Documente Academic

Documente Profesional

Documente Cultură

Micro Piles All

Încărcat de

Tato Del AguilaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Micro Piles All

Încărcat de

Tato Del AguilaDrepturi de autor:

Formate disponibile

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Micropiles

an Introduction

GeoProfound Engineering Sdn Bhd

Micropiles - Timeline

z 1952 - First introduced in Italy for foundation restoration

(underpinning) of WWII damaged buildings

z 1960’s – Widely used in Europe for underpinning old

sensitive structures

z mid 70’s – First introduced in USA (New York &

Boston)

z 1980’s – Being introduced in East Asia

z Today – ‘Micro-mini Revolution’ worldwide

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 1

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Micropile Applications

z Rock Socketting – where driven piles cannot

penetrate.

z Supporting New Loads in Congested Areas

z Seismic Retrofit

z Arresting Structural Settlement

z Resisting Uplift/Dynamic Loads

z Underpinning

z Excavation Support in Confined Areas

Different Types of Micropiles

Flexibility – Suits

the soil, Suits your

needs…

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 2

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Benefits of Micropiles

No.1

Reason

When you have

problems of low

headroom and

restricted

access…

Benefits of Micropiles

No.2 Reason :

High Performance

•Loading fr 3 – 500 tons!

•Higher As/Ac compared to RC Driven pile

As Micropile 4-8% vs As RC Pile <3%

-> Better in Bending, Lateral Loading

Shear resistance, Seismic performance

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 3

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Benefits of Micropiles

High

As/Ac

Good for

High

Lateral/

Seismic

Loading

Benefits of Micropiles

No.3 Reason :

Can Penetrate Anything

• Drilling thru stiff clay, sandstone, timber,

granite (except buried steel).

•Easier penetration in rock compared to bored pile.

By various creative ways

of drilling…

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 4

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Benefits of

Micropiles Can penetrate

anything…

Wash Boring – Roller (Tricone) Bit

Auger

Buried

Steel

Down Hole Hammer

Use Down-Hole-Hammer with Air Compressor to drill thru Rock/Granite

Benefits of Micropiles

No.4 Reason :

Flexibility

(Many Ways) to adjust to

difficult soils…

• Enhance End Bearing

•‘Cross-Breed’ with other Ground

Improvement technique…

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 5

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Typical Pile Loading

Capacity (Geotech+Structural)

Depending on soil & pile structure, some typical

working loads :

z Dia 250mm, Rebar 6T25, 5m socket in

Granite rock - (70+ tons)

z Dia 250mm, API Pipe As/Ac=8%, 40m in soft

soils - (100 tons)

z Dia 150mm, Rebar 3T25, 20m thru soft clay

+ hard sandy silt end-bearing - (50 tons)

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 6

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

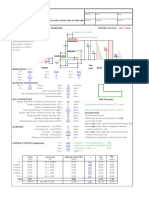

DESIGN PILE CAPACITY

In SOIL (Typical Design using SPT Values)

Skin Friction, fs = 2N kN/m2

End Bearing, fb = 400N/3 or 10000 kN/m2

DESIGN PILE CAPACITY

In ROCK (Socketing)

Skin Friction – Use extrapolation of SPT

(e.g.Granite N=300-500, Sandstone N=200)

fs = 2N kN/m2

Or use Rowe & Armitage (1987):

Skin Fric, fs=0.45 to 0.6(qu)0.5

Zhang & Einstein (1998):

End Bearing, fb = 3.0 to 6.6(qu)0.5

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 7

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Structural Capacity of Piles

Typical Reinforcement = Rebar T16, 20, 25, 32

Ultimate Axial Load:

fu = 0.4*fcu*Ac + 0.75*fy*As

Example : 6Y25 rebar in φ250mm micropile, grout

grade 30MPa, fy=500 N/mm2

fu = 1693kN = 169tons

CO$T

RM$150–350 /meter

Price Depends on :

z Reinforcement Type

z Rock Socketing ?

z Volume (φ) of hole

z Grouting Method (any post grouting)

z Location - Accessibility

z Length/Quantity of piles

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 8

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Production

Typical Production

Wash Boring Φ250mm x 25m,

Drag/roller bit, 4T25 cage,

silty soil,3m casing 2 piles/day

-ditto- sandstone/granite socket 2m, DTH

Hammer 2-3 piles/day

Typical Manpower Requirement

e.g. 100 micropiles, wash bore, φ250mm, 20m, 2 rigs.

Rig (2 No.) 1x2 driller

2x2 helpers Can cut down to

only 8-9 men for

Fabrication 1 welder concurrent

2 general workers activity planning

& utilising ready

Grouting etc 2 @ grout mixer mix or slurry

1 @ agitator tank pump mixer,

steel pipe &

1 pump operator

crane.

1 hoseman

Production >4

TOTAL 14 men piles/day/rig

Production 3 piles/day/rig

Overall cost reduction ~ 20-30% by increased production.

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 9

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Typical Site Setup

Grouting

Clearing of Plant

new area for Entrance/

setting out Delivery

Air

Compressor

Preparing

to grout

pile here

Ac

Water Tank

ce

Current

ss

Drilling

Rd

Location

Fabrication

Yard

Drilling

Pump

Small Quantity – Small Piles

For small sites,

use simpler

rigs with lower

torque, faster

RPM…

(depending on soil type)

e.g. SI rigs

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 10

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Small/Constrained sites -

SI Rig/ Portable Drill frame

e.g. ‘Jacro’ is the solution!

Big Quantity, Small machines…

Tmn Kotamas, Kota Tinggi, Johor

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 11

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Small Quantity, Big machine…

JB Inner Ring Road

Johor Bahru

Big Quantity, Big machine…

Vibro unit…

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 12

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Drilling Tools

Drilling Rig (Flexible) – Size, Rotary Torque, RPM, maneuverity

Drilling Type – Wash Bore, Dry Auger, DTH hammer (Rock Drill)

Drill Bit & Rods – Drag Bit, Roller Bit, DTH (flat/convex), Tubex.

Pump – Recirculating fluid – Diaphragm pump / Piston pump.

Jack-in- Micropile

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 13

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Monitor drilling parameters :

Thrust Force on Drilling bit

Drilling Fluid Flow Rate & Pressure

Rotary/top drive RPM

Rotary/top drive torque

Air Compressor Output Pressure

Recirculating Fluid Viscosity

Why?

Thrust Force : The thrust force is the force acting along the

axis of the drill during cutting. The thrust force plays a significant

role in the buckling of the drill.

Torque/RPM : The Torque/RPM signifies the power needed

by the machine tool to drill the hole. Also, Torque acting on the

drill can result in torsional vibrations affecting hole quality.

500kV Transmission Line

Micropiling Works

T8

Line

2

b4

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 14

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

500kV Transmission Line

Micropiling Works

T8

Line

2

After

500kV Transmission Line

Micropiling Works

T13

Line

2

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 15

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

500kV Transmission Line

Micropiling Works

T8

Line

2

500kV Transmission Line

Micropiling Works

T38

Line

1

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 16

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

500kV Transmission Line

Micropiling Works

T38

Line

1

500kV Transmission Line

Micropiling Works

Uplift

Load

Test

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 17

Third Arm Engineering Sdn Bhd -

Your Ground Improvement Solutions

Solutions for the Difficult Ground

www.geoprofound.com

Tel : 016-7236492, 07-2364932

alaneth@gmail.com 18

S-ar putea să vă placă și

- Micro PileDocument8 paginiMicro PileJennifer Pearson100% (3)

- Design of Pile FoundationsDocument186 paginiDesign of Pile FoundationsLavinia DamianÎncă nu există evaluări

- 50ft Deep Excavation Design Example - Deep ExcavationDocument7 pagini50ft Deep Excavation Design Example - Deep ExcavationAdrian FrantescuÎncă nu există evaluări

- Pile DesignDocument72 paginiPile DesignmrswcecivilÎncă nu există evaluări

- Rigless Intervention System: Efficiency and Safety Without The RigDocument4 paginiRigless Intervention System: Efficiency and Safety Without The Riggacm98Încă nu există evaluări

- Blast Hole DrillingDocument42 paginiBlast Hole DrillingDinesh KumarÎncă nu există evaluări

- Micropile Design ExampleDocument2 paginiMicropile Design ExampleLuis Orlando Ibanez Mora100% (2)

- Micropile Structural Capacity CalculationDocument7 paginiMicropile Structural Capacity CalculationEncik BadrulÎncă nu există evaluări

- Raft Foundations Bearing Capacity and Settlement Report PDFDocument9 paginiRaft Foundations Bearing Capacity and Settlement Report PDFixynnuddoÎncă nu există evaluări

- UBD-MPD Well Control Risk AssessmentDocument27 paginiUBD-MPD Well Control Risk AssessmentAli BoubeniaÎncă nu există evaluări

- Design of Retaining WallDocument69 paginiDesign of Retaining WallWanÎncă nu există evaluări

- Project: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)Document8 paginiProject: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)pakbilal1100% (1)

- Helical Pile Design - Equation Methods Vs Settlement Based ApproachDocument3 paginiHelical Pile Design - Equation Methods Vs Settlement Based ApproachSen HuÎncă nu există evaluări

- Micropile SpecificationDocument9 paginiMicropile SpecificationchongptÎncă nu există evaluări

- Soldier Pile WallDocument15 paginiSoldier Pile WallYousif Mohammed Yousif100% (1)

- Micro Pile MSDocument91 paginiMicro Pile MSYam BalaoingÎncă nu există evaluări

- Micropile Design CheckDocument12 paginiMicropile Design Checkbrudsman22100% (3)

- Micropiles Prospects & ChallengesDocument28 paginiMicropiles Prospects & Challengesbarad1Încă nu există evaluări

- Failure Analysis of Drillstring in Petroleum Industry - A ReviewDocument13 paginiFailure Analysis of Drillstring in Petroleum Industry - A ReviewUnmesh UnnikrishnanÎncă nu există evaluări

- Preloading Temp PropsDocument14 paginiPreloading Temp Propsparamarthasom1974Încă nu există evaluări

- Shallow Foundations: Discussions and Problem SolvingDe la EverandShallow Foundations: Discussions and Problem SolvingEvaluare: 5 din 5 stele5/5 (1)

- Micropile Design (Tension)Document12 paginiMicropile Design (Tension)qsultan100% (1)

- Retaining Wall DesignDocument1 paginăRetaining Wall Design// Library SSECÎncă nu există evaluări

- Method Statement For Static Load Test For Micro PilesDocument5 paginiMethod Statement For Static Load Test For Micro PilesAndy Lian100% (1)

- Pile - 1.2. Micropile DesignDocument1 paginăPile - 1.2. Micropile DesignWan Imran HasifÎncă nu există evaluări

- Aker Kvaerner Design On Fixed TopsideDocument9 paginiAker Kvaerner Design On Fixed TopsideVăn HoàngÎncă nu există evaluări

- Drilling ToolsDocument88 paginiDrilling ToolsSanja RadovicÎncă nu există evaluări

- Shoring Design - Contiguous Pile, Soldier Piles System, Secant Piles SystemDocument53 paginiShoring Design - Contiguous Pile, Soldier Piles System, Secant Piles Systemျမတ္ သူ ေအာင္Încă nu există evaluări

- MCE487 Steel Cage LiftingDocument5 paginiMCE487 Steel Cage LiftingAnonymous S7Cq7ZDgPÎncă nu există evaluări

- FHWA GEOTECHNICAL ENGINEERING CIRCULAR NO. 4 Ground Anchors and Anchored SystemsDocument304 paginiFHWA GEOTECHNICAL ENGINEERING CIRCULAR NO. 4 Ground Anchors and Anchored Systemsv100% (4)

- 2000 HP SCR Drilling Rig SpecificationsDocument24 pagini2000 HP SCR Drilling Rig Specificationsfatehul alam100% (2)

- Micro Pile Seminar PresentationDocument80 paginiMicro Pile Seminar PresentationXavier Pita100% (2)

- SUBMIT (Rev1.0) MicroPileCalculationSheet GTL5Document37 paginiSUBMIT (Rev1.0) MicroPileCalculationSheet GTL5Suneel MatchalaÎncă nu există evaluări

- Drilled Micropiles - Design and Practice in FranceDocument51 paginiDrilled Micropiles - Design and Practice in FranceHyunkyoun JinÎncă nu există evaluări

- Soldier Piles and Lagging SystemsDocument7 paginiSoldier Piles and Lagging SystemsArjun RajaÎncă nu există evaluări

- Micropile Design Magat SalamatDocument10 paginiMicropile Design Magat SalamatWilfredoEnghoyÎncă nu există evaluări

- CADS Bearing PileDocument42 paginiCADS Bearing PileDavidÎncă nu există evaluări

- Micropile Design 6Y22Document2 paginiMicropile Design 6Y22riefsaldy75% (4)

- Micro PileDocument4 paginiMicro PileLayaOPrakashÎncă nu există evaluări

- Secant Pile Wall Design For Deep ExcavationsDocument1 paginăSecant Pile Wall Design For Deep ExcavationsHorace Prophetic DavisÎncă nu există evaluări

- DSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Document16 paginiDSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Tato Del AguilaÎncă nu există evaluări

- Micro Pile Design and ConstructionDocument28 paginiMicro Pile Design and ConstructionMelissa SammyÎncă nu există evaluări

- 15-070 Micropile Design Calculation Rev 2-26-10 2015Document14 pagini15-070 Micropile Design Calculation Rev 2-26-10 2015Raghu Prakash AÎncă nu există evaluări

- Micro PileDocument7 paginiMicro PileWanZainuriadiÎncă nu există evaluări

- Pile Design CalculationDocument69 paginiPile Design Calculationhessian123Încă nu există evaluări

- Enabling Works Design Calculation ReportDocument9 paginiEnabling Works Design Calculation Reportbryan8eric-1Încă nu există evaluări

- UNDERPINNING Text MaterialDocument14 paginiUNDERPINNING Text MaterialYoga RajÎncă nu există evaluări

- 195 Micropiles - Recent Advances and Future TrendsDocument27 pagini195 Micropiles - Recent Advances and Future TrendsCarlos Rafael Obregón Mimbela100% (1)

- DSI USA Bonded Post Tensioning Systems Us 01Document32 paginiDSI USA Bonded Post Tensioning Systems Us 01Tato Del Aguila100% (1)

- State of Practice - Micropile Structural and Geotechnical DesignDocument123 paginiState of Practice - Micropile Structural and Geotechnical DesignJonathan Bennett PE DGE100% (5)

- C16-Chokes and DegasserDocument68 paginiC16-Chokes and Degasserrezoka100% (1)

- Pile Driving Analysis & Dynamic Pile TestingDocument88 paginiPile Driving Analysis & Dynamic Pile Testingbsitler100% (2)

- Design of Secant Pile WallDocument1 paginăDesign of Secant Pile WallAnitha Hassan KabeerÎncă nu există evaluări

- Some Comments On Modelling Deep Excavation Problems With PlaxisDocument5 paginiSome Comments On Modelling Deep Excavation Problems With Plaxisabfso5010100% (1)

- Design Example of A Sheet Pile Retaining WallDocument4 paginiDesign Example of A Sheet Pile Retaining WallKhurram Nazir100% (1)

- CV Design EngineerDocument3 paginiCV Design EngineerAhmed ShariffÎncă nu există evaluări

- Wellbore Clean UpDocument70 paginiWellbore Clean UpJeremy Haynes100% (2)

- DSI ALWAG-Systems CT-Bolt Combination Rock Bolt en 01Document8 paginiDSI ALWAG-Systems CT-Bolt Combination Rock Bolt en 01Tato Del AguilaÎncă nu există evaluări

- Macondo Report 20042011Document33 paginiMacondo Report 20042011Dr K GallowglaichÎncă nu există evaluări

- Micro Pile SpecificationsDocument3 paginiMicro Pile SpecificationsAnonymous 5VwQ0KC3Încă nu există evaluări

- Macro & Mini PilesDocument1 paginăMacro & Mini PilesAnonymous JZFSB3D0% (1)

- Caisson Piles Design & ConstructionDocument57 paginiCaisson Piles Design & ConstructionWan50% (2)

- Micropiles - An OverviewDocument76 paginiMicropiles - An OverviewtangkokhongÎncă nu există evaluări

- Compaction Grouting - Karst Guide SpecificationDocument7 paginiCompaction Grouting - Karst Guide SpecificationyoyoÎncă nu există evaluări

- Secant and Tangent PilesDocument8 paginiSecant and Tangent PilesFatima AhmedÎncă nu există evaluări

- Jack in Pile PDFDocument4 paginiJack in Pile PDFlattmdyÎncă nu există evaluări

- Loading Action On BuildingsDocument42 paginiLoading Action On BuildingsChi LiÎncă nu există evaluări

- Micropiles For Slope StabilizationDocument18 paginiMicropiles For Slope StabilizationedguortÎncă nu există evaluări

- s02 Case NucorDocument12 paginis02 Case NucorManas GhoshÎncă nu există evaluări

- Presentation On Basic Knowledge Railway Siding & Its Major ComponentsDocument11 paginiPresentation On Basic Knowledge Railway Siding & Its Major Componentsengr.kapilgambhir7862Încă nu există evaluări

- Article On Surface MinerDocument11 paginiArticle On Surface MinerShyamal Kumar Bag100% (1)

- Preparation of Concrete Using Gold Mine Waste - Civil Engineering Project TopicsDocument7 paginiPreparation of Concrete Using Gold Mine Waste - Civil Engineering Project Topicsmynameisguna100% (1)

- Casting Sand ReviewDocument7 paginiCasting Sand ReviewAlexis MarinÎncă nu există evaluări

- GlasGrid CatalogueDocument25 paginiGlasGrid CatalogueYuda OktoramdaniÎncă nu există evaluări

- DSI Underground Systems Cable Bolts US 01Document16 paginiDSI Underground Systems Cable Bolts US 01Tato Del AguilaÎncă nu există evaluări

- DSI Underground Systems Rebar Rock Bolts US 01Document14 paginiDSI Underground Systems Rebar Rock Bolts US 01Tato Del AguilaÎncă nu există evaluări

- Dsi Dywidag Gewi Flimu System en 01Document12 paginiDsi Dywidag Gewi Flimu System en 01Tato Del AguilaÎncă nu există evaluări

- DSI DYWIDAG ETA 06 0022 Bonded Post Tensioning System Using Strands enDocument47 paginiDSI DYWIDAG ETA 06 0022 Bonded Post Tensioning System Using Strands enTato Del AguilaÎncă nu există evaluări

- Dsi Dywidag Eta-12 0603 Dywi Drill Hollow Bar System 01Document31 paginiDsi Dywidag Eta-12 0603 Dywi Drill Hollow Bar System 01Tato Del AguilaÎncă nu există evaluări

- Dsi Dywidag z32!1!9 Gewi Piles 63 5mm enDocument19 paginiDsi Dywidag z32!1!9 Gewi Piles 63 5mm enTato Del AguilaÎncă nu există evaluări

- Barras GTDocument2 paginiBarras GTTato Del AguilaÎncă nu există evaluări

- Dsi-Usa Dywidag Soil Nails Us 01Document16 paginiDsi-Usa Dywidag Soil Nails Us 01Tato Del AguilaÎncă nu există evaluări

- 2008-Prefabricated Vertical Drain - The Squeeze Is On-Wick Drain (PVD)Document3 pagini2008-Prefabricated Vertical Drain - The Squeeze Is On-Wick Drain (PVD)Tato Del AguilaÎncă nu există evaluări

- Water Supply and Sewarage Handout PDFDocument99 paginiWater Supply and Sewarage Handout PDFmsea100% (1)

- AirROC T25 and D40 - Leaflet - Low ResDocument4 paginiAirROC T25 and D40 - Leaflet - Low ResNicolás San Martín0% (1)

- Oil RigDocument3 paginiOil RigrshafizanÎncă nu există evaluări

- Well Completion & WorkoverDocument2 paginiWell Completion & WorkoverAhmed BalochÎncă nu există evaluări

- Examples of Various Kinds ofDocument11 paginiExamples of Various Kinds ofVijay HatkarÎncă nu există evaluări

- Case Study Outburst & Gas ManagementDocument11 paginiCase Study Outburst & Gas ManagementAnshuman Das100% (1)

- SamplingDocument22 paginiSamplingramanaÎncă nu există evaluări

- Offshore201902 DLDocument68 paginiOffshore201902 DLBalkis FatihaÎncă nu există evaluări

- SWT Layout & SafetyDocument35 paginiSWT Layout & SafetyRizwan FaridÎncă nu există evaluări

- Vdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsDocument8 paginiVdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsMohamed SadekÎncă nu există evaluări

- Mud Pump Pressure Indicator Systems, Remote: Pressure Gauge, A Gauge Protector, and A HoseDocument2 paginiMud Pump Pressure Indicator Systems, Remote: Pressure Gauge, A Gauge Protector, and A Hosea_salehi100% (1)

- Red Kite Oil Filed ServicesDocument4 paginiRed Kite Oil Filed ServicesAhmed Imtiaz RaoÎncă nu există evaluări

- Boring Log: Geotechnics Philippines, IncDocument3 paginiBoring Log: Geotechnics Philippines, IncMarco Dela CruzÎncă nu există evaluări

- Shah Ali Hussain-CvDocument3 paginiShah Ali Hussain-Cvdr_shaikhfaisalÎncă nu există evaluări

- Dsi Usa Dywi-Drill Instruction Us 01Document32 paginiDsi Usa Dywi-Drill Instruction Us 01suvraÎncă nu există evaluări

- Rotary TableDocument4 paginiRotary TableUsman AhmedÎncă nu există evaluări

- 13 Lubrication SystemDocument5 pagini13 Lubrication Systemsalvador3410% (1)

- Bailey Road Multi Sectional Interchange, at Bailey Road, Patna (DR Ram Manohar Lohia Path Chakra)Document38 paginiBailey Road Multi Sectional Interchange, at Bailey Road, Patna (DR Ram Manohar Lohia Path Chakra)Ranjit KrÎncă nu există evaluări

- HCR 8Document3 paginiHCR 8kalel2711Încă nu există evaluări