Documente Academic

Documente Profesional

Documente Cultură

Lotus and F1 Engines

Încărcat de

shahrizalDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lotus and F1 Engines

Încărcat de

shahrizalDrepturi de autor:

Formate disponibile

Any User

Lotus and F1 Engines

Jamie Turner

Senior Technical Specialist

Lotus Powertrain Research Group Manager

27 February 2003 1

Colin Chapman and the DFV

• Colin Chapman was instrumental in the DFV concept;

the fact that its architecture allowed it to mounted as a

fully-stressed member was a Chapman revolution

• The DFV could therefore be considered as a Vee-engine

development of the FVA, with Chapman persuading

Ford to underwrite the project

• The Lotus 49 was purpose-designed to accept the DFV

27 February 2003 2

Title goes here 1

Any User

Lotus’ own Formula 1 Engines

• Lotus has investigated Formula 1 engines for four

different clients, two of whom are currently in F1

• The first was a compound charged 1.5 litre V6

- the Lotus code name was ‘L9’

• The second was a 3.5 litre V10 designed for a client to

compete in the common F1 and World Sports Car racing

engine formula in the late 1980s - the ‘W55’

• The third was a 120° 3.5 litre V12 - this was ‘FX’

• The most recent was a 3 litre V10, of a more conven-

tional modern architecture, but with a Wide Vee Angle

- for the current Engine Formula, called ‘T-Project’

27 February 2003 3

Formula 1 Engines - L9

• In the 1980s, Lotus built a 1.5 litre Compound Charged

V6 Formula 1 racing engine - the ‘L9’

• Concept was to eliminate

turbolag for street circuits

• Monoblock construction

with through-bolts

• Magnesium crankcase

• Gasoline Direct Injection

• Power: in excess of

1000bhp at 12000rpm (at

approximately 4.5bar boost)

27 February 2003 4

Title goes here 2

Any User

L9 - Charging System

• The L9 Charging System consisted of two

Turbochargers (Fixed or Variable Geometry)

connected in series after an Axial Flow Compressor

L9 - Axial Flow Compressor

• The Axial Compressor was designed and developed

by Lotus, and had a peak adiabatic efficiency of 83%

First Section: Second Section: 9:10 Cycloidal

4.216 x Crank Speed 4.685 x Crank Speed Gearing between Shafts

Title goes here 3

Any User

L9 Charging System Mapping

Turbocharger Mapping

Anti-Surge Piezo-Electric

Throttles GDI

L9 and Formula 1 Rule Changes

• The L9 Project was taken to race-ready status for 1985,

and a Lotus racecar was being designed to take it

• However, changes to the fuel consumption and boost

limitation regulations led to it not racing

• The supercharger consumed 200bhp at maximum

power

• The Piezo-Electric GDI system lives on as second

generation Common Rail systems start to come to the

marketplace

27 February 2003 8

Title goes here 4

Any User

WSC Championship

• The W55 engine was designed in the late 1980s for the

World Sports Car championship, for a manufacturer

then competing in it

• At that time the engine regulations shared some

commonality with F1

• W55 was a 3.5 litre Naturally Aspirated V10, decided

upon after extensive analysis

• The bank angle was 110° for low C of G

– First of the wide-angle V10s

• It had a centre Power Take-Off, split cooling and a full-

width shear panel to maintain bending and torsional

stiffness

27 February 2003 9

W55 Heads

Full Width

Shear Panel

Secondary “Shower

Form” Injectors

Split

Cooling

Cam Gear Drive

from Centre

Power Take-Off

27 February 2003 10

Title goes here 5

Any User

W55 Block Two Main and Four

Supplementary Bolts

per Bay

Close-Fitting Secondary Ribs

Scavenge Volume for Stiffness and Oil

Transport

27 February 2003 11

W55 Conclusions

• W55 was never fully built, though castings were

procured

• Target power was 690bhp at 12500rpm

• Much rig work was carried out on the lubrication and

cooling systems

• However, the regulations for Group C changed, allowing

the manufacturer to continue to race his loosely

production-based engine successfully (this eventually

won Le Mans), and so the W55 project was cancelled

• The extensive analysis and rig work was of value for the

F1 engine design that followed it

27 February 2003 12

Title goes here 6

Any User

Formula 1 Engines - FX

• The next F1 engine was the ‘FX’, a 120° 3.5 litre V12 with

centre-exit 12-into-3 exhaust system (early 1990s)

• This was intended to

maintain a V8

engine’s BMEP level

over a V12 engine’s

speed range

– By means of 4

cylinder exhaust

tuning

Twisted Crank

for Even Firing

27 February 2003 13

Formula 1 Engines - FX

Crossover

Centre Power Exhaust

Take-Off System

(12-into-3)

Centre Fed Twin Water

Crankshaft Pumps

27 February 2003 14

Title goes here 7

Any User

FX Architecture

Monobloc

Construction

2 Main Castings

Cross-over

Through-bolts

as per L9

Low Mounted

Intakes

2 Auxiliary

Drive Shafts

27 February 2003 15

Formula 1 Engines - FX

• This engine was to have raced in a Lotus F1 car

• Design and initial performance prediction work was

undertaken, but the project was not progressed to the

prototype stage

• Extensive data was gathered from a Cosworth DFR and

performance prediction of its performance correlated

very well; this suggested that FX would have had in the

region of 750bhp for 1992, its first racing season

• The project was stopped when the FIA changed the car

regulations to mandate faired-in rollover hoops; this

made the use of a high mounted airbox almost

impossible to avoid

27 February 2003 16

Title goes here 8

Any User

T-Project

• Recently, we were involved in an extremely detailed

study for a modern F1 engine, including machining and

manufacturing facilities

• It was to have had a wide Vee angle of 110-120°

• The first race season was to have been 2003

• The outline design was to have been done with another

consultancy, whose cars were to have used it; Lotus

was to have been responsible for its detail design,

development and manufacture

• Although the current regulations stifle innovation in the

architecture of an engine, Lotus had some radical ideas

to pursue

27 February 2003 17

Future Directions for F1 Engines

• Bonded Covers

– To reduce mass and increase the torsional and bending

stiffnesses of the entire engine assembly

• Bonded Auxiliaries

– To reduce the size of auxiliary castings through not having to

incorporate fixings, and so to reduce mass and bulk

simultaneously

• High Speed AVT

– To improve fuel consumption and torque curve shape

– Remove throttles and save bulk in the intake system

– Improve engine response

– Reduce engine width and height and to lower its C of G

27 February 2003 18

Title goes here 9

Any User

High Performance Engines

• T-Project was not progressed beyond the concept and

feasibility stages because of geographical problems

associated with the partner companies

• We believe we now have extremely good knowledge of

the internals, materials, manufacturing processes etc.

of a current F1 engine

• Lotus would still like to be involved in race engine

design and manufacture as it gives a good showcase

for innovation

• Perhaps the freest formula for innovation is the new

Four-Stroke MotoGP motorcycle road racing class

27 February 2003 19

Thank You for Listening

27 February 2003 20

Title goes here 10

S-ar putea să vă placă și

- PERKINS 800D SERVICE MANUAL Pages Copy 804D-33 804D-33 UK UL Courtesy of Worldwide Parts Source LLC Phone 269 673 2313 Engine PartsDocument97 paginiPERKINS 800D SERVICE MANUAL Pages Copy 804D-33 804D-33 UK UL Courtesy of Worldwide Parts Source LLC Phone 269 673 2313 Engine PartsPedro Lorenço Jorge100% (1)

- Constant-Pressure Turbocharger Matching by Michael M. W. de SilvaDocument32 paginiConstant-Pressure Turbocharger Matching by Michael M. W. de SilvaMichael M. W. de Silva100% (1)

- Owner Manual For Horseless CarrageDocument11 paginiOwner Manual For Horseless CarrageFrenchwolf420100% (1)

- Access Tuner HelpFile Mitsubishi EVOXDocument40 paginiAccess Tuner HelpFile Mitsubishi EVOXFagadar ClaudiuÎncă nu există evaluări

- Stromberg Carburetor Misc Service InformationDocument8 paginiStromberg Carburetor Misc Service Informationisland14Încă nu există evaluări

- 3412E Rocker Arm AssemblyDocument4 pagini3412E Rocker Arm AssemblyMohammed Mostafa100% (1)

- Briggs and Stratton Small Engine CareDocument8 paginiBriggs and Stratton Small Engine Carejankop100% (1)

- EM 8903iDocument9 paginiEM 8903iPeterson RamosÎncă nu există evaluări

- Racecar Engineering 2006 05 PDFDocument100 paginiRacecar Engineering 2006 05 PDFfreddyonnimiÎncă nu există evaluări

- The BMW F1 EngineDocument2 paginiThe BMW F1 EngineDalibor AngelovskiÎncă nu există evaluări

- Review of Combustion Instabilities F1 Engine. JPP (1993, Oefelein)Document21 paginiReview of Combustion Instabilities F1 Engine. JPP (1993, Oefelein)jleydencoÎncă nu există evaluări

- Materion Engine Technology International June 2018 PerforMet Piston RingsDocument5 paginiMaterion Engine Technology International June 2018 PerforMet Piston RingsrenatoeliegeÎncă nu există evaluări

- 3500 SW ProjectDocument31 pagini3500 SW ProjectDjebali Mourad100% (1)

- Holsetturbo Productionspecs PDFDocument1 paginăHolsetturbo Productionspecs PDFJulio Eduardo Candia AmpueroÎncă nu există evaluări

- Racecar Engineering 2012 11 PDFDocument100 paginiRacecar Engineering 2012 11 PDFfreddyonnimi100% (1)

- Efr Turbo Technical BriefDocument126 paginiEfr Turbo Technical BriefTM125Încă nu există evaluări

- F1 1958 Manual PDFDocument78 paginiF1 1958 Manual PDFJames OtreblaÎncă nu există evaluări

- 2020 Ferrea Racing CatalogDocument140 pagini2020 Ferrea Racing CatalogColdbloodedbikerÎncă nu există evaluări

- Mopar Factory Drag Cars: Dodge & Plymouth's Quarter-Mile Domination 1962-1972: Dodge & Plymouth's Quarter-Mile Domination: 1962-1972De la EverandMopar Factory Drag Cars: Dodge & Plymouth's Quarter-Mile Domination 1962-1972: Dodge & Plymouth's Quarter-Mile Domination: 1962-1972Încă nu există evaluări

- Turbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDocument19 paginiTurbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDeepak Satpathy0% (1)

- LOLA Racecar 1Document14 paginiLOLA Racecar 1Marcos Soar100% (1)

- Cam Selection - Jim McFarland HRM March 1966Document3 paginiCam Selection - Jim McFarland HRM March 1966garagepunkfanÎncă nu există evaluări

- A New Approach To Boost Pressure and EGR Rate Control Development For HD Truck Engines With VGTDocument12 paginiA New Approach To Boost Pressure and EGR Rate Control Development For HD Truck Engines With VGTRanjith Reddy KalluriÎncă nu există evaluări

- Modeling and CFD Analysis of Air FlowDocument15 paginiModeling and CFD Analysis of Air FlowTarik Hassan ElsonniÎncă nu există evaluări

- FACET 2018 Industrial CatalogDocument23 paginiFACET 2018 Industrial CatalogMMM-MMMÎncă nu există evaluări

- Jaguar V12Document7 paginiJaguar V12Ciprian MaiorÎncă nu există evaluări

- Development of High Speed Diesel EngineDocument7 paginiDevelopment of High Speed Diesel EngineJaikirat SinghÎncă nu există evaluări

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Document20 paginiUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniÎncă nu există evaluări

- 2019-10-01 Racecar Engineering 2Document100 pagini2019-10-01 Racecar Engineering 2Can not Formula NingÎncă nu există evaluări

- CZ Product CatalogDocument82 paginiCZ Product CatalogEurocorp DistributionÎncă nu există evaluări

- Turbocompounding TechnologyDocument23 paginiTurbocompounding TechnologyPawan BeniwalÎncă nu există evaluări

- Airflow FormulasDocument11 paginiAirflow FormulasVicky GilangÎncă nu există evaluări

- SG 186 R 3Document16 paginiSG 186 R 3geniunetÎncă nu există evaluări

- Cosworth StoryDocument32 paginiCosworth StoryTanoV12-Formula1AmarcordÎncă nu există evaluări

- Autosport Magazine 2018 03 01 EnglishDocument112 paginiAutosport Magazine 2018 03 01 EnglishAnna GajdácsiÎncă nu există evaluări

- Le Mans: Will New Cars Be The Fastest in The 24-Hours' History?Document38 paginiLe Mans: Will New Cars Be The Fastest in The 24-Hours' History?dk_moehammedÎncă nu există evaluări

- Porsche Engineering MagazineDocument24 paginiPorsche Engineering MagazinePrabu ArÎncă nu există evaluări

- On Renault F1 Turbo EnginesDocument11 paginiOn Renault F1 Turbo EnginesShaswata PanjaÎncă nu există evaluări

- Guide To The NordschleifeDocument28 paginiGuide To The NordschleifeRobin100% (4)

- Racecar Engineering 2005 06 PDFDocument99 paginiRacecar Engineering 2005 06 PDFfreddyonnimiÎncă nu există evaluări

- 2022 ARP CatalogDocument180 pagini2022 ARP Catalogdonny rebornÎncă nu există evaluări

- Racecar Engineering - January 2020Document102 paginiRacecar Engineering - January 2020Big Flores100% (1)

- Internal Combustion Engine Induction TuningDocument39 paginiInternal Combustion Engine Induction TuningTomás Sebastián Sanhueza Vásquez100% (2)

- Ic EngineDocument72 paginiIc Enginekedirabduri88Încă nu există evaluări

- Motorola MPC5xx Memory Maps: MPC555 MPC533/MPC534 MPC535/MPC536 MPC561/MPC562 MPC563/MPC564 MPC565/MPC566Document1 paginăMotorola MPC5xx Memory Maps: MPC555 MPC533/MPC534 MPC535/MPC536 MPC561/MPC562 MPC563/MPC564 MPC565/MPC566AlexandrÎncă nu există evaluări

- F1 EnginesDocument11 paginiF1 Enginessachin_sawant1985Încă nu există evaluări

- HC PDFDocument428 paginiHC PDFnetemma97Încă nu există evaluări

- AccessTUNER HelpFile MAZDASPEEDDocument71 paginiAccessTUNER HelpFile MAZDASPEEDFagadar ClaudiuÎncă nu există evaluări

- Turbo Tech 102 - Advanced: Understanding Air FlowDocument10 paginiTurbo Tech 102 - Advanced: Understanding Air FlowrodrigoracingÎncă nu există evaluări

- Ata 2019Document84 paginiAta 2019jorge Angel LopeÎncă nu există evaluări

- Turbo Testing OM617Document36 paginiTurbo Testing OM617antonio maloÎncă nu există evaluări

- Camshaft Design For An Inlet Restricted FSAE EngineDocument10 paginiCamshaft Design For An Inlet Restricted FSAE EngineAllan MachadoÎncă nu există evaluări

- The Corvette Hunter: Kevin Mackay's Greatest Corvette FindsDe la EverandThe Corvette Hunter: Kevin Mackay's Greatest Corvette FindsÎncă nu există evaluări

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)De la EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)Încă nu există evaluări

- Andy Priaulx: The Autobiography of the Three-time World Touring Car ChampionDe la EverandAndy Priaulx: The Autobiography of the Three-time World Touring Car ChampionEvaluare: 3 din 5 stele3/5 (1)

- LNR125 Soul GT ValveDocument1 paginăLNR125 Soul GT ValveDendi MiraeÎncă nu există evaluări

- SMC/TSMC 100 MK 4 LL Reciprocating Compressor Units: Spare Parts ManualDocument58 paginiSMC/TSMC 100 MK 4 LL Reciprocating Compressor Units: Spare Parts ManualHamza HafidiÎncă nu există evaluări

- Fuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDocument4 paginiFuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDaniel AndradeÎncă nu există evaluări

- 2008 Dt466.Electronic - Control.system - DiagDocument276 pagini2008 Dt466.Electronic - Control.system - DiagLuis Eduardo Corzo Enriquez100% (7)

- Thermal Engineering Lab Manual FinalDocument72 paginiThermal Engineering Lab Manual Finalrajeshkumar061087_58Încă nu există evaluări

- Yamaha YZF-R15 - Wikipedia PDFDocument19 paginiYamaha YZF-R15 - Wikipedia PDFRamsaranÎncă nu există evaluări

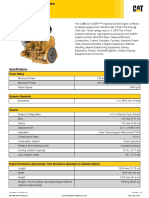

- Cat Engine c32Document5 paginiCat Engine c32wuub wuugfgÎncă nu există evaluări

- 9455470-Bobcat 853 F Parts Manual For Skid Steer Loader ImprovedDocument316 pagini9455470-Bobcat 853 F Parts Manual For Skid Steer Loader Improvedvitrola60% (5)

- ECR PDF PDFDocument331 paginiECR PDF PDFCamilo AvellanedaÎncă nu există evaluări

- 2AZ FE IntakeDocument7 pagini2AZ FE IntakeLuks Fernandez100% (2)

- Specifications: VHP5904LTDocument2 paginiSpecifications: VHP5904LTmuhammad wafiÎncă nu există evaluări

- Kent Bulldozer TY220Document1 paginăKent Bulldozer TY220MOZAMBiCARÎncă nu există evaluări

- Turb Fan Aero Engine Market BriefDocument37 paginiTurb Fan Aero Engine Market Briefsunrise_thangÎncă nu există evaluări

- Seven Valve NozzleDocument116 paginiSeven Valve NozzleАмурдеталь БлаговещенскÎncă nu există evaluări

- Ae6611 Aero Engine and Airframe LaboratoryDocument45 paginiAe6611 Aero Engine and Airframe LaboratoryvairamÎncă nu există evaluări

- LGE08 Mini Hydraulic Crawler ExcavatorDocument3 paginiLGE08 Mini Hydraulic Crawler Excavator王丽Încă nu există evaluări

- EGR SimulatorDocument9 paginiEGR Simulatorelyqg21Încă nu există evaluări

- 03 Final Hydraulic Pumps (Module-III)Document19 pagini03 Final Hydraulic Pumps (Module-III)Pyae Phyoe AungÎncă nu există evaluări

- Yamaha PartesDocument56 paginiYamaha PartesEduardo VasquezÎncă nu există evaluări

- Scania Catalogue 2015Document4 paginiScania Catalogue 2015Anita Miljkovic100% (1)

- Munteborg Crankshaft Seal ReportDocument7 paginiMunteborg Crankshaft Seal Reportdieselnozzle3dÎncă nu există evaluări

- Finals TVL-12 2019-2020Document3 paginiFinals TVL-12 2019-2020Mark Emerson MarinÎncă nu există evaluări

- Curso Mhawk4Document109 paginiCurso Mhawk4Omar Antonio Araque100% (1)

- The History of The Automobile: By: RohitDocument32 paginiThe History of The Automobile: By: RohitSIRISHASIRIIÎncă nu există evaluări

- MTU12V2000DS800 800kW Standby PDFDocument4 paginiMTU12V2000DS800 800kW Standby PDFJohn Jairo SimancaÎncă nu există evaluări

- Auxiliary Boiler Plants and Diesel Engine TheoryDocument49 paginiAuxiliary Boiler Plants and Diesel Engine TheoryMardainze LabacladoÎncă nu există evaluări