Documente Academic

Documente Profesional

Documente Cultură

Cheat Sheet PDF

Încărcat de

abbeyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cheat Sheet PDF

Încărcat de

abbeyDrepturi de autor:

Formate disponibile

Heat and Mass Transfer CHEE330 – Formula Sheet

Fourier’s law For a real (non-ideal) surface

𝑞 "

𝑞𝑒𝑒 = 𝐸 = 𝜀𝜀𝑇𝑠4

���⃗

𝑞" = = −𝑘𝑘𝑘

𝐴 ε= emissivity [-] -> black bodies: 𝜀=1, real surface: 0<𝜀<1

𝑞 Heat transfer rate through area A [W] Irradiation

𝑞

���⃗

𝑞" = Heat flux or heat transfer rate per unit area perpendicular to the " 4

𝐴

2 2

𝑞𝑖𝑖𝑖 = 𝐺 = 𝛼 𝜎 𝑇𝑠𝑠𝑠

transport direction [W/m =J/(s m ] 2

G = rate of incident radiation per unit area (W/m ) of the surface (radiation/heat

2

𝐴 Area perpendicular to heat flux [m ] flux absorbed by the surface) originating from its surroundings

k Thermal conductivity [W/(m K)] Tsur = absolute temperature of the surroundings [K]

∇𝑇 Temperature gradient (driving force) [K/m]

α = absorptivity of the surface [0< α <1], for a “grey” surface α=ε

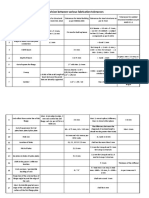

1-Dimensional Fourier’s law for different coordinate systems Net radiation exchange

"

Fourier’s law expressions and solutions for heat fluxes, heat rates and thermal 𝑞𝑟𝑟𝑟 = 𝐸 − 𝐺 = 𝜀𝜀𝑇𝑠4 − 𝛼 𝜎 𝑇𝑠𝑠𝑠

4

= ℎ𝑟 (𝑇𝑠 − 𝑇𝑠𝑠𝑠 )

resistances for steady-state, 1D heat transfer, constant k in various coordinate

Radiative heat transfer coefficient for grey surface ℎ𝑟 = 𝜎𝜀(𝑇𝑠 + 𝑇𝑠𝑠𝑠 )(𝑇𝑠2 − 𝑇𝑠𝑠𝑠

2 )

systems 2

[W/m K]

Plane Wall

Cylindrical Wall Spherical Wall

(Cartesian)

𝑑𝑑 𝑑𝑑 𝑑𝑑 Thermal circuits

Fourier’s law 𝑞"𝑥 = −𝑘 𝑞"𝑟 = −𝑘 𝑞"𝑟 = −𝑘

𝑑𝑑 𝑑𝑑 𝑑𝑑 𝑂𝑂𝑂𝑂𝑂𝑂𝑂 𝑑𝑑𝑑𝑑𝑑𝑑𝑑 𝑓𝑓𝑓𝑓𝑓 ∆𝑇

𝑘∆𝑇 𝑞= =

𝑘∆𝑇 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 𝑅

∆𝑇 R = thermal resistance [K/W]

Heat flux 𝒒" 𝑘 𝑟 1 1

𝐿 𝑟𝑟𝑟 �𝑟2 � 𝑟 2 �𝑟 − 𝑟 � Conductive resistance

1 1 2

2𝜋𝜋𝜋∆𝑇 4𝜋𝜋∆𝑇 Rcond = depends on geometry, see table left

Heat transfer ∆𝑇 Convective resistance

𝑘𝑘 𝑟 1 1

rate 𝒒 𝐿 𝑙𝑙 �𝑟2 � �𝑟 − 𝑟 � 1

1 1 2 𝑅𝑐𝑐𝑐𝑐 =

Thermal 𝑟2 1 1 ℎ𝐴

𝐿 𝑙𝑙 �𝑟 � �𝑟 − 𝑟 � Radiative resistance

resistance 1 1 2

Rcond

# 𝑘𝑘 1

2𝜋𝜋𝜋 4𝜋𝜋 𝑅𝑟𝑟𝑟 =

# 2

Ar=2πrL for cylindrical, Ar=4πr for spherical coordinates, r1=rin, r2=rout ℎ𝑟 𝐴

Thermal contact resistance

𝑇𝐴 − 𝑇𝐵

Radiation 𝑅"𝑡,𝑐 =

Stefan-Boltzmann law for an ideal radiator (black body) 𝑞𝑥 "

" TA,B = temperature contact surface A,B [K]

𝑞𝑒𝑒 = 𝐸 = 𝜎𝑇𝑠4

"

𝑞𝑒𝑒 = radiation/heat flux emitted from the surface

Ts = absolute temperature of the surface [K]

σ = Stefan-Boltzmann constant

Version 05/12/2014 Page 8

Heat and Mass Transfer CHEE330 – Formula Sheet

Resistance in series (q=const): Concentrations in a binary system of A and B

𝑅𝑡𝑡𝑡 = 𝑅1 + 𝑅2 +. . +𝑅𝑛 = � 𝑅𝑖

𝑛

Resistances in parallel (ΔT =const):

1 1 1 1

= + +. . + = � 1/𝑅𝑖

𝑅𝑡𝑡𝑡 𝑅1 𝑅2 𝑅𝑛

𝑛

Ideal gas law

𝑚

𝑝𝑉 =𝑛𝑅𝑇 = 𝑅𝑇

𝑀 3

𝑝 = pressure [Pa] V = volume [m ]

n = molar amount of substance [mol] m = mass of substance [kg]

M = Molar mass of substance [mol/g] T = Temperature in K [K]

R = universal gas constant = 8.3143 J/(mol K)

Buckingham method:

Step 1: List all independent variables involved in the problem

Q0 = F(Q1, Q2, ... , Qn)

Step 2: Express each of the variables in terms of basic dimensions

Step 3: Apply Buckingham 𝛱 theorem / Determine number of 𝛱 groups: Assumptions: ideal Gas

Number of dimensionless groups required to describe the problem is

k=(n+1)-j. Diffusive molar and mass fluxes for binary system A in B

n = number of independent variables identified for the problem

j = number of primary dimensions which have been used to express the variables.

Diffusive Flux Vector notation 1D planar (Cartesian)

Step 4: Selection of a dimensionally independent subset of (repeating)

Molar flux (Fick’s Law) 𝑑𝑐𝐴

j variables Q1...Qj (j ≤ n). ���⃗

𝐽𝐴 = −𝐷𝐴𝐴 𝛻𝑐𝐴 𝐽𝐴,𝑧 = −𝐷𝐴𝐴

𝑐 𝑜𝑜 𝜌 = 𝑐𝑐𝑐𝑐𝑐 𝑑𝑑

Step 5: Build 𝛱 groups by multiply one of the nonrepeating variables by

Mass flux (Fick’s Law) 𝑑𝜌𝐴

the product of the repeating variables, each raised to an exponent that will 𝚥𝐴 = −𝐷𝐴𝐴 𝛻𝜌𝐴

���⃗ 𝑗𝐴,𝑧 = −𝐷𝐴𝐴

𝑐 𝑜𝑜 𝜌 = 𝑐𝑐𝑐𝑐𝑐 𝑑𝑑

make the combination dimensionless. 𝑑𝑦𝐴

Step 6: Assume dimensional homogeneity and solve set of equations to Molar flux (de Groot) ���⃗

𝐽𝐴 = −𝑐𝐷𝐴𝐴 𝛻𝑦𝐴 𝐽𝐴,𝑧 = −𝑐𝐷𝐴𝐴

𝑑𝑑

obtain 𝛱 groups 𝑑𝜔𝐴

Mass flux (de Groot) 𝚥𝐴 = −𝜌𝐷𝐴𝐴 𝛻𝜔𝐴

���⃗ 𝑗𝐴,𝑧 = −𝜌𝐷𝐴𝐴

Step 7: Express result in form 𝛱1 = 𝐹(𝛱2 , 𝛱3 . . 𝛱𝑘 ) 𝑑𝑑

2 2

molar flux [mol/(m s)] mass flux [ kg/(m s)]

Version 05/12/2014 Page 9

Heat and Mass Transfer CHEE330 – Formula Sheet

Absolute molar and mass fluxes for binary system A in B Continious flow system

1

Absolute Flux Vector notation 1D planar (Cartesian) �𝑄̇𝑛𝑛𝑛 + 𝑊̇𝑛𝑛𝑛 � = 𝑚̇ �(ℎ2 − ℎ1 ) + (𝑣22 − 𝑣12 ) + 𝑔(𝑧2 − 𝑧1 )�

2

𝑑𝑦𝐴

����⃗

𝑁𝐴 = −𝐷𝐴𝐴 𝑐𝑐𝑦𝐴 𝑁𝐴,𝑧 = −𝐷𝐴𝐴 𝑐 𝑄̇𝑛𝑛𝑛 = net heat rate added to CV [W] 𝑊̇𝑛𝑛𝑛 = net rate of work done in CV [W]

Molar flux 𝑑𝑑 𝑚̇ = mass flow rate [kg/s] 𝑧𝑖 = height [m]

����⃗

+𝑦𝐴 (𝑁 �����⃗

𝐴 + 𝑁𝐵 ) +𝑦𝐴 (𝑁𝐴,𝑧 + 𝑁𝐵,𝑧 )

𝑣𝑖 = velocity [m/s] ℎ𝑖 = 𝑐𝑝 𝑇𝑖 = specific enthalpy [J/(kg K)]

𝑑𝜔𝐴

����⃗

𝑛 𝐴 = −𝜌𝜌𝐴𝐴 𝛻𝜔𝐴 𝑛𝐴,𝑧 = −𝜌𝜌𝐴𝐴 1 = inlet, 2=outlet

Mass flux 𝑑𝑑

+𝜔𝐴 (𝑛

����⃗

𝐴 + ����⃗)

𝑛𝐵

+𝜔𝐴 (𝑛𝐴,𝑧 + 𝑛𝐵,𝑧 )

Molar flux for Differential Equations of Heat Transfer

equimolar counter DAB 𝑐�yA,1 − yA,2 � �⃗)

for k = 𝒇(𝒙

����⃗

𝑁𝐴 = − DAB 𝑐𝑐𝑦𝐴 𝑁𝐴,𝑧 =

diffusion 𝑧2 − 𝑧1

����⃗

(𝑁𝐴 = −𝑁 �����⃗

𝐵) 𝜕𝜕

Molar flux for 𝐷𝐴𝐴 𝑐 𝜌𝑐𝑝 = 𝛻 ∙ (𝑘𝑘𝑘 ) + 𝑞̇ 𝑔

𝐷𝐴𝐴 𝑐

𝑁𝐴,𝑧 = ∙ 𝜕𝜕

unimolecular (𝑧2 − 𝑧1 )

����⃗

𝑁𝐴 = − 𝛻𝑦 1 − 𝑦𝐴,2

for k = constant

diffusion stagnant 1 − 𝑦𝐴 𝐴

ln � �

film (𝑁 �����⃗

𝐵 = 0) 1 − 𝑦𝐴,1

𝜕𝜕 𝑞̇ 𝑔

= 𝛼∆𝑇 +

Control volume balance on rate basis 𝜕𝜕 𝜌𝑐𝑝

3 3

In a defined control volume, there is 𝑞̇ 𝑔 = volumetric generation term [W/m ] 𝜌 = density [kg/m ]

k 2

ACCUMULATION = INPUT - OUTPUT + GENERATION α=

ρ cp

= thermal diffusivity [m /s] 𝑐𝑝 = specific heat capacity [kJ/(kg K)]

Energy:

𝑑𝐸𝑠 Boundary condition of first kind - Dirichlet condition

= 𝐸̇𝑖𝑖 - 𝐸̇𝑜𝑜𝑜 + 𝐸̇𝑔 Constant Temperature

𝑑𝑑

𝐸𝑠 = stored energy [J] 𝐸̇𝑖𝑖 = ingoing energy rate [W] 𝑇(𝑥 = 𝑥0 , 𝑡) = 𝑐𝑐𝑐𝑐𝑐.

𝐸̇𝑜𝑜𝑜 = outgoing energy rate [W] 𝐸̇𝑔 = generated energy rate [W] Boundary condition of second kind - Neumann condition

Constant gradient at a boundary (=constant flux)

Mass Species A 𝑑𝑑

� = 𝑐𝑐𝑐𝑐𝑐.

𝑑𝑀𝐴 𝑑𝑑 𝑥=𝑥0

= 𝑀̇𝐴,𝑖𝑖 − 𝑀̇𝐴,𝑜𝑜𝑜 + 𝑀̇𝐴,𝑔

𝑑𝑑 Boundary condition of third kind - Robin boundary condition

𝑀𝐴 = stored mass of A [kg] 𝑀̇𝐴,𝑖𝑖 = ingoing mass rate of A [kg/s]

The gradient at a boundary is described with a function (e.g. Newton’s Law of

𝑀̇𝐴,𝑜𝑜𝑜 = outgoing mass rate of A [kg/s] 𝑀̇𝐴,𝑔 = generated mass rate of A [kg/s]

cooling)

𝑑𝑑

� = 𝑓(𝑇)

𝑑𝑑 𝑥=𝑥0

Version 05/12/2014 Page 10

Heat and Mass Transfer CHEE330 – Formula Sheet

Differential Equations of Mass Transfer Vector operators for different coordinate systems

𝜕𝑐𝐴 (f = scalar function, e.g. Temperature T or concentration c):

= −𝛻 ∙ 𝑁�⃗𝐴 + 𝑅𝐴 Vector Cartesian Cylindrical Spherical

𝜕𝜕

�⃗𝐴 can be either the purely diffusive flux 𝐽���⃗ �⃗ operators (x,y,z) (𝒓, 𝜽, 𝒛) (𝒓, 𝜽, 𝝓)

𝑁 𝐴 or absolute flux 𝑁𝐴 of A

3

𝑅𝐴 = volumetric rate of mass generation [mol/(s m )]

𝜕𝜕 𝜕𝜕

𝜕𝑐𝐴 𝜕𝜕

�⃗ � + 𝑅𝐴

= 𝛻 ∙ (𝐷𝐴𝐴 𝑐𝑐𝑦𝐴 ) − 𝛻 ∙ �𝑐𝐴 𝑉

𝜕𝜕 ⎛𝜕𝜕 ⎞ ⎛ 𝜕𝜕 ⎞ 𝜕𝜕

𝜕𝜕 ⎛ ⎞

�⃗ =molar-average velocity [m/s]

𝑉

Gradient ⎜ ⎟

⎜𝜕𝜕 ⎟ ⎜1 𝜕𝜕 ⎟ ⎜ 1 𝜕𝜕 ⎟

𝜵𝜵 ⎜ ⎟ ⎜𝑟 𝜕θ ⎟ ⎜ ⎟

Boundary condition of first kind - Dirichlet condition 𝜕𝜕 ⎜ 𝑟 𝜕𝜕 ⎟

𝜕𝜕 1 𝜕𝜕

Constant Temperature

⎝ 𝜕𝜕 ⎠ ⎝ 𝜕𝜕 ⎠

𝑐𝐴 (𝑥 = 𝑥0 , 𝑡) = 𝑐𝑐𝑐𝑐𝑐. ⎝𝑟 𝑠𝑠𝑠 (𝜃) 𝜕𝜕⎠

Boundary condition of second kind - Neumann condition

Constant gradient at a boundary (=constant flux) 𝜕2𝑓 1 𝜕 𝜕𝑓 1 𝜕 2 𝜕𝜕

� � �𝑟 � � �𝑟 �

𝑑𝑐𝐴 𝜕𝑥 2 𝑟 𝜕𝑟 𝜕𝑟 𝑟 2 𝜕𝜕 𝜕𝜕

� = 𝑐𝑐𝑐𝑐𝑐. Laplace 𝜕2𝑓 1 𝜕2𝑓 1 𝜕 𝜕𝜕

𝑑𝑑 𝑥=𝑥0 + 2 + 2 2 + 2 �𝑠𝑠𝑠(𝜃) �

𝜵𝟐 𝒇 = 𝚫𝒇 𝜕𝑦 𝑟 𝜕𝜃 𝑟 𝑠𝑠𝑠(𝜃) 𝜕𝜕 𝜕𝜕

Boundary condition of third kind - Robin boundary condition 𝜕2𝑓 𝜕2𝑓 1 𝜕2𝑓

The gradient at a boundary is described with a function + 2� + 2� + 2 �

𝜕𝑧 𝜕𝑧 𝑟 𝑠𝑠𝑠2 (𝜃) 𝜕𝜙 2

𝑑𝑐𝐴

� = 𝑓(𝑐𝐴 )

𝑑𝑑 𝑥=𝑥0

1 𝜕(𝑟 2 𝐹𝑟 )

1 𝜕(𝑟 𝐹𝑟 ) �

𝜕𝐹𝑥 𝜕𝐹𝑦 � 𝑟 2 𝜕𝜕

Other Boundary conditions for mass transfer Divergence � + 𝑟 𝜕𝜕

𝜕𝜕 𝜕𝜕 1 𝜕(𝐹𝜃 𝑠𝑠𝑠(𝜃))

Evaporation and sublimation (Raoult’s Law) 𝜵 ∙ �𝑭⃗ 𝜕𝐹𝑧

1 𝜕𝐹θ 𝜕𝐹𝑧 +

+ + � 𝑟 𝑠𝑠𝑠(𝜃) 𝜕𝜕

+ � 𝑟 𝜕𝜕 𝜕𝜕

𝑝𝐴,𝑠 = 𝑥𝐴 𝑃𝐴,𝑠𝑠𝑠 𝜕𝜕 1 𝜕𝐹𝜙

+ �

𝑝𝐴,𝑠 = 𝑦𝐴,𝑠 𝑃= partial pressure of A in gas at the surface [bar] 𝑟 𝑠𝑠𝑠(𝜃) 𝜕𝜕

𝑃𝐴,𝑠𝑠𝑠 = saturation (vapor) pressure at the surface

Solubility of gases in liquids (Henry’s Law)

𝑝𝐴 = 𝐻𝐻𝐴

𝐻= Henry constant [Pa]

Solubility of gases in solids

𝑐𝐴,𝑠𝑠𝑠𝑠𝑠 = 𝑆 𝑝𝐴

3

𝑆= solubility [Pa m /mol]

Version 05/12/2014 Page 11

Heat and Mass Transfer CHEE330 – Formula Sheet

Convective heat transfer ṁ = mass flow rate [kg/s]

2

cp = specific heat capacity [kJ/(kg K)]

qs “= heat flux at the surface [W/m ]

Newton’s law of Cooling

𝑞 Average heat coefficient

= 𝑞" = ℎ∆𝑇

𝐴 2 1 𝐿

h = convective HT coefficient [W/(m K)] ∆𝑇 = temperature difference [K] ℎ𝐿 = � ℎ𝑥 𝑑𝑑

𝐿 0

Internal Flow ℎ𝐿 = average heat transfer coefficient over a spatial dimension L

ℎ𝑥 = local heat transfer coefficient at a certain position x

𝑞𝑐𝑐𝑐𝑐 = 𝑚̇𝑐𝑝 �𝑇𝑚,𝑜 − 𝑇𝑚,𝑖 � = ℎ 𝐴 ∆𝑇𝑙𝑙

Logarithmic temperature difference Convective mass transfer

∆𝑇𝑜 − ∆𝑇𝑖 𝑁𝐴 = 𝑘𝑐 ∆𝑐𝐴

∆𝑇𝑙𝑙 = NA = molar convective mass transfer flux [mol/(m s]

2

∆𝑇

𝑙𝑙 � ∆𝑇𝑜 � 𝑘𝑐 = concective mass transfer coefficient [m/s]

3

𝑖 ∆𝑐𝐴 = concentration difference [mol/m ]

Constant surface temperature

∆𝑇𝑜 = 𝑇𝑠 − 𝑇𝑜𝑜𝑜 Internal Flow

∆𝑇𝑖 = 𝑇𝑠 − 𝑇𝑖𝑖 Use an analogy to HT

Energy balance results in

𝑇𝑚,𝑜𝑜𝑜 − 𝑇𝑠 ℎ 4𝐿 Analogy between Heat, Mass and Momentum Transport

𝑙𝑙 � �+ =0

𝑇𝑚,𝑖𝑖 − 𝑇𝑠 𝑣𝑎𝑎𝑎 𝜌𝑐𝑝 𝐷 Skin friction

Use local skin friction for analogy of local coefficients

2𝜏𝑆,𝑥

Constant external temperature 𝐶𝑓,𝑥 =

𝜌𝑣∞2

use modified Newton’s Law

2

∆𝑇𝑙𝑙 𝜏𝑆,𝑥 = Local shear stress at position x [N/m ]

q= Use average skin friction for analogy of average coefficients

𝑅𝑡𝑡𝑡 2𝜏𝑆,𝐿

𝑅𝑡𝑡𝑡 = total resistance of convective and conductive HT 𝐶𝑓,𝐿 = 2

∆𝑇𝑙𝑙 built with 𝜌𝑣∞

𝐹

∆𝑇𝑜 = 𝑇∞ − 𝑇𝑜𝑜𝑜 𝜏𝑆,𝐿 = = Average shear stress = Drag force per surface area over spatial dimension

𝐴

2

L [N/m ]

∆𝑇𝑖 = 𝑇∞ − 𝑇𝑖𝑖

Reynolds analogy

Constant heat flux:

ℎ 𝐶𝑓 𝑘𝑐

Local mean temperature of the fluid: 𝑆𝑆 = = = 𝑆𝑡𝑚 =

𝑞𝑠 "𝑃 𝜌𝑣∞ 𝑐𝑝 2 𝑣∞

𝑇𝑚 (𝑥) = 𝑇𝑚,𝑖 + 𝑥 valid for Blasius solution (laminar flow) of the horizontal plate and Pr=1 and Sc=1

𝑚̇𝑐𝑃

Tm,i= mean temperature inlet [K] P=cross section perimeter [m]

Version 05/12/2014 Page 12

Heat and Mass Transfer CHEE330 – Formula Sheet

local skin friction σ = Stefan-Boltzmann constant σ = 5.67x10-8 W/(m2K4)

0.664

𝐶𝑓,𝑥 =

�𝑅𝑒𝑥 NA = Avogadro number 6.022 × 1023 mol−1

average skin friction for averaged coefficients Units of selected physical quantities:

1.328

𝐶𝑓,𝐿 = [Pressure] ≡ atm (standard) = 101325 Pa

�𝑅𝑒𝐿 bar = 105 Pa Pa = N/m2

Chilton-Colburn analogy [Force] ≡ N = kg m/s2

For laminar and turbulent flow where is no form drag such as flow over flat plate

and internal flows [Work] ≡ J = N m

𝐶𝑓 [Power] ≡ W = J/s

𝑗𝐻 = 𝑗𝐷 = [Charge] ≡ C

2

[Current] ≡ A = C/s

𝑗𝐻 = 𝑆𝑆 𝑃𝑃 2/3 [Voltage] ≡ V = J/C

valid for 0.5<Pr<50

𝑘𝑐 2/3

[Electrical resistance] ≡ Ω = V/A

𝑗𝐷 = 𝑆𝑆 [Dynamic viscosity] ≡ Pa s

𝑣∞

valid for 0.6<Sc<2500 [Kinematic viscosity] ≡ m2/s

Prandtl analogy Laminar-Turbulent transition criterion:

For turbulent flows where is no form drag such as flow over flat plate and internal Forced convection cylindrical pipe flow 𝑅𝑅 ≲ 2300

flows

𝐶𝑓 /2 Forced convection along vertical/horizontal plate 𝑅𝑅 ≲ 5𝑥105

𝑆𝑆 =

1 + 5�𝐶𝑓 ⁄2 (𝑃𝑃 − 1)

Forced convection over cylinder/sphere 𝑅𝑅 ≲ 2𝑥105

for mass transfer Stanton number use Sc instead of Pr. Natural convection along vertical plate 𝑅𝑅 ≲ 109

Constants

g = Gravitational acceleration =9.81 m2/s

k B = Boltzmann constant =1.38 × 10-23J/K

R = Universal gas constant = 8.3143 J/(mol K)

Version 05/12/2014 Page 13

Heat and Mass Transfer CHEE330 – Formula Sheet

Correlations for natural Convection

Use analogy for mass transfer. Arithmetic mean temperature for properties

Charact. Range of

Geometry Nu = f (Ra)

length Raleigh No.

1

RaL < 109 0.670𝑅𝑎𝐿4

𝑁𝑢𝐿 = 0.68 + 4

9 9

0.492 16

�1 + � 𝑃𝑃 � �

RaL = 104-109 𝑁𝑢𝐿 = 0.59 𝑅𝑎𝐿

1/4

L RaL = 1010-1013 1/3

𝑁𝑢𝐿 = 0.1 𝑅𝑎𝐿

2

⎛ 1 ⎞

entire range 0.387𝑅𝑎𝐿6

⎜ ⎟

𝑁𝑢𝐿 = ⎜0.825 + 8⎟

⎜ 9 27 ⎟

0.492 16

�1 + � 𝑃𝑃 � �

⎝ ⎠

Use vertical plate equations for the

upper surface of the cold plate and the

L lower surface for the hot plate

Replace g by g cos(θ) for 0 < θ < 60o

RaL = 104-107 𝑁𝑢𝐿 = 0.54 𝑅𝑎𝐿

1/4

RaL = 107-1011 𝑁𝑢𝐿 = 0.15 𝑅𝑎𝐿

1/3

𝐴𝑠 /𝑃

RaL = 105-1011 𝑁𝑢𝐿 = 0.27 𝑅𝑎𝐿

1/4

A vertical cylinder can be treated as a

vertical plate when

35𝐿

L 𝐷 ≥ 1/4

𝐺𝑟𝐿

2

⎛ 1 ⎞

𝑅𝑎𝐷 ≤ 10 12

⎜ 0.387𝑅𝑎𝐷6 ⎟

D 𝑁𝑢𝐷 = ⎜0.6 + 8⎟

⎜ 9 27 ⎟

0.559 16

�1 + � 𝑃𝑃 � �

⎝ ⎠

Version 5/12/2014 Page 14

Heat and Mass Transfer CHEE330 – Formula Sheet

𝑁𝑁𝐷 = 𝐶𝐶𝑎𝐷𝑛

with

𝑅𝑎𝐷 ≥ 1011 0.589𝑅𝑎𝐷4

𝑁𝑢𝐷 = 2 + 4

𝑃𝑃 ≥ 0.7 9 9

0.469 16

�1 + � 𝑃𝑃 � �

D

𝑃𝑃 ≈ 1 𝑁𝑁𝐷 = 2 + 0.43𝑅𝑎𝐷

1/4

5

1 < 𝑅𝑎𝐷 < 10

Correlations for forced convection in internal flow

For mass transfer, use appropriate analogy.

Geometry Flow regime Restrictions Nu = f (Re,Pr)

Cylindrical

pipe of

diameter D Laminar & fully

or developed

Non- (Graetz solution for

cylindrical long pipes)

duct with

Dh=4Ac/P

Properties are evaluated at arithmetic mean

Version 5/12/2014 Page 15

Heat and Mass Transfer CHEE330 – Formula Sheet

𝜇𝑏 𝐷 1/3 𝜇 0.14

0.0044 ≤ � � ≤ 9.75 𝑁𝑢𝐷 = 1.86 �𝑃𝑃 𝐿 � �𝜇 𝑏 �

𝜇𝑤 𝑤

𝜇𝑏 =viscosity bulk temperature

0.6 ≤ 𝑃𝑃 ≤ 5

𝜇𝑤 =viscosity wall temperature

Laminar within Al other properties are evaluated at

Cylindrical bulk temperature

velocity & thermal

pipe of

entrance length ℎ𝐿

diameter D 2≤L/D≤20

(short pipes) = 1 + (𝐷⁄𝐿)0.7

ℎ∞

ℎ𝐿

20<L/D<60 = 1 + 6(𝐷⁄𝐿)

ℎ∞

ℎ∞ = value for fully-developed regime

4

0.7 ≤ 𝑃𝑃 ≤ 100

𝑁𝑢𝐷 = 0.023𝑅𝑒𝐷 5 𝑃𝑃 𝑛

𝑅𝑅 > 104 n=0.4 for heating (Ts>Tm)

L/D>60 n=0.3 for cooling (Ts<Tm)

Cylindrical properties at arithmetic mean

Turbulent & fully

pipe of

developed

diameter D 0.7 ≤ 𝑃𝑃 ≤ 17000 −1

−

2 𝜇𝑏 0.14

𝑆𝑆𝐷 = 0.023𝑅𝑅𝐷 5 𝑃𝑃 3 � �

𝑅𝑅 > 104 𝜇𝑤

L/D>60 All properties, except μw evaluated at

bulk temperature

Correlations for forced convection for external flow

Plates: For mass transfer, use appropriate analogies.

Spheres, Cylinders: Analogies break down, use appropriate correlation

Geometry Flow regime Restrictions Nu = f (Re,Pr)

1

𝑃𝑃 ≥ 0.6 1

or 𝑁𝑢𝑥 = 0.332Re2x 𝑃𝑃 3

Flat plate of Laminar 1/2

0.6 ≤ 𝑆𝑆 ≤ 2500 𝑁𝑢𝐿 = 0.664ReL 𝑃𝑃 1/3

length L (Blasius solution)

𝑅𝑅 < 2 ⋅ 105 Properties are evaluated at

arithmetic mean

𝑁𝑢𝑥 = 0.0288𝑅𝑅𝑥 4/5 𝑃𝑃 1/3

Flat plate of 𝑁𝑢𝐿 = 0.036𝑅𝑅𝐿 4/5 𝑃𝑃1/3

Turbulent 𝑅𝑅 > 3 ⋅ 106

length L Properties are evaluated at

arithmetic mean

𝑁𝑢𝐷 = 𝐵 𝑅𝑒𝐷𝑛 𝑃𝑃 1/3

Cylinder

of diameter D Laminar Pr = 1

in crossflow

Version 5/12/2014 Page 16

Heat and Mass Transfer CHEE330 – Formula Sheet

1 1

0.62𝑅𝑒𝐷2 𝑃𝑃 3

𝑁𝑢𝐷 = 0.3 + 1

2 4

�1 + (0.4/𝑃𝑃)3 �

Cylinder

Laminar & 5 4/5

of diameter D Pr > 0.2 𝑅𝑒𝐷 8

turbulent �1 + � � �

in crossflow 282,000

Properties are evaluated at

arithmetic mean

20 ≲ 𝑅𝑒𝐷 ≲ 105 𝑁𝑢𝐷 ≈ 0.31 (𝑅𝑒𝐷 )0.6

𝜇∞ 1/4

Sphere 𝑁𝑢𝐷 = 2 + 𝑃𝑃 0.4 � �

Laminar 0.71 ≤ 𝑃𝑃 ≤ 380 𝜇𝑠

of diameter D 1 2

3.5 < 𝑅𝑒𝐷 < 7.6 ⋅ 104

�0.4𝑅𝑒𝐷2 + 0.06𝑅𝑒𝐷3 �

Properties are evaluated at T∞,

except μs which is evaluated at Ts

1/2

Falling spherical droplet of diameter D 𝑁𝑢𝐷 = 2 + 0.6𝑅𝑒𝐷 𝑃𝑃 1/3

For flux of species

A from a sphere

into an infinite sink 𝑆ℎ𝐷 = 2

of stagnant fluid B

1

2 2

3

Sphere For mass transfer 𝑃𝑃𝐴𝐴 < 10,000 𝑆ℎ = �4 + 1.21𝑃𝑃𝐴𝐴 �

of diameter D into liquid streams 𝑃𝑃𝐴𝐴 > 10,000

𝑆ℎ = 1.01 𝑃𝑃𝐴𝐴 1/3

2 < 𝑅𝑅 < 800

0.6 < 𝑆𝑆 < 2.7 1/2

For mass transfer 𝑆ℎ = 2 + 0.552𝑅𝑅 𝑆𝑐 1/3

or

into gas streams

1500 < 𝑅𝑅 < 12000

0.6 < 𝑆𝑆 < 1.85

Version 5/12/2014 Page 17

Heat and Mass Transfer CHEE330 – Formula Sheet

List of dimensionless groups

L= characteristic length scale external flow; R = characteristic length scale internal flow/particle

u= characteristic velocity; HT = heat transfer; MT = mass transfer, D = diffusivity

Dimensionless Groups Definition Interpretation

3 3

Archimedes number 𝑔𝑔𝐿 ∆𝜌 𝜌𝐿 gravitational force / viscous force

𝐴𝐴 = =

𝜇2 𝜈2

Arrhenius number 𝐸𝑎 activation energy / thermal energy

𝛼=

𝑅𝑅

Biot number (heat) ℎ𝐿 convective HT / conductive HT

𝐵𝐵 =

𝑘

Biot number (mass) ℎ𝑚 𝐿 convective MT / diffusive MT

𝐵𝑖𝑚 =

𝑘

Bodenstein number 𝑢𝐿 convective MT / axial diffusive MT

𝐵𝐵 =

𝐷𝑎𝑎 (Peclet number for chemical

reactors, 𝐷𝑎𝑎 =axial diffusion

coefficient)

Bond Number 𝑔�𝜌𝑙 − 𝜌𝑔 �𝐿 2 gravitational force / capillary force

𝐵𝐵 =

𝜎

Brinkmann number 𝜇𝑢2 viscous dissipation / thermal

𝐵𝐵 = conduction

𝑘(𝑇𝑤 − 𝑇0 )

Capillary number 𝜇 𝑢 viscous force / capillary (surface

𝐶𝐶 =

𝜎 tension) force

Dean number centrifugal force / viscous force

𝑢𝐿 𝐿 𝐿

𝐷𝐷 = � = 𝑅𝑅 �

𝜈 𝑅 𝑅

Eckert number 𝑢2 kinetic energy flow / boundary

𝐸𝐸 = layer enthalpy

𝑐𝑝 (𝑇𝑤 − 𝑇0 )

Euler number Δ𝑝 pressure force / inertial force

𝐸𝐸 = 2

𝜌𝑢

Fourier number HT 𝛼𝛼 𝑘𝑡 heat conduction / enthalpy

𝐹𝐹 = 2 =

𝐿 𝜌 𝑐𝑝 𝐿2 change; also dimensionless time

Fourier number MT 𝐷𝑡 diffusion rate / species

𝐹𝑜𝑚 = 2

𝐿 accumulation; dimensionless time

Inertial friction factor Δ𝑝 𝑅 specific pressure drop / inertial

𝑓𝑖𝑖 =

𝐿 𝜌𝑢2 force

Viscous friction factor Δ𝑝 𝑅 2 specific pressure drop / viscous

𝑓𝑣𝑣𝑣 = force

𝐿 𝜇𝑢

Froude number 𝑢2 inertial force / gravitational force

𝐹𝐹 =

𝑔𝐿

3

Galileo number 𝑔𝜌𝐿 𝐿2 𝑔 Reynolds x gravity force / viscous

𝐺𝐺 = = 𝑅𝑅 force

𝜇2 𝜇𝑢

Version 5/12/2014 Page 18

Heat and Mass Transfer CHEE330 – Formula Sheet

Graetz number HT 𝑅 2 𝜌 𝑢 𝑐𝑝 𝑅 thermal capacity flow / conductive

𝐺𝑧 = = 𝑅𝑅 𝑃𝑃 HT

𝐿𝑘 𝐿

Graetz number MT 𝑅2 𝑢 𝑅 mass capacity (flow) / diffusive MT

𝐺𝑧𝑧 = = 𝑅𝑅 𝑆𝑆

𝐿 𝐷 𝐿

Grashof number 𝑔 𝛽 (𝑇𝑤 − 𝑇0 )𝐿3 buoyant force / viscous force

𝐺𝐺 =

𝜈2

Knudsen number 𝜆 length of free mean path /

𝐾𝐾 =

𝐿 characteristic length

Lewis number 𝛼 thermal diffusivity / mass

𝐿𝐿 =

𝐷 diffusivity

Mach number 𝑢 velocity / speed of sound

𝑀𝑀 =

𝑢𝑠𝑠𝑠𝑠𝑠

Nusselt number ℎ𝐿 convective HT / conductive HT

𝑁𝑁 =

𝑘 (at boundaries)

Ohnesorge number 𝜇 √𝑊𝑊 viscous force / SQRT(inertial force

𝑂ℎ = = x capillary force)

�𝜌𝜌 𝜎 𝑅𝑅

Peclet number HT 𝑣 𝐿 𝑢 𝜌 𝑐𝑝 𝐿 convective HT / diffusive HT

𝑃𝑃 = = = 𝑅𝑅 𝑃𝑃

𝛼 𝑘 (in bulk liquid)

Peclet number MT 𝑢𝐿 convective MT / diffusive MT

𝑃𝑒𝑚 = = 𝑅𝑅 𝑆𝑆

𝐷 in bulk liquid

Prandtl number 𝜈 𝜇 𝑐𝑝 viscous diffusivity / thermal

𝑃𝑃 = =

𝛼 𝑘 diffusivity

Raleigh number 𝑅𝑅 = 𝐺𝐺 𝑃𝑃 natural convection HT /

conductive HT

Reynolds number 𝑢𝐿 𝑢𝐿 inertial force / viscous force

𝑅𝑅 = =

𝜈 𝜇/𝜌

Schmidt number 𝜈 𝜇/𝜌 momentum diffusivity / mass

𝑆𝑆 = =

𝐷 𝐷 diffusivity

Sherwood number 𝑘𝑐 𝐿 convective MT / diffusive MT

𝑆ℎ =

𝐷 (at boundaries)

Stanton number HT 𝑁𝑁 𝑁𝑁 convective HT / heat capacity

𝑆𝑆 = =

𝑅𝑅 𝑃𝑃 𝑃𝑃 (at boundaries)

Stanton number MT 𝑆ℎ 𝑆ℎ convective MT / mass capacity

𝑆𝑡𝑚 = =

𝑅𝑅 𝑆𝑆 𝑃𝑒𝑚 (at boundaries)

Stokes number 𝑡𝑝 𝑢 particle relaxation time /

𝑆𝑆𝑆 =

𝑅 convective time scale

Strouhal number 𝑓𝐿 characteristic frequency /

𝑆𝑆 =

𝑢 characteristic timescale-1

Weber number 𝜌𝑢2 inertial force / capillary force

𝑊𝑊 = 𝜎

𝐿

Version 5/12/2014 Page 19

S-ar putea să vă placă și

- SB 1803 R2 Operating TBO & HSI FrequencyDocument22 paginiSB 1803 R2 Operating TBO & HSI FrequencyDade Sobarna100% (4)

- Fluid Dynamics With A Computational PerspectiveDocument363 paginiFluid Dynamics With A Computational PerspectiveJorge AvilaÎncă nu există evaluări

- Test Results Velocity: Table 1Document2 paginiTest Results Velocity: Table 1DavidÎncă nu există evaluări

- The Role of Residual Stresses in The Mechanical Performance of Case Carburized SteelsDocument15 paginiThe Role of Residual Stresses in The Mechanical Performance of Case Carburized SteelsWylliam Diel WagnerÎncă nu există evaluări

- Chul Park The Limits of Two-Temperature ModelDocument13 paginiChul Park The Limits of Two-Temperature ModellazharÎncă nu există evaluări

- Introduction To Convective Heat Transfer Analysis Chapter 8 PDFDocument84 paginiIntroduction To Convective Heat Transfer Analysis Chapter 8 PDFhenrengÎncă nu există evaluări

- Tutorial 7 - Kinetics - SOLUTIONSDocument5 paginiTutorial 7 - Kinetics - SOLUTIONSJustin Chuong NguyenÎncă nu există evaluări

- Assignment PipelineDocument8 paginiAssignment PipelineDiego SerrateÎncă nu există evaluări

- UT PCN NotesDocument113 paginiUT PCN NotesThiru Raja95% (19)

- Easa Ar100 2006 PDFDocument33 paginiEasa Ar100 2006 PDFChecho Buenaventura100% (1)

- Function Generation Using Freudenstein's EquationDocument15 paginiFunction Generation Using Freudenstein's Equationvenkatanaveen306Încă nu există evaluări

- Kinematics and Dynamics of Multibody Systems With Imperfect Joints: Models and Case StudiesDocument210 paginiKinematics and Dynamics of Multibody Systems With Imperfect Joints: Models and Case StudiesKocaÎncă nu există evaluări

- THERMODYNAMICSDocument32 paginiTHERMODYNAMICSp_k_soni_iit_physicsÎncă nu există evaluări

- 102MAE Thermodynamics Formula SheetDocument2 pagini102MAE Thermodynamics Formula SheetBogdan ProfirÎncă nu există evaluări

- ME 207 - KOM Unit 1 PDFDocument113 paginiME 207 - KOM Unit 1 PDFdeepakmitrÎncă nu există evaluări

- Chemical Engineering ThermodynamicsDocument86 paginiChemical Engineering ThermodynamicsSreedhar BabuÎncă nu există evaluări

- Trajectory Control: T) Contains Centrifugal, Coriolis, and Gravitational Forces. TheDocument20 paginiTrajectory Control: T) Contains Centrifugal, Coriolis, and Gravitational Forces. TheCarlitos FerÎncă nu există evaluări

- Transport Phenomena Quiz 1 SolutionDocument2 paginiTransport Phenomena Quiz 1 SolutionAyman Al Kafrawy100% (1)

- CH 14Document161 paginiCH 14Priyanka CholletiÎncă nu există evaluări

- 1970-Petukhov - Heat Transfer and Friction in Turbulent Pipe Flow With Variable Physical PropertiesDocument62 pagini1970-Petukhov - Heat Transfer and Friction in Turbulent Pipe Flow With Variable Physical PropertiestomekzawistowskiÎncă nu există evaluări

- Vibration - Lecture 1Document23 paginiVibration - Lecture 1helmyÎncă nu există evaluări

- ASM Previus PaperDocument31 paginiASM Previus Paperdishant sakhareÎncă nu există evaluări

- Rayleigh FlowDocument2 paginiRayleigh FlowpraveenrajjÎncă nu există evaluări

- Flash ConceptsDocument2 paginiFlash ConceptsJuan Camilo HenaoÎncă nu există evaluări

- Thermodynamics Review SheetDocument2 paginiThermodynamics Review SheetAbinashSahooÎncă nu există evaluări

- CD Ebook PDFDocument11 paginiCD Ebook PDFMauroPellencinÎncă nu există evaluări

- Gas Dynamics-Rayleigh FlowDocument26 paginiGas Dynamics-Rayleigh FlowRahul100% (4)

- Cap7 Force ControlDocument19 paginiCap7 Force ControlCarlitos FerÎncă nu există evaluări

- Kinematics Ii: Differential Motion: 3.1. Kinematic Modeling of Instantaneous MotionsDocument12 paginiKinematics Ii: Differential Motion: 3.1. Kinematic Modeling of Instantaneous MotionsCarlitos FerÎncă nu există evaluări

- PDFDocument292 paginiPDFJesse Haney IIIÎncă nu există evaluări

- 4.plasma ReactorsDocument28 pagini4.plasma Reactors湯晴羽Încă nu există evaluări

- Lecture 9 - Prandtl Meyer FlowDocument38 paginiLecture 9 - Prandtl Meyer Flowvandamme789Încă nu există evaluări

- PHYSICS QB SolutionDocument94 paginiPHYSICS QB SolutionAashika DhareÎncă nu există evaluări

- 3b Lattice Vibrations PDFDocument25 pagini3b Lattice Vibrations PDFAnonymous 7VebQhIM0% (1)

- Shock Response Spectrum at Low FrequenciesDocument10 paginiShock Response Spectrum at Low FrequenciesjackÎncă nu există evaluări

- Electrochemical Noise IntroDocument23 paginiElectrochemical Noise IntroDanie-ElsÎncă nu există evaluări

- (Alan Lawley) International Journal of Powder MetaDocument86 pagini(Alan Lawley) International Journal of Powder MetagereÎncă nu există evaluări

- Space Technology Section-A, Module - 1, Lecture-2: 1.2 Thrust From A Stationary Rocket Engine / MotorDocument7 paginiSpace Technology Section-A, Module - 1, Lecture-2: 1.2 Thrust From A Stationary Rocket Engine / MotorSid Siddapa SidhuÎncă nu există evaluări

- Theories and Applications of CFD-DEM Coupling Approach For Granular Flow: A ReviewDocument42 paginiTheories and Applications of CFD-DEM Coupling Approach For Granular Flow: A ReviewgfdczxÎncă nu există evaluări

- ENGRD 221 - Thermodynamics (Prof. N. Zabaras) Prelim IDocument9 paginiENGRD 221 - Thermodynamics (Prof. N. Zabaras) Prelim IMurat TülekÎncă nu există evaluări

- Simulation of Viscoelastic Materials in AbaqusDocument5 paginiSimulation of Viscoelastic Materials in AbaqusRahulprabhakaran VannostranÎncă nu există evaluări

- Natural Convection in A 2d-Cavity With Vertical Isothermal Walls: Cross-Validation of Two Numerical SolutionsDocument6 paginiNatural Convection in A 2d-Cavity With Vertical Isothermal Walls: Cross-Validation of Two Numerical SolutionsSourav SahaÎncă nu există evaluări

- Cap4 StaticsDocument11 paginiCap4 StaticsCarlitos FerÎncă nu există evaluări

- Double Pipe DesignDocument4 paginiDouble Pipe DesignLuis RoseroÎncă nu există evaluări

- Thermodynamics of Fracture GrowthDocument13 paginiThermodynamics of Fracture GrowthMugume Rodgers Bangi100% (2)

- Propulsion Systems I: Dr. Oğuz UzolDocument37 paginiPropulsion Systems I: Dr. Oğuz UzolMudassir IqbalÎncă nu există evaluări

- Fluid Mechanics EquationsDocument8 paginiFluid Mechanics EquationsRaman ChawlaÎncă nu există evaluări

- Best2 Creep-Fatigue Crack Initiation Assessment ProceduresDocument12 paginiBest2 Creep-Fatigue Crack Initiation Assessment ProceduresGooftilaaAniJiraachuunkooYesusiinÎncă nu există evaluări

- Zocca2015 PDFDocument19 paginiZocca2015 PDFBeesam Ramesh KumarÎncă nu există evaluări

- Lecture13 PDFDocument31 paginiLecture13 PDFLado Kranjcevic100% (1)

- Churchill 1977Document7 paginiChurchill 1977LaviejafcÎncă nu există evaluări

- Natural Convection in A Rectangular Porous CavityDocument4 paginiNatural Convection in A Rectangular Porous CavityMani SankarÎncă nu există evaluări

- 10.1038@s42254 019 0068 9 PDFDocument2 pagini10.1038@s42254 019 0068 9 PDFLeonardo de AraujoÎncă nu există evaluări

- CRE Theory QuestionsDocument2 paginiCRE Theory QuestionsJunaid ParkerÎncă nu există evaluări

- Mae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsDocument28 paginiMae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsmibarjanÎncă nu există evaluări

- Pourbaix Diagram - 8 PagesDocument8 paginiPourbaix Diagram - 8 PagesEdilson JuniorÎncă nu există evaluări

- Solution For "Introduction To Chemical Engineering" Chapter 12Document6 paginiSolution For "Introduction To Chemical Engineering" Chapter 12jiholee1117Încă nu există evaluări

- Phase RuleDocument45 paginiPhase RuleSrinivasanÎncă nu există evaluări

- Chapter 3Document74 paginiChapter 3zeheeÎncă nu există evaluări

- Chapter3 1D SS Heat ConductionDocument69 paginiChapter3 1D SS Heat ConductionMechanical EngineersÎncă nu există evaluări

- 1D SS Heat ConductionDocument65 pagini1D SS Heat ConductionAbdullah aminÎncă nu există evaluări

- Lecture Guide 2 Steady State One Dimensional Conduction Heat TransferDocument6 paginiLecture Guide 2 Steady State One Dimensional Conduction Heat TransferCllyan ReyesÎncă nu există evaluări

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3De la EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Evaluare: 3 din 5 stele3/5 (2)

- Problem 1Document5 paginiProblem 1abbeyÎncă nu există evaluări

- Aaj Ami Kothao Jabo Naa by Hum Ayun Ahmed (BDeBooks - Com)Document4 paginiAaj Ami Kothao Jabo Naa by Hum Ayun Ahmed (BDeBooks - Com)abbeyÎncă nu există evaluări

- (Nukleonika) Neutronic and Thermal-Hydraulic Coupling For 3D Reactor Core Modeling Combining MCB and Fluent PDFDocument6 pagini(Nukleonika) Neutronic and Thermal-Hydraulic Coupling For 3D Reactor Core Modeling Combining MCB and Fluent PDFabbeyÎncă nu există evaluări

- 2013 Iter Annual Report PDFDocument56 pagini2013 Iter Annual Report PDFabbeyÎncă nu există evaluări

- 10.1038@s41567 017 0026 3 PDFDocument9 pagini10.1038@s41567 017 0026 3 PDFabbeyÎncă nu există evaluări

- Appel Bourses Master 2017 v6 1Document2 paginiAppel Bourses Master 2017 v6 1HaibelÎncă nu există evaluări

- Examination of Different Strengths of Octupole Correlations in Neutron-Rich PR and PM IsotopesDocument5 paginiExamination of Different Strengths of Octupole Correlations in Neutron-Rich PR and PM IsotopesabbeyÎncă nu există evaluări

- (Nukleonika) Neutronic and Thermal-Hydraulic Coupling For 3D Reactor Core Modeling Combining MCB and Fluent PDFDocument6 pagini(Nukleonika) Neutronic and Thermal-Hydraulic Coupling For 3D Reactor Core Modeling Combining MCB and Fluent PDFabbeyÎncă nu există evaluări

- Migration Impacts On Environment: A Case of Rohingya Influx in Ukhia Upazila, Cox's BazarDocument15 paginiMigration Impacts On Environment: A Case of Rohingya Influx in Ukhia Upazila, Cox's BazarabbeyÎncă nu există evaluări

- Controlling Fracture Cascades Through Twisting and QuenchingDocument6 paginiControlling Fracture Cascades Through Twisting and QuenchingabbeyÎncă nu există evaluări

- DELF A1 Exam Preparation Course OnlineDocument1 paginăDELF A1 Exam Preparation Course OnlineThachnatharenÎncă nu există evaluări

- Viscoelasticity 02 ExamplesDocument3 paginiViscoelasticity 02 ExamplesvmanirajannaedÎncă nu există evaluări

- Userguide EN LT25i 4 Android4.3Document115 paginiUserguide EN LT25i 4 Android4.3Rizki WahyuÎncă nu există evaluări

- Posobie Teplovoj Raschet 1 1Document95 paginiPosobie Teplovoj Raschet 1 1abbeyÎncă nu există evaluări

- 10.1038@s41567 018 0204 y PDFDocument6 pagini10.1038@s41567 018 0204 y PDFabbeyÎncă nu există evaluări

- Introduction To Convection PDFDocument16 paginiIntroduction To Convection PDFxkarezÎncă nu există evaluări

- Deconvolution AlgorithmsDocument2 paginiDeconvolution AlgorithmsabbeyÎncă nu există evaluări

- Lorentz Transformations: A Group Theory Approach: Neil & Pillon Erik October 21, 2017Document3 paginiLorentz Transformations: A Group Theory Approach: Neil & Pillon Erik October 21, 2017abbeyÎncă nu există evaluări

- Environmental LT25 2012Document4 paginiEnvironmental LT25 2012abbeyÎncă nu există evaluări

- Py Regex SampleDocument12 paginiPy Regex SampleabbeyÎncă nu există evaluări

- Diffusion Theory Fluxes and Bucklings: Department of Nuclear Science & EngineeringDocument1 paginăDiffusion Theory Fluxes and Bucklings: Department of Nuclear Science & EngineeringabbeyÎncă nu există evaluări

- Py RegexDocument50 paginiPy RegexabbeyÎncă nu există evaluări

- CalcIII HigherOrderPD PracticeDocument2 paginiCalcIII HigherOrderPD PracticeabbeyÎncă nu există evaluări

- Project Reporting Dates: Chowdhury Abhra NeelDocument1 paginăProject Reporting Dates: Chowdhury Abhra Neelabbey0% (1)

- The Essential Can DuDocument1.614 paginiThe Essential Can DumullanaÎncă nu există evaluări

- User Input Exercise: DescriptionDocument2 paginiUser Input Exercise: DescriptionabbeyÎncă nu există evaluări

- Spoken Chinese 900 - Part 2 PDFDocument104 paginiSpoken Chinese 900 - Part 2 PDFabbeyÎncă nu există evaluări

- CalcIII VectorArcLengthDocument5 paginiCalcIII VectorArcLengthabbeyÎncă nu există evaluări

- MATLAB TutorialDocument53 paginiMATLAB TutorialabbeyÎncă nu există evaluări

- Chilled Water System OptimizationDocument36 paginiChilled Water System OptimizationPramod EkÎncă nu există evaluări

- 3D Static and Dynamic AnalysisDocument32 pagini3D Static and Dynamic AnalysisvanmurthyÎncă nu există evaluări

- Catalog TechnorollDocument24 paginiCatalog TechnorollSummA Learning CenterÎncă nu există evaluări

- Module 2Document43 paginiModule 2Manchimsetty Sri NidhiÎncă nu există evaluări

- Axle Boot MarutiDocument2 paginiAxle Boot MarutinrjmanitÎncă nu există evaluări

- Art 10.1007 s00603-012-0220-7 Block Flexural Toppling Amini PDFDocument14 paginiArt 10.1007 s00603-012-0220-7 Block Flexural Toppling Amini PDFJosé Carlos Bustamante MoralesÎncă nu există evaluări

- Lab 2 Cantilever Shear Force Apparatus and Simply Supported BeamsDocument11 paginiLab 2 Cantilever Shear Force Apparatus and Simply Supported BeamsChing Wai YongÎncă nu există evaluări

- PHYSICS (CE & ME) (PH-21102) Introduction To Mechanics: Module 1: (8 Lectures)Document1 paginăPHYSICS (CE & ME) (PH-21102) Introduction To Mechanics: Module 1: (8 Lectures)Supratim RoyÎncă nu există evaluări

- flowIT FTBGDW-16Document1 paginăflowIT FTBGDW-16technicalsupportÎncă nu există evaluări

- FGM Piston Liner Kit IndexDocument88 paginiFGM Piston Liner Kit IndexLuis Arturo Arevalo LeonÎncă nu există evaluări

- Tutorial Vapor and Combined Power CyclesDocument3 paginiTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- Thread Standards - Tameson PDFDocument6 paginiThread Standards - Tameson PDFAmol JagtapÎncă nu există evaluări

- DepbDocument65 paginiDepbomkarniranjanÎncă nu există evaluări

- Modernizing The Opposed-Piston Two-Stroke Diesel Engine For More Efficient Commercial Vehicle ApplicationsDocument26 paginiModernizing The Opposed-Piston Two-Stroke Diesel Engine For More Efficient Commercial Vehicle ApplicationsChu TuấnÎncă nu există evaluări

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionDocument3 paginiFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택Încă nu există evaluări

- Sugar Industrial ValvesDocument9 paginiSugar Industrial ValvesRajeev KumarÎncă nu există evaluări

- Qip (Iit Indore) - Steel-Concrete Composite StructuresDocument33 paginiQip (Iit Indore) - Steel-Concrete Composite StructuresLong LothaÎncă nu există evaluări

- DMRC DBR Viaduct-Ph. III Latest-9-2Document29 paginiDMRC DBR Viaduct-Ph. III Latest-9-2Tarun Kant GoyalÎncă nu există evaluări

- Transmision Fuller 13 Vel Rtlo-14913aDocument37 paginiTransmision Fuller 13 Vel Rtlo-14913aCesar RamosÎncă nu există evaluări

- ZoellerDocument4 paginiZoellerWharfedaleÎncă nu există evaluări

- Turbine Operation Procedrue (A)Document148 paginiTurbine Operation Procedrue (A)ashishmathew100% (1)

- Válvula de Seguridad Anderson Greenwood Crosby - La Rosita - Jos-EDocument66 paginiVálvula de Seguridad Anderson Greenwood Crosby - La Rosita - Jos-EJose Flores100% (2)

- 125 Series Diesel: ConvertibleDocument2 pagini125 Series Diesel: ConvertibleLuis Alberto Serrano MesaÎncă nu există evaluări

- Iso 2503 2009 en PDFDocument11 paginiIso 2503 2009 en PDFВикторÎncă nu există evaluări

- Lecture 1 Ultimate Bearing CapacityDocument22 paginiLecture 1 Ultimate Bearing CapacityErica Jane TatelÎncă nu există evaluări

- L2C1 MEC420 1D Kinematics of Particle FS2 PDFDocument30 paginiL2C1 MEC420 1D Kinematics of Particle FS2 PDFMuhammad Danial Hakim Bin JohariÎncă nu există evaluări

- Comparision of Fabrication TolerancesDocument4 paginiComparision of Fabrication TolerancesSatish Keskar100% (1)

- Fiitjee: Answers, Hints & SolutionsDocument10 paginiFiitjee: Answers, Hints & SolutionsZayanmalikÎncă nu există evaluări