Documente Academic

Documente Profesional

Documente Cultură

Datasheet G3516 1200 RPM

Încărcat de

Verita SanjuánTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Datasheet G3516 1200 RPM

Încărcat de

Verita SanjuánDrepturi de autor:

Formate disponibile

Gas Engine G3516

Generator 1200 rpm

60 Hz

Set 460-820 kW

Continuous Power

CATERPILLAR® ENGINE SPECIFICATIONS

V-16, 4-Stroke-Cycle Spark-Ignited

Bore — in (mm). . . . . . . . . . . . . . . . . . . . . . . . . 6.7 (170)

Stroke — in (mm) . . . . . . . . . . . . . . . . . . . . . . . 7.5 (190)

Displacement — cu in (L) . . . . . . . . . . . . . . 4210 (67.4)

Aspiration . . . . . . . . . . . . Turbocharged-Aftercooled

Compression ratio . . . . . . . . . . . . . . . . . . . . . . 11:1, 9:1

Shown with

Optional Equipment

FEATURES

■ CATERPILLAR® FACTORY PACKAGE ■ LOW EXHAUST EMISSIONS

Factory designed, assembled, and tested. 2.0 gram/bhp-hr NOx. Lower emissions are

Supported by Caterpillar parts and labor achievable for selected applications; consult

warranty through your local Caterpillar your Caterpillar dealer.

dealer. ■ FUEL FLEXIBILITY

■ DIESEL STRENGTH BUILT IN Capability to burn a wide range of gaseous

Blocks, crankshafts, liners, and connecting fuels, including landfill gas, digester gas, coal

rods are common with higher loaded Cat® seam gas, and propane.

diesel engines. Robust design provides ■ GALLERY COOLED PISTONS

prolonged life at lower gas engine loads. Oil passageways provide cooler piston

■ ELECTRONIC IGNITION SYSTEM WITH temperatures which prevent carbon build-up

DETONATION SENSITIVE TIMING and increase detonation margin.

The Caterpillar Electronic Ignition System

(EIS) provides optimized spark timing for all ■ COOLING WATER TEMPERATURE

operating conditions. Timing is automatically Choice of cooling water temperature between

controlled to maintain continuous detonation 99° C and 127° C to match heat recovery

protection. requirements.

CATERPILLAR® SR4 GENERATOR

Type . . . . . . . . . . . Static regulator, brushless excited Voltage regulation . . . . . . . . . . . . . . . . Less than ± 1%

Construction. . . . . . . . Single bearing, close coupled Voltage gain . . . . . . . . Adjustable to compensate for

Three phase . . . . . . . . . . . . . . . . . . . . . Wye connected engine speed droop and line loss

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class F TIF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 50

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drip proof THF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 3%

Alignment. . . . . . . . . . . . . . . . . . Caterpillar pilot shaft

Overspeed capability . . . . . . . . . . . . . . . . . . . . . . 130%

Waveform . . . . . . . . . . . . . . . . Less than 5% deviation

Voltage regulator . . . . . . . . . . . 3-phase sensing with

Volts-per-Hertz

G3516 GAS ENGINE GENERATOR SET

STANDARD EQUIPMENT OPTIONAL EQUIPMENT

Air cleaners with Lifting eyes Cooling systems,

service indicator Manifold, exhaust, high temperature

Breather, crankcase watercooled Custom generator

Cooler, lubricating oil Paint, voltages

Filters, lubricating oil, RH Caterpillar yellow Exhaust fittings

Flywheel housing, Protection devices Generator mounted

SAE No. 00 Pumps control panel

Governor (Woodward), gear driven Load share governor

magneto engine: 2301 aftercooler water Low BTU arrangements

EIS engine: 2301A lubricating oil Low pressure gas fuel

Ignition system, jacket water system (2 psi)

Altronic III or Rails, mounting, 10 inch Muffler

Caterpillar EIS Regulator, Power takeoffs

Instrument panel, gas pressure Prelube pump

RH or LH SAE standard rotation Starting systems

exhaust temp. Thermostats Tachometer

intake manifold and housing

pressure Torsional vibration

intake manifold damper

temp.

oil pressure

oil pressure

differential

service meter

water temp.

G3516 GAS ENGINE GENERATOR SET

TECHNICAL DATA

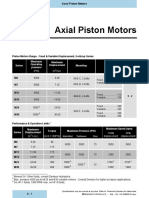

G3516 Gas Engine Generator Set–1200 rpm 90 LE 130 LE 90 TA 130 TA NA

Electrical Output @ 0.8 PF without Fan kW 820 770 770 750 460

Voltage 480/4160 480/4160 480/4160 480/4160 480

Compression Ratio 11:1 11:1 9:1 9:1 9:1

Minimum Gas Pressure Required psi 1 1 25 25 2

Shipping Weight lb 26 020 26 020 25 820 25 820 21 030

Gen Set Length in 192.3 192.3 192.3 192.3 183.4

Gen Set Width in 67.1 67.1 67.1 67.1 63.4

NOx g/bhp-hr 2.0 2.0 18.0 20.1 10.6

CO g/bhp-hr 1.3 1.5 1.0 1.0 38.5

HC (total) g/bhp-hr 4.2 3.9 1.0 1.1 3.3

HC (non-methane) g/bhp-hr 0.6 0.6 0.1 0.2 0.5

Fuel Consumption (100% load) Btu/hp-hr 7082 7011 7570 7506 8064

Fuel Consumption (75% load) Btu/hp-hr 7160 7174 7859 7895 8467

Air Inlet Flow Rate scfm 2300 2203 1579 1544 958

Exhaust Gas Flow Rate @ Stack F cfm 5827 5551 4446 4344 3087

Heat Rejection to Jacket Water (total) Btu/min 37 590 35 429 51 921 50 215 35 259

Heat Rejection to Exhaust (to 350° F) Btu/min 19 734 19 392 17 231 16 549 14 502

Heat Rejection to Aftercooler Btu/min 8132 6199 4777 3753 –

Heat Rejection to Atmosphere from Engine Btu/min 10 407 8644 8530 8132 4891

Exhaust Gas Stack Temperature Deg. F 769 781 872 864 1063

LE refers to low emission engine configuration.

TA refers to standard engine configuration.

90 refers to aftercooler water inlet temperature in °F.

130 refers to aftercooler water inlet temperature in °F.

All data is based on standard conditions.

These ratings do not allow for overload capability.

G3516 GAS ENGINE GENERATOR SET

TOP VIEW

1156.4 (45.53)

2323.0 (91.45)

03

RD

201

1170.0 (46.06)

851.5 (33.52) 104

401 700.0 (27.56)

402

446.7 (17.59)

02 02

103

424.2 (16.70)

304.8 (12.00) 401

523.2 (77.46)

521

308

03

2740.3 (107.89)

295.3 (11.63)

02 Centerline of Engine 201 Fuel Inlet 521 Conduit Entrance

03 Rear Face of Cylinder Block 308 Oil Filter RD Removal Distance

103 Water Inlet 401 Air Inlet

104 Water Outlet 402 Exhaust

See general dimension drawing 114-1975 for additional For magneto ignition system engines see general

Electronic Ignition System (EIS) engine detail and NA dimension drawing 7C-5067.

information.

Note: General configuration not to be used for

installation.

CONDITIONS AND DEFINITIONS

Ratings are based on SAE J1349 standard Turbocharged-aftercooled ratings apply to

conditions of 29.61 in Hg (100 kPa) and 77° F 5000 ft (1525 m) and 77° F (25° C). Naturally

(25° C). These ratings also apply at ISO3046/1, aspirated engines apply to 500 ft (150 m) and

DIN6271, and BS5514 standard conditions of 85° F (29° C). For applications which exceed these

29.61 in Hg (100 kPa) and 81° F (27° C); and limits consult your Caterpillar dealer.

API 7B-11C standard conditions of 29.38 in Hg

Continuous – Output available without varying

(99 kPa) and 85° F (29° C) also apply.

load for an unlimited time. Continuous power in

Ratings are based on dry natural gas having a low accordance with ISO8528, ISO3046/1, AS2789,

heat value of 905 btu/ft3 (35.22 MJ/m3). Variations DIN6271, and BS5514.

in altitude, temperature and gas composition Additional ratings may be available for specific

from standard conditions may require a reduction customer requirements. Consult your Caterpillar

in engine horsepower. representative for details.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

LEHX6196 © 1996 Caterpillar Inc. Printed in U.S.A.

Supersedes LEHX0643 All rights reserved.

S-ar putea să vă placă și

- Liebherr D936 ManualDocument179 paginiLiebherr D936 ManualVentsislav Venev94% (17)

- PC75UU-3 Parts BookDocument195 paginiPC75UU-3 Parts BookOecox Cah Djadoel100% (10)

- Caterpillar XQ80 Towable Diesel Generator SetDocument5 paginiCaterpillar XQ80 Towable Diesel Generator SetMacAllister MachineryÎncă nu există evaluări

- Alineacion CatDocument4 paginiAlineacion CatAndrea Zalamea100% (1)

- Service Manual EY35 EY40 RobinDocument51 paginiService Manual EY35 EY40 RobinAgus YulfizarÎncă nu există evaluări

- 3500 and 3500B Generator With MUI and EUI Engines Electrical SystemDocument4 pagini3500 and 3500B Generator With MUI and EUI Engines Electrical Systemkrisari90% (1)

- Specsheet 3516 1825 kVA PrimeDocument6 paginiSpecsheet 3516 1825 kVA PrimeYusman EkaÎncă nu există evaluări

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocument16 pagini(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- Camless Engine ReportDocument29 paginiCamless Engine Reportsushant kumar80% (5)

- Sagar Kumar Seminar Report PDFDocument20 paginiSagar Kumar Seminar Report PDFPRASHANTA BAL100% (1)

- Linde Forklift H12 14 1618 20 Parts ManualDocument517 paginiLinde Forklift H12 14 1618 20 Parts ManualVăn Duyên Phạm100% (1)

- 3306 164-200KW PRDocument4 pagini3306 164-200KW PRvanaselvan vpÎncă nu există evaluări

- 2301 Woodward Speed ControlDocument4 pagini2301 Woodward Speed ControlManuel Otero100% (1)

- Cat-3412 Tripping Problems Rectification Report: BackgroundDocument2 paginiCat-3412 Tripping Problems Rectification Report: Backgroundget_engineer05Încă nu există evaluări

- Transformadores de Sensado CaterpillarDocument1 paginăTransformadores de Sensado CaterpillarRoberto EspinÎncă nu există evaluări

- Dief ControllerDocument1 paginăDief ControllerMohammad HazbehzadÎncă nu există evaluări

- 1100 Series PerkinsDocument2 pagini1100 Series PerkinsGilberto Diaz CastilloÎncă nu există evaluări

- Voltage Regulator vr6 - 2Document20 paginiVoltage Regulator vr6 - 2Manuel Otero0% (1)

- InstallingDocument11 paginiInstallingMatthewÎncă nu există evaluări

- CL160CD&E InstallDocument4 paginiCL160CD&E InstallJosë Rodríguez100% (1)

- Generator Bearing ServiceDocument10 paginiGenerator Bearing ServiceMustafa A.W100% (1)

- Regulador Marathon Magnamax PM100Document33 paginiRegulador Marathon Magnamax PM100Manuel OteroÎncă nu există evaluări

- Guangzhou Electway Technology Co.,LtdDocument21 paginiGuangzhou Electway Technology Co.,Ltdabdelhamed mahmoudÎncă nu există evaluări

- Cat G3520C Engine Coal Mine GasDocument6 paginiCat G3520C Engine Coal Mine GasJSH100Încă nu există evaluări

- 9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection SystemsDocument37 pagini9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection Systemsosama100% (2)

- CAT - 3516H Engine OverspeedsDocument3 paginiCAT - 3516H Engine Overspeedswagner_guimarães_1Încă nu există evaluări

- Tool Catalog P 4Document15 paginiTool Catalog P 4cav4444Încă nu există evaluări

- C32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpDocument4 paginiC32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpJoséÎncă nu există evaluări

- Maintenance Bintang Diesel 3516Document635 paginiMaintenance Bintang Diesel 3516bintang Diesel100% (1)

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 paginiSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudÎncă nu există evaluări

- Chapters - Perkins 2800 Workshop Manual (Page 2) - ManualsLibDocument1 paginăChapters - Perkins 2800 Workshop Manual (Page 2) - ManualsLibHassan Eltayeb100% (1)

- Eq Generacion Electrica Iluminacion Olympian GEP150Document5 paginiEq Generacion Electrica Iluminacion Olympian GEP150Gianni EscalanteÎncă nu există evaluări

- Perkins 2806a E18tag1 2806a E18tag2 Briz MotorDocument20 paginiPerkins 2806a E18tag1 2806a E18tag2 Briz MotorAdry MendeÎncă nu există evaluări

- Woodward - Iom - Eg-6p, Eg-6pc, Eg-10p, Eg-10pc Actuator 825Document40 paginiWoodward - Iom - Eg-6p, Eg-6pc, Eg-10p, Eg-10pc Actuator 825Jorge Contreras100% (1)

- G3606 - Lehw0039-02 P1Document4 paginiG3606 - Lehw0039-02 P1Martin KratkyÎncă nu există evaluări

- 1.3.1. LEHE1448-02r - G3512HDocument7 pagini1.3.1. LEHE1448-02r - G3512HJuan Valdivieso100% (2)

- Valve Mechanism: Shutdown SISDocument3 paginiValve Mechanism: Shutdown SISMoslem KhanlarpourÎncă nu există evaluări

- Circuit SDMDocument8 paginiCircuit SDMMohammedasifÎncă nu există evaluări

- Alternators Alternators LSA 43.2 - 4 Pole LSA 43.2 - 4 PoleDocument12 paginiAlternators Alternators LSA 43.2 - 4 Pole LSA 43.2 - 4 PoleOdien SalehÎncă nu există evaluări

- Olympian GEP 450 PrimeDocument4 paginiOlympian GEP 450 PrimeMTU650100% (1)

- Crank Terminate Speed CalibrationDocument2 paginiCrank Terminate Speed CalibrationRichard ChuaÎncă nu există evaluări

- Ea06 Manual enDocument6 paginiEa06 Manual enabuzer1981Încă nu există evaluări

- GPU 2 Manual de InstalaciónDocument75 paginiGPU 2 Manual de InstalaciónjjcanoolivaresÎncă nu există evaluări

- Motor Caterpillar 3512cDocument16 paginiMotor Caterpillar 3512chugo1983100% (1)

- (نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Document1 pagină(نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Mahmood NabilÎncă nu există evaluări

- C450N6 A042j403 G-01Document5 paginiC450N6 A042j403 G-01JoseLuisAramayoÎncă nu există evaluări

- G3600 A4 Brochures PDFDocument4 paginiG3600 A4 Brochures PDFVictor NunezÎncă nu există evaluări

- CAT 3616 Fuel Timing DimensionDocument1 paginăCAT 3616 Fuel Timing DimensionAlfred MaspaitellaÎncă nu există evaluări

- Caterpillar InstallationDocument297 paginiCaterpillar InstallationBustershiithaPortugues100% (1)

- Testing For Excessive Cylinder Blowby in 3500 EnginesDocument10 paginiTesting For Excessive Cylinder Blowby in 3500 EnginesPILAR MARTINEZÎncă nu există evaluări

- Diesel Generator Set QSL9 Series Engine: Power GenerationDocument4 paginiDiesel Generator Set QSL9 Series Engine: Power Generationsdasd100% (1)

- Woodward 3161 GovernorDocument4 paginiWoodward 3161 GovernorHashmat Ali100% (1)

- FDMDocument4 paginiFDMKrishna PardeshiÎncă nu există evaluări

- QSK19G PerformanceDocument5 paginiQSK19G PerformancetroyÎncă nu există evaluări

- Doosan DP222LC PDFDocument4 paginiDoosan DP222LC PDFLuisDelaHozÎncă nu există evaluări

- 3516C XQ2000 Power Module Electrical System 307-4710 PDFDocument4 pagini3516C XQ2000 Power Module Electrical System 307-4710 PDFwillian100% (2)

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Document2 paginiMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverÎncă nu există evaluări

- 500kW User ManualDocument83 pagini500kW User ManualvanhoackdÎncă nu există evaluări

- KTA38-G1 EnglishDocument7 paginiKTA38-G1 EnglishAlberto100% (2)

- 3412 - 810kVA PrimeDocument6 pagini3412 - 810kVA PrimeCharl PietersenÎncă nu există evaluări

- Generac QTS ManualDocument166 paginiGenerac QTS ManualChris MaytumÎncă nu există evaluări

- Cummins Onan 175HDKBRDocument4 paginiCummins Onan 175HDKBRpetey100% (1)

- Lehx6234 GAS ENG GENERATOR SET - G3406 50HZ 1500RPM CONTINUOUDocument4 paginiLehx6234 GAS ENG GENERATOR SET - G3406 50HZ 1500RPM CONTINUOUVYNZ StoreÎncă nu există evaluări

- CaT G3516LE HQ PDFDocument4 paginiCaT G3516LE HQ PDFzona amrullohÎncă nu există evaluări

- G3306 Gas Engine Generator Set: Continuous Power Caterpillar Engine SpecificationsDocument4 paginiG3306 Gas Engine Generator Set: Continuous Power Caterpillar Engine SpecificationsVYNZ StoreÎncă nu există evaluări

- 2023 Ford F150 Engine Oil CapacityDocument10 pagini2023 Ford F150 Engine Oil CapacityMadhurjya DuttaÎncă nu există evaluări

- E40xmhl PartsDocument67 paginiE40xmhl PartsCarlos FigueredoÎncă nu există evaluări

- D0X Hydraulic System (HD) UpdateDocument4 paginiD0X Hydraulic System (HD) UpdateStelian CrisanÎncă nu există evaluări

- Mazda Pick-Ups 1972-93 B2000 and B2200 Engines (With Timing Belt)Document1 paginăMazda Pick-Ups 1972-93 B2000 and B2200 Engines (With Timing Belt)Migue KuroÎncă nu există evaluări

- LF12 LF18 Service Manual PDFDocument275 paginiLF12 LF18 Service Manual PDFJulwenÎncă nu există evaluări

- Kinetic Luna TFR Plus MopedDocument33 paginiKinetic Luna TFR Plus MopedSubodh Sonawane50% (2)

- General Purpose Engine: GX390T1 GX390T2Document267 paginiGeneral Purpose Engine: GX390T1 GX390T2Marine Perez PerezÎncă nu există evaluări

- Grand Cherokee 96 4.0l - Full Motores CehckDocument2 paginiGrand Cherokee 96 4.0l - Full Motores CehckCristhian HaroÎncă nu există evaluări

- DireccionDocument3 paginiDireccioneverÎncă nu există evaluări

- Main Engine (S) Unit 6 OverhaulDocument4 paginiMain Engine (S) Unit 6 OverhaulMocanu MarianÎncă nu există evaluări

- Toyota 4Y Engine Cylinder HeadDocument17 paginiToyota 4Y Engine Cylinder HeadJose Antonio PalumboÎncă nu există evaluări

- Denison (M11, M14) Axial Piston MotorsDocument4 paginiDenison (M11, M14) Axial Piston MotorsFernando RíosÎncă nu există evaluări

- PB Engine Gamma EngDocument14 paginiPB Engine Gamma EngSuksan SananmuangÎncă nu există evaluări

- Toyota U240E Automatic Transaxle Repair Manual RM740UDocument136 paginiToyota U240E Automatic Transaxle Repair Manual RM740Ustephany castro100% (1)

- Unit, Direct Support, and General Support Maintenance Repair Parts and Special Tools Lists FORDocument511 paginiUnit, Direct Support, and General Support Maintenance Repair Parts and Special Tools Lists FORRoland GoetzaÎncă nu există evaluări

- Series 90 130 CC Axial Piston Pump: Parts ManualDocument132 paginiSeries 90 130 CC Axial Piston Pump: Parts ManualGaren HovsepianÎncă nu există evaluări

- Step by Step: Installation of Piston RingsDocument1 paginăStep by Step: Installation of Piston RingsOspen Noah SitholeÎncă nu există evaluări

- SU Carburatores - LandRoverDocument24 paginiSU Carburatores - LandRoverChevronelleÎncă nu există evaluări

- Cooling SystemDocument5 paginiCooling SystemIzz BaharÎncă nu există evaluări

- Polaris Special ToolsDocument132 paginiPolaris Special ToolsBrianCook0% (1)

- Guide: E.G. Ty 0822 01 D AgDocument113 paginiGuide: E.G. Ty 0822 01 D AgJorge Luis Garcia Arevalo100% (1)

- TUNINGBOT DPF Removal and Procedure GuideDocument10 paginiTUNINGBOT DPF Removal and Procedure GuideArunlal Thuruthel Sreedharan100% (1)

- Navi Star Powerstroke Diesel Engine PartsDocument35 paginiNavi Star Powerstroke Diesel Engine PartsJonathan Carlson100% (1)

- Notes of Combustion Chamber PDFDocument4 paginiNotes of Combustion Chamber PDFbhushan m dusaneÎncă nu există evaluări