Documente Academic

Documente Profesional

Documente Cultură

Design and Analysis of Centrifugal Pump Impeller Using Ansys Fluent

Încărcat de

Ampera marzelaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design and Analysis of Centrifugal Pump Impeller Using Ansys Fluent

Încărcat de

Ampera marzelaDrepturi de autor:

Formate disponibile

International Journal of Science, Engineering and Technology Research (IJSETR), Volume 4, Issue 10, October 2015

DESIGN AND ANALYSIS OF

CENTRIFUGAL PUMP IMPELLER USING

ANSYS FLUENT

Ajith M Sˡ, Dr Jeoju M Issac²

impeller. CFD helps the designer to identify the optimal

Abstract— In this study, Computational Fluid Dynamics parameters of the impeller by numerical flow

(CFD) approach was suggested to investigate the flow in simulation.[3-5] Applying classical mechanics theory,

the centrifugal pump impeller using the Ansys Fluent. assuming viscosity of the liquid equal to zero and no energy

Impeller is designed for the head (H) 70 m; discharge (Q) loss for the work of energy transferring from impeller to the

80 L/sec; and speed (N) 1400 rpm. Impeller vane profile streamlines which means that, all separate flow will be

was generated by circular arc method and point by point uniforms (this approximations of physical reality to get the

method and CFD analysis was performed for the impeller simpler as solid state mechanism than hydraulic

vane profile. Further the impeller was analyzed for both mechanism)[6-7]

forward and backward curved vane. The simulation on Radial flow centrifugal pumps are widely used where head

vane profile was solved by Nevier-Stokes equations with and discharge required are moderate. In radial type vanes,

modified k - ω turbulence model. The impeller-Velocity the vane profile is a curve that connects the inlet and outlet

and pressure distribution were analyzed for these diameter of the impeller. Infinite number of curves can be

Impellers. drawn between two points, the length of the vane and hence

the passage length can be different for same diameter D1 and

Index Terms— CFD, Semi Circular pipe, Solar flat plate D2 and same blade angle β1 and β2. Hence, it is necessary to

collector, Operating conditions define the shape of the vanes.[8] If the length of the passage

is short, the divergence angle may increase gradually which

I INTRODUCTION will result in separation of flow and formation of eddies. In a

longer passage frictional loss will be more. Only an

Centrifugal pumps are a sub-class of dynamic axisymmetric appropriate passage length will give minimum losses. For

work-absorbing turbomachinery. Centrifugal pumps are used designing an efficient blade profile an appropriate blade

to transport fluids by the conversion of rotational kinetic design method should be selected [9-10]

energy to the hydrodynamic energy of the fluid flow. The

rotational energy typically comes from an engine or electric General methods available to design radial flow impeller

motor. The fluid enters the pump impeller along or near to vanes are simple arc method, double arc method, concentric

the rotating axis and is accelerated by the impeller, flowing circular arc method and point by point method. Here

radially outward into a diffuser or volute chamber (casing), concentric circular arc method and point by point method

from where it exits. Centrifugal pumps are widely used in methods are discussed in detail along with the calculations of

many applications, so the pump system may be required to blade design Further modeling of pump impeller with these

operate over a wide flow range in different applications. The methods and CFD analysis can be carried out to obtain the

most previous numerical studies were focused on the design performance curve for comparing the efficiency and head

or near-design state of pumps. [1] obtained with different blade design method at various

discharge conditions [11].

Common uses include air, water, sewage, petroleum and

petrochemical pumping. The reverse function of the

centrifugal pump is a water turbine converting potential

energy of water pressure into mechanical rotational energy. It

is essential for a pump manufactured at low cost and

consuming less power with high efficiency.[2] The overall

performance is based on the impeller parameters and it is

essential to identify the optimized design parameter of the

Ajith M S, PG Scholar, Department of Mechanical Engg, Mar Athanasius

College of Engineering, Kothamangalam 9497277803 Figure 1 methodology

Dr Jeoju M Issac, Professor, Department of Mechanical Engg, Mar

Athanasius College of Engineering, Kothamangalam

ISSN: 2278 – 7798 All Rights Reserved © 2015 IJSETR 3640

International Journal of Science, Engineering and Technology Research (IJSETR), Volume 4, Issue 10, October 2015

II METHODOLOGY 2.2.2 blade ange design

By using inlet and outlet velocity triangles the inlet and outlet

2.1.1 specification of the pump blade angles are calculated .Inlet velocity triangle is drawn

flow is assumed to be radial at inlet and meridian component

A radial pump specification from the standard data is of velocity is calculated in such way that it is slightly higher

selected for design and analysis. Pump specification are than velocity at impeller eye

Head =70m

Discharge=80litres/s.

Rpm=1400

The impeller was designed for the operational condition of

head (H) = 70m; flow rate (Q) = 80litre/sec; and speed (N) =

1400rpm

2.1.2predesign specific speed

Pre design specific speed is calculated using the empirical

relation shown and nq=16.8 and it falls in the radial pump

range.

Figure 2.3 Velocity triangles at inlet and outlet

2.3.vane profile development

Figure 2.1 specific speed

Vane profile is developed using two methods

2.2design calculations 1. Circular arc method

2. Point by point method

2.2.1 meridion design

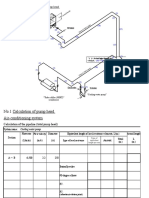

By using Cordier diagram and value of specific speed (б) the 2.3.1 circular arc method

optimum values of outer diameter (D2) shroud diameter (Ds)

and width of trailing edge are calculated. These values The impeller is arbitrarily divided into a number of

strongly decides the capitation behavior of the pump concentric rings between r1 and r2. The radius of arc ρ,

between any two rings rb and ra is obtained from the

Equation. The computations of the values of ρ for various

rings and the radii of arc of the vane are shown in Figure 5

Figure 2.2 cordier diagram

The remaining dimensions are selected accordingly from the

hand book to reduce the chance of cavitations. Inlet diameter

is slightly larger than shroud diameter and leading edge is

slightly larger than the trailing edge .

Inlet diameter (D1)=0.172m

Leading edge width (b1) =0.05m Figure 2.4 Circular arc method

ISSN: 2278 – 7798 All Rights Reserved © 2015 IJSETR 3641

International Journal of Science, Engineering and Technology Research (IJSETR), Volume 4, Issue 10, October 2015

2.3.2 point by point method Navier-Stokes equations using the k-omega turbulence

model with the Finite Volume Method (FVM)

The co-ordinates for developing the vane profile together

with the inlet and outlet angle depends on the radius (r).

Tabular integration method is used for obtaining the 2.5.1 governing equations

co-ordinates. The radiuses with respect to angle are obtained

from the Equation . The values of the vane profile The principles of conservation law governed by fluid

coordinates and the vane profile are shown in figure6 dynamics are

Mass continuity:

Navier stoke’s:

Energy :

2.5.2 k-ω turbulence model

A two transport equation model solving for k and ω the

specific dissipation rate (ε /k) based on Wilcox. This is the

default k-ω model. Demonstrates superior performance for

Figure 6 Point by point method wall bounded and low-Re flows. Shows potential for

predicting transition.SST K-ω A variant of the standard-ω

2.4modeling and meshing model, Combines the original Wilcox model (1988) for use

near walls and standard k-ε model away from walls using a

Geometry of point by point impeller and Circular arc blending function. Also limits turbulent viscosity to

impeller are created using Catia V5 software. The grids are guarantee that τ t , K.

generated using ICEM CFD. The basic principle in meshing

is that it should have finer elements to get better accuracy of 2.5.3 boundary conditions

the result. At the same time, number of grids should not

exceed available computational capacity. To achieve this The operating pressure was taken as 0 Pa, since all the

objective, fine mesh was used where the solution gradient is experimental measurements are taken at absolute pressure.

higher and coarse mesh was used where there is low solution Inlet velocity is defined as boundary condition at inlet and at

gradient. outlet mass flow rate is defined as boundary condition, and

Relative velocity of the impeller is set as global rotating

reference frame.

2.6 results and discussions.

Four impellers CAFC, CABC, PPFC and PPBC were

analyzed using Ansys fluent 14.5. The analyses were made

for the circular arc method and point by point method with

forward and backward curved vanes. The results of the flow

field investigation are presented in terms of velocity and

pressure distribution of the impeller passages. Figure7 shows

the velocity distributions and pressure distributions on the

Figure 2.5 Geometry and meshed models

vane-to-vane for impeller CAFC, CABC, PPFC and PPBC,

2.5 flow simulation using cfd respectively. Noting the fact that flow distributions in the

backward curved vane have high efficiency compared with

CFD approach was carried out to analyze the behavior of forward curved vane. Hence it is evident from Figure the

flow field in the impeller using the Ansys fluent 14.5 backward curved vanes have better flow distribution than the

software. Fluent software is a powerful CFD tool that enables forward curved vane. The pressure increases normally on the

designers to quickly and easily simulate fluid flow for the pressure Surface than on the suction surface on each plane.

success of designs. Design cycles are expensive and Impeller CABC has gradual pressure distribution in the

time-consuming. CFD analysis is able to help the designers stream wise direction than other impellers as shown in

to optimize the designs by simulating several concepts and Figure. The maximum efficiency of the impeller was

scenarios to make absolute assessment. Fluent solves obtained for the backward curved vane profile. However, the

time-dependent three-dimensional Reynolds-averaged maximum efficiency is 58.53% for the backward curved

circular arc method

ISSN: 2278 – 7798 All Rights Reserved © 2015 IJSETR 3642

International Journal of Science, Engineering and Technology Research (IJSETR), Volume 4, Issue 10, October 2015

arc and point by point leads to similar head rise. Therefore

whichever is easier to manufacture that can be followed by

designer.

ACKNOWLEDGMENT

I have great pleasure in submitting this paper. It give me

immense pleasure to record my debt of gratitude and my

warmest regards to all the faculties of Mechanical

Department. The various values that tried to learn from them

shall remain a source of inspiration for me forever.

I am thankful to my family and friends for their whole

hearted blessings are always for me support and constant

encouragement towards the fulfillment of the work

REFERENCES

[1] S R Shaha et al. CFD for centrifugal pumps stae of the art, Chemical, Civil

and Mechanical engineeringTracks of 3 rd Nirma University International

conference journal

[2] Peter Hlbocana et al. Prime Geometry Solution of a Centrifugal Impeller

Within a 3D Setting, XIIIth International Scientific and Engineering

Conference ―HERVICON-2011‖

[3] Raghavendra S Muttalli et al. CFD Simulation of Centrifugal Pump

Impeller Using ANSYS-CFX, International Journal of Innovative Research in

Science, Engineering and technology Vol. 3, Issue 8, August 2014

[4] Tilahun Nigussie et al. Design and CFD Analysis of Centrifugal Pump,

International Journal of Engineering Research and General Science Volume 3,

Issue 3, May-June, 2015 ISSN 2091-2730

[5] . Maitelli et al. Simulation of flow in a centrifugal pump of esp systems

using computational fluid dynamics, BRAZILIAN JOURNAL OF

PETROLEUM AND GAS , v. 4 n. 1 ,p. 001-009 ,2010 ,ISSN 1982-0593

[6] Mehul et al. CFD analysis of mixed flow pump impeller, International

Journal of Advanced Engineering Research and Studies,E-ISSN2249–8974

[7] Alpeshkumar et al. CFD Analysis and Experimental Study on Impeller of

Centrifugal Pump, IJSRD - International Journal for Scientific Research &

Development| Vol. 3, Issue 02, 2015 | ISSN (online): 2321-0613

[8] S.Rajendran et al. Analysis of a centrifugal pump impeller using

ANSYS-CFX, International Journal of Engineering Research & Technology

(IJERT)Vol. 1 Issue 3, May - 2012ISSN: 2278-018

[9] P.Gurupranesh et al. CFD Analysis of centrifugal pump impeller for

performance enhancement, IOSR Journal of Mechanical and Civil

Engineering (IOSR-JMCE) e-ISSN: 2278-1684, p-ISSN: 2320-334X PP

33-41

[11] Ashish Bowade et al A Review of Different Blade Design Methods for

Radial Flow Centrifugal Pump,International Journal of Scientific Engineering

Figure 2.6Pressure and velocity distributions in PPFC PPBC and Research (IJSER) www.ijser.in ISSN (Online): 2347-3878

CAFC AND CABC.

III CONCLUSIONS

Numerical investigations were carried out to analyze the flow

field in the pump impeller using Ansys fluent 14.5. To design

a centrifugal pump impeller a procedure is proposed. The

design procedure leads to good results in a lesser time. The Ajith M S, PG Scholar, Department of Mechanical Engg, Mar Athanasius

effect of the forward curved vane and backward curved vane College of Engineering, Kothamangalam 9497277803.

were analyzed. From the numerical results the backward Dr Jeoju M Issac, Professor, Department of Mechanical Engg, Mar

Athanasius College of Engineering, Kothamangalam

curved vanes have better performance than the forward

curved vane. The vane profile was developed by two methods

viz. circular arc method and point by point method. The flow

simulation gives a result that both of the methods i.e. circular

ISSN: 2278 – 7798 All Rights Reserved © 2015 IJSETR 3643

S-ar putea să vă placă și

- Poultry Business Plan For Layers and BroilersDocument8 paginiPoultry Business Plan For Layers and BroilersOgieva ElvisÎncă nu există evaluări

- Contents Table Broiler Chicken Production Business Plan PDFDocument3 paginiContents Table Broiler Chicken Production Business Plan PDFEin-Ein AsariÎncă nu există evaluări

- ROT2ROTI-Business-Plan Biogas PDFDocument25 paginiROT2ROTI-Business-Plan Biogas PDFSakhawat Husain75% (4)

- Free Packaged Sachet Pure Water Startup Plan PDFDocument24 paginiFree Packaged Sachet Pure Water Startup Plan PDFAlabi OlanrewajuÎncă nu există evaluări

- Brick Making Poverty Alleviation Project Business Plan 2005 Maluti A Phofung Local MunicipalityDocument27 paginiBrick Making Poverty Alleviation Project Business Plan 2005 Maluti A Phofung Local MunicipalitySandeep PaulÎncă nu există evaluări

- Catfish FarmingDocument11 paginiCatfish FarmingPeyer timonÎncă nu există evaluări

- Sample Business Plan: Poultry House Project CCDocument6 paginiSample Business Plan: Poultry House Project CCnelsonÎncă nu există evaluări

- FISH Feed Enterprise Business PlanDocument6 paginiFISH Feed Enterprise Business PlanELIJAH100% (2)

- Feasibility Study Egg Farm HermelDocument13 paginiFeasibility Study Egg Farm HermelSamuel FanijoÎncă nu există evaluări

- Fish Farming Business ProposalDocument13 paginiFish Farming Business Proposalmekuanit100% (1)

- Reynolds Average Navier-Stokes EquationDocument4 paginiReynolds Average Navier-Stokes EquationhilmanmuntahaÎncă nu există evaluări

- Scovia PDFDocument25 paginiScovia PDFlaniÎncă nu există evaluări

- Business Proposal: Godwith UdohDocument5 paginiBusiness Proposal: Godwith UdohGodwith UdohÎncă nu există evaluări

- Feasibility Study 1 2Document9 paginiFeasibility Study 1 2Nicole TabatÎncă nu există evaluări

- Fish Carp-Tilapia PolycultureDocument49 paginiFish Carp-Tilapia PolycultureSaurav LamichhaneÎncă nu există evaluări

- Fish BusinessDocument30 paginiFish BusinessToha Hossain Utsha100% (1)

- Deliverability Appraisal: Same Person As The Project Sponsor)Document7 paginiDeliverability Appraisal: Same Person As The Project Sponsor)Keeme100% (1)

- Poultry Busniess PlanDocument32 paginiPoultry Busniess Plandaniyal ahmadÎncă nu există evaluări

- Final Drafting PoultryDocument17 paginiFinal Drafting PoultryMoh'd Aminu UsmanÎncă nu există evaluări

- 智能新一代孵化控制器 New Generation Intelligent Incubator ControllerDocument10 pagini智能新一代孵化控制器 New Generation Intelligent Incubator Controllerkhoa minhÎncă nu există evaluări

- Poltry FormingDocument7 paginiPoltry FormingAzhar Abbas KulaChIÎncă nu există evaluări

- Beraid Broiler Project Profile FinalDocument6 paginiBeraid Broiler Project Profile FinalMd Enamul Haque100% (1)

- PROJECT PROFILE On-Poultry-FarmDocument33 paginiPROJECT PROFILE On-Poultry-FarmOUSMAN SEIDÎncă nu există evaluări

- Project Report On Goat FarmingDocument10 paginiProject Report On Goat FarmingArka SadhukhanÎncă nu există evaluări

- Poultry Farm Business PlanDocument24 paginiPoultry Farm Business PlanAnwar jemal100% (1)

- Broiler Prodution Business PlanDocument8 paginiBroiler Prodution Business PlantichaonaÎncă nu există evaluări

- MPP Goat FarmingDocument7 paginiMPP Goat FarminggavinilaaÎncă nu există evaluări

- Business Plan For Nkondola Fish Supply CompanyDocument10 paginiBusiness Plan For Nkondola Fish Supply CompanyEmanuel Acray Nkondola100% (1)

- Paper 3 - Aplication of Green Tech - UMK PDFDocument40 paginiPaper 3 - Aplication of Green Tech - UMK PDFHafiz JamaludinÎncă nu există evaluări

- Project Profile For Lyantonde Animal Feed Mill - Table of ContentsDocument4 paginiProject Profile For Lyantonde Animal Feed Mill - Table of ContentsInfiniteKnowledge100% (1)

- (PDF) A Business Plan On Fish Farming in Kashere Community Gombe State - S225908Document14 pagini(PDF) A Business Plan On Fish Farming in Kashere Community Gombe State - S225908photosynergy technologyÎncă nu există evaluări

- Elliot Goat BPDocument18 paginiElliot Goat BPElliot BalesamangÎncă nu există evaluări

- Cafe Proposal 2-2Document6 paginiCafe Proposal 2-2Alok ShenoyÎncă nu există evaluări

- Business Plan of Poultry FarmDocument7 paginiBusiness Plan of Poultry FarmTewfic SeidÎncă nu există evaluări

- 3 Dif and 5 Dif CBCDocument13 pagini3 Dif and 5 Dif CBCAbcdÎncă nu există evaluări

- Lekan Poultry Farm Business - PlanDocument29 paginiLekan Poultry Farm Business - PlanMAVERICK MONROEÎncă nu există evaluări

- ON Dry Fish Business: Submitted byDocument6 paginiON Dry Fish Business: Submitted byKartik DebnathÎncă nu există evaluări

- Rape Rampart Business: Description Cost Per Unit (US) Total Cost (US)Document3 paginiRape Rampart Business: Description Cost Per Unit (US) Total Cost (US)hondo tinemi d100% (1)

- Business Plan For Dairy Farm 30 Animals Final11Document17 paginiBusiness Plan For Dairy Farm 30 Animals Final11dauda kizitoÎncă nu există evaluări

- Poultry Farming Business Plan ExampleDocument36 paginiPoultry Farming Business Plan ExampleBER LUKEÎncă nu există evaluări

- Poultry - PACRA Research - Jan'21 - 1611148534Document29 paginiPoultry - PACRA Research - Jan'21 - 1611148534Bakhtawar100% (1)

- A Feasibility Study Business Plan On PouDocument8 paginiA Feasibility Study Business Plan On PouKoghorong ShepherdÎncă nu există evaluări

- Establishment of A Commercial Catfish and Tilapia Farm in Nigeria PDFDocument34 paginiEstablishment of A Commercial Catfish and Tilapia Farm in Nigeria PDFSegun AdebayoÎncă nu există evaluări

- Sheep BusinessDocument10 paginiSheep BusinessFTÎncă nu există evaluări

- 8.business Plan of Srinagar Agro FarmDocument9 pagini8.business Plan of Srinagar Agro FarmSantosh BhandariÎncă nu există evaluări

- ST Hannah's High-School-Fees-Structure-2020 PDFDocument1 paginăST Hannah's High-School-Fees-Structure-2020 PDFRUTIYOMBA Eustache100% (1)

- Executive SummaryDocument5 paginiExecutive Summarymustafe omerÎncă nu există evaluări

- Business Plan For Poultry Farming in Rural PhilippinesDocument2 paginiBusiness Plan For Poultry Farming in Rural Philippineskyle data100% (1)

- Business Assisting Agencies 2Document6 paginiBusiness Assisting Agencies 2Kevo KENTROCKERZÎncă nu există evaluări

- FINE FABRICATORS Broiler Feasibility For 30,000Document9 paginiFINE FABRICATORS Broiler Feasibility For 30,000Saad Malik100% (1)

- Farm DocumentDocument14 paginiFarm DocumentKatu2010Încă nu există evaluări

- Dairy Farm Project-Self WorkDocument12 paginiDairy Farm Project-Self WorkPankaj Narendrasinh RajÎncă nu există evaluări

- Business Plan Tomato Production Ndola Zimbabwe (1) - OptimizeDocument3 paginiBusiness Plan Tomato Production Ndola Zimbabwe (1) - Optimizekelil Gena komichaÎncă nu există evaluări

- Zee Proposal PiggeryDocument11 paginiZee Proposal PiggeryMosunmola YetundeÎncă nu există evaluări

- Guide For Keeping Egg Laying Birds (Layers) in Uganda: Before Your Layer Chicks Arrive at HomeDocument4 paginiGuide For Keeping Egg Laying Birds (Layers) in Uganda: Before Your Layer Chicks Arrive at HomeSabila Alex100% (1)

- Poultry Farm Business PlanDocument20 paginiPoultry Farm Business PlanGizachew NadewÎncă nu există evaluări

- Poultry Farming Gains Popularity in SomaliaDocument3 paginiPoultry Farming Gains Popularity in SomaliaAMISOM Public Information Services100% (1)

- Fish Farm Planning PDFDocument33 paginiFish Farm Planning PDFVinit Kant MajumdarÎncă nu există evaluări

- Pig Production in AustraliaDe la EverandPig Production in AustraliaJaa GardnerEvaluare: 2 din 5 stele2/5 (1)

- Quail Farming Mastery: Expert Insights and Solutions to Common ChallengesDe la EverandQuail Farming Mastery: Expert Insights and Solutions to Common ChallengesÎncă nu există evaluări

- Nozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsDocument1 paginăNozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsAmpera marzelaÎncă nu există evaluări

- Peeimoger Compact Ac Gearmotor 001 PDFDocument4 paginiPeeimoger Compact Ac Gearmotor 001 PDFAmpera marzelaÎncă nu există evaluări

- User'S Manual For Centrifugal BlowerDocument20 paginiUser'S Manual For Centrifugal BlowerAmpera marzelaÎncă nu există evaluări

- COP TG (K) Ta (K) TC (K) Te (K) : Generator Temp Vs Evaporator TempDocument4 paginiCOP TG (K) Ta (K) TC (K) Te (K) : Generator Temp Vs Evaporator TempAmpera marzelaÎncă nu există evaluări

- 2250 Heavy Lift Wire Rope Specifications 8025 ADocument3 pagini2250 Heavy Lift Wire Rope Specifications 8025 AAmpera marzelaÎncă nu există evaluări

- NACM Welded Chain SpecificationsDocument12 paginiNACM Welded Chain SpecificationsAmpera marzelaÎncă nu există evaluări

- Density&Viscosity CalculatorDocument15 paginiDensity&Viscosity CalculatorDennis Angelo PablicoÎncă nu există evaluări

- Ravenol Rup Sae 5W-40Document3 paginiRavenol Rup Sae 5W-40Ion DumaÎncă nu există evaluări

- Autonomous Maintenance Step 4 Lubrication ModuleDocument30 paginiAutonomous Maintenance Step 4 Lubrication ModulejesusmemÎncă nu există evaluări

- BOMBA DE 2.5 A 4 - Datasheet - 1052 - en PDFDocument5 paginiBOMBA DE 2.5 A 4 - Datasheet - 1052 - en PDFROMEO Y PALETA FLORESTAÎncă nu există evaluări

- Watersheds and River Basins ActivityDocument3 paginiWatersheds and River Basins Activityapi-330049990Încă nu există evaluări

- FLOWSHEET Minyak Ikan PenampungDocument2 paginiFLOWSHEET Minyak Ikan PenampungdausykÎncă nu există evaluări

- 2 Condenser 3: CompressorDocument16 pagini2 Condenser 3: CompressorLeslie CatindigÎncă nu există evaluări

- DEN233 Low Speed Aerodynamics-Week2-3Document123 paginiDEN233 Low Speed Aerodynamics-Week2-3BrandleValleyÎncă nu există evaluări

- Lecture 1Document18 paginiLecture 1bob buiddddddÎncă nu există evaluări

- Velocity PotentialDocument14 paginiVelocity PotentialGeorge DukeÎncă nu există evaluări

- Covenant University Nigeria: Tutorial Kit Omega SemesterDocument21 paginiCovenant University Nigeria: Tutorial Kit Omega SemesterthareendaÎncă nu există evaluări

- Oil-Water Separators Design Applications Aug2020 RevisionDocument4 paginiOil-Water Separators Design Applications Aug2020 RevisionFernando Ivan Fuentes RomoÎncă nu există evaluări

- BREWTUS IV Parts Diagram PDFDocument28 paginiBREWTUS IV Parts Diagram PDFMarian PÎncă nu există evaluări

- Mesin Skala IndustriDocument2 paginiMesin Skala IndustriSandi MahesaÎncă nu există evaluări

- No.1 Calculation of Pump Head.: "Cooling Tower"Document20 paginiNo.1 Calculation of Pump Head.: "Cooling Tower"GandiPermanaÎncă nu există evaluări

- Leader Neo 10W-30 enDocument2 paginiLeader Neo 10W-30 ennitty shiggersÎncă nu există evaluări

- Improving Descale Performance With The Descalejet ProDocument7 paginiImproving Descale Performance With The Descalejet ProAdmiral FighterÎncă nu există evaluări

- Pipe LineDocument417 paginiPipe LinesaxraviÎncă nu există evaluări

- Orifice Plate Calculator Pressure Drop CalculationDocument6 paginiOrifice Plate Calculator Pressure Drop Calculationlutfi awnÎncă nu există evaluări

- Filed Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222Document4 paginiFiled Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222sqmiÎncă nu există evaluări

- CE8403 - 2M IQ QB - by WWW - EasyEngineering.net 1Document24 paginiCE8403 - 2M IQ QB - by WWW - EasyEngineering.net 1NAAC CivilÎncă nu există evaluări

- Curva KFL10X - 400GPM@115PSI - 3500RPMDocument2 paginiCurva KFL10X - 400GPM@115PSI - 3500RPMJulio VizacarraÎncă nu există evaluări

- Laminar FlowDocument6 paginiLaminar FlowRenuja LakviduÎncă nu există evaluări

- Restriction Orifice RO Flow Control InstrumentDocument3 paginiRestriction Orifice RO Flow Control Instrumentmsr22Încă nu există evaluări

- Cross Reference Mann 00025Document1 paginăCross Reference Mann 00025GerenciamentoÎncă nu există evaluări

- Centrifugal Pump Definition Components Working Priming Advantages Disadvantages and Applications PDFDocument7 paginiCentrifugal Pump Definition Components Working Priming Advantages Disadvantages and Applications PDFMuhammad Yasar JavaidÎncă nu există evaluări

- Aerodynamics-II Part B QuestionsDocument7 paginiAerodynamics-II Part B QuestionsAeronaughtycs Hamdan100% (1)

- Rising MainDocument2 paginiRising MainJitesh KumarÎncă nu există evaluări

- Take Test - Fluid Mechanics - Section 04 Quiz Questions - ..Document8 paginiTake Test - Fluid Mechanics - Section 04 Quiz Questions - ..MAJ kÎncă nu există evaluări