Documente Academic

Documente Profesional

Documente Cultură

Example 3

Încărcat de

SeymurH-v0 evaluări0% au considerat acest document util (0 voturi)

7 vizualizări2 pagininc programming

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentnc programming

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

7 vizualizări2 paginiExample 3

Încărcat de

SeymurH-vnc programming

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Serra}

fe

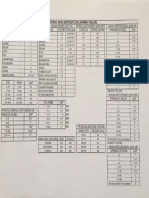

Job setup data

listing

Machine

start-up

sequence,

Change

to tool 1

Hole operation 1

sequence

Machine stop

sequence

Machine

start-up

‘sequence.

Change

to tool 1

Word address command

Meaning

00903

Program number

(XOYO IS THE LOWER LEFT-HAND CORNER)

(ZO IS THE TOP OF THE PART)

(TOOL1: 4 MM CENTER DRILL)

(TOOL2: 6.7 MM DRILL)

Comments

NOO10 G90 G21 G40 G80

Absolute, metric mode, cancel

cutter diameter compensation and

fixed cycles.

N0020 G91 G28 XO YO 20

Return to reference point ().

NOO30 G92 X-460. Y115. ZO

Preset absolute zero point.

NOO40 T1 M6

Change to tool 1

(TOOL 1: DRILL (3) 4.0 MM DIA. HOLES THRU)

NOO50 GO G90 x45. Y15. 20. $2200 M3

Rapid move to ®. Start spindle (CW)

at 2200 rpm.

NOO6O G43 22.5 H1

Rapid movement of tool 1 to 2.5 mm

above part.

NOO70 m8)

Coolant on,

NOO80 G83 X 45. Y15. 2-13 5 R2.5 Q2.5 F60.

Start deep drill cycle at ®. Final

drill depth is 13.5 mm, 2.5 mm

depth of peck at feed 60 mm/min.

Return to 2.5 mm above part.

NOO9O x33. ¥26.

Deep drill hole at X 5Y-1.625@ .

NO100 X11.

Deep drill hole at X 4Y -1.625@ .

NO110 G80

Cancel any fixed cycles (G83 cycle

canceled),

NO120 GO G90 22.5 M5

Rapid move to 2.5 mm above part.

Stop spindle,

NO130 M9 Coolant off.

NO140 G91 G28 Z0 YO Rapid move to tool change position ® .

NOI50 T2 M6 Change to tool 2.

(TOOL 2: DRILL (2) 6.7 MM DIA, HOLES THRU)

NO160 GO G90 x22. Y8. Z0 $1800 M3

Rapid move to © . Start spindle

(CW) at 1800 rpm.

NO170 G43 22.5 H2

Rapid movement of tool 2 to 2.5

mm above part.

NO180 MB

Coolant on

NO190 G83 X22. Y8. Z-14.6 R2.5 G3. F90.

Start deep drill cycle at ©. Final

drill depth is 14.6 mm, 3 mm depth

of peck at feed 90 mm/min. Return

to 2.5 mm above part.

NO200 X55.

Deep drill hole at X55 Y8mm @ .

NO200 G80

Cancel any fixed cycles (G83 cycle

canceled).

NO210 GO G90 22.5 M5

Rapid move to 2.5 mm above part.

Stop spindle,

NO220 M9 Coolant off.

NO230 G91 G28 ZO YO Rapid move to X¥Z reference point ®.

NO240 M30 Program end, memory reset.

S-ar putea să vă placă și

- Y # - Y Matrix SetupDocument11 paginiY # - Y Matrix SetupSeymurH-vÎncă nu există evaluări

- Multi-Material Additive Manufacturing of Functionally Graded CompositesDocument15 paginiMulti-Material Additive Manufacturing of Functionally Graded CompositesSeymurH-vÎncă nu există evaluări

- Q1 11Document5 paginiQ1 11SeymurH-vÎncă nu există evaluări

- Certificate C-UMRWY9XNZSDocument1 paginăCertificate C-UMRWY9XNZSSeymurH-vÎncă nu există evaluări

- CSWP DT CertificateDocument1 paginăCSWP DT CertificateSeymurH-vÎncă nu există evaluări

- View Creation: The Following Images Are To Be Used To Answer Question 1Document21 paginiView Creation: The Following Images Are To Be Used To Answer Question 1SeymurH-vÎncă nu există evaluări

- FEA - 2aDocument13 paginiFEA - 2aSeymurH-vÎncă nu există evaluări

- Note Jan 16, 2019Document5 paginiNote Jan 16, 2019SeymurH-vÎncă nu există evaluări

- CertificateOfCompletion - Cert Prep - SOLIDWORKS SurfacingDocument1 paginăCertificateOfCompletion - Cert Prep - SOLIDWORKS SurfacingSeymurH-vÎncă nu există evaluări

- Velocity Profile Between PlatesDocument1 paginăVelocity Profile Between PlatesSeymurH-vÎncă nu există evaluări

- Rplot 01Document1 paginăRplot 01SeymurH-vÎncă nu există evaluări

- Comparison of Solutions: Quadratic Solution Linear Solution Exact SolutionDocument1 paginăComparison of Solutions: Quadratic Solution Linear Solution Exact SolutionSeymurH-vÎncă nu există evaluări

- FEM 2d 1 VarDocument3 paginiFEM 2d 1 VarSeymurH-vÎncă nu există evaluări

- Success Stories and Applications of FRAMDocument2 paginiSuccess Stories and Applications of FRAMSeymurH-vÎncă nu există evaluări

- Revit TutorialDocument4 paginiRevit TutorialSeymurH-vÎncă nu există evaluări

- CFM and Capacity CalculatorsDocument13 paginiCFM and Capacity CalculatorsSeymurH-vÎncă nu există evaluări

- EC Declaration of Conformity - Air - DistributionDocument1 paginăEC Declaration of Conformity - Air - DistributionSeymurH-vÎncă nu există evaluări

- Plumbing FF SyllabusDocument4 paginiPlumbing FF SyllabusSeymurH-vÎncă nu există evaluări

- Class Schedule: Me4-Gra Ce1-Gra Me4-Gra Me1-Gra Me4-Grb Ce1-Grb Me4-Grb Me1-Grb Me1-Gra Me1-GrbDocument2 paginiClass Schedule: Me4-Gra Ce1-Gra Me4-Gra Me1-Gra Me4-Grb Ce1-Grb Me4-Grb Me1-Grb Me1-Gra Me1-GrbSeymurH-vÎncă nu există evaluări

- Boru Tesisati Cap Tayini CedveliDocument1 paginăBoru Tesisati Cap Tayini CedveliSeymurH-vÎncă nu există evaluări

- TechnologyDocument1 paginăTechnologySeymurH-vÎncă nu există evaluări

- PE100 Polietilen Pipe AvailabilityDocument2 paginiPE100 Polietilen Pipe AvailabilitySeymurH-vÎncă nu există evaluări

- Perspective 02Document19 paginiPerspective 02SeymurH-vÎncă nu există evaluări

- Ansi Y14.24m-1989Document89 paginiAnsi Y14.24m-1989SeymurH-vÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)