Documente Academic

Documente Profesional

Documente Cultură

In 2 o 3

Încărcat de

shadiehatamie0 evaluări0% au considerat acest document util (0 voturi)

27 vizualizări2 paginiMetal oxide electrical properties span a vast range from metallic, to semiconducting, to insulating. The majority of reported metal oxide-based TFTs are fabricated by vapor-phase deposition. High-quality In2O3 thin films are currently grown by low-pressure physical vapor deposition processes.

Descriere originală:

Titlu original

in2o3

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMetal oxide electrical properties span a vast range from metallic, to semiconducting, to insulating. The majority of reported metal oxide-based TFTs are fabricated by vapor-phase deposition. High-quality In2O3 thin films are currently grown by low-pressure physical vapor deposition processes.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

27 vizualizări2 paginiIn 2 o 3

Încărcat de

shadiehatamieMetal oxide electrical properties span a vast range from metallic, to semiconducting, to insulating. The majority of reported metal oxide-based TFTs are fabricated by vapor-phase deposition. High-quality In2O3 thin films are currently grown by low-pressure physical vapor deposition processes.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Published on Web 08/29/2008

High Performance Solution-Processed Indium Oxide Thin-Film Transistors

Hyun Sung Kim, Paul D. Byrne, Antonio Facchetti,* and Tobin J. Marks*

Department of Chemistry and Materials Research Center, Northwestern UniVersity, 2145 Sheridan Road,

EVanston, Illinois 60208

Received June 11, 2008; E-mail: t-marks@northwestern.edu

Metal oxide electrical properties span a vast range from metallic,

to semiconducting, to insulating, all of which are essential

characteristics for thin-film transistor (TFT) components.1 The

attraction of metal oxide semiconductors includes high carrier

mobilities, wide band gaps, broad transparency windows, tunable

doping levels, and amenability to room-temperature film growth.

So far, however, metal oxide-based TFTs are far from optimum,

with the majority of reported devices fabricated by vapor-phase

deposition of the component layers.2 Low-pressure growth processes Figure 1. Fabrication of In2O3 TFTs on Si-SAND (16.5 nm) substrates. L

are expensive to scale for large areas and high throughput, while (channel length) ) 50 or 100 µm, W (channel width) ) 500 µm.

solution-phase processes such as printing, spin-coating, dip-coating,

electrophoresis, and roll-coating offer promising device fabrication

alternatives.3 Nevertheless, the metal oxide TFTs fabricated to date

by semiconductor solution deposition techniques have generally

exhibited marginal performance, i.e., low field-effect mobilities,

low Ion/Ioff ratios, and large operating voltages, all of which preclude

practical application. Note also that, in these TFTs, the gate

dielectrics were not solution-processed.

Among metal oxides, In2O3 is a promising n-type semiconductor

having a wide band gap (3.6-3.75 eV), high single crystal mobility

(160 cm2/V s), and good visible region transparency (>90%).4

High-quality In2O3 thin films are currently grown by low-pressure

physical vapor deposition processes,5 as in high-performance

transparent TFTs fabricated at 25 °C by ion-assisted deposition

(IAD).6 These hybrid TFTs combine the excellent semiconducting

properties of In2O3 with a solution-processed, robust, high-k organic

self-assembled nanodielectric (SAND) for the channel and gate Figure 2. (A) θ-2θ XRD scans of In2O3 films grown on Si/SiO2 substrates

and then annealed at the indicated temperatures (EAA/In3+ ) 10). (B) XRD

dielectric layers, respectively.7 They exhibit field-effect mobilities

patterns of In2O3 films on Si/SiO2 (black lines) and Si/SAND (red lines)

as high as 130 cm2 V-1 s-1, Ion/Ioff ) 105, subthreshold gate voltage substrates fabricated from precursor solutions having the indicated EAA/

swing ) 190 mV/decade and operate at ∼2.0 V.6 These results In3+ molar ratios and annealed at 400 °C. AFM images of In2O3 films grown

raise the question of whether and by which methodology TFT- on Si/SiO2 (C) and Si/SAND (D); EAA/In3+ ) 10.

applicable In2O3 films might be grown by simple solution tech- maximized TFT performance (∼30 nm, Vide infra) was achieved.

niques. We report here the first demonstration of solution-processed Other work shows that SAND films are stable to such annealing

In2O3 TFTs using SiO2 and SAND as gate dielectrics (Figure 1). conditions.8 The TFT structure was completed by Au thermal

We demonstrate that optimized film precursor stoichiometry in evaporation through a shadow mask to define the source/drain

combination with the SAND gate dielectrics enables high-mobility contacts (Figure 1).

In2O3 film growth and excellent TFT performance. The critical effect of the ethanolamine concentration used in the

In2O3 film precursor solutions were prepared with InCl3 as the precursor solutions is evident in the XRD scans of In2O3 films

In3+ source and ethanolamine (EAA) as an added base. After some shown in Figure 2. Independent of the underlying gate dielectric,

experimentation, the optimal InCl3 concentration was found to be the annealed films deposited from base-free formulations are

0.1 M in methoxyethanol (see Table S1), while the EAA/In3+ molar textured but exhibit low carrier mobility and mixed (222) and (004)

ratio was varied systemically from 0.0 to 15. These homogeneous In2O3 reflections. However, as the EAA/In3+ molar ratio is increased

solutions were stirred for 30 min at room temperature and then to 7.5-10, the (222) reflection disappears, and the growth orienta-

spin-coated onto SiO2 (300 nm)- and SAND (∼16.5 nm)-coated tion associated with the higher carrier mobility (004)9 reflection

n+-Si substrates (TFT gate contact). Next, the spin-coated films becomes predominant (Figure 2B). Interestingly, when the EAA/

were annealed at 400 °C for 10 min in a tube furnace under air In3+ molar ratio is increased further (10 f 15), the corresponding

(see Supporting Information). This temperature was found to be films become less crystalline and an additional InOOH (∼25°)

optimum by X-ray diffraction (XRD) monitoring of the film reflection appears. It will be shown that these microstructural

crystallization process in annealing between 200 and 400 °C (Figure features strongly influence the TFT response.

2A). After annealing, the films were cooled to room temperature, The morphologies and grain sizes of the present solution-

and the spin-coating process was repeated x times (x ) 0 - 4, processed In2O3 thin films were examined by tapping-mode atomic

depending on the formulation) until the In2O3 film thickness which force microscopy (AFM). Figure 2C and D show that the In2O3

12580 9 J. AM. CHEM. SOC. 2008, 130, 12580–12581 10.1021/ja804262z CCC: $40.75 2008 American Chemical Society

COMMUNICATIONS

encouraging for high-speed applications at very low operating

voltages (0.0-4.0 V).

All of the present solution-processed In2O3 films are colorless

to the eye and spectroscopically transparent, with films deposited

on glass substrates exhibiting an average transparency of ∼95% in

the visible region (Figure S1A). The optical band gap (3.65 eV)

was estimated from the transmittance spectrum by extrapolating

the linear part of (Rhυ)2 vs hυ plots to R ) 0 (Figure S1B). The

transmittance and band gap data suggest that these In2O3 thin films

are ideal n-channel materials for transparent TFTs.

In conclusion, these results demonstrate that hybrid integration

of solution-processed metal oxide semiconductor films with nano-

scopic organic dielectrics enables TFTs exhibiting performance

unobtainable via conventional approaches. Such hybrid TFT

strategies should be applicable to other metal oxide based transistor

structures (bottom-contact, top-gate) as well as to other transparent

semiconductors and organic dielectric combinations. A key enabler

of the present process is an In2O3 film precursor formulation with

a proper base/In3+ molar ratio, which optimizes the semiconductor

film microstructure.

Figure 3. Transfer (A, C) and output (B, D) plots for In2O3-based TFTs Acknowledgment. We thank Polyera Corp. and the US-Israel

having the following structures: (A and B) Si/SiO2 (300nm)/In2O3 (30nm)/ BSF for support of this research, and the Northwestern MRSEC

Au (50nm), L ) 100 µm, W ) 1000 µm. (C and D) Si/SAND (16.5 nm)/ (NSF DMR-0520513) for characterization facilities. H.S.K. thanks

In2O3 (30nm)/Au (50nm), L ) 100 µm, W ) 500 µm.

the Korea Research Foundation for a postdoctoral fellowship (KRF-

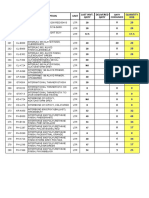

Table 1. In2O3-Based TFT Parameters in Ambient with SiO2 or 2007-357-C00055).

SAND as Gate Dielectrics for Semiconducting Films Spin-Coated Supporting Information Available: Experimental details, field-

from the Formulations Having the Indicated EAA/In3+ Molar Ratios

effect device characteristics of TFTs, figures of In2O3 film optical

EAA/In3+ diel. µ (cm2/V s)a Ion/Ioff Vth (V) S (V/dec) properties. This material is available free of charge via the Internet at

0.0 SiO2 0.04 ( 0.01 104 42.6 23.8 http://pubs.acs.org.

1.0 SiO2 ∼0.01 104 44.3 16.0

5.0 SiO2 0.05 ( 0.01 104 54.2 15.3 References

7.5 SiO2 0.12 ( 0.03 104 38.0 11.4

10.0 SiO2 0.70 ( 0.09 106 29.8 5.7 (1) (a) Sun, Y.; Rogers, J. A. AdV. Mater. 2007, 19, 1897. (b) Nomura, K.;

Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Nature 2004,

12.5 SiO2 0.35 ( 0.05 105 44.6 11.2 432, 488. (c) Sun, B.; Peterson, R. L.; Sirringhaus, H.; Mori, K. J. Phys.

15.0 SiO2 0.22 ( 0.03 103 36.5 26.0 Chem. C 2008, 111, 18831. (d) Ko, S. H.; Park, I.; Pan, H.; Misra, N.; Rogers,

0.0 SAND 5.50 ( 0.6 104 2.6 0.4 M. S.; Grigoropoulos, C. P.; Pisano, A. P. Appl. Phys. Lett. 2008, 92, 154102.

10.0 SAND 43.7 ( 4.8 106 2.2 0.3 (e) Kim, J. S.; Park, J. H.; Lee, J. H.; Jo, J.; Kim, D.-Y.; Cho, K. Appl.

Phys. Lett. 2007, 91, 112111. (f) Pal, B. N.; Sun, J.; Jung, B. J.; Choi, E.;

Andreou, A. G.; Katz, H. E. AdV. Mater. 2008, 20, 1023.

a

Calculated in saturation from the equation µ ) (2ISDL)/[WCOX(VSG (2) (a) Ohya, Y.; Niwa, T.; Ban, T.; Takahashi, Y. Jpn. J. Appl. Phys 2001, 40,

- Vth)2]. 297. (b) Hoffman, R. L.; Norris, B. J.; Wager, J. F. Appl. Phys. Lett. 2003,

82, 733. (c) Chiang, H. Q.; Wager, J. F.; Hoffman, R. L.; Jeong, J.; Keszler,

D. A. Appl. Phys. Lett. 2005, 86, 013503. (d) Jackson, W. B.; Hoffman,

films fabricated on the different dielectrics are compact, dense, R. L.; Herman, G. S. Appl. Phys. Lett. 2005, 87, 193503. (e) Görrn, P.;

uniform, and reasonably smooth (rms roughness ∼3 nm on SiO2, Sander, M.; Meyer, J.; Kröger, M.; Becker, E.; Johannes, H.-H.; Kowalsky,

W.; Riedl, T. AdV. Mater. 2006, 18, 738.

∼6 nm on SAND). These films are less smooth than those reported (3) (a) Ong, B. S.; Li, C.; Li, Y.; Wu, Y.; Loutfy, R. J. Am. Chem. Soc. 2007,

using the aforementioned vapor-phase deposition processes.6 129, 2750. (b) Sun, B.; Sirringhaus, H. J. Am. Chem. Soc. 2006, 128, 16231.

(c) Lee, D-H.; Chang, Y-J.; Herman, G. S.; Chang, C-H. AdV. Mater. 2007,

After TFT fabrication, the devices were evaluated in ambient 19, 843. (d) Cheng, H-C.; Chen, C-F.; Tsay, C-Y. Appl. Phys. Lett. 2007,

atmosphere. Typical I-V plots are shown in Figure 3, and Table 1 90, 012113. (e) Cho, J. H.; Lee, J.; He, Y.; Kim, B.; Lodge, T. P.; Frisbie,

C. D. AdV. Mater. 2008, 20, 686. (f) Loi, M. A.; Da Como, E.; Dinelli, F.;

summarizes performance parameters as a function of precursor Murgia, M.; Zamboni, R.; Biscarini, F.; Muccini, M. Nat. Mater. 2005, 4,

EAA/In3+ molar ratio and dielectric type. Interestingly, as the base/ 81–85.

(4) (a) Nakazawa, H.; Ito, Y.; Matsumoto, E.; Adachi, K.; Aoki, N.; Ochiai, Y.

In3+ ratio is increased, the mobility tracks the microstructural J. Appl. Phys. 2006, 100, 093706. (b) Gupta, A.; Cao, H.; Parekh; Rao,

evolution observed by XRD. In all cases, the greatest mobility is K. K. V.; Raju, A. R.; Waghmare, U. V. J. Appl. Phys. 2007, 101, 09N513.

(5) (a) Zhang, D.; Liu, Z.; Li, C.; Tang, T.; Liu, X.; Han, S.; Lei, B.; Zhou, C.

observed for an EAA/In3+ molar ratio ∼10. For these formulations, Nano. Lett. 2004, 10, 1919. (b) Dhananjay; Chu, C-W. Appl. Phys. Lett.

the In2O3 devices on the SiO2 gate dielctric exhibit reasonable field- 2007, 91, 132111. (c) Vygranenko, Y.; Wang, K.; Nathan, A. Appl. Phys.

Lett. 2007, 91, 263508. (d) Presley, R. E.; Munsee, C. L.; Park, C-H.; Hong,

effect responses (µ ) 0.7 cm2/V s; Ion/Ioff ) 106) for operating D.; Wager, J. F.; Keszler, D. A. J. Phys. D: Appl. Phys. 2004, 37, 2810. (e)

voltages in the 0.0-100 V range. Note that there is an optimal Lavareda, G.; de Carvalho, C. N.; Fortunato, E.; Ramos, A. R.; Alves, E.;

Conde, O.; Amaral, A. J. Non-Cryst. Solids 2006, 352, 2311. (f) Lorenz,

In2O3 film thickness (∼30 nm) where both the carrier mobility and H.; Stoger-Pollach, M.; Schwarz, S.; Pfaller, K.; Klotzer, B.; Bernardi, J.;

Ion/Ioff are large (Table S2). Since Ioff should increase proportionately Penner, S. J. Phys. Chem. C 2008, 112, 918.

(6) (a) Wang, L.; Yoon, M-H.; Facchetti, A.; Marks, T. J. AdV. Mater. 2007,

with semiconductor thickness, we are currently investigating the 19, 3252. (b) Wang, L.; Yoon, M.-H.; Lu, G.; Yang, Y.; Facchetti, A.; Marks,

origin of these unusual effects. In contrast to the SiO2 results, the T. J. Nat. Mater. 2006, 5, 893.

(7) Yoon, M-H.; Facchetti, A.; Marks, T. J. Proc. Natl. Acad. Sci. U.S.A. 2005,

In2O3-organic hybrid TFTs fabricated with the SAND dielectrics 102, 4678.

exhibit excellent I-V characteristics (Figure 3C, D) with classical/ (8) (a) Byrne, P. D.; Facchetti, A.; Marks, T. J. AdV. Mater. 2008, 20, 1. (b)

crisp pinch-off linear curves and saturation at very low operating Lin, H. C.; Kim, S. K.; Chang, D.; Xuan, Y.; Mohammadi, S.; Ye, P. D.;

Lu, G.; Facchetti, A.; Marks, T. J. Appl. Phys. Lett. 2007, 91, 092103.

voltages (0.0-4.0 V). Analysis of the n+-Si/SAND/In2O3/Au TFT (9) Mirzapour, S.; Rozati, S. M.; Takwale, M. G.; Marathe, B. R.; Bhide, V. G.

electrical response reveals large saturation-regime field-effect Mater. Lett. 1992, 13, 275.

mobilities, up to 43.7 cm2 V-1 s-1, Ion/Ioff ) 106, which is JA804262Z

J. AM. CHEM. SOC. 9 VOL. 130, NO. 38, 2008 12581

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Group Iiia: "The Boron Family" BalgaintlnhDocument8 paginiGroup Iiia: "The Boron Family" BalgaintlnhSherylene VillegasÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 3M Adesivos EstruturaisDocument28 pagini3M Adesivos EstruturaisAnonymous mq0U43UsPÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- SPE-130726 - Updated EOR Screening CriteriaDocument24 paginiSPE-130726 - Updated EOR Screening Criteriadina mutia sariÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Difference Between Cast Iron and Ductile IronDocument2 paginiThe Difference Between Cast Iron and Ductile Ironlilama45-1Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Installation of Exterior Windows, Doors and Skylights: Standard Practice ForDocument88 paginiInstallation of Exterior Windows, Doors and Skylights: Standard Practice ForBetsy WiedenfeldÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Santhakumar A R and Uma Rao Santhakumar A R and Uma RaoDocument6 paginiSanthakumar A R and Uma Rao Santhakumar A R and Uma RaoVirat DesaiÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Topic 2 Exercise 6 - More Complex CalculationsDocument1 paginăTopic 2 Exercise 6 - More Complex Calculationsupeka weerasinghaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Part Design For Ultrasonic Welding: Three Major Joint Design CharacteristicsDocument6 paginiPart Design For Ultrasonic Welding: Three Major Joint Design CharacteristicsMiguel ArriecheÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Oxygen Removal Sysytem in PP Iii Project Instrument Index: DOC. NO.: AF-1333003-DD-I04 PROJECT NO.: AF-1333003Document2 paginiOxygen Removal Sysytem in PP Iii Project Instrument Index: DOC. NO.: AF-1333003-DD-I04 PROJECT NO.: AF-1333003Inam AhmedÎncă nu există evaluări

- Batch Manufacturing RecordDocument7 paginiBatch Manufacturing RecordAnu JoshiÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Practice For Determination of GelsDocument3 paginiPractice For Determination of Gelsjohn georgeÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Case Study - : HRSG Tube Failure: Cogeneration Plant, Hazira Plant OngcDocument37 paginiCase Study - : HRSG Tube Failure: Cogeneration Plant, Hazira Plant OngcTushar MeshramÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Goodyear Black Belt Catalog 2010Document72 paginiGoodyear Black Belt Catalog 2010piero_rsÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- CaseStudies PortugalDocument11 paginiCaseStudies PortugalRossel Franklin Condori MamaniÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- TDS Fixoflex H PDFDocument4 paginiTDS Fixoflex H PDFLulzim BeqirajÎncă nu există evaluări

- Design of Water Storage Tanks, and Down Take Pipes - Lecture 1Document46 paginiDesign of Water Storage Tanks, and Down Take Pipes - Lecture 1sakshi meherÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- DRIAPPC Typical Combustion Gas Turbine MaterialsDocument10 paginiDRIAPPC Typical Combustion Gas Turbine Materialsmika cabelloÎncă nu există evaluări

- Associate MemberDocument4 paginiAssociate Memberjohn labuÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Fire Performance of Mass TimberDocument5 paginiFire Performance of Mass TimberciviliiiÎncă nu există evaluări

- Construction Schedule With S-CurveDocument23 paginiConstruction Schedule With S-CurveJp Gallardo100% (2)

- Lista Mestra - DE 08 - 2013 A 07-2014Document9 paginiLista Mestra - DE 08 - 2013 A 07-2014aldairlopesÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Manufacturing Processes & Production TechniquesDocument3 paginiManufacturing Processes & Production TechniquesQwer QwerÎncă nu există evaluări

- Jurnal Kimia Sains Dan Aplikasi: Natural Zeolite Modification Using Dithizone and Its Application As Adsorbent of Cu (II)Document4 paginiJurnal Kimia Sains Dan Aplikasi: Natural Zeolite Modification Using Dithizone and Its Application As Adsorbent of Cu (II)Isna DewiyantiÎncă nu există evaluări

- Spaceandmore HORECA KatalógusDocument619 paginiSpaceandmore HORECA KatalógusMolnár KataÎncă nu există evaluări

- Tiled Steam Room and Steam Shower Technical Design ManualDocument96 paginiTiled Steam Room and Steam Shower Technical Design ManualLATICRETE® International100% (3)

- Handbook 2017Document106 paginiHandbook 2017Arnaud LegrosÎncă nu există evaluări

- Zinc StearateDocument2 paginiZinc StearateAlexi Del Castillo MustaineÎncă nu există evaluări

- AERI-09-16-5 Matadeen Ramchandra Agrawal - Cement PhysicalDocument2 paginiAERI-09-16-5 Matadeen Ramchandra Agrawal - Cement PhysicalAhmedabad Engineering Research InstituteÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Casting Material Gray Iron in ASTM A48Document5 paginiCasting Material Gray Iron in ASTM A48Novaldi Andryoga 1707122616Încă nu există evaluări

- PAINTS INVENTORY Apr.14 2016Document1 paginăPAINTS INVENTORY Apr.14 2016Pavel ViktorÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)