Documente Academic

Documente Profesional

Documente Cultură

32

Încărcat de

il26Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

32

Încărcat de

il26Drepturi de autor:

Formate disponibile

CSM Instruments

Advanced Mechanical Surface Testing

APPLICATIONS BULLETIN

Characterization of thermal spray coatings by

instrumented indentation and scratch testing Part II:

Indentation of plasma sprayed coatings

//// Introduction One of the most significant advantages of instrumented

The first part of this CSM Instruments Application Bul- indentation is the possibility of automated measurements

letin was dedicated to the demonstration of the use of due to the hardness and elastic modulus calculation from

instrumented indentation and scratch testing for charac- the loading-unloading curve. The automation can be di-

terization of HVOF coatings. This second part extends the vided into two types:

application of the instrumented indentation method to > spatial automation (matrix indentation),

plasma sprayed ceramics and metals. The paper will focus > automated indentation load increase

on advantages of instrumented indentation when applied (depth profiling).

to plasma sprayed coatings with respect to their heteroge-

neous microstructure. //// Visual matrix indentation

Visual matrix indentation is a particular case of spatially

//// Instrumented indentation features resolved matrix indentation where indentation sites are

The instrumented indentation method reveals much more located under the microscope and then indented auto-

information about a thermal spray coating than conven- matically. This type of measurement is especially useful for

tional Vickers or Knoop microhardness methods. Though heterogeneous thermal spray coatings. Most of the results

the force range can overlap, the results of instrumented presented in this paper were obtained by the Visual matrix

indentation bring more information about mechanical indentation method.

properties of the coatings such as elastic modulus, elastic/

plastic work of indentation and creep or cyclic behavior. //// Continuous Multi Cycle indentation (CMC)

Due to its force-displacement recording capability, the in- This efficient cyclic indentation method allows automatic

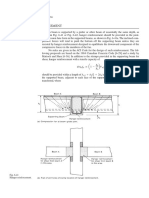

strumented indentation method is able to sense when an increase of maximum load on each subsequent cycle. Da-

indentation is performed on a void: the depth suddenly taset of indentation depth and hardness or elastic modu-

increases without a corresponding increase in force (Fig. lus is obtained within ten or twenty minutes depending

1). Such effects would probably not be noticed in conven- on the number of cycles. This method is particularly effec-

tional Vickers measurements. tive for studying hardness and elastic modulus of thermal

spray coatings at various loads and depths.

//// Indentation parameters

Two CSM Instruments systems were used for characteriza-

tion of the mechanical properties of the coatings: Nanoin-

dentation Tester (NHT) and Micro Indentation Tester (MHT).

The NHT was used in its NHT-TTX standalone version, a

full performance nanoindentation system with load range

of 0.1 mN to 500 mN equipped with Berkovich indenter,

motorized tables and optical microscope. The MHT (load

range 0.03 N to 10 N, Vickers indenter) was mounted on

a Compact Platform equipped with a confocal microscope

and optical microscope. All measurements were done by

the CMC method and the indented areas were selected by

Visual matrix in most cases. On each sample five to seven

Fig. 1 – Loading-unloading indentation curve presenting two measurements of the same type were performed and only

‘indenter drops’ due to indentation on voids or other defects.. average values are presented.

No.32 May 2010

//// Plasma sprayed alumina

The water stabilized plasma (WSP) spraying is a unique

technique for high throughput spraying of ceramics

and metals. It has been used for many years for spray-

ing of e.g. high quality alumina (Al2O3), chromium oxide

(Cr2O3) and steel coatings. The main advantage of the

WSP spraying is high enthalpy of the plasma which allows

for spraying of materials with high melting point and high

throughput.

The presented study deals with white alumina sprayed at

various feeding and spraying distances. The spraying and

feeding distances are essential spraying parameters as

they determine the mechanical properties of the material.

The coatings were sprayed at the Institute of Plasma Phys- Fig. 2 – Hardness (a) and elastic modulus (b) as a function of

ics (Prague, Czech Republic) on steel substrates. Three indentation depth measured on cross-section of alumina coat-

combinations of feeding and spraying distances were ings. For clarity reasons the error bars were omitted.

used (see Table 1).

As there was a significant difference between the materi-

als behavior below and above 2 m, the depth of 2 m

was considered the ‘limit depth’. Above this depth the

influence of load on the mechanical properties of plasma

sprayed coatings can be considered as negligible. This

result was confirmed also for other plasma and HVOF

sprayed ceramics and cermets. Outcomes of a larger ex-

Table 1 – List of WSP alumina samples according to feeding (FD) perimental study presented at the 4RIPT conference in Lille

and spraying distance (SD). (France, 2009) are now being reviewed for publication in

a scientific journal.

The coatings were 1100 to 1300 m thick and they were

removed from the substrate after deposition in order to The differences between coatings sprayed with different

provide free-standing coatings and access to both free- parameters were observed mainly at low loads (see Fig. 3)

surface and substrate-coating interface side of the coat- where hardness of the 80-500 was the highest, followed

ing. The interface surface (on the coating-substrate inter- by the 60-425 coating and the 40-350 coating. Though

face) and the top surface were polished; the coating was the differences in the microstructure between the coat-

also cut and polished on the cross-section. ings were quite small [1], the indentation method revealed

slightly different mechanical properties of each coating at

The results obtained on cross-sectioned samples are shown low loads. These differences were very likely due to the

in Fig. 2. The figures contain results from both NHT and different local temperature history of the deposited lay-

MHT. Despite a certain inconsistency at depths covered ers. Such measurements of mechanical properties would

by both NHT and MHT instruments (~1,5 m), the curves be very difficult to perform with the conventional Vickers

for all samples follow a very similar trend: rapid decrease microhardness as the indents would be very small and the

of both hardness and elastic modulus at low depths and results would contain rather large errors.

stabilization of the hardness and elastic modulus values The indentation on the polished top- and interface surface

above 2 m depth. was also done. The previously described decrease of the

hardness and elastic modulus with increasing depth was

observed in most of the measurements. In general, both

the hardness and elastic modulus were higher at the top

interface than at the substrate-coating interface. However,

even despite careful polishing, the surface was often (due

to the brittle nature of alumina splats and frequent pull-

outs) so rough that only a few results could be successfully

evaluated. This applied even to high load indentation up

to 10 N and very likely similar problems would occur with

conventional Vickers microhardness measurements.

No.32 May 2010

In the case of the 1408, 1410 and 1411 coatings the ox-

ides formed a rather thin layer around the metallic splats

and measurement of the properties of the oxides would

be strongly influenced by the surrounding metallic splats.

Therefore indentation on metallic splats only was per-

formed. On sample 1412 however, the fraction of oxides

was sufficiently high and single indentations could be car-

ried out on both metallic and oxide particles (Fig. 4). The

prevailing metallic particles in all coatings were easy to

target for both cyclic indentation and single load indenta-

tions. The chart in Fig. 5 shows the results of single inden-

tation at 10 mN for all steel samples.

Fig. 3 – Hardness for the alumina coatings as a function of in-

dentation depth. Error bars are omitted for clarity.

//// Plasma sprayed stainless steel

Stainless steel coatings were selected to represent a dif-

ferent type of materials to the plasma sprayed ceramics.

The steel coatings were sprayed using the WSP torch from

a 316L stainless steel powder onto a steel substrate. The

thickness of the coatings was ~ 1300 m except for sam-

ple 1412 whose thickness was 900 m. The samples were

sprayed under different conditions to achieve different

fraction of oxides (Table 2) which are typical for metallic

coatings sprayed in air.

Fig. 5 – Hardness and elastic modulus of the steel coatings.

Note high hardness of the oxides in sample 1412.

Table 2 – Oxide content in the 316L steel coatings. There was little variation in hardness and elastic modu-

lus of all coatings observed; elastic modulus of all metallic

The indentation was done with the CSM Instruments splats was close to 200 GPa, which is the known value for

Nanoindentation Tester (NHT) at loads from 1 mN up to bulk steel. Low load indentation can therefore effectively

100 mN with 20 cycles using the CMC method. Further, measure single phases or constituents in heterogeneous

selected homogeneous areas were tested by single load material such as thermal spray coating. Oxide particles on

indentations at 10 mN. All indentations were done with a sample 1412 were clearly visible – though still relatively

Berkovich indenter. small – and their hardness was much higher than that of

the surrounding metallic splats. On the other hand, the

elastic modulus of the oxides (~150 GPa) is surprisingly

lower than that of steel (~200 GPa). This could be ex-

plained by internal porosity of the oxide particles or in-

tra-particular cracking [2] though a more detailed study

would be required for proper understanding of this result.

The cyclic mode indentation showed that there was lit-

tle decrease of neither hardness nor elastic modulus with

increasing indentation depth (Fig. 6). This finding proves

different mechanical behavior of the metal-based coat-

ing where the formation of the intrasplat cracks was sup-

pressed due to the possibility of evolution of plastic defor-

mation.

Fig. 4 – Precise location of indentations on WSP® sprayed steel

(100 mN maximum load). Arrows show the indents.

No.32 May 2010

//// Conclusions

This Application Bulletin reports on the application of in-

strumented indentation over a large range of loads on

plasma sprayed ceramic and metal coatings. It shows the

advantages of this method on heterogeneous materials

and allows both a detailed study of individual coating con-

stituents and overall coating’s properties which was not

previously possible. The most important advantage of in-

strumented indentation for thermal spray coatings is its

ability to make localized measurements: targeted testing

of small volumes can reveal important material properties

which can help to understand large scale (bulk) phenom-

ena such as cracking and wear, originating from small

structural units.

//// Acknowledgements

The author would like to thank Radek Musalek and Jiri

Matejicek of the Institute of Plasma Physics in Prague (CZ)

for providing the sample and fruitful discussions during

preparation of this Applications Bulletin.

//// References

1. Musalek, R. Matejicek, J. Vilemova, M. Kovarik, O:

Non-linear mechanical behavior of plasma sprayed alumi-

na under mechanical and thermal spray loading. JTST, Vol.

Fig. 6 – Hardness (a) and elastic modulus (b) of steel coatings as

19(1-2) Jan 2010, p. 422-428.

a function of indentation depth, each data point is mean value

from about 5 indents.

2. Musalek, R. Kovarik, O. Matejicek, J.: In-situ ob-

servation of crack propagation in thermally sprayed coat-

The elastic modulus measurements by both cyclic and sin-

ings. Accepted for publication in Surface and Coatings

gle load instrumented indentation are in very good agree-

Technology, 2010.

ment with the known values of elastic modulus of stain-

less steel. This confirms that the elastic modulus obtained

by instrumented indentation corresponds to that obtained

by other methods such as four point bending or tensile

tests.

//// Indentation hardness dependence: force or

indentation depth?

As mentioned above, in the CSM Instruments Applica-

tion bulletin 29 and also elsewhere, hardness and elas- This Applications Bulletin is published quarterly and features inter-

esting studies, new developments and other applications for our

tic modulus of thermal sprayed coatings often depend full range of mechanical surface testing instruments.

on the indentation load. It is due to the heterogeneity of

their structure, where different phenomena are involved

621005.10 v1 CSM Instruments / Printed in Switzerland

Editor Dr Jiri NOHAVA

when different volumes are tested. Many people report

mechanical properties at a given loads. However, we sug-

Should you require further information, please contact:

gest that rather than load the indentation depth should

be cited when hardness or elastic modulus values are

reported. The indentation depth can be easily related to CSM Instruments Tel: + 41 32 557 5600

the dimensions of the structural units of the coating and Rue de la Gare 4 Fax: +41 32 557 5610

CH-2034 Peseux info@csm-instruments.com

the variations of mechanical properties can be more easily Switzerland www.csm-instruments.com

explained and predicted. A plot showing dependence of

depth on indentation load can be included in the result to

link the depth-related data to load.

No.32 May 2010

S-ar putea să vă placă și

- Bunkie Plan 1Document17 paginiBunkie Plan 1Daniel100% (3)

- Hang Glider Design and PerformanceDocument13 paginiHang Glider Design and Performancefranco.didio1945Încă nu există evaluări

- Mill Quick Start GuideDocument65 paginiMill Quick Start Guideil26Încă nu există evaluări

- ORD 5700 Parker O-Ring HandbookDocument292 paginiORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- ORD 5700 Parker O-Ring HandbookDocument292 paginiORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- ORD 5700 Parker O-Ring HandbookDocument292 paginiORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- The BlueJ TutorialDocument39 paginiThe BlueJ TutorialSifu SeinÎncă nu există evaluări

- Tin NanowiresDocument1 paginăTin Nanowiresil26Încă nu există evaluări

- Catia Training MaterialDocument523 paginiCatia Training Materialnikhilcon100% (9)

- Iepc 2007 240Document17 paginiIepc 2007 240il26Încă nu există evaluări

- Q6LTT3 Data Sheets enDocument2 paginiQ6LTT3 Data Sheets enil26100% (1)

- ClarkPaper2009FINAL 12Document10 paginiClarkPaper2009FINAL 12il26Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A New Sintering Additive For Silicon Carbide CeramicDocument5 paginiA New Sintering Additive For Silicon Carbide CeramicyinxinshixianÎncă nu există evaluări

- Understanding "Position" in WeldingDocument116 paginiUnderstanding "Position" in WeldingThaksenÎncă nu există evaluări

- Petroleum Production Engineering Ii: Sucker Rod PumpingDocument27 paginiPetroleum Production Engineering Ii: Sucker Rod PumpingMohammed Khaled Al-ThobhaniÎncă nu există evaluări

- BondingDocument55 paginiBondingJoshua lopezÎncă nu există evaluări

- Static Analysis Laterally Loaded Pile Design PPTX CaliendoDocument55 paginiStatic Analysis Laterally Loaded Pile Design PPTX CaliendoAshishÎncă nu există evaluări

- Astm A 53 PDFDocument22 paginiAstm A 53 PDFminhyÎncă nu există evaluări

- Climate of PakistanDocument23 paginiClimate of PakistanRayyan MalikÎncă nu există evaluări

- 2018Document71 pagini2018Kamran AliÎncă nu există evaluări

- User's Manual: ULTRA CFR Nd:YAG Laser SystemDocument55 paginiUser's Manual: ULTRA CFR Nd:YAG Laser SystemLeonardo PantojaÎncă nu există evaluări

- E192Document3 paginiE192Milenita Paez AcuñaÎncă nu există evaluări

- ChemicalEq DroppersDocument13 paginiChemicalEq DroppersUtkarsh SharmaÎncă nu există evaluări

- Introduction To A Realistic Quantum PhysicsDocument84 paginiIntroduction To A Realistic Quantum PhysicsAhmed Muhdar100% (2)

- Fluid Formulas (1st Chapter)Document2 paginiFluid Formulas (1st Chapter)teresapulga6Încă nu există evaluări

- Serge Florens and Antoine Georges - Quantum Impurity Solvers Using A Slave Rotor RepresentationDocument18 paginiSerge Florens and Antoine Georges - Quantum Impurity Solvers Using A Slave Rotor RepresentationYidel4313Încă nu există evaluări

- Effects of Nonuniform Tire Contact Stresses On Pavement ResponseDocument7 paginiEffects of Nonuniform Tire Contact Stresses On Pavement ResponseBarnali DebnathÎncă nu există evaluări

- Calculations and Assumptions For Penetration ModelDocument5 paginiCalculations and Assumptions For Penetration Modelvksingh_188005Încă nu există evaluări

- Mixer GrinderDocument29 paginiMixer GrinderChockalingam AthilingamÎncă nu există evaluări

- Essentials of Materials Science and Engineering Si Edition 3rd Edition Askeland Solutions ManualDocument26 paginiEssentials of Materials Science and Engineering Si Edition 3rd Edition Askeland Solutions Manualhanhgloria0hge5100% (32)

- 关于HANGERDocument3 pagini关于HANGERNEOÎncă nu există evaluări

- Price Summary: Date: 22/5/2019Document72 paginiPrice Summary: Date: 22/5/2019Reda ChattahyÎncă nu există evaluări

- Angle of Shearing ResistanceDocument3 paginiAngle of Shearing Resistancezarakkhan masoodÎncă nu există evaluări

- The Chemical Bonding GameDocument12 paginiThe Chemical Bonding GameZara RejusoÎncă nu există evaluări

- 987 9 PDFDocument205 pagini987 9 PDFHerman JamalÎncă nu există evaluări

- Chapter 3-Thermodynamics FinalDocument20 paginiChapter 3-Thermodynamics Finalgsudhanta1604Încă nu există evaluări

- Science: Learning Activity SheetDocument9 paginiScience: Learning Activity SheetResttie ĐaguioÎncă nu există evaluări

- NosaDocument9 paginiNosaosaroboÎncă nu există evaluări

- FEM For Heat Transfer Problems (Finite Element Method) Part 3Document16 paginiFEM For Heat Transfer Problems (Finite Element Method) Part 3Sibilla UnniÎncă nu există evaluări

- Table 2 Quantity To Be Measured Instrument S.L. UnitDocument4 paginiTable 2 Quantity To Be Measured Instrument S.L. UnitAdrian RamroopÎncă nu există evaluări

- Monsoon in India Upsc Notes 58Document3 paginiMonsoon in India Upsc Notes 58nikitasharma1431234Încă nu există evaluări

- BS 5950 - Worked Example 3Document9 paginiBS 5950 - Worked Example 3mustafurade1Încă nu există evaluări