Documente Academic

Documente Profesional

Documente Cultură

9320a225g Plano LH

Încărcat de

ForteLubTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

9320a225g Plano LH

Încărcat de

ForteLubDrepturi de autor:

Formate disponibile

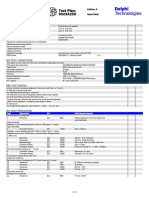

9320A220 Issue No: 1

Test Plan

Vista T2164 Date: 00/00/00

PUMP SPECIFICATION

Rotation: Clockwise.

Governor type: Mechanical all-speed.

Gov. Link Length: 41.5 ± 0.5 mm.

Gov. Link Length: 10.1 ± 0.5 mm.

(DP210 Workshop Manual Section 4.6.4)

Plunger Diameter: 7.0 mm (4 off).

Drive Type: Supported shaft.

Transfer pressure: adjustable.

Viscosity compensating device in end plate.

Cambox pressurising valve.

Servo Advance with:

- Speed advance, LLA & CA

Torque trimmer.

Solenoid voltage: See Service Instruction Note DT294.

OEM Code: 2644H012 Setting Code: YR/2/2350

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified and the

following test benches: HA3000/HA2500/HA700/AVM/PGM

Test Fluid: ISO 4113 at 40 ± 2°C.

Inlet feed pressure: 5.0 psi

Backleak pressure: 0.0 psi

Nozzles: YDB286 (BDL0S6844)

Nozzle Opening Pressure: 172 + 3 - 0 bar.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy.

H.P. pipes: 6 x 1.8 x 450 mm

PRE-TEST NOTES

Screw transfer pressure adjuster fully out and then 4.5 turns

in before commencing test.

CA solenoid to be de-energised unless otherwise stated.

Torque trimmer plug to be wound out until thread appears.

Latch valve adjuster, if fitted, screw fully in then

8 turns out

Turn light load adjuster valve fully in ,then 2 turns out.

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

1. Priming (C) 200 Obtain delivery from all injectors

and backleak.

Close throttle.

Stabilise. Cycle speed between 100 to 400 rpm 5 times.

Open throttle.

2. Transfer Press. (S) 1100 90 to 92 psi

3. Delivery (S) 1100 82.0 ± 0.5 mm3/st.

4. Governor (S) 1220 12.0 to 16.0 mm3/st.

Stabilise. Cycle speed between 100 to 1230 rpm 5 times.

Stabilise and run at 1100 rpm until backleak temperature

is 38°C min.

5. Backleakage (C) 1100 Flow rate 500 to 1000 cm3/min.

6. Cambox Press. (C) 1100 6 to 10 psi.

7. Transfer Press. (S) 1100 Press at test(6 ) + 82.5to 83.5psi

Run test machine down to 0 rpm.

8. Transfer Press. (C) 100 Minimum 12 psi.

9. Transfer Press (C) 1100 As test (7 ) ± 1.0 psi

If incorrect repeat from test (6 ).

Stop test machine.

Remove pressure gauges and fit stop solenoid or plug.

10. Advance (S) 500 0° (Datum advance gauge)

11. Advance (C) 750 0.3° Max.

12. Advance (C) 1050 0.8 to 1.2°.

13. Advance (C) 1100 0.8 to 1.2°.

Stop test machine.

Energise CA solenoid.

14. Advance (C) 700 3.8 to 5.5°.

De-energise CA solenoid.

15. Advance - (S) 1100 2.8to 3.2° 37to 41mm3/st.

Light load Adjust throttle/torque screw

& LLA valve.

Run test machine down to 0 rpm.

16. Advance - (C) 1100 2.8to 3.2° 39.0 ± 2.0mm3/st.

Light load Use throttle/Torque screw.

17. Advance - (C) 1100 7.8to 8.2° 23.0 ± 8.0mm3/st.

Light load Use throttle/Torque screw.

18. Advance - (C) 700 1.8to 2.2° 48.0 ± 7.0mm3/st.

Light load Use throttle/Torque screw.

19. Advance - (C) 1100 0.5to 1.5° 50.0 ± 0.5mm3/st.

Light load Use throttle/Torque screw.

Open throttle.

Stop test machine.

Fit CPS tool

20. Torque Trimmer (S) 1100 Datum CPS reading to 0.0mm.

21. Torque Trimmer (S) 600 Adjust CPS to -0.2 to -1.05mm

CPS

22. Torque Trimmer (S) 650 Adjust CPS to 0.2 to 0.25mm

CPS

Run test machine down to 0 rpm.

23. Torque Trimmer (C) 1100 As test (20) ± 0.05 mm

CPS

24. Torque Trimmer (C) 725 As test (23) + 0.8 ± 0.3 mm

CPS

25. Torque Trimmer (C) 550 As test (23) - 0.8 ± 0.6 mm

CPS

If correct continue with test (26), if not, adjust shimming

and then repeat test(s) (20 to 25 ).

Screw latch valve adjuster fully in.

26. Latch Valve S/C 250 CPS = -0.5 to -2.0 mm

If incorrect, adjust LV pre-load

& repeat test.

Run test machine down to 0 rpm.

27. Torque Trimmer (C) 220 Check CPS is 0.0 to 5.0mm

CPS

28. Torque Trimmer (C) 280 Check CPS is -0.5 to -2.0mm

CPS

If incorrect or adjusted, stop machine and repeat from test (26).

29. Delivery (C) 100 Minimum 75.0 mm3/st.

30. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 2.0 mm3/st.

Stop test machine.

Close throttle.

31. Idle delivery (S) 405 12.0 to 16.0 mm3/st. Throttle closed.

32. Delivery (C) 510 Maximum 3.0 mm3/st.

Stop test machine.

Fit Max Fuel adjuster tool

Open throttle.

33. Max. Delivery (S) 1100 82.0 ± 0.3 mm3/st.

Max. spread 5.0 mm3/st.

34. Delivery (C) 750 As test (33) + 11.0 ± 3.0 mm3/st.

35. Delivery (C) 1100 Record delivery mm3/st.

36. Governor (S) 1190 12.0 to 16.0 mm3/st.

37. Gov. cut-off (C) 1240 Maximum 3.0 mm3/st.

38. Delivery (C) 1100 Throttle as test (36).

Minimum as test (35) - 1.0 mm3/st.

39. Dynamic timing Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 184.1°

speed (S) 1100 Trigger level 25 %

.

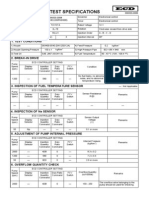

ISO OVERCHECK PROCEDURE

.

The Overcheck section of this plan has been developed in

conjunction with the Original Equipment Manufacturer.

Providing all values are achieved, the pump settings will

maintain the original homologated engine performance. Failure to

attain any one of the values will indicate a pump setting or

function failure and require further investigation.

.

PRE-OVERCHECK NOTES

Dynamic timing - record zero angle - (refer to DT339)

Drive shaft lock bolt to remain locked until zero angle

recorded.

CA advance motor to be de-energised unless otherwise stated.

No adjustments to be made unless otherwise stated.

Close throttle.

Stabilise. Cycle speed between 100 to 500 rpm 3 times.

Open throttle.

Stabilise. Cycle speed between 100 to 1250 rpm 5 times.

Stabilise and run at 1100 rpm until backleak temperature

is 38°C min.

40. Advance (S) 500 0° (Datum advance gauge)

41. Advance (C) 1100 0.7 to 1.3°.

42. Advance - (C) 1100 2.8to 3.2° 39.0 ± 4.0mm3/st.

Light load Use throttle/Torque screw.

43. Advance - (C) 1100 7.8to 8.2° 23.0 ± 10.0mm3/st.

Light load Use throttle/Torque screw.

44. Advance - (C) 700 1.8to 2.2° 48.0 ± 7.0mm3/st.

Light load Use throttle/Torque screw.

Stop test machine.

Energise CA solenoid.

45. Advance (C) 700 3.8 to 5.5°.

De-energise CA solenoid.

Open throttle.

Fit CPS tool

46. Torque Trimmer (S) 1100 Datum CPS reading to 0.0mm.

47. Torque Trimmer (C) 735 As test (46) + 0.8 ± 0.3 mm

CPS

48. Torque Trimmer (C) 540 As test (46) - 0.8 ± 0.6 mm

CPS

Move throttle lever to closed position for tests (49 ).

49. Delivery (C) 520 Maximum 3.0 mm3/st.

Open throttle.

50. Delivery (C) 100 Minimum 70.0 mm3/st.

51. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 3.0 mm3/st.

Run test machine down to 0 rpm.

52. Delivery (C) 1100 80.0 to 84.0 mm3/st.

53. Delivery (C) 750 As test (52) + 11.0 ± 4.0 mm3/st.

54. Gov. cut-off (C) 1240 Maximum 3.0 mm3/st.

55. Dynamic timing Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 184.1°

speed (S) 1100 Trigger level 25 %

S-ar putea să vă placă și

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 paginiTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215Încă nu există evaluări

- Optimize pump specification test plan titleDocument4 paginiOptimize pump specification test plan titleLIONN SOFTWARESÎncă nu există evaluări

- Ford HSDI pump specification and ISO test procedureDocument2 paginiFord HSDI pump specification and ISO test proceduretaniaÎncă nu există evaluări

- Test Plan: Pump SpecificationDocument3 paginiTest Plan: Pump SpecificationBaytolgaÎncă nu există evaluări

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 paginiTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Test Plan for Perkins Vista A 80 KVA @ 15 KVA GeneratorDocument2 paginiTest Plan for Perkins Vista A 80 KVA @ 15 KVA Generatormarco rod100% (1)

- 3042f843 Plano de TesteDocument1 pagină3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Test Plan Delphi TechnologiesDocument2 paginiTest Plan Delphi TechnologiesFRANCISCOÎncă nu există evaluări

- 9521A030H DATA CatalogDocument3 pagini9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test Plan: 9320A210: Pump SpecificationDocument7 paginiTest Plan: 9320A210: Pump SpecificationBaytolgaÎncă nu există evaluări

- EU/5/2360 Test PlanDocument2 paginiEU/5/2360 Test PlanOseasJuniorÎncă nu există evaluări

- Test Plan: 9521A030: Pump SpecificationDocument3 paginiTest Plan: 9521A030: Pump Specificationjohnny sabinÎncă nu există evaluări

- 9520A192G - PlanDocument3 pagini9520A192G - PlanMihai-Eugen Popa100% (1)

- 3340F401G Plano de Teste DelphiDocument2 pagini3340F401G Plano de Teste DelphiJunior Iung100% (1)

- 745 4410Document2 pagini745 4410murillo_rodriguez8382100% (1)

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- Inj. Pump Calibration Data: 1. Test ConditionsDocument6 paginiInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasÎncă nu există evaluări

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 paginiInj. Pump Calibration Data: 1. Test ConditionsBrigida Torres Moreno0% (1)

- Injection Pump Calibration DataDocument2 paginiInjection Pump Calibration DataСергей ВладимировичÎncă nu există evaluări

- CALIBRATION DATA FOR INJECTION PUMPDocument2 paginiCALIBRATION DATA FOR INJECTION PUMPMiguel RojasÎncă nu există evaluări

- BOSCH EP test values for diesel fuel injection equipmentDocument3 paginiBOSCH EP test values for diesel fuel injection equipmentNemo NeoÎncă nu există evaluări

- (Oto-Hui - Com) Edc Hino s05Document2 pagini(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500Încă nu există evaluări

- 196000-0990 DaihatsuDocument13 pagini196000-0990 DaihatsuEdinson Ariel Chavarro QuinteroÎncă nu există evaluări

- lt1000d6 PDFDocument3 paginilt1000d6 PDFJo Ferry0% (1)

- Injection Pump Calibration Data: Assy No.: 106671-0224Document4 paginiInjection Pump Calibration Data: Assy No.: 106671-0224Elson DorigonÎncă nu există evaluări

- Injection pump test specifications for Hino W04D engineDocument2 paginiInjection pump test specifications for Hino W04D engineBaytolgaÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test Specificationsadmin tigasaudaraÎncă nu există evaluări

- 101402-9770 Test PlanDocument3 pagini101402-9770 Test PlanMihai-Eugen Popa100% (1)

- Perkins - CAT EngineDocument2 paginiPerkins - CAT EngineAnky IsmasÎncă nu există evaluări

- F 002 A0z 755 Spare PartsDocument17 paginiF 002 A0z 755 Spare PartsGowtham100% (1)

- 104780-3031 Test PlanDocument4 pagini104780-3031 Test PlanMihai-Eugen PopaÎncă nu există evaluări

- Test SpecificationsDocument2 paginiTest SpecificationsBest Auto Tech100% (1)

- DATODocument1 paginăDATOMiguel RojasÎncă nu există evaluări

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pagini096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungÎncă nu există evaluări

- 101402-9770 Parts ListDocument3 pagini101402-9770 Parts ListMihai-Eugen Popa100% (1)

- Injection Pump Test S Pecifications 196000-417#Document4 paginiInjection Pump Test S Pecifications 196000-417#Juan Gabriel Ochoa100% (1)

- 9161Document5 pagini9161BaytolgaÎncă nu există evaluări

- Injection Pump Calibration Data: 1. Test ConditionsDocument3 paginiInjection Pump Calibration Data: 1. Test ConditionsElson DorigonÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- Bosch EP test values for diesel fuel injection equipmentDocument3 paginiBosch EP test values for diesel fuel injection equipmentTamer Moustafa100% (1)

- Dpico: Inj. Pump Calibration DataDocument3 paginiDpico: Inj. Pump Calibration DataСергей ВладимировичÎncă nu există evaluări

- Aplic Bombas ChinasDocument2 paginiAplic Bombas ChinasMiguel ChaconÎncă nu există evaluări

- Injection Pump Test Specifications 092000-512#Document3 paginiInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- INJECTION PUMP CALIBRATION DATADocument3 paginiINJECTION PUMP CALIBRATION DATAElson DorigonÎncă nu există evaluări

- Inj - P Ump Cal Ibration DataDocument3 paginiInj - P Ump Cal Ibration DataСергей ВладимировичÎncă nu există evaluări

- Calibration Data AdjustmentDocument4 paginiCalibration Data AdjustmentMas Inyeccion ElectronicaÎncă nu există evaluări

- Bosch Common Rail Injector Test DataDocument76 paginiBosch Common Rail Injector Test Datalennon r100% (2)

- Injection P Ump Test Specifications 196000-327#Document4 paginiInjection P Ump Test Specifications 196000-327#Manuel João JoãoÎncă nu există evaluări

- 0 400 866 208 TestPlanDocument2 pagini0 400 866 208 TestPlanคุณชายธวัชชัย เจริญสุข100% (2)

- Two-Spring Nozzle Holder Calibration Data: For IsuzuDocument61 paginiTwo-Spring Nozzle Holder Calibration Data: For IsuzuLuis MirandaÎncă nu există evaluări

- Injection Pump Test Specifications 196000-517#Document4 paginiInjection Pump Test Specifications 196000-517#Edinson Ariel Chavarro QuinteroÎncă nu există evaluări

- Test and diagnose Bosch VE EDC diesel pump actuator faultsDocument1 paginăTest and diagnose Bosch VE EDC diesel pump actuator faultsCharaf-eddine RamehÎncă nu există evaluări

- PDFDocument2 paginiPDFRAVIKANT100% (1)

- 2.8 Zexel Pump1Document2 pagini2.8 Zexel Pump1cork_ieÎncă nu există evaluări

- db4429 5514Document4 paginidb4429 5514WillianPachecoÎncă nu există evaluări

- 101401-9271 Calibration DataDocument5 pagini101401-9271 Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- 4720Document3 pagini4720Junior IungÎncă nu există evaluări

- Temp 753Document2 paginiTemp 753Neelakandan Krishnan100% (1)

- 9323A271G Catalog DATADocument4 pagini9323A271G Catalog DATALIONN SOFTWARESÎncă nu există evaluări

- 9323a251g PTDocument3 pagini9323a251g PTClarice Alves de FreitasÎncă nu există evaluări

- Sistemas de inyección dieselDocument14 paginiSistemas de inyección dieselErick SantiagoÎncă nu există evaluări

- COVEC F Service ManualDocument55 paginiCOVEC F Service Manualorsm100% (12)

- ECD V3 V5 Ve Pump Denso Repair ManualDocument118 paginiECD V3 V5 Ve Pump Denso Repair Manualsimplu64997% (35)

- 101061-8530 - Bba ExplodidaDocument1 pagină101061-8530 - Bba ExplodidaForteLubÎncă nu există evaluări

- 781307Document23 pagini781307ForteLubÎncă nu există evaluări

- 1564Document3 pagini1564ForteLubÎncă nu există evaluări

- 1047012043Document10 pagini1047012043ForteLubÎncă nu există evaluări

- 2170Document9 pagini2170ForteLubÎncă nu există evaluări

- 1068714150Document6 pagini1068714150ForteLubÎncă nu există evaluări

- 01EJ3051Document3 pagini01EJ3051ForteLubÎncă nu există evaluări

- 8134Document5 pagini8134ForteLubÎncă nu există evaluări

- Injection Pump Calibration Data: Engine ModelDocument1 paginăInjection Pump Calibration Data: Engine ModelForteLubÎncă nu există evaluări

- INJECTION PUMP TEST SPECIFICATIONS 096500-0080Document3 paginiINJECTION PUMP TEST SPECIFICATIONS 096500-0080ForteLub100% (1)

- 01EJ2010Document3 pagini01EJ2010ForteLubÎncă nu există evaluări

- 01EJ2000Document3 pagini01EJ2000ForteLubÎncă nu există evaluări

- 10 Chapter 1Document44 pagini10 Chapter 1Abeera Hassan ChohanÎncă nu există evaluări

- Engineering Physics FundamentalsDocument29 paginiEngineering Physics Fundamentalsabi niveshÎncă nu există evaluări

- Van Der Meer - Application and Stability Criteria For Rock and Artificial UnitsDocument24 paginiVan Der Meer - Application and Stability Criteria For Rock and Artificial Unitsapi-3709579100% (1)

- InvolutesDocument13 paginiInvolutesmbeaelnaaÎncă nu există evaluări

- Save Data in Arabic in MySQL DatabaseDocument2 paginiSave Data in Arabic in MySQL DatabaseyoussefeÎncă nu există evaluări

- Zemichael Berhe MehariDocument99 paginiZemichael Berhe Meharidhanesh kumarÎncă nu există evaluări

- Signature FileDocument28 paginiSignature FileLaxmi BlossomÎncă nu există evaluări

- Lesson Plan4Document3 paginiLesson Plan4api-410721710Încă nu există evaluări

- Lab 4 Exercise: Data sources and calculated columnsDocument4 paginiLab 4 Exercise: Data sources and calculated columnsSITI FATIMAH AMALINA ABDUL RAZAKÎncă nu există evaluări

- Geometry m2 Topic C Lesson 12 TeacherDocument14 paginiGeometry m2 Topic C Lesson 12 TeacherMae RohÎncă nu există evaluări

- Corrosion of Aluminum and Its Alloys - Forms of Corrosion - Total Materia ArticleDocument4 paginiCorrosion of Aluminum and Its Alloys - Forms of Corrosion - Total Materia ArticleDavide CongiuÎncă nu există evaluări

- Basic Blueprint ReadingDocument219 paginiBasic Blueprint ReadingJShearer93% (15)

- QB 10 Chapter 5&6Document4 paginiQB 10 Chapter 5&6Nitin SÎncă nu există evaluări

- Math For Real LifeDocument213 paginiMath For Real LifezagarzusemÎncă nu există evaluări

- Sequences WorksheetDocument8 paginiSequences WorksheetAsh LoopsÎncă nu există evaluări

- The Standard Model of Particle PhysicsDocument95 paginiThe Standard Model of Particle PhysicsaliakouÎncă nu există evaluări

- 19-02 RIP The Routing Information ProtocolDocument12 pagini19-02 RIP The Routing Information Protocolrichard akpagniÎncă nu există evaluări

- Sinotruk: Hw19170T Transmission Spare Parts CatalogDocument20 paginiSinotruk: Hw19170T Transmission Spare Parts Catalogየብእር ስምÎncă nu există evaluări

- Vinyl ChlorideDocument79 paginiVinyl ChlorideKunal Yadav100% (13)

- Lab - Principles of BiomechanicsDocument2 paginiLab - Principles of BiomechanicsMikaela SteyerÎncă nu există evaluări

- 17 PCS ResourceGuide Full Final1 PDFDocument68 pagini17 PCS ResourceGuide Full Final1 PDFMako ZoltanÎncă nu există evaluări

- GDM Ch-17 Abuts Ret WallsDocument136 paginiGDM Ch-17 Abuts Ret WallsNguyen Ngoc DuyenÎncă nu există evaluări

- Exp6 - Comparative Investigation of Organic CompoundsDocument3 paginiExp6 - Comparative Investigation of Organic Compoundssmcm11Încă nu există evaluări

- Anexo 04 - Datasheet MódulosDocument2 paginiAnexo 04 - Datasheet MódulosJoao Vitor FonsecaÎncă nu există evaluări

- Thesis Antenna HfssDocument5 paginiThesis Antenna Hfssafkofvidg100% (2)

- Calculus For Engineers: Chapter 16 - Laplace TransformsDocument41 paginiCalculus For Engineers: Chapter 16 - Laplace TransformsscreamÎncă nu există evaluări

- CPA Review School Philippines Final Exam GuideDocument14 paginiCPA Review School Philippines Final Exam GuideAzureBlazeÎncă nu există evaluări

- Instrument Check List PDFDocument9 paginiInstrument Check List PDFBrijesh Srivastav100% (1)

- Calculation of Displacement, LWT and DWTDocument18 paginiCalculation of Displacement, LWT and DWTM.Neuer91% (45)