Documente Academic

Documente Profesional

Documente Cultură

Welding Engineer

Încărcat de

jesycoc0 evaluări0% au considerat acest document util (0 voturi)

50 vizualizări1 paginăWeld engi

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWeld engi

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

50 vizualizări1 paginăWelding Engineer

Încărcat de

jesycocWeld engi

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

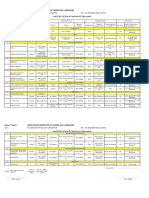

GENERAL SUMMARY

Reviews customer contract specifications, drawings and code requirements to determine the

welding requirements for procedure and personnel qualifications in accordance with applicable

welding codes, internal customer standards and specific requirements.

MAJOR DUTIES & RESPONSIBILITIES

1. Commit to safety procedures

2. Follow all welding Engineering standards

3. Initiate travelers for preparation of Welding Procedure Specification (WPS) and Welding Material

test samples.

4. Formalize and release WPS and Procedure Qualification Record (PQR) from completed travelers

and approved test results.

5. Initiate procurement action by preparing and processing purchase orders for all weld material

tests and all welder performance and procedure qualification sample testing

6. Set up and maintain master WPS and PQR files in accordance with AWS D1.1, AWS D8.8, AWS

D1.2 and internal customer requirements.

7. Set up and maintain record of welder or welding operator qualification tests for each welder’s

qualification file, in accordance with applicable customer codes contract requirements

8. Prepare and issue/maintain operator qualification matrix at least every six months or whenever

sufficient changes occur warranting reissuance, in accordance with code requirements

9. Assist in Engineering, Quality and Estimating departments with any technical issues regarding

welding and fabricability requirements for projects.

10. Apply knowledge of production specifications, properties and characteristics of metals and

metal alloys to develop welding techniques, procedures, and application of welding equipment to

problems involving fabrication of metals

11. Develop and test new fabrication processes and procedures, improve existing or develop new

welding equipment, develop new or modify current welding methods, techniques, and procedures

12. Identify and evaluate latest welding equipment, materials and techniques for possible

application to shop welding practices or production processes

13. Serve as customer contact for technical issues regarding welding requirements

14. Develop internal audits (CQI-15)

15. Develop training on visual inspection requirements regarding welding customer codes

SKILLS / KNOWLEDGE REQUIRED:

1. Written and verbal communication skills, leadership abilities, problem solving and analytical skills

2. PC-based application skills such as MS Office (Word, Excel, Power-Point)

3. Ability to work in a team-oriented environment to meet customer contract requirements and

expectations

KEY COMPETENCIES:

Strategic orientation; results oriented; team and customer orientation; leading change; flexibility;

innovation; detail oriented; excellent skills in communication, time management, organization,

problem solving and analysis

EDUCATION / EXPERIENCE REQUIREMENTS:

BS degree in Weld Engineering or an Engineering or Welding-related field or CWI. Previous work

experience in Welding

Engineering or a welding related field a plus. Experience with codes, visual inspection.

S-ar putea să vă placă și

- Job Description Mechanical Design EngineersDocument1 paginăJob Description Mechanical Design Engineersyinkaakins2001Încă nu există evaluări

- Piping ResponsibilitiesDocument14 paginiPiping Responsibilitiesshivabtowin3301Încă nu există evaluări

- Rupak Choudhary: Work ExperienceDocument5 paginiRupak Choudhary: Work ExperiencePradhipta W NurrobbiÎncă nu există evaluări

- NDT TechnicianDocument5 paginiNDT TechnicianMdk bloreÎncă nu există evaluări

- Welding Engineer - 01 - 01 - 2021Document1 paginăWelding Engineer - 01 - 01 - 2021tan yahyaÎncă nu există evaluări

- Associate - Senior Associate - Business AnalystDocument1 paginăAssociate - Senior Associate - Business Analystkamlesh kumariÎncă nu există evaluări

- Job SummaryDocument4 paginiJob Summaryabeer789Încă nu există evaluări

- Engineering Manager Job RolesDocument3 paginiEngineering Manager Job Rolesresp-ectÎncă nu există evaluări

- Resume Sarfaraj Shaikh Project ManagerDocument4 paginiResume Sarfaraj Shaikh Project ManagerSarfaraj ShaikhÎncă nu există evaluări

- Quality Manager ConstructionDocument2 paginiQuality Manager ConstructionAbdullah AnsariÎncă nu există evaluări

- Curriculum Vitae (Rahul Ramdas Yelve)Document5 paginiCurriculum Vitae (Rahul Ramdas Yelve)prashantghodkeÎncă nu există evaluări

- Roles of QA QC ManagerDocument3 paginiRoles of QA QC ManagerAbdullah AnsariÎncă nu există evaluări

- Post Doc Letters ExamplesDocument1 paginăPost Doc Letters ExamplesArshadAliÎncă nu există evaluări

- Bechtel QAQC AdvisorDocument5 paginiBechtel QAQC Advisoryoonchankim0911100% (1)

- Mon Finlqaqce. 3Document4 paginiMon Finlqaqce. 3ulocksystemÎncă nu există evaluări

- Ajin BabuDocument4 paginiAjin BabuJithuJohnÎncă nu există evaluări

- Manoj Raj P R - Uae - UpdatedDocument4 paginiManoj Raj P R - Uae - UpdatedMano LazyboyÎncă nu există evaluări

- Resume: Kasar Mayur TulsidasDocument4 paginiResume: Kasar Mayur TulsidasFAB HUBÎncă nu există evaluări

- Chintan Raval: Welding Engineer - Fabtech EngineeringDocument3 paginiChintan Raval: Welding Engineer - Fabtech Engineeringabidaliabid1Încă nu există evaluări

- Abdullah Alshaghab - CV - March 2016Document3 paginiAbdullah Alshaghab - CV - March 2016Ahmad fayyazÎncă nu există evaluări

- Curriculum Vitae: Name: Upendra KumarDocument6 paginiCurriculum Vitae: Name: Upendra KumarNitin KarboÎncă nu există evaluări

- Summary of Experience: MD Aamir ShahnawazDocument4 paginiSummary of Experience: MD Aamir ShahnawazEr Md AamirÎncă nu există evaluări

- Resume of Nure AlamDocument8 paginiResume of Nure AlamEngr. Shahidul IslamÎncă nu există evaluări

- Do Things Right - Successfully Completed More Than 25 Design Function Tasks With 100%Document2 paginiDo Things Right - Successfully Completed More Than 25 Design Function Tasks With 100%bsagguÎncă nu există evaluări

- JOB DESCRIPTION: Mechanical Design Engineer: OverviewDocument2 paginiJOB DESCRIPTION: Mechanical Design Engineer: OverviewAspire SuccessÎncă nu există evaluări

- Curriculum Vitae Of: Correspondence/Permanent Address: EmailDocument19 paginiCurriculum Vitae Of: Correspondence/Permanent Address: EmailsojeckÎncă nu există evaluări

- Curriculum Vitae: Khermache MokhtarDocument4 paginiCurriculum Vitae: Khermache MokhtarMokhtar KhermacheÎncă nu există evaluări

- Mubeen Ahmed CVDocument7 paginiMubeen Ahmed CVMonis Hyder100% (1)

- ChaDocument6 paginiChaBala KrishnanÎncă nu există evaluări

- Specialized Industrial Services Co. Ltd. JOB DESCRIPTION - Lead Quality Control Job Title: Department: Report To: Job SummaryDocument2 paginiSpecialized Industrial Services Co. Ltd. JOB DESCRIPTION - Lead Quality Control Job Title: Department: Report To: Job SummarymuhammadazharÎncă nu există evaluări

- Qa - QC ManagerDocument14 paginiQa - QC Managermunawar hussainÎncă nu există evaluări

- Job Skill NeedDocument2 paginiJob Skill NeedRajvikashÎncă nu există evaluări

- Welder Level C Program OutlineDocument185 paginiWelder Level C Program OutlineRon Carlo DiosoÎncă nu există evaluări

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Document7 paginiResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinÎncă nu există evaluări

- Job Description - Senior Welding InspectorDocument3 paginiJob Description - Senior Welding InspectorJennifer FrenchÎncă nu există evaluări

- GasDocument18 paginiGassojeck0% (1)

- Qa/Qc Welding Inspector: Curriculum VitaeDocument5 paginiQa/Qc Welding Inspector: Curriculum Vitaenaveed7861Încă nu există evaluări

- Recruitment PT Jurong Engineering Lestari - QC Coordinator 20210209Document2 paginiRecruitment PT Jurong Engineering Lestari - QC Coordinator 20210209Dera ChoanjiÎncă nu există evaluări

- Aravindhan PT CV CSWIP TrainerDocument4 paginiAravindhan PT CV CSWIP TrainerGanesan RamamoorthyÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfddfdffdDocument1 paginăPositions Vacant: QC Welding: AafdfddfdffdsanketÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfddfdffdddDocument1 paginăPositions Vacant: QC Welding: AafdfddfdffdddsanketÎncă nu există evaluări

- Positions Vacant: QC WeldingDocument1 paginăPositions Vacant: QC WeldingsanketÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfddfdffdddsdgDocument1 paginăPositions Vacant: QC Welding: AafdfddfdffdddsdgsanketÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfdDocument1 paginăPositions Vacant: QC Welding: AafdfdsanketÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfddfdffDocument1 paginăPositions Vacant: QC Welding: AafdfddfdffsanketÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfddfDocument1 paginăPositions Vacant: QC Welding: AafdfddfsanketÎncă nu există evaluări

- Positions Vacant: QC Welding: AafdfddfdffdddsdDocument1 paginăPositions Vacant: QC Welding: AafdfddfdffdddsdsanketÎncă nu există evaluări

- Field Application Engineer - Job DescriptionDocument2 paginiField Application Engineer - Job DescriptionSean FernandesÎncă nu există evaluări

- Saif Ullah Updated AramcoDocument4 paginiSaif Ullah Updated AramcoHaleem Ur Rashid BangashÎncă nu există evaluări

- Rakesh Rahulan1Document6 paginiRakesh Rahulan1rakeshÎncă nu există evaluări

- Job Description - Welding Engineer - ViergeDocument2 paginiJob Description - Welding Engineer - Viergeait.koufiÎncă nu există evaluări

- JD QAQC Engineer Mech 2016Document2 paginiJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- Usman CV Qaqc 1Document2 paginiUsman CV Qaqc 1Digital InfoÎncă nu există evaluări

- Welding Skills ResumeDocument7 paginiWelding Skills Resumeafdlxeqbk100% (1)

- Recume Welding SupervisorDocument5 paginiRecume Welding SupervisorhitanshuÎncă nu există evaluări

- Quality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaDocument4 paginiQuality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaArunÎncă nu există evaluări

- Sreekumar.S.I: Mechanical Engineer (B.E)Document3 paginiSreekumar.S.I: Mechanical Engineer (B.E)JunaidAsrarÎncă nu există evaluări

- Quality EngineerDocument4 paginiQuality Engineerapi-78526036Încă nu există evaluări

- Weld SDocument1 paginăWeld SjesycocÎncă nu există evaluări

- Weld RtyuiiDocument1 paginăWeld RtyuiijesycocÎncă nu există evaluări

- Weld YtDocument1 paginăWeld YtjesycocÎncă nu există evaluări

- Weld SinDocument1 paginăWeld SinjesycocÎncă nu există evaluări

- Welding GaugesDocument1 paginăWelding GaugesjesycocÎncă nu există evaluări

- Weld 7Document1 paginăWeld 7jesycocÎncă nu există evaluări

- Laser WeldingDocument1 paginăLaser WeldingjesycocÎncă nu există evaluări

- b2.1 QualificationDocument306 paginib2.1 Qualificationjesycoc100% (1)

- Welding GaugesDocument1 paginăWelding GaugesjesycocÎncă nu există evaluări

- Saw WeldDocument1 paginăSaw WeldjesycocÎncă nu există evaluări

- CQI.9.Heat Treat System AssessmentDocument51 paginiCQI.9.Heat Treat System AssessmentDung Tran KienÎncă nu există evaluări

- Listado Personal ProduccionDocument210 paginiListado Personal ProduccionjesycocÎncă nu există evaluări

- MaterialDocument1 paginăMaterialjesycocÎncă nu există evaluări

- CotizacionDocument1 paginăCotizacionjesycocÎncă nu există evaluări

- ES-14-602-01 Site Fab and Ist PipingDocument26 paginiES-14-602-01 Site Fab and Ist PipingKhas BaniÎncă nu există evaluări

- Riser GuideDocument120 paginiRiser GuideAndrea ZuritaÎncă nu există evaluări

- Hand Out ASME IX Rev 10 - Nov 2019Document76 paginiHand Out ASME IX Rev 10 - Nov 2019luthfi otoyÎncă nu există evaluări

- Fracture TestDocument1 paginăFracture TestYuvaraj SathishÎncă nu există evaluări

- Aws-D17.1 PDFDocument60 paginiAws-D17.1 PDFssÎncă nu există evaluări

- QAP For Overall Mechanical ActivitiesDocument2 paginiQAP For Overall Mechanical ActivitiesMaheshwar polepallyÎncă nu există evaluări

- Arc StrikeDocument9 paginiArc StrikeBulut YildizÎncă nu există evaluări

- Procedure Qualification Record (PQR)Document2 paginiProcedure Qualification Record (PQR)Ankit KumarÎncă nu există evaluări

- En 15085Document3 paginiEn 15085ShowanHydraulics60% (5)

- Ga-201 Centrif PumpsDocument31 paginiGa-201 Centrif PumpsCarlos Luis Esquerdo MarcanoÎncă nu există evaluări

- Iso 15614 8 2002 PDFDocument26 paginiIso 15614 8 2002 PDFumur kaçamaklıÎncă nu există evaluări

- CWB FCAW Prequalified SetDocument77 paginiCWB FCAW Prequalified Setרונן לבÎncă nu există evaluări

- Data Sheet For Welding of Pressure Containing Equipment and PipingDocument9 paginiData Sheet For Welding of Pressure Containing Equipment and PipingPramod AthiyarathuÎncă nu există evaluări

- 77-104 - 2012 Check ValvesDocument11 pagini77-104 - 2012 Check ValvespradeepÎncă nu există evaluări

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pagini2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524Încă nu există evaluări

- Fabrication ProcedureDocument17 paginiFabrication ProcedureThi Pham100% (9)

- AAR Manual of Standards and Recommended Practices Specifications For Tank CarsDocument38 paginiAAR Manual of Standards and Recommended Practices Specifications For Tank CarsCentre For Total Quality ManagementÎncă nu există evaluări

- Inspection and Test Planrev01Document16 paginiInspection and Test Planrev01Nguyễn MinhÎncă nu există evaluări

- 09 Welding Procedures and Qualifcations As Per ASME SEC IXDocument7 pagini09 Welding Procedures and Qualifcations As Per ASME SEC IXvilukÎncă nu există evaluări

- Mock Up, WPS & PQRDocument12 paginiMock Up, WPS & PQRVaibhav100% (1)

- Pr-w-1102.21-4012-004 Rev A Welder Qualification Testing For Steel Structure (WQT) - SWDocument18 paginiPr-w-1102.21-4012-004 Rev A Welder Qualification Testing For Steel Structure (WQT) - SWMehmet Soysal100% (1)

- Aramco CBT Questions-Answere For QAQC Welding-PART-04Document14 paginiAramco CBT Questions-Answere For QAQC Welding-PART-04Abdul Hafeez50% (2)

- Asme Ix WPS TestDocument6 paginiAsme Ix WPS Testmuhammad hadiÎncă nu există evaluări

- Asme B31.3 2020Document4 paginiAsme B31.3 2020Tuugii OtgooÎncă nu există evaluări

- Asme Weld NumberDocument22 paginiAsme Weld NumberahmedÎncă nu există evaluări

- Module 12 - Design & Construction - Rev 5 - May 15Document107 paginiModule 12 - Design & Construction - Rev 5 - May 15sskiitb100% (1)

- Inspection of Storage TankDocument19 paginiInspection of Storage TanknovazhaiÎncă nu există evaluări

- Guidelines On Welding ProcedureDocument9 paginiGuidelines On Welding ProcedureadelÎncă nu există evaluări

- BCSA - P50-09 Typical Welding Procedure Specifications For Structural Steelwork - Welding BookDocument0 paginiBCSA - P50-09 Typical Welding Procedure Specifications For Structural Steelwork - Welding BookDifa Liu100% (1)

- TSPP8Document76 paginiTSPP8Ian Naylor100% (1)