Documente Academic

Documente Profesional

Documente Cultură

Afowler TT

Încărcat de

zuheib63Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Afowler TT

Încărcat de

zuheib63Drepturi de autor:

Formate disponibile

How many drillholes do I need to projects from the last ten years, reported in

upgrade my Inferred Mineral Resource? accordance with the Australasian JORC

Andrew Fowler, Kathy Zunica 1

Code and the Canadian NI 43-101

2

AMC Consultants Pty Ltd

requirements.

Summary For each case study, two consecutive

Mineral Resource reports are compared. .

The aim of an in-fill drilling programme is to The percentage increase in the number of

gain more detailed information so as to drillholes between the two reports is then

convert lower-confidence Inferred Mineral plotted against the proportional increase in

Resources to the higher-confidence units of contained metal and/or tonnage in

categories of Indicated and Measured the higher resource categories relative to

(grouped together in this paper as “higher the Inferred Mineral Resource category.

resource categories”). This upgrade in The resulting statistics act as proxies for

resource category is necessary to convert a drillhole spacing and resource category

resource to an Ore/Mineral Reserve. upgrade, and allow comparison across

Generally, an in-fill drilling programme different projects and commodity groups.

increases the proportion of higher resource The outcomes of the comparisons vary, but

categories relative to Inferred. Ideally, this there is a pattern. Some in-fill drilling

is done using the fewest drillholes possible. programmes, for example, result in

Can we, however, quantify this relationship substantial conversion to higher resource

between drillhole number and conversion to categories. Others result in little change.

higher resource categories? This could help Despite this variance, the data displays a

to develop a benchmark that companies consistent pattern when grouped into

could use to determine how many drillholes different populations. This suggests a

would be required to upgrade a desired general relationship between increased

proportion of their Inferred Mineral drillhole density and conversion from

Resource. Inferred to higher resource categories.

Through an analysis of 50 case studies, this The authors hope that the results and

paper aims to see if this relationship can be discussion presented here will elicit further

quantified. In doing so, it is hoped that we questions and discussion that will ultimately

can also assist companies to answer other improve and optimize in-fill drilling

pertinent questions, including: programmes.

Does the drilling programme meet our

Resource upgrade expectations? Introduction

Are factors such as the commodity type

or a change in the Competent Person Comparing mining operations by cost and

/Qualified Person (CP/QP) influencing productivity metrics is common in the

whether in-fill drilling programmes are mining industry and is referred to as

benchmarking. Benchmarking can be

achieving the desired outcome?

defined as measuring an organization’s

What are our expectations of the change policies, products, programmes, and

in grade when we change the proportion strategies, and comparing these with

of higher resource categories relative to

Inferred? 1

Australasian Code for Reporting of Exploration Results, Mineral Resources

and Ore Reserves, 2012 Edition, prepared by the Joint Ore Reserves Committee

The 50 case studies analysed were of the Australasian Institute of Mining and Metallurgy, Australian Institute of

Geoscientists and Minerals Council of Australia.

selected from the AMC Consultants Pty Ltd 2

The CIM Definition Standards on Mineral Resources and Reserves (CIM

(AMC) project database and publically Definition Standards) establish definitions and guidance on the definitions for

mineral resources, mineral reserves, and mining studies used in Canada. The

available information. They include precious Mineral Resource, Mineral Reserve, and Mining Study definitions are

incorporated, by reference, into National Instrument 43-101 – Standards of

metal, base metal and bulk commodity Disclosure for Mineral Projects (NI 43-101).

standard measurements or the

Increase in

measurements of the company’s peers. 18%

drilling

(BusinessDictionary.com, 2014).

Indicated proportion = Indicated proportion of total in

AMC has undertaken benchmarking studies

units of contained metal. Mt = million tonnes, Ag =

of mining operations for more than 20

years. As a result, it has built a substantial Silver, g/t = grams per tonne

database of open-pit and underground

data, with the aim of identifying and The method and calculations used in the

quantifying improvement opportunities for study are detailed below:

its clients. (Berry, 2014; Scholz, 2014).

1. Projects were found in the AMC project

In benchmarking studies, geological database or online that met the following

functions have not generally received the criteria:

same scrutiny as mining functions. This is a. Two consecutive Mineral Resource

mainly due to the difficulty of establishing reports were available that

appropriate metrics for geological functions documented:

that allow comparison across mine sites i. Mineral Resource tonnage and

(Berry, 2014). Nevertheless, there are grade by Mineral Resource

examples where a number of projects or category at the same cut-off grade.

operations have been compared and where ii. Number of drillholes that informed

implications for geological data capture each Mineral Resource estimation.

have been assessed (Berry & McCarthy, b. The two reports showed a change in

2006). the Mineral Resource by category.

2. Project information, tonnage, grade,

This study applies AMC’s benchmarking number of drillholes, and reasons for the

methodology to compare 50 mineral change in the Mineral Resource were

projects and establish a relationship recorded by the authors in a database.

between in-fill drilling programmes and 3. Percentage change in drillholes was

conversion of Mineral Resources from calculated as:

Inferred to higher Resource categories.

Method

Where:

Table 1 below is an example of the method DHcurr = Number of drillholes in the most

used in this study, applied to publically- recent Mineral Resource report

available information on the Juanicipio

DHprev = Number of drillholes in the

Silver Project in Mexico. It compares two

previous Mineral Resource report

consecutive Mineral Resource reports (from

2012 and 2014). The proportions are

4. Measured + Indicated Mineral Resource

calculated on the basis of contained metal.

proportion change was calculated as:

Table 1 – Example of applied method

2012 estimate 2014 estimate

Tonnag Ag Tonnag Ag Where:

e (Mt) (g/t) e (g/t) MIcurr = Measured + Indicated contained

(Mt) metal as a percentage of total contained

metal in the most recent Mineral

Inferred 4.3 513 5.1 372 Resource report

Indicated 5.7 702 10.1 511 MIprev = Measured + Indicated contained

Indicated metal as a percentage of total contained

0.64 0.73 metal in the previous Mineral Resource

proportion

report

proportion

+0.09

change

MIcurr calculated as:

Drillhole

222 262

number

The case studies were selected from

AMC’s in-house project database and from

publically available NI 43-101 Technical

Reports. The earliest case study is from

Where: 2002, although the majority of studies are

MTcurr = Measured Mineral Resource from the last three years (2012–2014).

tonnage in the most recent Mineral

Resource report The projects represented in the case

MGcurr = Measured Mineral Resource studies are located in twenty-one countries

grade in the most recent Mineral across six continents (see Figure 1 below).

Resource report Figure 1 – Case Studies by Country

ITcurr = Indicated Mineral Resource

tonnage in the most recent Mineral

Resource report

IGcurr = Indicated Mineral Resource

grade in the most recent Mineral

Resource report

TTcurr = Measure + Indicated Mineral

Resource tonnage in the most recent

Mineral Resource report

TGcurr = Measured + Indicated Mineral

In Figure 2, the case studies are grouped

Resource grade in the most recent

into commodity types.

Mineral Resource report

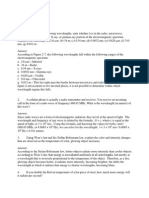

Figure 2 – Case Studies by Commodity

Similarly, MIprev was calculated as: Group

Commodity Group

Where: 28% 12%

MTprev = Measured Mineral Resource

tonnage in the previous Mineral

Resource report

40%

MGrev = Measured Mineral Resource 20%

grade in the previous Mineral Resource

report

ITprev = Indicated Mineral Resource

tonnage in the previous Mineral Bulk Commodity

Resource report Base Metal

IGprev = Indicated Mineral Resource Precious Metal - Epithermal/Porphyry

Precious Metal - Shear/Breccia

grade in the previous Mineral Resource

report

TTprev = Measure + Indicated Mineral Table 2 lists the number of case studies by

Resource tonnage in the previous deposit type.

Mineral Resource report

Table 2 – Case Studies by Deposit Type

TGprev = Measured + Indicated Mineral

Resource grade in the previous Mineral Deposit Type Commodity Group Number

Resource report Base Metal/PM

Shear/Breccia hosted (Shear/Breccia) 1/12

5. Various charts were plotted from the Porphyry Base Metal/PM 7/3

resulting output. Epithermal PM (Epithermal) 7

Skarn Base Metal 3

Case studies Iron Formation BC 4

Carlin-type gold PM (Shear/Breccia) 2

Stratiform Copper Base Metal 2 1. An optimal population where upgrade

Ultramafic Ni-Cu sulphide Base Metal 2 to higher Mineral Resource

Iron Oxide Copper Gold Base Metal 1

categories is positively correlated

Mineral sand: Zircon with increased drilling. The optimal

Titanium BC 1 group is defined as those projects

Nickel Laterite Base Metal 1 where greater proportion increase is

Pegmatite Lithium Base Metal 1 achieved with the least amount of

Phosphate: upwelling type BC 1 drilling.

Sedimentary Lead-Zinc- 2. A sub-optimal population, where

Silver Base Metal 1

there is generally a positive

VMS Base Metal 1

correlation between upgrade to

Note: VMS = Volcanogenic Massive Sulphide, BC =

higher Mineral Resource categories

Bulk Commodity, PM = Precious Metal

with increased drilling. The sub-

optimal group is offset from the

The relationship between in-fill drilling

and resource upgrade optimal group because it shows that

significantly more drilling was

To investigate the relationship between in- required to achieve similar proportion

fill drilling and resource upgrade, changes.

proportional change in higher resource

3. Extensional drilling population

categories is plotted against percentage

increase in drilling in Figure 3. Each point showing negative proportional

represents one of the 50 case studies or change. This population will not be

projects evaluated. considered further in this study,

because the projects in this

The dashed line in the figure divides the population do not contain a

positive–proportion change projects from significant in-fill drilling component.

the negative–proportion change projects. 4. No significant in-fill drilling

Positive proportion change means the

population, where significant upgrade

higher resource categories have increased

at the expense of the Inferred Mineral to higher Mineral Resource

Resource. Conversely, negative proportion categories has occurred with little or

change means the Inferred Mineral no change in drilling. This population

Resource has increased at the expense of will not be included in the analysis,

the higher resource categories. because the projects in this

It is important to note that most drilling population do not contain a

programmes actually include a combination significant in-fill drilling component.

of in-fill and extensional drilling. However, in However, the proposed reasons for

a normal situation, only the in-fill drilling will the upgrade are presented below.

lead to conversion to higher Resource

categories. Conversely, purely extensional Figure 3 – Proportion change (metal) versus

drilling often adds to the Inferred Mineral percentage change in drillholes

Resource and not the Measured or

Indicated Mineral Resource. Therefore, the

authors interpret that the positive

proportional change projects are dominated

by in-fill drilling, while the negative

proportional change projects are dominated

by extensional drilling. This is a

simplification of reality, but it aids

interpretation of the plots.

The 50 projects fall into four populations, as

annotated in Figure 3:

Note:

A = Dominant effect is in-fill drilling method, and confidence in the

B = Dominant effect is extensional drilling

Mineral Resource estimate. Very few

Optimal and sub-optimal populations additional drillholes were completed

The optimal population exhibits a similar between estimates.

linear trend to the sub-optimal population.

However, significantly more drilling was

required to achieve the same proportion The correlation between in-fill drilling

changes in the sub-optimal population. and resource upgrade for the optimal

and sub-optimal populations

The authors analyzed the resource reports The aim of the paper is to investigate how

and propose the following reasons to in-fill drilling programmes affect the upgrade

account for the sub-optimal population: of Mineral Resources, with the ultimate aim

1. The in-fill drilling programme did not of establishing a benchmark for how many

intersect sufficient mineralization drillholes are required to upgrade a desired

above cut-off and/or did not target proportion of the Mineral Resource from

areas that would increase the Inferred to higher resource categories.

confidence in the Mineral Resource.

2. The initial estimation method and/or The optimal and sub-optimal populations

interpretation was inappropriate. The both exhibit a positive correlation between

additional information changed the increased drilling and resource upgrade

understanding of the deposit. The (Figure 4). Trend lines fitted to each

change in understanding meant that population give correlation coefficients of

more drillholes were required to 0.54 for the optimal population and 0.77 for

increase the confidence in the the sub-optimal population, respectively.

deposit. The steeper slope of the optimal population

suggests that fewer drillholes are resulting

No significant in-fill drilling population in a higher proportion change relative to the

This population represents projects where

sub-optimal population. The authors

there was very little additional drilling

between estimates, but there was consider that these are meaningful

significant upgrading to the higher resource correlations that further studies will help to

categories for other reasons. refine and improve. The results are

elaborated upon further in the discussion

The authors have analyzed the resource section of this paper.

reports and propose the following reasons

for the significant upgrading: Figure 4 – Proportion change (metal)

1. The initial estimate was based only versus percentage change in drillholes: in-

on historical data, but then a limited fill drilling projects only

drilling programme verified historical

data, resulting in large portions of the

resource being upgraded from

Inferred to Indicated.

2. The initial estimate was based only

on historical data, but then an

additional validation work improved

confidence in the historical data,

resulting in large portions of the

resource being upgraded from

Inferred to Indicated. No additional

drilling occurred between estimates.

3. A change in Competent Person

(CP)/Qualified Person (QP) led to

considerable changes in the

geological interpretation, estimation

Commodity type, Resource size and

change of CP/QP

The relationship between in-fill drilling and

resource upgrade is investigated further by

plotting the case studies by commodity

groups (Figure 5), resource size groups

(Figure 6), and if the CP/QP changed

between estimates (Figure 7). The results

are interpreted in the discussion section of

this paper.

Figure 5 – Proportion change (metal)

versus percentage change in drillholes Relationship between resource upgrade

grouped by commodity type and grade

The effect on grade when the resource is

upgraded from Inferred to higher resource

categories is investigated by plotting

positive and negative grade change against

resource proportional change. The grade

changes are calculated as percentages.

The resource proportional changes are

calculated as changes in tonnes rather than

metal, as in the examples above. The

results are grouped by comodity type

(Figure 8) and are interpreted in the

discussion section.

Figure 6 – Proportion change (metal) Figure 8 – Proportion change (tonnes)

versus percentage change in drillholes versus grade change: grouped by

grouped by total Resource size commodity type

Discussion

Drilling programmes with a significant in-fill

Figure 7 – Proportion change (metal)

component, display a positive linear

versus percentage change in drillholes

correlation between percentage increase in

grouped by total change in CP/QP

drilling and proportional increase in higher

resource categories. This positive linear

correlation was observed in two populations

— the optimal and sub-optimal.

The authors propose that projects in the

sub-optimal population relate to instances

where:

1. The CP/QP was not adequately whether this is impacted by commodity

consulted during the planning phase to type. The mean percentage grade change

avoid redundancy in the drilling is negative across all commodity types,.

programme. This suggests that earlier interpretations

2. The initial geological interpretation of based on fewer drillholes assumed

the project was simplistic and continuity that subsequent drilling

subsequent drilling revealed disproved. This is possibly a reflection of

complexity that reduced, rather than human nature, as we tend to be optimistic

increased, geological confidence. in our geological interpretation at the early

3. There were managerial, contractual, stage of a project.

regulatory or other requirements to

complete drillholes that were not Another trend observed in Figure 8is the

specifically related to resource large variation in grade changes for the

upgrading. precious metal projects relative to the bulk

commodities. This is expected considering

An optimal in-fill drilling programme will that precious metal deposits are naturally

upgrade the resource using the fewest more variable than bulk commodities. What

drillholes, targeting locations that will define was unexpected by the authors, however,

mineralization and increase confidence in was the trend towards more negative-mean

the grade and geological continuity. grade changes as the variability of the

deposit increases. An interesting question

CPs and QPs should design drilling that is raised by this is: if the grade is

programmes that lie within the optimal expected to decrease with in-fill drilling,

population. For example, if a company should this not affect how we classify the

wishes to have a proportion change of 0.2, Mineral Resources in the first place?

the company should increase drilling by Further investigation is required to better

25%. In contrast, achieving a proportion understand how the grade is impacted with

change of 0.2 would require a 110% in-fill drilling and the increasing confidence

increase in drilling in the sub-optimal in the Mineral Resource.

population.

The authors consider that there is further

Figures 5–7 in this paper attempt to opportunity to expand on the results

quantify whether commodity type, resource presented in this paper. In particular,

size, or CP/QP influences can explain the through acquiring and analyzing more case

optimal and sub-optimal populations. studies, there is opportunity to confirm the

Firstly, there appears to be no obvious optimal population and whether the optimal

relationship between commodity type and population versus the sub-optimal

whether the project sits in the optimal population is a real phenomenon. This

population or sub-optimal population. might allow the establishment of a

However, there is one trend that warrants benchmark for CP/QPs to aspire to.

further investigation – the fact that the

majority of base metal projects lie in the

optimal population. Conclusion

Regarding resource size, the majority of The study results and discussion are

projects with less than 20 Mt in total Mineral presented to assist CP/QPs that are

Resource lie within the optimal population. planning drill programmes and managers

A possible reason for this could be that that approve drilling budgets. It is hoped

when there is a smaller area that requires that the results will prompt CP/QPs and

in-fill drilling, design of the programme is managers to ask if the proposed drill

relatively straightforward. Again, further programme will meet the resource upgrade

investigation is required. Regarding change objectives. Where the proposed drill

of the CP/QP, there seem to be no obvious programme is not expected to produce the

trends. resource upgrade predicted by the optimal

population, it might be pertinent to consider

Figure 8 explores how the grade changes if there is redundancy in the drilling

with the in-fill drilling programme and programme.

Further research will build upon what is

considered in this paper and will help

exploration geologists, CP/QPs and budget

managers to achieve their drilling

programme objectives while minimizing

expenditure. Practical tools that optimize

the drilling programme so that it does not

fall into the sub-optimal population should

be the focus of future work.

REFERENCES

Berry, M and McCarthy, P, 2006. Practical

consequences of geological uncertainty,

in Proceedings Sixth International Mining

Geology Conference, pp 253-258 (The

Australasian Institute of Mining and

Metallurgy: Melbourne).

Berry, M., (2014). “Benchmarking – Does it

have a role in Improving the performance

of mining geology?”, in Proceedings

Ninth International Mining Geology

Conference, pp 361 – 366. (The

Australasian Institute of Mining and

Metallurgy: Melbourne).

BusinessDictionary.com, (2015). [Online].

Available from:

http://www.businessdictionary.com/definit

ion/benchmarking.html.

Ross, D., Cox, J., Krutzelmann, H., (2014).

“Technical Report on the Mineral

Resource update for the Juanicipio joint

venture, Zacatecas State, Mexico.”

Prepared for MAG Silver Corp by Roscoe

Postle Associates Incorporated.

Scholz, M., (2014) “Real Benchmarking”

[Online]. Available from:

http://www.amcconsultants.com/digging

deeper articles/real-benchmarking

Thomas, M., Thalenhorst, H., Riles, A.,

(2012). “Minera Juanicipio Property, Con formato: Español (Perú)

Zacatecas State, Mexico. Technical

Report.” Prepared for Minera Juanicipio

S.A. de C.V. by AMC Mining Consultants

(Canada) Limited.

S-ar putea să vă placă și

- YoungDocument4 paginiYoungShan YasirÎncă nu există evaluări

- Silva 2014Document9 paginiSilva 2014Nicolas Pacheco NeckelÎncă nu există evaluări

- Geothermal Resource Assessment - Case Example, Menenengai Phase IDocument8 paginiGeothermal Resource Assessment - Case Example, Menenengai Phase IAjeng HamidahÎncă nu există evaluări

- A Novel Method For Reconciliation - Julian Et. AlDocument12 paginiA Novel Method For Reconciliation - Julian Et. AlIgnacio UribeÎncă nu există evaluări

- 300 000 052 772 - ReconciliationDocument8 pagini300 000 052 772 - ReconciliationLuis RojasÎncă nu există evaluări

- A Simple and Accurate Method For Ore Reserve Estimation in SLC MinesDocument15 paginiA Simple and Accurate Method For Ore Reserve Estimation in SLC MinesRalain NgatchaÎncă nu există evaluări

- Spe 168220 PaDocument12 paginiSpe 168220 PaBourhenÎncă nu există evaluări

- Geochemical Parameters Required From The SKB Site Characterisation ProgrammeDocument57 paginiGeochemical Parameters Required From The SKB Site Characterisation ProgrammeMohammad Rizwan KhanÎncă nu există evaluări

- Validation of Sampling and Assaying QualityDocument11 paginiValidation of Sampling and Assaying QualityAndrea GonzalezÎncă nu există evaluări

- Categorization of Mnineral Resources 2019Document23 paginiCategorization of Mnineral Resources 2019lear_veÎncă nu există evaluări

- Categorization of Mineral Resources Based On Different Geostatistical Simulation Algorithms: A Case Study From An Iron Ore DepositDocument25 paginiCategorization of Mineral Resources Based On Different Geostatistical Simulation Algorithms: A Case Study From An Iron Ore DepositSyahrul AzizÎncă nu există evaluări

- 2009 Fouet - Standardising The Reconciliation Factors Required in Governance ReportingDocument14 pagini2009 Fouet - Standardising The Reconciliation Factors Required in Governance Reportinganuar pires100% (1)

- A Real-Time Implementation of MSEDocument14 paginiA Real-Time Implementation of MSEAmeer MuhammadÎncă nu există evaluări

- Procedia Cirp: Xiaoju Chen, H. Scott Matthews, Rebecca Hanes, Alberta CarpenterDocument4 paginiProcedia Cirp: Xiaoju Chen, H. Scott Matthews, Rebecca Hanes, Alberta CarpenterR JÎncă nu există evaluări

- 20 V 113 GDocument10 pagini20 V 113 GChani PradasaraÎncă nu există evaluări

- Dealing With High Grade Data in ResourceDocument10 paginiDealing With High Grade Data in ResourceEliseo AlcaláÎncă nu există evaluări

- Activity 5 - DAHUYLA, Jef Michael L.Document11 paginiActivity 5 - DAHUYLA, Jef Michael L.Jef Michael L. DahuylaÎncă nu există evaluări

- Maybe e 2010Document15 paginiMaybe e 2010Mário de FreitasÎncă nu există evaluări

- Mineral Supply For Sustainable Development Requires Resource GovernanceDocument10 paginiMineral Supply For Sustainable Development Requires Resource GovernanceLynn ShiyayoÎncă nu există evaluări

- RFP For Soil Testing - NDocument16 paginiRFP For Soil Testing - NAbhishek Kumar SinhaÎncă nu există evaluări

- 320 GC2018 Tech Evaluation of CarbonOxyge Logs Lamar Field Maracaibo Lake Basin VenezuelaDocument5 pagini320 GC2018 Tech Evaluation of CarbonOxyge Logs Lamar Field Maracaibo Lake Basin VenezuelaAissa MeskineÎncă nu există evaluări

- Anas 2020 IOP Conf. Ser. Mater. Sci. Eng. 875 012050Document12 paginiAnas 2020 IOP Conf. Ser. Mater. Sci. Eng. 875 012050María Alejandra Vera BurauÎncă nu există evaluări

- Quantifying Uncertainty in Mineral Resources by Use ofDocument21 paginiQuantifying Uncertainty in Mineral Resources by Use ofJose Javier Rojas MoralesÎncă nu există evaluări

- Information Technology SolutionsDocument8 paginiInformation Technology SolutionsPaulo IvoÎncă nu există evaluări

- Mine Value Chain Reconciliation - Demonstrating VaDocument15 paginiMine Value Chain Reconciliation - Demonstrating VaIrvin SamaniegoÎncă nu există evaluări

- Sabour Resources PolicyDocument11 paginiSabour Resources PolicyDavid Esteban Meneses RendicÎncă nu există evaluări

- 2012 Annual US Geothermal Power Production and Development Report FinalDocument35 pagini2012 Annual US Geothermal Power Production and Development Report FinalBittuKumarÎncă nu există evaluări

- AG Post PrintDocument29 paginiAG Post PrintDeo PambudiÎncă nu există evaluări

- Ibp1587 12Document11 paginiIbp1587 12Marcelo Varejão CasarinÎncă nu există evaluări

- Mineral Resource Classification. How The Viability of Your Project May Hang On A Qualified Person'S JudgementDocument9 paginiMineral Resource Classification. How The Viability of Your Project May Hang On A Qualified Person'S JudgementAlexandra Paola Rodriguez CaicedoÎncă nu există evaluări

- Wre Micro ProjectDocument16 paginiWre Micro ProjectTejas DeoreÎncă nu există evaluări

- Tr-Form 01: Exploration Results and Mineral Resources: Rogel A. Santos, PHDDocument20 paginiTr-Form 01: Exploration Results and Mineral Resources: Rogel A. Santos, PHDEmmanuel CaguimbalÎncă nu există evaluări

- PFS Results v8 - FinalDocument8 paginiPFS Results v8 - FinalKenton Johnson0% (1)

- Advances in Engineering Software: T. TaskiranDocument7 paginiAdvances in Engineering Software: T. TaskiranAravindanÎncă nu există evaluări

- Recent Advances in Coring and Core Analysis For Reservoir EvaluationDocument24 paginiRecent Advances in Coring and Core Analysis For Reservoir EvaluationjanlayaÎncă nu există evaluări

- How Many Drillholes Do I Need To Upgrade My Inferred Resource?Document20 paginiHow Many Drillholes Do I Need To Upgrade My Inferred Resource?zuheib63Încă nu există evaluări

- Standard Definitions For The Benchmarking of Availability and Utilization of EquipmentDocument14 paginiStandard Definitions For The Benchmarking of Availability and Utilization of EquipmentTyler GoodwinÎncă nu există evaluări

- Quantifying Uncertainty in Mineral Resources WithDocument13 paginiQuantifying Uncertainty in Mineral Resources WithHeber HernándezÎncă nu există evaluări

- Energies: Power Transformer Diagnostics, Monitoring and Design FeaturesDocument5 paginiEnergies: Power Transformer Diagnostics, Monitoring and Design FeaturesNanang Puji NugrohoÎncă nu există evaluări

- International Journal of Mining Science and TechnologyDocument6 paginiInternational Journal of Mining Science and TechnologyIrvin SamaniegoÎncă nu există evaluări

- Geomet CIMDocument15 paginiGeomet CIMareftawana31Încă nu există evaluări

- A Numerical Study For A Mining Project Using Real Options Valuation PDFDocument9 paginiA Numerical Study For A Mining Project Using Real Options Valuation PDFJuan David Vergara AgudeloÎncă nu există evaluări

- Formation Evaluation and Properties Models of 103a Field Sirt BasinDocument6 paginiFormation Evaluation and Properties Models of 103a Field Sirt Basinnn1129374Încă nu există evaluări

- Dunham and Vann 2007Document8 paginiDunham and Vann 2007OROSCOROCAÎncă nu există evaluări

- Resourcemodelling 1 ActheroDocument22 paginiResourcemodelling 1 ActheroAndy ParkÎncă nu există evaluări

- Mine Planning 2011Document17 paginiMine Planning 2011Mditsa1991Încă nu există evaluări

- Play & CRS PaperDocument8 paginiPlay & CRS PaperHamid HussainÎncă nu există evaluări

- SPE 164820 MS Probabilistic and Deterministic Methods Applicability in Unconventional Reservoirs PDFDocument12 paginiSPE 164820 MS Probabilistic and Deterministic Methods Applicability in Unconventional Reservoirs PDFNGT56Încă nu există evaluări

- 2022 Chapter 3 Mine Valuation & EconomicsDocument28 pagini2022 Chapter 3 Mine Valuation & EconomicsOUMAR PATHE BARRYÎncă nu există evaluări

- Economic Evaluation of Watershed Projects An Overview Methodology and Application'Document6 paginiEconomic Evaluation of Watershed Projects An Overview Methodology and Application'juan carlos molano toroÎncă nu există evaluări

- Mining Geometrical Modelling Approach For The Estimation of Cut-Off Grade of Open-Pit Mines, Through Maximization of The Net Present ValueDocument14 paginiMining Geometrical Modelling Approach For The Estimation of Cut-Off Grade of Open-Pit Mines, Through Maximization of The Net Present ValueSirri BlessingÎncă nu există evaluări

- SPE 87358 Technology: Catalyst For Coalgas GrowthDocument7 paginiSPE 87358 Technology: Catalyst For Coalgas Growthmsmsoft90Încă nu există evaluări

- 12 - 1 - ValidationRes - Azulcocha - 110927Document27 pagini12 - 1 - ValidationRes - Azulcocha - 110927Antonino VasquezÎncă nu există evaluări

- Iyer Et Al-2022Document17 paginiIyer Et Al-2022Dariush JavaniÎncă nu există evaluări

- Literature Review On Water SupplyDocument7 paginiLiterature Review On Water Supplyaflspbnyu100% (1)

- Information Fusion: Yingying Liang, Yanbing Ju, Jindong Qin, Witold PedryczDocument18 paginiInformation Fusion: Yingying Liang, Yanbing Ju, Jindong Qin, Witold PedryczToni NguyenÎncă nu există evaluări

- Geometallurgical Modeling at Olympic DamDocument22 paginiGeometallurgical Modeling at Olympic DamW ZuoÎncă nu există evaluări

- Using Different Methods To Predict Oil in Place in Mishrif Formation / Amara Oil FieldDocument6 paginiUsing Different Methods To Predict Oil in Place in Mishrif Formation / Amara Oil Fieldرجل من كوكب اخرÎncă nu există evaluări

- JPT2007 - 05 - Reserves Estimation-The Challenge For The IndustryDocument10 paginiJPT2007 - 05 - Reserves Estimation-The Challenge For The Industry유인항Încă nu există evaluări

- Energy Sources: Fundamentals of Chemical Conversion Processes and ApplicationsDe la EverandEnergy Sources: Fundamentals of Chemical Conversion Processes and ApplicationsÎncă nu există evaluări

- Piedras Verdes 2010 Technical Report Acrobat X.2691621Document218 paginiPiedras Verdes 2010 Technical Report Acrobat X.2691621zuheib63Încă nu există evaluări

- Pages 57 To 101 From MGrayBarrenacionQAQC2014May30reducedsize.51160923Document45 paginiPages 57 To 101 From MGrayBarrenacionQAQC2014May30reducedsize.51160923zuheib63Încă nu există evaluări

- Gold Exploration in Mexico Status Report 2016: by Matthew D. Gray Resource Geosciences de Mexico SA de CV 26 October 2016Document83 paginiGold Exploration in Mexico Status Report 2016: by Matthew D. Gray Resource Geosciences de Mexico SA de CV 26 October 2016zuheib63Încă nu există evaluări

- Pages 1 To 56 From MGrayBarrenacionQAQC2014May30reducedsize.51160900 PDFDocument56 paginiPages 1 To 56 From MGrayBarrenacionQAQC2014May30reducedsize.51160900 PDFzuheib63Încă nu există evaluări

- Bridgeport Ventures M Gray 43-101 Report On Blackrock Argentite Bellview Horsethief Nevada Gold Project Portfolio 2010 Nov 26 1130 Hours FINAL Acrobat X.26101802Document138 paginiBridgeport Ventures M Gray 43-101 Report On Blackrock Argentite Bellview Horsethief Nevada Gold Project Portfolio 2010 Nov 26 1130 Hours FINAL Acrobat X.26101802zuheib63Încă nu există evaluări

- Summary Report On The Rosario Copper-Gold Project, Region III, Atacama, ChileDocument94 paginiSummary Report On The Rosario Copper-Gold Project, Region III, Atacama, Chilezuheib63Încă nu există evaluări

- Mexico's Next Big Gold Discovery: by Matthew D. Gray Resource Geosciences de Mexico SA de CV February 2017Document74 paginiMexico's Next Big Gold Discovery: by Matthew D. Gray Resource Geosciences de Mexico SA de CV February 2017zuheib63Încă nu există evaluări

- Discovery of The HS Zone La Trinidad Mine Sinaloa M Gray 2017apr5 Sanitized.95193047Document77 paginiDiscovery of The HS Zone La Trinidad Mine Sinaloa M Gray 2017apr5 Sanitized.95193047zuheib63Încă nu există evaluări

- Cerro Caliche Technical Report M Gray For Corex Gold 2007july31.10591820Document120 paginiCerro Caliche Technical Report M Gray For Corex Gold 2007july31.10591820zuheib63Încă nu există evaluări

- Gray PDAC 2006.26104016Document45 paginiGray PDAC 2006.26104016zuheib63Încă nu există evaluări

- Camino Rojo Project Zacatecas Mexico Orla Mining LTD M Gray C Defilippi 43-101report 2018jan24.28124455Document77 paginiCamino Rojo Project Zacatecas Mexico Orla Mining LTD M Gray C Defilippi 43-101report 2018jan24.28124455zuheib63Încă nu există evaluări

- Ramirez LE PDFDocument13 paginiRamirez LE PDFzuheib63Încă nu există evaluări

- M Gray Mexico Silver Presentation 2014oct22.51161446 PDFDocument74 paginiM Gray Mexico Silver Presentation 2014oct22.51161446 PDFzuheib63Încă nu există evaluări

- Aster User Guide v2Document135 paginiAster User Guide v2Jesús TrujilloÎncă nu există evaluări

- Código JORCDocument44 paginiCódigo JORCPatricio LeddyÎncă nu există evaluări

- D 6032 - 96 - Determining Rock Quality Designation (RQD) of Rock CoreDocument4 paginiD 6032 - 96 - Determining Rock Quality Designation (RQD) of Rock Corezuheib63Încă nu există evaluări

- Analitics 001Document281 paginiAnalitics 001zuheib63Încă nu există evaluări

- How Many Drillholes Do I Need To Upgrade My Inferred Resource?Document20 paginiHow Many Drillholes Do I Need To Upgrade My Inferred Resource?zuheib63Încă nu există evaluări

- 001 001Document68 pagini001 001zuheib63Încă nu există evaluări

- Acquire v4Document12 paginiAcquire v4El Zurdo ObregonÎncă nu există evaluări

- Daftar PustakaDocument2 paginiDaftar PustakaWisnu PerdanaÎncă nu există evaluări

- SP Khullar Horoscope RectificationDocument7 paginiSP Khullar Horoscope RectificationAnonymous N2Q5M6100% (1)

- Ucsp EvolutionpptDocument25 paginiUcsp EvolutionpptangelÎncă nu există evaluări

- DictationDocument2 paginiDictationAryo CalmÎncă nu există evaluări

- World MapsDocument20 paginiWorld MapsGreg Kennedy100% (1)

- Lecture 2 Levels of Biological OrganizationDocument15 paginiLecture 2 Levels of Biological OrganizationEsther Suan-LancitaÎncă nu există evaluări

- GR 9 Natural Science ANS SHEET Eng PDFDocument8 paginiGR 9 Natural Science ANS SHEET Eng PDFJillrey RegondolaÎncă nu există evaluări

- ScriptDocument3 paginiScriptShot TimeÎncă nu există evaluări

- Editors Francisco J.ayala and Walter M.fitch NAS Colloquium Genetics and The Origin of Species From Darwin To Molecular Biology 60 YearsDocument119 paginiEditors Francisco J.ayala and Walter M.fitch NAS Colloquium Genetics and The Origin of Species From Darwin To Molecular Biology 60 YearsAndrei CorneaÎncă nu există evaluări

- ASAS Catalogue of Variable Stars RRLyrDocument60 paginiASAS Catalogue of Variable Stars RRLyrfdzgeosÎncă nu există evaluări

- 1 The Origin of The UniverseDocument11 pagini1 The Origin of The UniverseBuzz manzhjanaÎncă nu există evaluări

- Doyens of Geology Kerala, II: Prof.K.K.MenonDocument3 paginiDoyens of Geology Kerala, II: Prof.K.K.MenonDr.Thrivikramji.K.P.100% (1)

- Daftar PustakaDocument6 paginiDaftar PustakaEstherÎncă nu există evaluări

- Statistical and Thermal Physics Fundamentals and ApplicationsDocument13 paginiStatistical and Thermal Physics Fundamentals and Applicationsgul jahanÎncă nu există evaluări

- Analysis Report: Residential Building, Dhapasi, KathmanduDocument7 paginiAnalysis Report: Residential Building, Dhapasi, KathmanduKalpanaÎncă nu există evaluări

- Rocks and Minerals WebquestDocument3 paginiRocks and Minerals Webquestapi-265481802Încă nu există evaluări

- Astronomy - October 2015 USADocument80 paginiAstronomy - October 2015 USASORAYA RODRIGUESÎncă nu există evaluări

- DTCB The Journey of Botswanas DiamondsDocument68 paginiDTCB The Journey of Botswanas DiamondsChristineNyambeÎncă nu există evaluări

- Hydraulic Design of Upstream Scouring Sluice: 99.05 M 95.64 M 96.75 M 100.65 MDocument8 paginiHydraulic Design of Upstream Scouring Sluice: 99.05 M 95.64 M 96.75 M 100.65 MIlman AdlyÎncă nu există evaluări

- Bhava Lords in Various BhavasDocument12 paginiBhava Lords in Various BhavasAstroSunilÎncă nu există evaluări

- Naskah Soal UasDocument10 paginiNaskah Soal UasElsa FitriÎncă nu există evaluări

- The Xylariaceae: A Case Study in Biological and Chemical DiversityDocument11 paginiThe Xylariaceae: A Case Study in Biological and Chemical DiversityAshen NirodyaÎncă nu există evaluări

- Krushna: H 2, M.I.D.C. Area, Satara, MAHARASHTRA .. 415004Document7 paginiKrushna: H 2, M.I.D.C. Area, Satara, MAHARASHTRA .. 415004Subramaniam Raju Krishnan100% (1)

- PH-120-04 Homework Ch02 AnswersDocument3 paginiPH-120-04 Homework Ch02 AnswersJon KimballÎncă nu există evaluări

- Naresh Astro ChartDocument7 paginiNaresh Astro Chartpurinaresh85Încă nu există evaluări

- Keplers Law of Planetary MotionDocument3 paginiKeplers Law of Planetary MotionFreddie AbulenciaÎncă nu există evaluări

- SphaeromatidaeDocument69 paginiSphaeromatidaeMatthew Peter ClareÎncă nu există evaluări

- Af - Tropical Rainforest Climate - Tropical Monsoon Climate - Tropical Savanna ClimateDocument4 paginiAf - Tropical Rainforest Climate - Tropical Monsoon Climate - Tropical Savanna ClimateRemya R. KumarÎncă nu există evaluări

- Engineering Geology For Underground Works (P. Gattinoni, E.M. Pizzarotti, L. Scesi, 2014) Geolibrospdf PDFDocument312 paginiEngineering Geology For Underground Works (P. Gattinoni, E.M. Pizzarotti, L. Scesi, 2014) Geolibrospdf PDFAlexiz MezaÎncă nu există evaluări

- Capt. by Than Three Mansfield, Several Selected Receive Are A RsDocument1 paginăCapt. by Than Three Mansfield, Several Selected Receive Are A RsMarcianitosVerdesÎncă nu există evaluări