Documente Academic

Documente Profesional

Documente Cultură

Avery Hardoll DM Series Bulkmeter

Încărcat de

we2020 evaluări0% au considerat acest document util (0 voturi)

81 vizualizări4 paginiThe Steel Case Bulkmeter DM series is a positive displacement bulkmeter designed for accurate measurement of liquid flows in tank truck loading depots. It provides high accuracy without being affected by pressure or temperature variations. The rotor inside the meter revolves due to fluid pressure on its vanes, accurately measuring the volume. Accessories include electronic controllers, calibration and pulse transmission components, valves, and indicators. The meter is constructed of materials suitable for petroleum products and can handle flows up to 2500 lpm continuously.

Descriere originală:

Avery Hardoll Dm Series Bulkmeter

Titlu original

Avery Hardoll Dm Series Bulkmeter

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe Steel Case Bulkmeter DM series is a positive displacement bulkmeter designed for accurate measurement of liquid flows in tank truck loading depots. It provides high accuracy without being affected by pressure or temperature variations. The rotor inside the meter revolves due to fluid pressure on its vanes, accurately measuring the volume. Accessories include electronic controllers, calibration and pulse transmission components, valves, and indicators. The meter is constructed of materials suitable for petroleum products and can handle flows up to 2500 lpm continuously.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

81 vizualizări4 paginiAvery Hardoll DM Series Bulkmeter

Încărcat de

we202The Steel Case Bulkmeter DM series is a positive displacement bulkmeter designed for accurate measurement of liquid flows in tank truck loading depots. It provides high accuracy without being affected by pressure or temperature variations. The rotor inside the meter revolves due to fluid pressure on its vanes, accurately measuring the volume. Accessories include electronic controllers, calibration and pulse transmission components, valves, and indicators. The meter is constructed of materials suitable for petroleum products and can handle flows up to 2500 lpm continuously.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

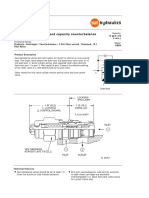

PRO MEA 15

PRODUCTS - Measurement

STEEL CASE BULKMETER DM SERIES

The ultimate loading meter

• Avery Hardoll accuracy in a steel meter

• Positive displacement performance at turbine economy

• Compact lightweight design

• Insensitive to pressure changes

• Free from installation effects

The Avery Hardoll Steel Bulkmeter is specifically ACCURACY

designed to meet the rigorous demands of the The positive displacement principle is the only

modern tank truck loading depot. It provides the accurate method of measuring liquid flow. No

highest level of repeatability and accuracy other technology e.g. turbine meters can achieve

combined with minimal down time for service, the same level of accuracy. This is particularly

without the inconvenience and cost of double true in depot applications where flow rates,

casing. pressure and temperature can vary during a

delivery. The Avery Hardoll Bulkmeter positively

measures fluid volume with minimum scope for

error and with minimal effect from pressure

variations, temperature change or turbulence from

near by valves or bends etc.

OPERATION

The product enters the meter and causes the rotor

to revolve by pressure on the vanes.The proximity of

the rotor to the body forms an efficient seal, whilst

the profile of the body ensures that the vanes are

guided through the measuring crescent , where the

volume of product is accurately measured.

An extension shaft driving through a pressure tight

gland in the meter front cover, transmits the rotor

revolutions either directly to a pulse transmitter or

through gearing to a stepless mechanical calibrator

driving the counter.

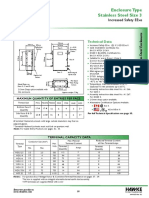

VISCOUS PRODUCTS

Avery Hardoll bulkmeters can be used on all Consequently when using products with viscosities

petroleum products of all viscosities that are (at operating conditions) above 100 centistokes, it is

normally pumped. However there is obviously an necessary to reduce the maximum permitted

increase in pressure drop with more viscous fuels flowrate. As a guide it is suggested that the

which will, under normal circumstances, limit the pressure drop through the meter should not exceed

maximum flowrate obtainable.It is recommended 10 psi (0.7 bar) for continuous running at maximum

that the pressure drop through a bulkmeter should speed or 15 psi (1 bar) for continuous running at

not exceed 15 psi (1 bar), above which the load on half speed.

the bearings will start to cause wear.

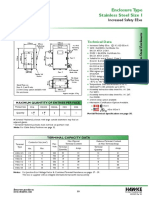

ACCESSORIES CONSTRUCTION

MASTERLOAD: BODY: CARBON STEEL - ASTM 216 WCB

Electronic meter controller - See data sheet 201 END COVERS: CARBON STEEL

ROTOR: ALUMINIUM ALLOY

MECHANICAL CALIBRATION: VANES: CARBON

With Veeder Root counters reading in a wide range BEARINGS: NON CORRODIBLE STAINLESS

of units

STEEL

PULSE TRANSMITTERS: SEALS: HIGH NITRILE or FLUOROCARBON

Accepts all pulse transmitters in common use

PRESET VALVES: SPECIFICATION

Linkage or microswitch operated MAX FLOW RATE: 2500 lpm Continuous

3000 lpm Intermittent

TICKET PRINTERS: FLANGES: 4" ANSI 150

With or without identifiers, either zero or

MAX WORKING PRESSURE: 10.5 bar (150psi)

accumulative start

TEST PRESSURE: 21 bar (300psi)

MECHANICAL RATE OF FLOW INDICATORS TEMPERATURE RANGE: -28º C TO 100º C

VOLUME PER REVOLUTION: 5.75 LITRES

SWIVEL TURN DOWN RATIO: 10:1

LINEARITY WITHIN: + 0.15%

EXTENDED COUNTER DRIVES

REPEATABILITY BETTER THAN: 0.02%

STRAINER: WEIGHT (WITH TRANSMITTER): 70kg

Essential to prevent damage to the meter and is

available with 80, 100 and 120 mesh baskets,

witheither cast iron or cast steel body. Both basket

and `Y' type strainers are available.

S-ar putea să vă placă și

- Transducer Handbook: User's Directory of Electrical TransducersDe la EverandTransducer Handbook: User's Directory of Electrical TransducersÎncă nu există evaluări

- Avery Hardoll CM Series BulkmeterDocument8 paginiAvery Hardoll CM Series Bulkmeterhendro saputroÎncă nu există evaluări

- Measure Fluids Precisely with BM Series Mechanical BulkmetersDocument8 paginiMeasure Fluids Precisely with BM Series Mechanical BulkmetersLismanÎncă nu există evaluări

- S6065 Honeywell Flow SwitchDocument4 paginiS6065 Honeywell Flow SwitchAbbasÎncă nu există evaluări

- Coriolis vs. Ultrasonic FlowmetersDocument10 paginiCoriolis vs. Ultrasonic FlowmetersreliableplacementÎncă nu există evaluări

- Coriolis vs. Ultrasonic FlowmetersDocument10 paginiCoriolis vs. Ultrasonic FlowmetersRaja GanguliÎncă nu există evaluări

- Liq TurbineFM Series1500 DSDocument12 paginiLiq TurbineFM Series1500 DSElinton De Jesus SarmientoÎncă nu există evaluări

- EW370 Series Woltman Flow Meters: Dn50 300 For Heating and Chilled Water ApplicationsDocument4 paginiEW370 Series Woltman Flow Meters: Dn50 300 For Heating and Chilled Water ApplicationsLe HieuÎncă nu există evaluări

- Page 1271Document1 paginăPage 1271EmilyTheDwarfÎncă nu există evaluări

- Field Devices - Pressure: Product SpecificationsDocument12 paginiField Devices - Pressure: Product SpecificationsMohsenÎncă nu există evaluări

- Protect gas networks with fast-acting SBC 782 slam shut valvesDocument8 paginiProtect gas networks with fast-acting SBC 782 slam shut valvesRadhakrishnan PaulÎncă nu există evaluări

- Type 2625 and 2625NS Volume BoostersDocument4 paginiType 2625 and 2625NS Volume Boostershamz786Încă nu există evaluări

- Jspl-Refilling StationDocument21 paginiJspl-Refilling StationNaveen Kumar ChauhanÎncă nu există evaluări

- Active Sensors CERAVAC Transmitters CTR 100 / CTR 91: Advantages To The User Typical ApplicationsDocument4 paginiActive Sensors CERAVAC Transmitters CTR 100 / CTR 91: Advantages To The User Typical Applicationsreza behroozÎncă nu există evaluări

- 测试仪合集Document24 pagini测试仪合集jackÎncă nu există evaluări

- 100 HP DatasheetDocument6 pagini100 HP DatasheetPUNiiZIHIEIRÎncă nu există evaluări

- G77x_-77xK valve_catalogueDocument8 paginiG77x_-77xK valve_catalogueEzgi PelitÎncă nu există evaluări

- Types of Flow Measurements AND Their ApplicationsDocument44 paginiTypes of Flow Measurements AND Their ApplicationsRaghÎncă nu există evaluări

- 2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-MetersDocument7 pagini2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-Metersichi ezzahraÎncă nu există evaluări

- MS100-00 - (M-MA Series)Document6 paginiMS100-00 - (M-MA Series)atorresh090675Încă nu există evaluări

- VSO Low Flow: Thermally Compensated Proportional ValveDocument6 paginiVSO Low Flow: Thermally Compensated Proportional Valvebiomed2083Încă nu există evaluări

- Ar-Mite Low Flow Armored FlowmeterDocument12 paginiAr-Mite Low Flow Armored FlowmeterVasabinskiyÎncă nu există evaluări

- Bouche Laboratories, 1000AD Shaker 10-50kHz PDFDocument2 paginiBouche Laboratories, 1000AD Shaker 10-50kHz PDFLulu Sweet ThingÎncă nu există evaluări

- 03 - Pigsar - Metrological ForumDocument27 pagini03 - Pigsar - Metrological ForumShahnoza TorayevaÎncă nu există evaluări

- ELH 05059 en NaDocument2 paginiELH 05059 en NaOmar Velazquez HernandezÎncă nu există evaluări

- Hygienic Flow Transmitter Technical SpecificationsDocument4 paginiHygienic Flow Transmitter Technical SpecificationsMicImportacionesÎncă nu există evaluări

- Low & Absolute Pressure Measurement for Fluids and GasesDocument5 paginiLow & Absolute Pressure Measurement for Fluids and GasesHanÎncă nu există evaluări

- Pressure CalibratorDocument12 paginiPressure CalibratorB P REDDYÎncă nu există evaluări

- 521B0841 DKCFNPD040A902 VRH3060120PressureReliefValve GBDocument5 pagini521B0841 DKCFNPD040A902 VRH3060120PressureReliefValve GBlayetajÎncă nu există evaluări

- Airflow Sensors AWM5000 Series High Flow Mass Airflow/AmplifiedDocument4 paginiAirflow Sensors AWM5000 Series High Flow Mass Airflow/AmplifiedwidsonmeloÎncă nu există evaluări

- Deadweight Testers BrochureDocument2 paginiDeadweight Testers BrochureAliÎncă nu există evaluări

- Control Valve SelectionDocument31 paginiControl Valve SelectionJitendra Sharma100% (1)

- Test Separator WT 16Document4 paginiTest Separator WT 16jairaso2950Încă nu există evaluări

- WCM 7300 - Specification PDFDocument2 paginiWCM 7300 - Specification PDFzaffarÎncă nu există evaluări

- Dr.R.K.bansal Fluid Mechanics and Hydraulic MachinesDocument2 paginiDr.R.K.bansal Fluid Mechanics and Hydraulic MachinesnavyageethikaÎncă nu există evaluări

- Rotametro ABBDocument10 paginiRotametro ABBjoticamario123Încă nu există evaluări

- Woltmann Helix Helical Vane Water Meters: Permanent Flow Rate (Q) KL/H Size - Nominal Diameter (DN) MMDocument2 paginiWoltmann Helix Helical Vane Water Meters: Permanent Flow Rate (Q) KL/H Size - Nominal Diameter (DN) MMMijomirÎncă nu există evaluări

- Screwpump Series Technical SpecificationsDocument12 paginiScrewpump Series Technical SpecificationsMick VÎncă nu există evaluări

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pagini5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevÎncă nu există evaluări

- F8834 VR75 GB 06 007 LowDocument6 paginiF8834 VR75 GB 06 007 LowŁukasz OlszewskiÎncă nu există evaluări

- RV Series: High Pressure Anti-Cavitation Relief ValvesDocument6 paginiRV Series: High Pressure Anti-Cavitation Relief Valveselectrico65Încă nu există evaluări

- Control Valve PresentationDocument61 paginiControl Valve PresentationBorabta MstÎncă nu există evaluări

- 11 GM Data SheetDocument12 pagini11 GM Data Sheetemi alvaradoÎncă nu există evaluări

- VSO Data Sheet - 20191101Document8 paginiVSO Data Sheet - 20191101Eduardo EvaristoÎncă nu există evaluări

- GLOBE 2 WAY CONTROL VALVE SERIESDocument9 paginiGLOBE 2 WAY CONTROL VALVE SERIESsam123potterÎncă nu există evaluări

- AIR LEAK TESTER PANDA-341 - A4 - 5001506 - WebDocument2 paginiAIR LEAK TESTER PANDA-341 - A4 - 5001506 - WebHenry ChangÎncă nu există evaluări

- Wika Wallace Tiernan Series 65 120 Portable Pneumatic CalibratorDocument4 paginiWika Wallace Tiernan Series 65 120 Portable Pneumatic CalibratorGilda JimenezÎncă nu există evaluări

- CRM 100BDocument2 paginiCRM 100BPUNNAPRA SubstationÎncă nu există evaluări

- AVL Blow by Meter Product DescriptionDocument4 paginiAVL Blow by Meter Product DescriptionDennis WangÎncă nu există evaluări

- 3 Way Sauter ValveDocument8 pagini3 Way Sauter ValverkssÎncă nu există evaluări

- LPV Hydraulic Pump Catalog PDFDocument20 paginiLPV Hydraulic Pump Catalog PDFJAGDEV PANESARÎncă nu există evaluări

- Awm 700Document4 paginiAwm 700azerinoÎncă nu există evaluări

- Gauges and Ancillary EquipmentDocument26 paginiGauges and Ancillary EquipmentAlbertoÎncă nu există evaluări

- Microflow - Positive Displacement Gear MeterDocument2 paginiMicroflow - Positive Displacement Gear MeterSchneider ParadaÎncă nu există evaluări

- Vickers: Proportional Pressure Control Valve With Integrated ElectronicsDocument8 paginiVickers: Proportional Pressure Control Valve With Integrated ElectronicsAlex KarimÎncă nu există evaluări

- Flow MeterrsDocument19 paginiFlow MeterrsRobertoVitorianoÎncă nu există evaluări

- Astm Compression Tester Accessories: ADR Advanced Digital ReadoutDocument7 paginiAstm Compression Tester Accessories: ADR Advanced Digital ReadoutJorge SanchezÎncă nu există evaluări

- Nuflo Gas Turbine Flow Meters PDFDocument2 paginiNuflo Gas Turbine Flow Meters PDFPleneador MantenimientoÎncă nu există evaluări

- Experimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionDe la EverandExperimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionEvaluare: 4 din 5 stele4/5 (2)

- Astm A139 2000Document6 paginiAstm A139 2000Rolando CastilloÎncă nu există evaluări

- 753 Cable Gland Type: Explosion ProofDocument1 pagină753 Cable Gland Type: Explosion Proofwe202Încă nu există evaluări

- American Taper Pipe Thread Specifications (ANSI B 1.20.1Document1 paginăAmerican Taper Pipe Thread Specifications (ANSI B 1.20.1Ali BelhaylaÎncă nu există evaluări

- Pipeline Operations and Maintenance ManualDocument72 paginiPipeline Operations and Maintenance Manualwe202Încă nu există evaluări

- 501/421 Cable Gland Type: Flameproof and Increased SafetyDocument1 pagină501/421 Cable Gland Type: Flameproof and Increased Safetywe202Încă nu există evaluări

- Stainless Steel Size 1 Enclosure Type: Increased Safety EexeDocument1 paginăStainless Steel Size 1 Enclosure Type: Increased Safety Eexewe202Încă nu există evaluări

- 15.6 Color Coding RequirementDocument4 pagini15.6 Color Coding Requirementwe202Încă nu există evaluări

- ASTM A36 - Standard Specification For Carbon Structural SteelDocument3 paginiASTM A36 - Standard Specification For Carbon Structural SteelLeo Kapmas SinambelaÎncă nu există evaluări

- AnsiDocument10 paginiAnsiwe202Încă nu există evaluări

- Prepare For A New ERA: InternationalDocument4 paginiPrepare For A New ERA: Internationalwe202Încă nu există evaluări

- Gex Sis Switchboard WireDocument2 paginiGex Sis Switchboard Wirewe202Încă nu există evaluări

- Industrial General Purpose: Cable Gland Selection TableDocument1 paginăIndustrial General Purpose: Cable Gland Selection Tablewe202Încă nu există evaluări

- Epc1 - Floating Production UnitDocument15 paginiEpc1 - Floating Production Unitwe202Încă nu există evaluări

- Stainless Steel Size 3 Enclosure Type: Increased Safety EexeDocument1 paginăStainless Steel Size 3 Enclosure Type: Increased Safety Eexewe202Încă nu există evaluări

- Type 501-453-Universal PDFDocument1 paginăType 501-453-Universal PDFwe202Încă nu există evaluări

- Type ICG 653-UniversalDocument1 paginăType ICG 653-Universalwe202Încă nu există evaluări

- DFJ-AE3 Heat DetectorDocument1 paginăDFJ-AE3 Heat Detectorwe202Încă nu există evaluări

- 121 Cable Gland Type: Industrial General PurposeDocument1 pagină121 Cable Gland Type: Industrial General Purposewe202Încă nu există evaluări

- Cable Solutions: Harsh EnvironmentDocument1 paginăCable Solutions: Harsh Environmentwe202Încă nu există evaluări

- Brochure Paga 1700 810121Document4 paginiBrochure Paga 1700 810121we202Încă nu există evaluări

- 701 Cable Gland Type: Industrial General PurposeDocument1 pagină701 Cable Gland Type: Industrial General Purposewe202Încă nu există evaluări

- Cross Link Process ComparisonDocument1 paginăCross Link Process Comparisonwe202Încă nu există evaluări

- Mpa 1600 Paga VB 186677Document4 paginiMpa 1600 Paga VB 186677we202Încă nu există evaluări

- Vesda Sped PDFDocument11 paginiVesda Sped PDFwe202Încă nu există evaluări

- FM-200 (GX-20)Document4 paginiFM-200 (GX-20)Cipon MariponÎncă nu există evaluări

- 1756 Control Logix ControllerDocument44 pagini1756 Control Logix Controllerwe202Încă nu există evaluări

- DRAKA - XLPE Cable PDFDocument2 paginiDRAKA - XLPE Cable PDFwe202Încă nu există evaluări

- Ns SpecsDocument7 paginiNs Specswe202Încă nu există evaluări

- Critch LeyDocument17 paginiCritch LeyhendrabudimanÎncă nu există evaluări

- Extra Writing: Has A Shower Six O'clock Quarter Past SixDocument1 paginăExtra Writing: Has A Shower Six O'clock Quarter Past SixAnonymous 0PRCsW6100% (1)

- Dan's ResumeDocument2 paginiDan's Resumedwels002Încă nu există evaluări

- Driving A Class 158Document4 paginiDriving A Class 158Frank NelsonÎncă nu există evaluări

- Case Study on Marketing Forces Faced by Kamdar GroupDocument9 paginiCase Study on Marketing Forces Faced by Kamdar GroupNatasya SyafinaÎncă nu există evaluări

- Grimslingers Quick ReferenceDocument2 paginiGrimslingers Quick ReferenceIntyaleÎncă nu există evaluări

- DIY Belt Sander Stand - WoodArchivistDocument4 paginiDIY Belt Sander Stand - WoodArchivistEricsÎncă nu există evaluări

- Deaf Life and Silent News PublicationsDocument12 paginiDeaf Life and Silent News Publicationsapi-252764331Încă nu există evaluări

- SOCO - Valve Lube Fitting (Email) PDFDocument13 paginiSOCO - Valve Lube Fitting (Email) PDFcaesar_jfking8063Încă nu există evaluări

- Everyone Loves You When Youre Dead SupplementDocument44 paginiEveryone Loves You When Youre Dead SupplementMarin JanušÎncă nu există evaluări

- Moody AC-41 DS BrochureDocument19 paginiMoody AC-41 DS BrochurePeter GedeonÎncă nu există evaluări

- Lesson Plan - AdjectiveDocument8 paginiLesson Plan - AdjectiveBenediktus R. RattuÎncă nu există evaluări

- Listado de Juegos para PC Con EmuladorDocument5 paginiListado de Juegos para PC Con EmuladorMarcelo IbañezÎncă nu există evaluări

- Brazilian Rhythms - Douglas Lora - Tonebase WorkbookDocument27 paginiBrazilian Rhythms - Douglas Lora - Tonebase WorkbookMattia Fogato100% (2)

- Pre Spanish LiteratureDocument12 paginiPre Spanish Literaturekayaa crumbsÎncă nu există evaluări

- Verb TO BE sentencesDocument4 paginiVerb TO BE sentencesjuanpablo5321Încă nu există evaluări

- Gymnastics Sports Events ExplainedDocument2 paginiGymnastics Sports Events Explainedmarian marianÎncă nu există evaluări

- Boarding Pass PDFDocument2 paginiBoarding Pass PDFSilviuGabrielÎncă nu există evaluări

- Digi Shock G Product Sheet 2019Document2 paginiDigi Shock G Product Sheet 2019IndarTo Setyo Budi UtomoÎncă nu există evaluări

- Mechanical Puller Catalog - EU PDFDocument20 paginiMechanical Puller Catalog - EU PDFAlvaroÎncă nu există evaluări

- What The Dime Is in A Name - Mwadimeh Wa'keshoDocument3 paginiWhat The Dime Is in A Name - Mwadimeh Wa'keshogreattrek100% (1)

- Acoustic - May 2016Document108 paginiAcoustic - May 2016SergeiÎncă nu există evaluări

- Rite of InvestitureDocument6 paginiRite of InvestitureAaron Ricardo Veloso100% (1)

- Achmad Sauqi Alex - 22012010464 - B.Inggris 615Document7 paginiAchmad Sauqi Alex - 22012010464 - B.Inggris 615Mras AlexÎncă nu există evaluări

- O Level m1 r5 January 2021Document3 paginiO Level m1 r5 January 2021Ishika GandhiÎncă nu există evaluări

- Vizio P42hdtv10a Service ManualDocument219 paginiVizio P42hdtv10a Service ManualTony AndMichelle WilsonÎncă nu există evaluări

- Nanna Stork PDFDocument14 paginiNanna Stork PDFStoian Elena GabrielaÎncă nu există evaluări

- 5.3.1.3 Lab - Observing DNS Name ResolutionDocument3 pagini5.3.1.3 Lab - Observing DNS Name Resolutionmadhwan sharmaÎncă nu există evaluări

- Compare and CotrastDocument1 paginăCompare and CotrastJoanna ManaloÎncă nu există evaluări

- For Each Question, Choose The Correct Answer. Camping: A. Way A. Tour B. Carry A. Map C. Sure C. ThrowDocument4 paginiFor Each Question, Choose The Correct Answer. Camping: A. Way A. Tour B. Carry A. Map C. Sure C. ThrowMoon ChâuÎncă nu există evaluări

- Module Two Wellness Plan ResultsDocument13 paginiModule Two Wellness Plan ResultsJames Verdugo CalleÎncă nu există evaluări