrew CompressorsAnu MalikÎncă nu există evaluări

- Gem 50 TD enDocument208 paginiGem 50 TD enIonut SomneaÎncă nu există evaluări

- AVR Features AGN023 - B PDFDocument6 paginiAVR Features AGN023 - B PDFAnonymous BBX2E87aHÎncă nu există evaluări

- SP275 50HZ Perkins Generator STAMFORDDocument4 paginiSP275 50HZ Perkins Generator STAMFORDsunshinemachineryÎncă nu există evaluări

- Fault Finding Manual: For Stamford AC GeneratorsDocument3 paginiFault Finding Manual: For Stamford AC GeneratorsAlexander OngÎncă nu există evaluări

- BE2000E BrochureDocument4 paginiBE2000E BrochureOrlando VeladoÎncă nu există evaluări

- ABB DrivesDocument36 paginiABB DrivesGurmeet SinghÎncă nu există evaluări

- Himoinsa BrochureDocument12 paginiHimoinsa BrochurePowerTechÎncă nu există evaluări

- Installation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVDocument14 paginiInstallation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVOmer HejeirÎncă nu există evaluări

- Abb Contactors Price List 01.06.2010Document39 paginiAbb Contactors Price List 01.06.2010Alok DahiyaÎncă nu există evaluări

- Corporate BrochureDocument9 paginiCorporate BrochureSarthak KathuriaÎncă nu există evaluări

- SB OffGrid TI en 41W PDFDocument4 paginiSB OffGrid TI en 41W PDFfalinhas_mansasÎncă nu există evaluări

- Powerwizard 1.0 & 2.0: Control Systems User ManualDocument18 paginiPowerwizard 1.0 & 2.0: Control Systems User ManualIslam ElMasryÎncă nu există evaluări

- 99 MTU 4000 SeriesDocument6 pagini99 MTU 4000 Serieswaleed yehiaÎncă nu există evaluări

- Air Circuit Breakers DW Series PDFDocument102 paginiAir Circuit Breakers DW Series PDFDeny PradanaÎncă nu există evaluări

- Manual PCS 3300 - GasDocument128 paginiManual PCS 3300 - GasO mecanico100% (2)

- Variable Frequency GeneratorDocument8 paginiVariable Frequency GeneratorSARAVANAÎncă nu există evaluări

- Alternator Voltage Regulator With Droop CT Connections: DescriptionDocument4 paginiAlternator Voltage Regulator With Droop CT Connections: Descriptionمصطفئ العراقي AlfailyÎncă nu există evaluări

- Shutdown Solenoids CatalogueDocument10 paginiShutdown Solenoids CataloguepevareÎncă nu există evaluări

- Big 40 WGDocument80 paginiBig 40 WGsquibgo100% (1)

- Voltas Hvac DivisionDocument11 paginiVoltas Hvac Divisionmails4gaurav360Încă nu există evaluări

- 002-004 Tapa de Cilindro-3Document34 pagini002-004 Tapa de Cilindro-3Jose Leandro Del ZarÎncă nu există evaluări

- Boosters Guide Brochure PDFDocument8 paginiBoosters Guide Brochure PDFpowermanagerÎncă nu există evaluări

- GCM01 Mu GB 12.2Document33 paginiGCM01 Mu GB 12.2Kaiser IqbalÎncă nu există evaluări

- SGPDocument5 paginiSGPgopala krishnanÎncă nu există evaluări

- Ec Fans: Operating ManualDocument48 paginiEc Fans: Operating ManualMihai Butnaru-Palade100% (1)

- Copeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACDocument3 paginiCopeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACjacc42Încă nu există evaluări

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 paginiDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshÎncă nu există evaluări

- Split Air ConditionerDocument15 paginiSplit Air ConditionerMuhammad Ahsen100% (1)

- TDI Catalog TurboStartTwo Brochure PDFDocument4 paginiTDI Catalog TurboStartTwo Brochure PDFEva Karia colorado MartinezÎncă nu există evaluări

- ABB ACS560 DescriptionDocument15 paginiABB ACS560 Descriptionbalaji ummadi100% (1)

- Sim10 PDFDocument66 paginiSim10 PDFDaniel OliveraÎncă nu există evaluări

- 10 tm21-m tm126b 201309 dn-3zw214-bDocument60 pagini10 tm21-m tm126b 201309 dn-3zw214-bkosmitoÎncă nu există evaluări

- K38 910kVA Prime PDFDocument4 paginiK38 910kVA Prime PDFapandey070273Încă nu există evaluări

- Data Sheets Nta855 g7Document4 paginiData Sheets Nta855 g7Macra MatthewÎncă nu există evaluări

- RCZ ManualDocument276 paginiRCZ ManualEden Abdula100% (1)

- LT-636 FA-200 Installation and Operation Manual1Document52 paginiLT-636 FA-200 Installation and Operation Manual1Ksmart1973Încă nu există evaluări

- Model: Macro-Tech 5000VZDocument43 paginiModel: Macro-Tech 5000VZTeguh RiswantoÎncă nu există evaluări

- Tm4 Sumo HD: Motor / Inverter SystemDocument2 paginiTm4 Sumo HD: Motor / Inverter SystemFire Library0% (1)

- CAT 3616 Fuel Timing DimensionDocument1 paginăCAT 3616 Fuel Timing DimensionAlfred MaspaitellaÎncă nu există evaluări

- Camshaft EPS and Camwheel TimingDocument7 paginiCamshaft EPS and Camwheel TimingNosaErnest100% (1)

- YcavDocument310 paginiYcavOmar PiñaÎncă nu există evaluări

- Druid Energizer User ManualDocument9 paginiDruid Energizer User ManualKatherine Weber100% (1)

- Chicao Pneumatic Compressors Brochure (US)Document16 paginiChicao Pneumatic Compressors Brochure (US)Sumit BhasinÎncă nu există evaluări

- QSK19G PerformanceDocument5 paginiQSK19G PerformancetroyÎncă nu există evaluări

- Installation Manual-Perfect YORKDocument19 paginiInstallation Manual-Perfect YORKjesÎncă nu există evaluări

- Boge DryersDocument20 paginiBoge Dryersigor_sandulenkoÎncă nu există evaluări

- PillerDocument12 paginiPillerEnrique RiberoÎncă nu există evaluări

- Cummins Onan 175HDKBRDocument4 paginiCummins Onan 175HDKBRpetey100% (1)

- Sudhir Gensets Training FileDocument47 paginiSudhir Gensets Training FileabhishekÎncă nu există evaluări

- 4006-23tag2a 3a (Tpd1512e-4)Document14 pagini4006-23tag2a 3a (Tpd1512e-4)Soubhik MishraÎncă nu există evaluări

- Eg YegDocument6 paginiEg YegPankaj KambleÎncă nu există evaluări

- Low Voltage - TroubleshootDocument3 paginiLow Voltage - Troubleshootwagner_guimarães_1Încă nu există evaluări

- Kluber Paraliq Ga 351Document2 paginiKluber Paraliq Ga 351Rolando DaclanÎncă nu există evaluări

- Manual Motor Siemens 1la8Document174 paginiManual Motor Siemens 1la8Jair ArmandoÎncă nu există evaluări

- Fenner Wedge & V-Belt Tensioning Instructions PDFDocument2 paginiFenner Wedge & V-Belt Tensioning Instructions PDFAlejandro Rosette88% (8)

- Fenner Belt Tension Pen Data Sheet PDFDocument2 paginiFenner Belt Tension Pen Data Sheet PDFSadi KutkutÎncă nu există evaluări

- W 300 3 PDFDocument44 paginiW 300 3 PDFMahesh Daxini ThakkerÎncă nu există evaluări

- Practical Cookery 14th Edition SAMPLEDocument16 paginiPractical Cookery 14th Edition SAMPLETendaiÎncă nu există evaluări

- BRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Document12 paginiBRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Justiniano Martel67% (3)

- 感應馬達安裝、保養使用說明書31057H402E (英)Document17 pagini感應馬達安裝、保養使用說明書31057H402E (英)Rosyad Broe CaporegimeÎncă nu există evaluări

- Certification "Products Made of Compostable Materials" Procedure No. 3355757Document3 paginiCertification "Products Made of Compostable Materials" Procedure No. 3355757Rei BymsÎncă nu există evaluări

- Hydrogen Production From The Air: Nature CommunicationsDocument9 paginiHydrogen Production From The Air: Nature CommunicationsdfdffÎncă nu există evaluări

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDocument29 paginiUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemÎncă nu există evaluări

- #1 - The World'S Oldest First GraderDocument6 pagini#1 - The World'S Oldest First GraderTran Van ThanhÎncă nu există evaluări

- Arann Magazine, Issue 1-2-Online VersionDocument36 paginiArann Magazine, Issue 1-2-Online VersionmujismileÎncă nu există evaluări

- Citizen's 8651 Manual PDFDocument16 paginiCitizen's 8651 Manual PDFtfriebusÎncă nu există evaluări

- 10.0 Ms For Scaffolding WorksDocument7 pagini10.0 Ms For Scaffolding WorksilliasuddinÎncă nu există evaluări

- Lathe Operators Manual 96-8900 Rev A English January 2014Document458 paginiLathe Operators Manual 96-8900 Rev A English January 2014coyoteassasin0% (1)

- Grain Silo Storage SizesDocument8 paginiGrain Silo Storage SizesTyler HallÎncă nu există evaluări

- D05 Directional Control Valves EngineeringDocument11 paginiD05 Directional Control Valves EngineeringVentas Control HidráulicoÎncă nu există evaluări

- Management of Developing DentitionDocument51 paginiManagement of Developing Dentitionahmed alshaariÎncă nu există evaluări

- Grounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiDocument42 paginiGrounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiSatyam PathakÎncă nu există evaluări

- Espiritualidad AFPP - 2018 PDFDocument5 paginiEspiritualidad AFPP - 2018 PDFEsteban OrellanaÎncă nu există evaluări

- SM FBD 70Document72 paginiSM FBD 70LebahMadu100% (1)

- EDAH EnglishDocument2 paginiEDAH EnglishMaría SanchoÎncă nu există evaluări

- Dam Lecture 14 - Design Criteria Earth DamsDocument4 paginiDam Lecture 14 - Design Criteria Earth DamsCarolineMwitaMoseregaÎncă nu există evaluări

- AppendicitisDocument7 paginiAppendicitisTim LuoÎncă nu există evaluări

- Afforestation Powerpoint For NandniDocument9 paginiAfforestation Powerpoint For NandniFagun Sahni100% (1)

- EngineCleaningAndVolcanicAsh InternDocument69 paginiEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaÎncă nu există evaluări

- Lohmann GuideDocument9 paginiLohmann GuideRomulo Mayer FreitasÎncă nu există evaluări

- APPSC Calender Year Final-2017Document3 paginiAPPSC Calender Year Final-2017Krishna MurthyÎncă nu există evaluări

- Mbs KatalogDocument68 paginiMbs KatalogDobroslav SoskicÎncă nu există evaluări

- Owner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13Document18 paginiOwner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13mediacampaigncc24Încă nu există evaluări

- Private Standard: Shahram GhanbarichelaresiDocument2 paginiPrivate Standard: Shahram Ghanbarichelaresiarian tejaratÎncă nu există evaluări

- Chapter 54 - Drugs Acting On The Upper Respiratory TractDocument13 paginiChapter 54 - Drugs Acting On The Upper Respiratory TractJonathonÎncă nu există evaluări

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 paginiAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutÎncă nu există evaluări

- Cheap TBE Inverter TeardownsDocument33 paginiCheap TBE Inverter TeardownsWar Linux92% (12)