Documente Academic

Documente Profesional

Documente Cultură

Underground Distribution System

Încărcat de

wafikmh4Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Underground Distribution System

Încărcat de

wafikmh4Drepturi de autor:

Formate disponibile

SECTION 16402

UNDERGROUND DISTRIBUTION SYSTEM

PART 1 – GENERAL

1.01 DESCRIPTION:

A. Provide complete underground distribution system as indicated and specified.

B. Conform to lines, grades, elevations, and dimensions. Resolve interferences with other

underground conduit and piping or equipment. Match components suitable for proper

installation.

C. Provide concrete encasement of duct system. Include forms and reinforcing in

installation.

D. Provide cast-in-place or pre-cast manholes and handholes complete with ground rods,

windows, ladders, frames, covers, cable racks, supports, pulling irons, and other inserts.

Use reinforced concrete.

E. Provide Schedule 40 polyvinylchloride (PVC) conduits for power and control circuits

within concrete encased ductbank system. Provide rigid galvanized steel conduits for

instrumentation, communication, I/O, fire alarm and data highway cable circuits within a

concrete encased ductbank system.

1.02 RELATED WORK:

A. Division 1: General Requirements

B. Section 16050: Electrical Work - General

C. Section 16110: Electrical Raceway System

D. Section 16120: Electric Wires and Cables

E. Section 16450: Grounding

F. Section 16998: Field Inspection and Acceptance Testing

1.03 REFERENCES - As specified herein or equivalent IEC or BS Standards::

A. National Electrical Code.

B. National Electric Safety Code.

Libya Infrastructure Master Spec 16402-1 20-Nov-08

C. Equivalent British/European codes and standards may be used; however, the equivalency

shall be demonstrated and submitted by the Contractor and approved by the CM/CS.

1.04 SUBMITTALS:

A. Shop Drawings: Submit the following in accordance with Section 01300 -

SUBMITTALS:

1. Submit shop drawings and manufacturers' product data for all components and

materials used in the construction of underground distribution systems in

accordance with requirements of Section 16050.

2. Manhole and handhole buoyancy calculations.

3. Provide "As-Built" drawings of underground ductbank system in accordance with

Section 01300.

1.05 DELIVERY, STORAGE AND HANDLING:

A. Provide delivery, storage, and handling of equipment and materials in accordance with

Section 01610.

1.06 QUALITY ASSURANCE:

A. Provide in accordance with Section 01400.

1.07 SEISMIC DESIGN REQUIREMENTS:

A. Conform to the requirements indicated on the structural drawing S-1 and as specified in

Section 01900.

PART 2 - PRODUCTS

2.01 MANUFACTURERS:

A. Polyvinylchloride (PVC) Conduit:

1. Specified in Section 16110.

B. Rigid Steel Conduit, Galvanized:

1. Specified in Section 16110.

C. Manhole Waterproofing Material:

1. Heavy Duty Black, No. 46-449, by Tnemec Company, Inc.

Libya Infrastructure Master Spec 16402-2 20-Nov-08

2. Hi-Build Bituminous Coating, No. 64-J-5, by Valspar Corporation.

3. Bitumastic Super Service Black, by Kop-Coat, Inc.

4. Or equal.

D. Concrete Red Pigment:

1. Pulverized natural Iron Ore, Number 302 by DCS.

2. Red Iron Oxide Pigment by Bayer Corporation.

3. Red Iron Oxide Pigment by Davis Colors by Beltville.

4. Or equal.

2.02 MATERIALS AND COMPONENTS:

A. Conduit Spacers: Furnish conduit spacers made of plastic to maintain spacing between

conduits.

B. Concrete: Minimum compressive strength, 4,000 psi.

C. Hot-dipped galvanized steel conduit used underground to be painted with bituminous

paint.

D. Manhole Frames and Covers:

1. Heavy duty gray cast iron capable of withstanding a 20-ton wheel load transferred

through dual rubber tires.

2. Conform to details indicated on the drawings and as specified.

3. Provide machine-finished seat.

4. Mark "ELECTRICAL" on cover of manhole unless otherwise specified on

Drawings.

E. Cable Supports in Manholes and Handholes:

1. Cable racks, stainless steel.

2. Cable supports, stainless steel.

3. Insulators, high grade dry-process porcelain with smooth-glazed surfaces.

Libya Infrastructure Master Spec 16402-3 20-Nov-08

PART 3 - EXECUTION

3.01 GENERAL:

A. Perform work in accordance with the National Electrical Code and project drawings.

3.02 INSTALLATION OF CONDUITS:

A. Lay conduits, indicated to be direct buried in the ground, in trench on 3-inch (76.2 mm_

bed of sand and cover with an equivalent 3-inch (76.2 mm) bed of sand. Ensure that no

rocks come in contact with conduit during backfilling. Dig trenches to depth and location

indicated.

B. Provide minimum separation of power and control conduits of 3 inches (76.2 mm) both

vertically and horizontally. Build ductbank layer by layer, backfill and compact each

layer to provide support for next layer.

C. Separate power and control ducts from instrument telephone, fire alarm and signal ducts

by a minimum of 12 inches (304.8 mm).

D. Backfill ductbank in layers and tamp or puddle as indicated in Section 02210. Provide

yellow ductbank marker tapes, reading "Caution - Electrical Lines Below", over entire

length of ductline. Locate tapes 12 inches (304.8 mm) below grade. Provide a tape for

every 12 inches (304.8 mm) of width of ductline.

E. Install conduit, encased in concrete with spacers and reinforcing, as specified. Rigid

galvanized steel conduits to be painted with bituminous paint.

F. Install conduit runs following routing on drawing and running in straight lines. Provide

end bells where ducts enter manholes or handholes of the same material as the duct

system. Where deviation from a straight line becomes necessary, install bends of radius

which allow for rodding and installation of cable.

G. Accomplish changes in direction of runs exceeding total of 10 degrees, either vertical or

horizontal, by long sweep bends having minimum radius of curvature of 25 ft (7.6 m).

Manufactured bends can be used at ends of short runs of 100-ft (30.5 m). or less, and then

only at or close to the end of run. Provide long sweep bends made up of one or more

curved or straight sections and/or combinations thereof. Install manufactured bends with

minimum radius of 36-in (914.4 mm). where larger radius cannot be used.

H. Lay ductlines to minimum slope of 4 inches per 100-ft (30.5 m). and slope to manholes

and handholes from a high point between the manholes and handholes. Ductlines are to

slope away from buildings.

Libya Infrastructure Master Spec 16402-4 20-Nov-08

I. Install spacers at intervals of approximately 4 ft. (1.2 m) and stagger between tiers of

ducts to provide not less than 12-in (304.8 m). of longitudinal separation. Install base

spacers to provide at least 3-in (76.2 mm). between bottom of trench and underside of

bottom conduits. Completely fill space with concrete. Firmly wire conduits and spacers

together before concrete is placed.

J. Ductbanks are to be formed, unless trench conditions allow for neat placement of

concrete with specified clearances.

K. Prior to placing of concrete, remove all dirt, sand, and any other debris from between

conduits and from trench bottoms. Hold conduits in place to prevent floating or

accidental movement.

L. Stagger joints in conduits at least 6-in (152.4 mm). Do not allow couplings to rest on

bottom of trench. Install couplings for plastic conduit in accordance with manufacturer's

recommendations.

M. Install concrete encasements so minimum clearance of 12-in (304.8 mm). from concrete

to parallel pipes, lines, structures, etc., is maintained. Where ducts cross, minimum

clearance of 6 inches (152.4 mm) is required. Do not allow the top of concrete to be less

than 30-in (762 mm). below finished grade or paving. Submit special conditions which

may require lesser clearances or special conditions which may require greater than 30

inch (762 mm) depth for approval.

N. Where a connection is made to existing ductline, bond or dowel concrete encasement to

existing encasement. Use waterstop between ductpours and between manholes or

buildings and ductwork as indicated.

O. Do not use power-driven vibrators for spading of concrete around ducts.

P. Roll and grade backfill, and restore surface to condition equal to the site finish grade, or

as otherwise indicated.

Q. Keep conduits clean of concrete, dirt, and other substances during the course of

construction. After the ductlines have been completed, pull a standard flexible mandrel

not less than 12-in. (1.2 m) long, having a diameter approximately 1/4-in. (6.35 mm) less

than the inside diameter of the conduit, through each conduit, after which pull a brush

with stiff bristles through each conduit to make certain that no particles of earth, sand, or

gravel have been left in the line. Replace conduit runs that do not allow the passage of

the mandrel. Pneumatic rodding may be used to draw in the lead wire. Install in spare

conduits a pull wire or rope, and plug and seal spare conduits after cleaning.

R. Trowel Conduit Red pigment into the top of all ductbanks. Resulting surface is to be

uniform in both texture and the color red. Blend 5 pounds of red ironoxide pigment with

94 pounds of cement and apply to freshly poured concrete surface after screeding.

Trowel the pigment into the cement.

Libya Infrastructure Master Spec 16402-5 20-Nov-08

3.03 MANHOLES AND HANDHOLES:

A. Construct manholes and handholes of 4,000 psi concrete cast in place or pre-cast.

B. Install manholes with cable racks, hooks, insulators, and other features, as indicated.

C. Place a minimum 8 inch (203.2 mm) compacted sand base under each manhole and

handhole.

D. Construct cast-in-place manholes and handholes with forms, complete with centering

cores and molds, to conform to shape, form, line, and grade required and maintain

sufficiently rigid to prevent deformation under load. Make all joints leakproof and

arrange horizontally or vertically. Place forms on successive units for continuous

surfaces and fit to accurate alignment, assuring a smooth completed surface, free from

irregularities.

E. At convenient point close to wall, drive a ground rod into earth. Extend ground rod

approximately 6-in. (152.4 mm) above finished manhole and handhole floor. After

completion of manhole or handhole, connect 6 foot length of No. 4 bare copper ground

wire to ground rod. Connect grounding bushings, cable racks, covers, other metallic

parts, splices, and ground wire installed with each feeder to ground loop.

F. Size space, and place reinforcing bars as indicated and as specified.

G. Set manhole and handhole frames to the required grade, in full bed of concrete mortar to

make watertight connection.

H. Install tops of manhole and handhole covers in unpaved areas approximately 1/2-in. (12.7

mm) above finished grade, and in paved areas install flush with finished surface of

paving.

I. Install 316 stainless steel corrosion-resistant channel support, with continuous slot and

required fittings designed for concrete encasement.

J. Install inserts in the manholes as indicated.

K. Install two cable pulling irons in wall opposite each ductbank entrance into manhole, one

6-in. (152.4 mm) above floor and one 6-in. (152.4 mm) below the roof of manhole.

Where indicated on drawings, install additional features such as openings in manhole

walls for future conduit entrances. Seal future entrances with required courses of brick.

L. Where ductlines enter manholes, terminate conduits in end bells. Terminate steel conduit

entering manholes and handholes in grounding bushing.

Libya Infrastructure Master Spec 16402-6 20-Nov-08

M. Manhole and handhole frames and covers shall be capable of withstanding a 20-tone

wheel load transferred through dual rubber tires.

N. Manhole and handhole covers shall be marked “Electrical”.

3.04 MANHOLE AND HANDHOLE WATERPROOFING:

A. Apply two coats of bituminous waterproofing material to exterior surfaces of manholes

and handholes. Apply by brush or spray, in accordance with manufacturer's printed

instructions. Allow time between coats to permit sufficient drying.

1. Two coats applied with a minimum dry film thickness of 12 to 14 mils per coat.

3.05 RECORD DRAWINGS OF UNDERGROUND WORK:

A. Furnish two sets of marked copies of contract drawings, showing exact routing and

depths of all underground conduit, duct handholes and manholes. Furnish scaled plot

plans, showing principal outline of buildings and structures. Reference conduits, ducts,

and manholes, and all bends deviating from straight line, dimensionally from fixed

objects or structures.

END OF SECTION

Libya Infrastructure Master Spec 16402-7 20-Nov-08

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Proctor TP - 1 3881Document1 paginăProctor TP - 1 3881wafikmh4Încă nu există evaluări

- BH#1#3888 LL&PLBH#13888, BH#13888, BH#13888 LM ChartReportDocument1 paginăBH#1#3888 LL&PLBH#13888, BH#13888, BH#13888 LM ChartReportwafikmh4Încă nu există evaluări

- Shear Box Test ASTM D3080: R e Sults Summa RyDocument2 paginiShear Box Test ASTM D3080: R e Sults Summa Rywafikmh4Încă nu există evaluări

- Particle Size Distribution AnalysisDocument3 paginiParticle Size Distribution Analysiswafikmh4Încă nu există evaluări

- Sieve BH#1 & BH#2 3881Document7 paginiSieve BH#1 & BH#2 3881wafikmh4Încă nu există evaluări

- TOC Vol.1 Part 6Document1 paginăTOC Vol.1 Part 6wafikmh4Încă nu există evaluări

- Location NameDocument1 paginăLocation Namewafikmh4Încă nu există evaluări

- LL&PL BH#1 & BH#2 3881Document2 paginiLL&PL BH#1 & BH#2 3881wafikmh4Încă nu există evaluări

- C 014 PDFDocument1 paginăC 014 PDFwafikmh4Încă nu există evaluări

- Annex A PDFDocument4 paginiAnnex A PDFwafikmh4Încă nu există evaluări

- NTS: The Following Two Paragraphs Should Be Deleted For Smaller ProjectsDocument18 paginiNTS: The Following Two Paragraphs Should Be Deleted For Smaller Projectswafikmh4Încă nu există evaluări

- LightingDocument13 paginiLightingwafikmh4Încă nu există evaluări

- C 000a PDFDocument1 paginăC 000a PDFwafikmh4Încă nu există evaluări

- Verification of Strength (Sample)Document9 paginiVerification of Strength (Sample)Giri WakshanÎncă nu există evaluări

- Design Calculations in GeotechnicsDocument139 paginiDesign Calculations in Geotechnicsgmazzucco100% (8)

- Design Calculations in GeotechnicsDocument139 paginiDesign Calculations in Geotechnicsgmazzucco100% (8)

- Guidelines For Master SpecificationsDocument2 paginiGuidelines For Master Specificationswafikmh4Încă nu există evaluări

- Earth Pressures Against and Stability of Retaining - StructuresDocument200 paginiEarth Pressures Against and Stability of Retaining - StructuresIon PusculitaÎncă nu există evaluări

- Design Criteria For Infrastructure ProjectsDocument7 paginiDesign Criteria For Infrastructure Projectswafikmh4Încă nu există evaluări

- NTS: The Following Two Paragraphs Should Be Deleted For Smaller ProjectsDocument18 paginiNTS: The Following Two Paragraphs Should Be Deleted For Smaller Projectswafikmh4Încă nu există evaluări

- 06 EC2WS Frank Geotechnics PDFDocument55 pagini06 EC2WS Frank Geotechnics PDFLuigiForgerone100% (1)

- Guidelines For Master SpecificationsDocument2 paginiGuidelines For Master Specificationswafikmh4Încă nu există evaluări

- Quality ManualDocument114 paginiQuality ManualPanneer SelvamÎncă nu există evaluări

- Electrical Design CriteriaDocument27 paginiElectrical Design Criteriawafikmh4Încă nu există evaluări

- Design Criteria For Infrastructure ProjectsDocument7 paginiDesign Criteria For Infrastructure Projectswafikmh4Încă nu există evaluări

- Design Criteria For Infrastructure Projects - Rev 03 - Nov 2010Document456 paginiDesign Criteria For Infrastructure Projects - Rev 03 - Nov 2010wafikmh4100% (2)

- PavementDocument38 paginiPavementwafikmh4Încă nu există evaluări

- SP 007Document51 paginiSP 007Obak PrithibiÎncă nu există evaluări

- TOC Vol.1 Part 4Document1 paginăTOC Vol.1 Part 4wafikmh4Încă nu există evaluări

- Health and Safety PlanDocument11 paginiHealth and Safety Planwafikmh4Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Details of Measurement: Total Qnty Nos. Length Breadth Height SN Description of Item Unit MEASUREMENT (In MTRS)Document6 paginiDetails of Measurement: Total Qnty Nos. Length Breadth Height SN Description of Item Unit MEASUREMENT (In MTRS)Biswajit SahooÎncă nu există evaluări

- Technology Guide No. 19: SSPC: The Society For Protective CoatingsDocument3 paginiTechnology Guide No. 19: SSPC: The Society For Protective CoatingsMia AndinoÎncă nu există evaluări

- Thermanit X Stick Electrode for Stainless Steel WeldingDocument2 paginiThermanit X Stick Electrode for Stainless Steel WeldingMadhusudan YeoleÎncă nu există evaluări

- Psae Sample Question Engineering ShopDocument7 paginiPsae Sample Question Engineering ShopAlfredo CondeÎncă nu există evaluări

- Renovate Galvanized SteelDocument1 paginăRenovate Galvanized SteelSam SamuelsonÎncă nu există evaluări

- Solutions: Solutions Manual For Welding Principles and Practices 5Th Edition BohnartDocument7 paginiSolutions: Solutions Manual For Welding Principles and Practices 5Th Edition BohnartBassel AlshamiÎncă nu există evaluări

- Indestructible Corner Clamp (Jig) For Welding ProjectsDocument1 paginăIndestructible Corner Clamp (Jig) For Welding ProjectsTomas Tom MlÎncă nu există evaluări

- Density of Metals and AlloysDocument3 paginiDensity of Metals and Alloysbalacvpl84Încă nu există evaluări

- A705A705MDocument7 paginiA705A705MAnderson TadeuÎncă nu există evaluări

- Department of Education: Science 5Document5 paginiDepartment of Education: Science 5ronaldÎncă nu există evaluări

- Choosing The Best Pocket Knife: Knife Steel Composition ChartDocument12 paginiChoosing The Best Pocket Knife: Knife Steel Composition ChartNguyễn Thống NhấtÎncă nu există evaluări

- Kimia Bahan 3 - BajaDocument47 paginiKimia Bahan 3 - BajaIkeÎncă nu există evaluări

- GX40 CR Ni Si 2512Document2 paginiGX40 CR Ni Si 2512Diego BoiagoÎncă nu există evaluări

- Prepare SMAW Materials and ToolsDocument14 paginiPrepare SMAW Materials and ToolsDaryl TesoroÎncă nu există evaluări

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Document3 paginiPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambÎncă nu există evaluări

- Unit 8 PDFDocument43 paginiUnit 8 PDFAnurag RanaÎncă nu există evaluări

- Alloy Selector Guide AmericasttechDocument63 paginiAlloy Selector Guide AmericasttechIsabel Christina Gonzalez MoralesÎncă nu există evaluări

- Autokast Limited-AnanthDocument27 paginiAutokast Limited-AnanthananthÎncă nu există evaluări

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 paginăBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaÎncă nu există evaluări

- (AIR PRODUCTS) Inomaxx TIG - T1 ArH2 PDFDocument2 pagini(AIR PRODUCTS) Inomaxx TIG - T1 ArH2 PDFaauriscÎncă nu există evaluări

- Is 1570-2.1schedules For Wrought SteelsDocument20 paginiIs 1570-2.1schedules For Wrought Steelssan1985deepÎncă nu există evaluări

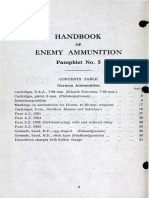

- Handbook of Enemy Ammunition, Pamphlet 5Document53 paginiHandbook of Enemy Ammunition, Pamphlet 5Marlin ZamoraÎncă nu există evaluări

- Item Wise QtyDocument257 paginiItem Wise QtyArif AhmedÎncă nu există evaluări

- Chemical Resistance Guide: Chemical Resin Type Specific Gravity Rating Fitting Material Gasket Material Bolt MaterialDocument1 paginăChemical Resistance Guide: Chemical Resin Type Specific Gravity Rating Fitting Material Gasket Material Bolt MaterialGokul VenugopalÎncă nu există evaluări

- ISO 2819-2018 Choque TérmicoDocument27 paginiISO 2819-2018 Choque TérmicoRosario Castaño100% (1)

- Swing Check Valve - Flanged Ends: Schematic DrawingDocument1 paginăSwing Check Valve - Flanged Ends: Schematic Drawingbhima irabattiÎncă nu există evaluări

- F1267-12 Standard Specification For Metal, Expanded, SteelDocument8 paginiF1267-12 Standard Specification For Metal, Expanded, Steeltjt4779100% (2)

- GRINNELL Figure 780 Grooved Snap Couplings 1-1/4 Thru 8 Inch (DN32 Thru DN200) General DescriptionDocument2 paginiGRINNELL Figure 780 Grooved Snap Couplings 1-1/4 Thru 8 Inch (DN32 Thru DN200) General DescriptionСергей КолесниковÎncă nu există evaluări

- ASTM A502 Steel Structural RivetsDocument6 paginiASTM A502 Steel Structural RivetsKaliita Chavez GarciaÎncă nu există evaluări

- Goodway Fan Box Catalogue - 2022Document1 paginăGoodway Fan Box Catalogue - 2022Miles LingÎncă nu există evaluări