Documente Academic

Documente Profesional

Documente Cultură

Formosa Ldpe Data Sheet

Încărcat de

Basant AGarwalDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Formosa Ldpe Data Sheet

Încărcat de

Basant AGarwalDrepturi de autor:

Formate disponibile

FORMOSA TAISOX®

FORMOSA PLASTICS

High Density Polyethylene ( HDPE ) CORPORATION

Film Flat Yarn & Monofilament Blow Drum

Grade 9000 9001 8010 8012 8006 7003 8003 8003H 9003 7001 7501 7500

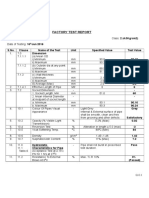

Properties Unit Test Method

Melt Index MI2.16 g/10min ASTM D1238 0.07 0.05 1.0 1.1 0.55 0.35 0.25 0.30 0.25 0.07 0.02 0.01

Melt Index MI5/MI21.6 g/10min ASTM D1238 0.30 / 9.0 0.10 / 4.0 < 0.10 / 2.0

3

Density g/cm ASTM D1505 0.950 0.950 0.956 0.957 0.960 0.955 0.958 0.958 0.952 0.949 0.951 0.951

Thermal properties

Melting point FPC Method 130 130 134 134 134 132 134 134 132 131 134 134

Brittleness point ASTM D746 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70

Softening point ASTM D1525 123 123 127 127 127 125 127 127 124 126 127 127

Mechanical properties

Tensile strength at

yield Kg/cm2 ASTM D638 260 260 295 300 280 300 300 300 270 250 270 290

Tensile strength at 2

break Kg/cm ASTM D638 370 380 390 380 300 350 320 320 300 350 380 380

Elongation at break ASTM D638 850 800 >1000 >1000 800 1000 1000 1000 1000 >600 >800 >800

Tensile Impact 2

Strength kgcm/cm ASTM D1822 650 800 350 350 300 400 350 350 400 400 500 600

Izod Impact Strength Kg-cm/cm notch ASTM D256 22 22 > 50 > 50 15 30 25 >40 13 >40 NB NB

Hardness Shore D ASTM D2240 65 65 69 69 70 67 69 69 66 65 67 67

ESCR Hours ASTM D1693 500 >1000 < 30 60 30 30 200 >600 >1000 >1000

Die Swell Ratio FPC Method 1.60 1.65 1.58 1.48 1.52 1.70 1.75 1.75

Pinch-off thickness — FPC Method Good Good Good Good Good Excellent Excellent Excellent

Electrical properties

Dielectric Constant 1MHz ASTM D1531

Dissipation Factor 1MHz ASTM D1531

Volume Resistivity Ohm-cm ASTM D257

High film strength High film strength Good stretchability Good stretchability Excellent stiffness high melt strength Good stiffness Good stiffness Good ESCR Good melt strength High rigidity stiffness High rigidity stiffness

and toughtness and toughtness High tenacity High tenacity Low taste good balance of High rigidity High rigidity High toughness Excellent impact Good melt strength Good melt strength

Hig-speed Excellent Good processability Good processability high speed molding ESCR and stiffness Chemical resistance Good impact Chemical resistance Excellent ESCR Excellent impact Excellent impact

Characteristics processability processing stability High impact strength High impact strength strength Chemical Chemical resistance Excellent ESCR Excellent ESCR

Good film Good film Good glossy resistance Chemical resistance Chemical resistance

thickness distribution thickness distribution

Small shopping bag Shopping bag Ropes and nets Ropes and nets Lightweight Water tank up to Water tank up to Small bottle up to Cosmetic bottle 20-150L Drum 180-220L Drum 180-220L Drum

Roll bag Roll bag Tarpaulin Tarpaulin container for milk , 25L, Industrial 25L, dairy bottle, 5L, dairy bottle, Detergent bottle Chemical tank L-ring type Drum L-ring type Drum

Super thinness bag Garbage bag Woven bags Woven bags distilled water fruit containers Medicine cans, Medicine cans, Engine oil bottle Industrial containers Chemical tank Chemical tank

Applications Underground sewer Extruder sheet Extruder sheet juices , soft drink Soy sauce tank, Soy sauce tank, Medicine cans Industrial containers

pipe Foam sheet Foam sheet Tool box, Toys Tool box, Toys Shoe last

Tool box

Toys

1. Film processing temp.= 180 - 220℃、BUR= 3 ~ 6 5. General blow molding temp.= 160 - 180℃

2. For high throughput or thin film application, reducing die-gap gets 6. Blow molding temp. for drum= 190 - 230℃

Notes better processibility. 7. All HDPE products meet FDA 21-177-1520

3. Yarn processing temp.= 190 - 210℃ 8. Data shown are average values and should not be examined for specifications.

4. Filament processing temp.= 260 - 280℃

Formosa Plastics Corporation, Polyolefin Division

Sales Dept. Tel : (+886)-2-27178141 Fax :(+886)-2-27193260

2006.02.01 revised www.fpc.com.tw

FORMOSA TAISOX®

FORMOSA PLASTICS

High Density Polyethylene ( HDPE ) CORPORATION

Pipe Coating Wire & Cable Injection

Grades 8001 9002 9007 9040 8040 8050 8070 7200 8230 8300

Properties Unit Test Method

Melt Index MI2.16 g/10min ASTM D1238 0.05 0.15 0.80 4.0 4.0 6.0 6.0 22 21 30

Melt Index MI5/MI21.6 g/10min ASTM D1238 0.25 / 7.0

3

Density g/cm ASTM D1505 0.948 0.948 0.951 0.953 0.957 0.960 0.961 0.955 0.952 0.952

Thermal properties

Melting point FPC Method 129 129 130 131 132 133 135 133 131 131

Brittleness point ASTM D746 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70

Softening point ASTM D1525 122 123 120 122 125 125 125 123 122 122

Mechanical properties

Tensile strength at

yield Kg/cm2 ASTM D638 240 250 230 230 300 310 310 285 270 270

Tensile strength at 2

break Kg/cm ASTM D638 360 330 250 240 260 240 240 150 150 150

Elongation at break ASTM D638 850 800 600 900 900 900 900 700 800 700

Tensile Impact 2

Strength kgcm/cm ASTM D1822 750 550 260 200 180 140 150 95 90 80

Izod Impact Strength Kg-cm/cm notch ASTM D256 >30 18 6 10 12 6 8 3.5 4 3

Hardness Shore D ASTM D2240 64 65 65 66 69 70 70 67 67 67

ESCR Hours ASTM D1693 >1000 >1000 >48

Die Swell Ratio FPC Method

Pinch-off thickness — FPC Method

Electrical properties

Dielectric Constant 1MHz ASTM D1531 2.3

Dissipation Factor 1MHz ASTM D1531 0.00006

Volume Resistivity Ohm-cm ASTM D257 1×1017

Good ESCR Good Impact High Toughness Easy Processing Easy Processing Easy Processing Easy Processing Good Flow Good Flow

High creep Excellent ESCR Excellent ESCR High Rigidity High Rigidity High Rigidity High Rigidity Suitable for Fast Suitable for Fast Cycling-Application

Cycling-Application

High intensity Good Strength and High-speed- High Strength High Warpage Good Impact Good Impact High Warpage Resistance

Characteristics Good mechanical toughness moldability High ESCR Resistance Strength Strength

High Warpage

Good chemical- Excellent coating- Very Good Resistance

resistance appearance

Impact Strength

Gas pipe Steel Pipe Coating Telephone wire Bottle cap Pails Crates Housewares

Potable water pipe Steel wire rope- insulation(C C P) High Toughness Pallet Boxes Thin Walled Food Containers

Sewer & drain pipe coating Outer skin in Parts Waste Carts Seats PET bottle base cup

Applications Chemical pipe "foam-skin" (F.S) Industrial Pallet

Cable conduct containers

1. 8001 is certified as PE100 according to ISO 9080 :2003(E) 5. General injaction temp.= 170 - 190℃

2. Pipe extrusion temp.= 180 - 220℃ 6. All HDPE products meet FDA 21-177-1520.

Notes 3. Steel pipe coating processing temp.= 180 - 210℃ 7. Data shown are average values and should not be examined for specifications.

4. Wire & cable coating processing temp.= 220 - 250℃

Formosa Plastics Corporation, Polyolefin Division

Sales Dept. Tel : (+886)-2-27178141 Fax :(+886)-2-27193260

2006.02.01 revised www.fpc.com.tw

FORMOSA TAISOX®

FORMOSA PLASTICS

CORPORATION

Low Density Polyethylene ( LDPE )

Injection Coating Film

Grade 6630M 6810M 6520G 6030F 6130F 6323F 6330F 6334F 6534F 6634F

Properties Unit Method

ASTM

Melt Index MI 2.16 g/10min

D1238

25 50 8.0 0.27 0.8 2.5 2.1 2.1 5.0 8.0

ASTM

Density g/cm3

D1505

0.918 0.915 0.916 0.922 0.924 0.918 0.924 0.924 0.924 0.924

Thermal properties

Melting point ℃ DSC 106 104 105 113 113 107 113 113 112 112

Brittleness point ℃ ASTM D746 -60 -60 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70

ASTM

Softening point ℃

D1525

92 80 85 96 98 95 96 96 92 92

Mechanical properties

Tensile strength at yield Kg/cm2 ASTM D638 120 90 90 95 120 100 100 100 110 110

Tensile strength at

break

Kg/cm2 ASTM D638 90 100 110 190 170 150 150 150 140 120

Elongation at break % ASTM D638 400 500 500 700 700 600 600 600 600 500

Flexural modulus Kg/cm2 ASTM D790 1800 1100 1100 1500 1800 1700 1800 1800 1800 1900

ASTM

Hardness Shore D

D2240

50 45 52 51 54 52 53 53 52 52

Mechanical properties of film

ASTM D882B

Tensile strength at yield Kg/cm2 MD/TD 100/100 100/110 100/110 100/110 100/110 110/120 100/110

Tensile strength at ASTM D882B

break

Kg/cm2 MD/TD 250/220 220/190 210/170 230/180 230/180 170/150 160/140

ASTM D882B

Elongation at break % MD/TD 380/580 380/600 250/550 280/580 280/580 270/500 280/500

ASTM D882B

Secant modulus 1% Kg/cm2 MD/TD 1700/1900 1900/2150 1900/2200 2000/2300 2000/2300 1900/2200 1800/2100

ASTM D1922

Tear resistance (elmendorf) N/mm MD/TD 40/50 45/60 70/50 70/50 80/50 80/60 80/60

ASTM

Dart drop test g

D1709

260 180 100 100 100 70 65

ASTM

Coefficient of friction(COF) >0.5 >0.5 <0.13 >0.5 <0.12 <0.12 <0.12

D1894

Optical qualities

ASTM

Haze %

D1003

15 10 13 6.5 6.5 8 8

ASTM

Gloss 45。 %

D2457

50 70 60 95 95 90 90

Recommended film

thickness

μ 50-250 30-120 25-80 25-80 25-80 15-60 10-50

Additives

Slip agent Level None None Medium None High High High

Anti blocking agent Level None None None None Medium Medium Medium

Excellent flowability Excellent flowability Excellent High-mechanical Excellent- Excellent- Excellent- Excellent- High optical High-flowability

High gloss High gloss processability shrinkage Good processability processability processability Excellent draw- Medium-rigidity

Characteristics Medium-rigidity Good flexibility Good adhesion optical medium- Flexibility Excellent-optical Excellent-optical down

Small Neck-in rigidity

Housewares Artificial flowers Coating on Heavy duty Shrink film General film General General Thin transparent- Thin transparent-

High gloss toys Low thickness articles Aluminum、paper Agricultural Lamination-film X-linked Foam transparent- film transparent- film film film

Applications Low thickness articles powder coating substrates shrink film Blow molding Zipper bag Lamination-film Lamination-film Injection-articles

Injection-articles Blow molding

Foam material

1. Injection temp.=150-180℃ 3. Film processing: screw=60mmψ、L/D=30、BUR=2.5,film thickness= 30μ ( MI>1.2 ) / 50μ ( MI<1.2 ) 。

2. Coating temp.=270-340℃ 4. Film processing temp.= 160 - 200℃ ,may need higher for low MI

Notes 5. All LDPE products meet FDA 21-177-1520.

6. Data shown are average values and should not be examined for specifications.

Formosa Plastics Corporation, Polyolefin Division

Sales Dept. Tel : (+886)-2-27178141 Fax :(+886)-2-27193260

2006.02.01 revised www.fpc.com.tw

FORMOSA TAISOX®

FORMOSA PLASTICS

CORPORATION

Linear Low Density Polyethylene ( LLDPE )

Rotational

Blown film Cast film Injection

molding

Grade Grade

3210 3214 3220 3224 3224D 3225 3840 3470 3490

Properties Unit Method Properties Unit Test Method

MI2.16 g/10min ASTM D1238 1.0 2.0 2.0 Melt Index MI2.16 g/10min ASTM D1238 5.0 21 50

Density g/cm

3

ASTM D1505 0.920 0.919 0.921 0.922 0.919 Density g/cm 3

ASTM D1505 0.938 0.924 0.926

Thermal Properties Thermal properties

Melting point ℃ DSC 122 122 122 Melting point FPC Method 125 122 124

Brittleness point ℃ ASTM D746 <-70 <-70 <-70 Brittleness point ASTM D746 <-70 <-70 <-70

Softening point ℃ ASTM D1525 93 93 93 Softening point ASTM D1525 118 93 95

Mechanical Properties Mechanical properties

ASTM D882B

Tensile strength at yield Kg/cm

2

MD/TD 100/110 100/110 100/110 Tensile strength at yield Kg/cm2 ASTM D638 150 117 120

ASTM D882B Tensile strength at

Tensile strength at break Kg/cm 2

MD/TD 410/320 360/280 360/280 break

Kg/cm2 ASTM D638 220

ASTM D882B

Elongation at break % MD/TD 620/840 600/800 600/800 Elongation at break ASTM D638 >1000 850 350

ASTM D882B

Secant Modulus 1% Kg/cm 2

MD/TD 1450/1600 1500/2100 1500/2100 Tensile Impact Strength kgcm/cm2 ASTM D1822 140

g/25μ ASTM D1922

Elmendort Tear Resistance

m MD/TD 145/370 40/430 110/300 Izod Impact Strength Kg-cm/cm notch ASTM D256 20

Dart Drop Test g ASTM D1709 150 120 120 Hardness Shore D ASTM D2240 60 48 50

Optical Properties

Haze % ASTM D1003 12 14 19 20 25 3

Gloss45 。 % ASTM D2457 53 51 57 55 51 96

Clarity % 70 61 73 64 52 95

Additives

Slip Agent None Medium None Medium Medium None

Antiblocking Agent None Medium None Medium High None

Better sealing Better sealing High Puncture Easy Processing High Puncture Better Sealing

High puncture Resistance High Strength Resistance

Greater Drawdown High output Rate

Greater drawdown Good Low

resistance

Characteristics Greater drawdown Good extrudability Greater Characteristics Temperature Brittle Good extrudability Excellent Drawdown

High tensile strength Drawdown High Puncture

Good

extrudability Resistance

Heavy duty sacks Light,Medium duty film Cast Stretch Large Crate Cast Stretchfilm Cast Stretchfilm

Agricultural films Stretchfilm film Containers Overwrap Film Overwrap Film

Applications Liners Overwrap Film Applications Tank

Produce bags Barricade

Stretchfilm

1. Blown film condition:temp.=200℃、throughput=10kg/hr、BUR=2.0、 5. General injection temp.= 170 - 190℃

2. Cast film condition:temp.= 260℃、film thickness= 20μm 6. All LLDPE products meet FDA 21-177-1520.

Notes 3. All LLDPE products contain anti-oxidants. Notes 7. Data shown are average values and should not be examined for specifica

4. All LLDPE products are made in gas phase process. 8. All LLDPE products are ethylene-butene-1

Formosa Plastics Corporation, Polyolefin Division

Sales Dept. Tel : (+886)-2-27178141 Fax :(+886)-2-27193260

2006.02.01 revised www.fpc.com.tw

FORMOSA TAISOX®

FORMOSA PLASTICS

Ethylene-Vinyl Acetate copolymer( EVA )

CORPORATION

Powder

Film Injection/Foam Injection / Foam Coating

Hot melt

Grade

7130F 7140F 7350F 7620M 7660M 7240M 7310M 7320M 7340M 7350M 7360M 7470M 7920M 7A50H 7B50H

Properties Unit Method

Melt Index MI 2.16 g/10min ASTM D1238 0.9 0.7 1.8 9.0 20 1.5 2.5 4.0 2.5 2.5 2.0 6.0 80 150 400

Density g/cm3 ASTM D1505 0.930 0.934 0.938 0.930 0.940 0.935 0.928 0.930 0.934 0.938 0.941 0.948 0.925 0.934 0.933

Vinyl Acetate content % 9 14 18 9 20 15 6 9 14 18 21 26 9 19 19

Thermal properties

Melting/Freezing point ※ ℃ DSC 93 90 84 95 83 87 102 96 90 84 80 76 95 78/57※ 77/55※

Brittleness point ℃ ASTM D746 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 <-70 — —

Softening point-Vicat ℃ ASTM D1525 80 75 60 73 60 65 90 74 70 60 58 48 70 44(91)5 38(89)5

Mechanical properties

Tensile strength at yield Kg/cm2 ASTM D638 60 70 45 40 30 55 80 60 80 45 40 30 15 — —

2

Tensile strength at break Kg/cm ASTM D638 180 200 150 130 110 150 150 140 140 150 180 140 80 70 40

Elongation at break % ASTM D638 650 750 800 700 800 700 700 700 700 800 800 800 600 700 660

2

Flexural modulus Kg/cm ASTM D790 250 230 400 240 130 210 360 250 230 150 150 70 300 — —

Hardness Shore A ASTM D2240 95 92 88 96 83 92 98 96 96 88 86 82 96 73 72

Hardness Shore D ASTM D2240 45 40 38 46 32 42 47 46 45 38 36 32 45 23 22

Mechanical properties of film

Tensile strength at yield Kg/cm2 ASTM D882B MD/TD 50/40 50/40 40/30

2

Tensile strength at break Kg/cm ASTM D882B MD/TD 300/280 310/280 280/250

Elongation at break % ASTM D882B MD/TD 400/550 450/600 500/600

2

Secant modulus 1% Kg/cm ASTM D882B MD/TD 350/400 370/420 350/380

Tear resistance (elmendorf) N/mm ASTM D1922 MD/TD 10/24 10/24 10/24

Dart drop test g ASTM D1709 550 620 650

Coefficient of friction(COF) ASTM D1894 >0.5 >0.5 >0.5

Optical qualities

Haze % ASTM D1003 5 3 3

Gloss 45 。 % ASTM D2457 80 90 90

Recommended film thickness μ 30-150 30-150 30-150

Good Good Good Good Good High Good Good High Good Excellent- Excellent- Excellent excellent adhesion

processability processability processability processability processability elasticity chemical chemical elasticity chemical elasticity elasticity processabilit high flowability

Good Good Good Heat sealing Heat sealing Good- resistance resistance High flexible resistance High flexible High flexible yHigh soft properties

Characteristics toughness toughness toughness toughness mechanical Good- Good- Excellent- Good

elasticity

Non-BHT Highly optical Highly optical High optical processability elasticity elasticity toughness toughness

content Non-BHT Non-BHT foaming High flexible High optical

content content

Greenhouse Greenhouse Greenhouse Injection Injection Flexible Flexible items Flexible Flexible X-linked X-linked X-linked Powder packaging

Lamination items X- X-linked items items Foam-shoes, Foam-shoes Foam-shoes coating for bookbinding

film

General film

General film

General Lamination

Extrusion- linked Foam Foam X-linked X-linked Mid-sole , Mid-sole Gaskets non-woven &

purpose

film packaging

sanitary packaging

sanitary Extrusion- woodworking

Applications coating

coating -Sandal , Foam Foam Gaskets Gaskets Blend polymer

Build

fabrics

applications applications X-linked Slipper PEVA Protecting

X-linked Foam sheeting film

materials

Foam Wallpaper

Hot melt

1. Film processing condition : screw=60mm ψ 、 L/D=30 、 4. Injection temp.= 150 - 180℃。

BUR=2.5

2. Film thickness 30μ ( MI>1.2 ) / 50μ ( MI<1.2 ) 5. ( ) Softening point of Bitumen (Ring-and-Ball Apparatus), ASTM E28

Notes 3. Film processing temp.= 160 - 200℃ 6. All EVA products meet FDA 21-177-1350.

7. Data shown are average values and should not be examined for specifications.

Formosa Plastics Corporation, Polyolefin Division

Sales Dept. Tel : (+886)-2-27178141 Fax :(+886)-2-27193260

2006.02.01 revised www.fpc.com.tw

S-ar putea să vă placă și

- ASTM D 529 - 00 Enclosed Carbon-Arc Exposures of Bituminous MaterialsDocument3 paginiASTM D 529 - 00 Enclosed Carbon-Arc Exposures of Bituminous Materialsalin2005Încă nu există evaluări

- Elvax Molding GuideDocument11 paginiElvax Molding GuideSlava SlesarenkoÎncă nu există evaluări

- Rilsan PA11 RenewableDocument32 paginiRilsan PA11 RenewableManish TiwariÎncă nu există evaluări

- nx5 KeyboardcommandsDocument1 paginănx5 KeyboardcommandsShaheen ArihaÎncă nu există evaluări

- Design Guide DSM GuideDocument0 paginiDesign Guide DSM GuideDavid García SalvatierraÎncă nu există evaluări

- Ultramid - Polyamide (PA) PDFDocument64 paginiUltramid - Polyamide (PA) PDFkfarav100% (1)

- Fortron PPS PDFDocument57 paginiFortron PPS PDFmichaelÎncă nu există evaluări

- Polystyrene Processing GuideDocument4 paginiPolystyrene Processing GuidemadogodÎncă nu există evaluări

- Characterization and Ageing Study of PLA Films Plasticized with Oligomeric Lactic AcidDocument8 paginiCharacterization and Ageing Study of PLA Films Plasticized with Oligomeric Lactic AcidTOUFIKÎncă nu există evaluări

- Flexible Intermediate Bulk Containers Specifications PDFDocument13 paginiFlexible Intermediate Bulk Containers Specifications PDFZahir Khira100% (1)

- Presentation World Investment Casting v5Document21 paginiPresentation World Investment Casting v5Caio Fazzioli Tavares100% (1)

- Scratch Resistance Test BSENISO15182001Document14 paginiScratch Resistance Test BSENISO15182001Jose Antonio Lucero CruzÎncă nu există evaluări

- Kopla Pa6 KNG1015Document3 paginiKopla Pa6 KNG1015agungÎncă nu există evaluări

- F Essenbeck ErDocument22 paginiF Essenbeck Eranhntran4850Încă nu există evaluări

- Performance, Engine Compartment and Underbody WSS-M15P50-B Plastic Components 1. ScopeDocument9 paginiPerformance, Engine Compartment and Underbody WSS-M15P50-B Plastic Components 1. ScopeJaqueline PereiraÎncă nu există evaluări

- PC Makrolon 2405 - 2407 - 2456-DatasheetDocument4 paginiPC Makrolon 2405 - 2407 - 2456-DatasheetNhox Xu0% (1)

- A Guide To Polyolefin Blow Molding PDFDocument57 paginiA Guide To Polyolefin Blow Molding PDFwantamanualÎncă nu există evaluări

- Accelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Document3 paginiAccelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Satya kaliprasad vangaraÎncă nu există evaluări

- Ptfe PDFDocument12 paginiPtfe PDFseeralan_1986Încă nu există evaluări

- Desmopan BayerDocument22 paginiDesmopan BayerGabriel SalomonÎncă nu există evaluări

- 30 Automotive Applications of Plastics: Past, Present, and FutureDocument23 pagini30 Automotive Applications of Plastics: Past, Present, and FuturePatito Lisbhet Romero BuenoÎncă nu există evaluări

- 21 CFR 177Document6 pagini21 CFR 177i_flyÎncă nu există evaluări

- 32 Battling The Effects of Reversion in Natural Rubber Compounds Ken Bates STRUKTOLDocument20 pagini32 Battling The Effects of Reversion in Natural Rubber Compounds Ken Bates STRUKTOLfrancisco ñancoÎncă nu există evaluări

- Santoprene Blow Molding Guide EnpdfDocument23 paginiSantoprene Blow Molding Guide EnpdfNikhil AherÎncă nu există evaluări

- PV3307 Inglese 08 - 2004Document4 paginiPV3307 Inglese 08 - 2004silviaÎncă nu există evaluări

- CDI NORSOK Testing Elastomers Tech Report WebDocument2 paginiCDI NORSOK Testing Elastomers Tech Report WebwholenumberÎncă nu există evaluări

- Process Engineer CV TemplateDocument2 paginiProcess Engineer CV Templatemalavur100% (1)

- FP - EN - GreenFlux 200 - BB - 1014 - 1Document1 paginăFP - EN - GreenFlux 200 - BB - 1014 - 1tribolas100% (1)

- Rubber Properties Chart PDFDocument1 paginăRubber Properties Chart PDFsefaÎncă nu există evaluări

- Intrinsic Viscosity As Quality Control Parameter of PET: Relevant For: Polymers, Plastics, ISO 1628, PETDocument3 paginiIntrinsic Viscosity As Quality Control Parameter of PET: Relevant For: Polymers, Plastics, ISO 1628, PETParesh Hadkar100% (1)

- RUBBER COMPOUNDING: RAW MATERIALS AND APPLICATIONSDocument16 paginiRUBBER COMPOUNDING: RAW MATERIALS AND APPLICATIONSMadan Saini100% (1)

- DU Sliding Material SpecificationsDocument55 paginiDU Sliding Material SpecificationsMichał AmborÎncă nu există evaluări

- Drawdown Ratio and Draw Ratio Balance (DDR & DRB) : Outer LayerDocument5 paginiDrawdown Ratio and Draw Ratio Balance (DDR & DRB) : Outer LayerItay100% (1)

- Abp-2030 Tds-Iso-EngDocument2 paginiAbp-2030 Tds-Iso-Engkatolokchok100% (2)

- ISO 2230-2002 Shelf Life Classification GuideDocument1 paginăISO 2230-2002 Shelf Life Classification GuidePahe DriveÎncă nu există evaluări

- Properties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerDocument10 paginiProperties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerabiliovieiraÎncă nu există evaluări

- Technology Profile: MHA Production ProcessDocument1 paginăTechnology Profile: MHA Production ProcessBramJanssen76100% (1)

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire IndustriesDocument5 paginiA Review On Rubber Compound Mixing in Banbury Mixer at Tire IndustriesPrashantha NandavarÎncă nu există evaluări

- Acronyms - Six Sigma - LeanDocument3 paginiAcronyms - Six Sigma - LeanRone Da-anoyÎncă nu există evaluări

- KOSHYMA Electroplating SolutionsDocument9 paginiKOSHYMA Electroplating SolutionsaadinathhariharÎncă nu există evaluări

- Rubber Properties ChartDocument1 paginăRubber Properties Chartabhay guptaÎncă nu există evaluări

- Overmolding GuidelinesDocument18 paginiOvermolding GuidelinesRJCIIIÎncă nu există evaluări

- Measuring Thermal Crystallinity in PET: Spe Antec Indianapolis 2016Document5 paginiMeasuring Thermal Crystallinity in PET: Spe Antec Indianapolis 2016Silviani SilvyÎncă nu există evaluări

- Mar 2017Document76 paginiMar 2017deshmukhdpraveenÎncă nu există evaluări

- Brochure Carbon Additives For PolymersDocument24 paginiBrochure Carbon Additives For PolymersTUNGÎncă nu există evaluări

- shinEtsuRubber PDFDocument12 paginishinEtsuRubber PDFAmier FaudziÎncă nu există evaluări

- Ryton Mechanical PropertiesDocument12 paginiRyton Mechanical PropertiesClaudia MmsÎncă nu există evaluări

- UntitledDocument12 paginiUntitledapi-256504985Încă nu există evaluări

- Nissan Standard for Marking Polymeric PartsDocument14 paginiNissan Standard for Marking Polymeric PartsKarthic BhrabuÎncă nu există evaluări

- Adhesive Systems For Industrial ApplicationsDocument12 paginiAdhesive Systems For Industrial Applicationsjaswanth kumarÎncă nu există evaluări

- Licensed Technologies BrochureDocument16 paginiLicensed Technologies BrochureThanh Linh NguyenÎncă nu există evaluări

- Iso News 23e PDFDocument5 paginiIso News 23e PDFThảo PhạmÎncă nu există evaluări

- Elvax Molding GuideDocument11 paginiElvax Molding GuideAsima AtharÎncă nu există evaluări

- Chapter 2-RRL BindersDocument4 paginiChapter 2-RRL BindersAlfred Louie RimorinÎncă nu există evaluări

- Coating and Drying Defects: Troubleshooting Operating ProblemsDe la EverandCoating and Drying Defects: Troubleshooting Operating ProblemsEvaluare: 5 din 5 stele5/5 (1)

- Metal Bearing Waste Streams: Minimizing, Recycling and TreatmentDe la EverandMetal Bearing Waste Streams: Minimizing, Recycling and TreatmentÎncă nu există evaluări

- Animal Cell Vs Plant CellDocument4 paginiAnimal Cell Vs Plant CellRizza Mae Samalca100% (2)

- Determination of Phenolic Compounds in The Marine Environment of Thermaikos Gulf Northern GreeceDocument13 paginiDetermination of Phenolic Compounds in The Marine Environment of Thermaikos Gulf Northern GreeceAnonymous GdWMlV46bUÎncă nu există evaluări

- Dr. Fixit Modern Tile Adhesive: DescriptionDocument3 paginiDr. Fixit Modern Tile Adhesive: DescriptionkiranÎncă nu există evaluări

- Calculations and units in analytical chemistryDocument17 paginiCalculations and units in analytical chemistryangelaÎncă nu există evaluări

- AucosticsDocument98 paginiAucosticswendodavidÎncă nu există evaluări

- Ecosystem Poster - Introduction and RubricDocument7 paginiEcosystem Poster - Introduction and Rubricapi-271661638Încă nu există evaluări

- Asma Zaghbani Publications ScientifiquesDocument2 paginiAsma Zaghbani Publications Scientifiquesapi-227010260Încă nu există evaluări

- Dapust 21Document5 paginiDapust 21Dewo BontangÎncă nu există evaluări

- Catálogo de Gaviones Tejidos PRODAC (Inglés) PDFDocument9 paginiCatálogo de Gaviones Tejidos PRODAC (Inglés) PDFpapolamÎncă nu există evaluări

- TL10PFM - 75P Dec182018Document1 paginăTL10PFM - 75P Dec182018Anonymous pVoSWn8yh0Încă nu există evaluări

- 2017 Sato Dentin Bonding Durability of Two-Step Self-Etch Adhesives With Improved of Degree of Conversion of Adhesive ResinsDocument7 pagini2017 Sato Dentin Bonding Durability of Two-Step Self-Etch Adhesives With Improved of Degree of Conversion of Adhesive ResinsComarzzoÎncă nu există evaluări

- RK-RB UkDocument3 paginiRK-RB UkpamururamuÎncă nu există evaluări

- A Comparison of The Environmental Impacts of Different Categories of Insulation MaterialsDocument9 paginiA Comparison of The Environmental Impacts of Different Categories of Insulation Materialsminsara madtÎncă nu există evaluări

- Answer Tutorial - Pharmaceutical CalculationsDocument11 paginiAnswer Tutorial - Pharmaceutical CalculationsNur Nabilah50% (2)

- 2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Document14 pagini2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Vicente SosaÎncă nu există evaluări

- FTRDocument1 paginăFTRanon_127491670Încă nu există evaluări

- Chemistry Investigatory ProjectDocument18 paginiChemistry Investigatory ProjectDinesh Singh Choudhary0% (1)

- Aqsiq Notice No.151 (2012)Document16 paginiAqsiq Notice No.151 (2012)arbor02Încă nu există evaluări

- Fire Characteristics of Styropor FoamsDocument4 paginiFire Characteristics of Styropor FoamsRosman Al-QadriÎncă nu există evaluări

- Heat Transfer in Fire Tube Boiler Software SumulationDocument7 paginiHeat Transfer in Fire Tube Boiler Software SumulationLiam Moylan50% (2)

- What is Ozone? Explaining its Role in Protecting Earth from UV RadiationDocument1 paginăWhat is Ozone? Explaining its Role in Protecting Earth from UV RadiationTenveer BhuttaÎncă nu există evaluări

- Pelican Cases Catalog 2021Document29 paginiPelican Cases Catalog 2021thanakornÎncă nu există evaluări

- Class Xii 2016 2017 Main PDFDocument16 paginiClass Xii 2016 2017 Main PDFsribalajicybercity100% (1)

- (Physics) 2010 TSSM Unit 4 ExamDocument37 pagini(Physics) 2010 TSSM Unit 4 ExamakashÎncă nu există evaluări

- GUIDELINES FOR PREPARATION OF OIL SPILL RESPONSE CONTINGENCY PLAN OISD - GUIDELINES-200 Amended Edition October 2002 - OISD-GDN-200Document36 paginiGUIDELINES FOR PREPARATION OF OIL SPILL RESPONSE CONTINGENCY PLAN OISD - GUIDELINES-200 Amended Edition October 2002 - OISD-GDN-200Vaishnavi JayakumarÎncă nu există evaluări

- Determining The Rate Law From Experimental DataDocument45 paginiDetermining The Rate Law From Experimental Datasospeter barasaÎncă nu există evaluări

- Fluid Mechanics IIDocument26 paginiFluid Mechanics IIarunajsÎncă nu există evaluări

- Rep19 MaseDocument66 paginiRep19 Mase3utiaÎncă nu există evaluări

- Bio FermentationDocument8 paginiBio FermentationCecil ClaveriaÎncă nu există evaluări