Documente Academic

Documente Profesional

Documente Cultură

SM Waterstops en Brochure Web

Încărcat de

dianaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SM Waterstops en Brochure Web

Încărcat de

dianaDrepturi de autor:

Formate disponibile

CONCRETE ACCESSORIES

Sika® Southern Metal

WATERSTOPS

Sika® Southern Metal WATERSTOPS

Offering a variety of solutions across all categories of waterstops,

Sika has the knowledge and time tested products to meet the most

demanding applications.

́́ Water/Waste Water Treatment Plants

́́ Lock and Dam Systems

́́ Reservoirs and Aqueducts

́́ Flood Walls

́́ Retaining Walls

́́ Foundations

́́ Tunnels and Culverts

́́ Bridge Abutments

́́ Containment Structures and Tanks

́́ Slabs-on-Ground

When you specify Sika, you are specifying THE first name in waterstops

and the trusted source for superior technical and

customer service.

Sika® Southern Metal WATERSTOPS

2 Concrete Accessories

CHOOSING THE RIGHT WATERSTOP

WATERSTOP BASIC USE

Embedded in concrete, across and/or along the joint, waterstops

form a watertight diaphragm that prevents the passage of liquid

through the joint. Sika® Southern Metal Waterstops are precision

engineered for vertical and horizontal expansion joints between

cast-in-place concrete units where conditions may subject the

concrete to hydro-static pressure or moisture seepage…they

are manufactured with the highest quality PVC to provide the

strongest tensile strength and elongation capabilities possible

with a superior resistance to alkalis, acids, ozone and waterborne

chemicals.

Sika® Southern Metal’s complete line of shapes and sizes assures

a long, lasting, watertight seal for every above or below grade

concrete structure…they do not discolor concrete, nor do they

produce or support electrolytic action with metal structures nearby

or with embedded rebar steel.

Sika® Southern Metal Waterstops maintain their integrity

indefinitely…they are the premium choice for strength,

impermeability and elongation.

SUGGESTED WATERSTOP DESIGN CHECKLIST

́́ Verify chemical containment requirements, if any

́́ Verify hydrostatic head pressure requirements

́́ Determine joint type and joint movement requirements

́́ Specify material type for best water sealing performance

́́ Specify profile and size (by product number, if possible)

́́ Verify joinery details of dissimilar or asymmetric waterstop

profiles, if any (consider using one profile throughout to

simplify intersections)

́́ Specify factory fabrications and fittings for transitions and

intersections

́́ Specify appropriate method for securing waterstop in

position (see Sika® Southern Metal CSI-formatted product

specifications for additional guidance)

Photo courtesy of Paul C. Rizzo Associates, Inc.

Sika® Southern Metal WATERSTOPS

Concrete Accessories 3

MOVEMENT JOINTS

SELECTING A WATERSTOP SHAPE

MOVEMENT JOINTS are typically designed to accommodate significant movement due to drying shrinkage,

temperature changes, settlement, creep, or live load deflections. The waterstop profile selected must have

the ability to accommodate expected joint movement, typically achieved through the use of a centerbulb,

tear web, or other suitable waterstop geometry designed to accommodate joint movement. Movement

joints typically include contraction joints, expansion joints, and isolation joints. The following profiles are

suitable for Movement joints:

Ribbed with Centerbulb Dumbbell with Centerbulb

shapes are the most versatile shapes accommodate

type of waterstops available. lateral, transverse, and

The centerbulb accommodates shear movement. Larger

lateral, transverse, and centerbulbs will accommodate

shear movement. Larger greater movement.

centerbulbs will accommodate Consider using Ribbed with

greater movement. Centerbulb for better sealing

characteristics.

Tear Web shapes Base Seal with Tear Web

accommodate large shapes accommodate

movements. When joint lateral, transverse, and shear

movement occurs, the tear movement. Larger tear web

web ruptures and allows the bulbs will accommodate

U-bulb to deform without greater movement. Base

placing the material in Seal waterstops have some

tension. limitations with transitions

and intersections.

PRODUCT AND MATERIAL OPTIONS

Sika has the industry's most comprehensive collection of waterstop products and

solutions to meet the most demanding applications. This catalogue is primarily

dedicated to PVC (polyvinyl chloride) waterstops, but general information is

included for chemical resistant waterstops (TPE-R, PE, Stainless Steel), strip-

applied waterstops (Hydrotite, SikaSwell®-A, Sika® Swellstop®, Lockstop) and for

SikaFuko® Injection Hose Systems. Complete catalogues and technical data for

each of these products are available in print or online.

Sika® Southern Metal WATERSTOPS

4 Concrete Accessories

NONMOVING JOINTS

SELECTING A WATERSTOP SHAPE

NONMOVING JOINTS typically have 100% of the bonded steel reinforcement continuous through the joint,

and expose the waterstop to negligible or no movement. Flat waterstop profiles without a centerbulb or

tear web are suitable for nonmoving joints. Other waterstop materials may be considered for nonmoving

joints as well, such as strip-applied or injectable hose waterstops. Examples of waterstop profiles suitable

for nonmoving joints are as follows:

Flat Ribbed shapes are Base Seal is ideal for slab-on-

preferred for nonmoving grade joints or backfilled walls

joints and provide the best and are easy to form. Base

sealing characteristics. Seal waterstops have some

limitations with transitions

and intersections.

Dumbbell shapes are Labyrinth is primarily used

an alternate profile for in vertical joints. Labyrinth

nonmoving joints. Consider shapes create a keyed joint

ribbed shapes for better and do not require split

sealing characteristics. bulkheads. Labyrinth can be

difficult to use in horizontal

joints and there are some

limitations with transitions

and intersections.

Split Flange shapes can simplify forming. The split flange is opened and

attached to the bulkhead for placement of the first concrete element. After

stripping the bulkhead, the flange is closed and anchored for placement of

the adjoining element. Split waterstops are suitable for straight runs only.

Transitions and intersections are not practical with these profiles.

New Concrete Waterstops for Retrofit Strip-applied Waterstops are

Applications seal joints where adhered along concrete joints or

new construction meets an penetrations and encapsulated by

existing structure and can be a subsequent concrete placement.

suitable for moving joints. Hydrotite is the state of the art

Systems include stainless for hydrophilic waterstop and is

steel batten bars and a high-performance, chloroprene

Existing Concrete

fasteners for anchoring to the rubber material that expands when

existing structure with the aid exposed to moisture to create

of an epoxy gel. a compression seal within and

along the joint. For less critical

applications, Sika also offers

SikaSwell®-A and Sika® Swellstop®

expanding waterstops.

Sika® Southern Metal WATERSTOPS

Concrete Accessories 5

Sika® Southern Metal

PVC WATERSTOPS

Sika® Southern Metal, one of the first manufacturers of polyvinyl chloride (PVC) waterstop, has formulated, compounded and

manufactured PVC waterstop for years. Sika® Southern Metal has the knowledge, experience and desire to provide the highest

quality joint sealing solutions and services available.

PVC is the industry standard for flexible waterstops, which are typically embedded across and along the joint. PVC is the most

versatile waterstop material, offering the broadest design selection and is accepted under the ACI 350 "Code Requirements for

Environmental Engineering Concrete Structures". It has great inherent elasticity and is resistant to many waterborne chemicals. It

will not discolour concrete or produce electrolytic action.

Sika® Southern Metal offers the industry's widest array of PVC waterstop designs, typically ranging in widths from 100 to 300 mm

(4 to 12 in) and thicknesses from 3 to 12 mm (1/8 to 1/2 in). Depending on size, most waterstop shapes are provided in 15 or 30 m

(50 or 100 ft) coils. Please contact Sika Canada Inc. for further information or if you need assistance in selecting a waterstop.

PHYSICAL PROPERTIES SIKA CONDUCTS REGULAR

All Sika® Southern Metal PVC waterstops are specially formulated

and manufactured to meet or exceed industry standard product

TESTING OF MATERIALS.

specifications.

Sika® Southern Metal PVC Waterstops Independent laboratory tests are available

Property Test Value for the following applicable standards:

Water absorption ASTM D570 0.15% max. • Corps of Engineers CRD-C 572-74

Tear resistance ASTM D624 300 lb/in min.

Ultimate elongation ASTM D638 350% min.

• Bureau of Reclamation

Tensile strength ASTM D638 2000 psi min. • CH2M HILL

Low temperature Passes @

brittleness

ASTM D746

-35°F / -37°C • MWH

Stiffness in flexure ASTM D747 700 psi min. • Various State Highway and/or Public

Specific gravity ASTM D792 1.38 max.

Works Department Standards

Hardness Shore A15 ASTM D2240 79±3

Accelerated extraction

-Tensile strength 1600 psi min. Test results conducted using British

-Elongation Corps of 300% min.

Effect of Alkali Engineers Standards are also available. Consult a

-Weight change +0.25% -0.10% Sika Canada representative for more

CRD-C 572

-Hardness change +/-5 points information.

Sika® Southern Metal WATERSTOPS

6 Concrete Accessories

INSTALLATION AIDS AND

FABRICATIONS

PVC waterstops must be securely positioned in the forms to

prevent deflection or misalignment during concrete placement.

This is achieved by tying off the outer edge of the waterstop to

adjacent reinforcing steel. Sika offers options to properly anchor

PVC waterstop, including:

́́ PUNCHED FLANGES - most ribbed shapes can be provided

with punched flanges

́́ GROMMETS - select shapes can be provided with brass

grommets Hog Rings and Pliers

́́ HOG RINGS AND PLIERS - available for field application and

suitable for most shapes

Virtually every concrete structure requiring a PVC waterstop is

going to encounter a joint that will change direction or intersect

with another joint. One of the benefits PVC offers is the

ability to heat weld the material to create a continuous sealing

diaphragm within the joints of a concrete structure.

Waterstop failures are often the result of improper

field fabricated transitions and intersections. To avoid

potential problems, Sika strongly recommends FACTORY

FABRICATIONS and maintains an inventory of the most

common fabrications to meet the demands of a construction

schedule.

SPLICING IRONS are available in various sizes for field welding

lengths of PVC waterstop. More information can be found on

page 14.

Splicing Irons

Factory Fabrications

Sika® Southern Metal WATERSTOPS

Concrete Accessories 7

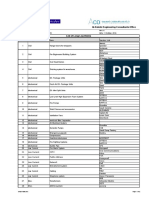

DESIGN AND SIZES

Ribbed waterstops provide the best sealing characteristics.

RIBBED CENTER BULB

10RCB .48 lb/ft Head Press. 65’ 11RCB .74 lb/ft Head Press. 65’ 13RCB .42 lb/ft Head Press. 50’

5/16” ID & 9/16" OD

3/16" 7.9mm ID & 14.3mm OD 3/16" 1/4” ID & 3/4" OD CH2M HILL 3/16" 3/16” ID & 3/8" OD

4.8mm 4.8mm 6.4mm ID & 19.1mm OD 4.8mm 4.8mm ID & 9.5mm OD

7/16" 1/8"

4" 11.1mm 3.2mm 4" 4"

101.6mm 101.6mm 101.6mm

12RCB .86 lb/ft Head Press. 100’ 14RCB .73 lb/ft Head Press. 100’ 42RCB .98 lb/ft Head Press. 100’

3/16" 3/16” ID & 1/2" OD 1/4” ID & 5/8" OD 1/4” ID & 11/16" OD

1/8" 3/16" 6.4mm ID & 15.9mm OD 3/16" 1/4" 6.4mm ID & 17.5mm OD

4.8mm 4.8mm ID & 12.7mm OD 3.2mm 4.8mm 4.8mm 6.4mm

1/8"

3.2mm

6" 6" 6"

152.4mm 152.4mm 152.4mm

15RCB 1.19 lb/ft Head Press. 125’ 16RCB 1.41 lb/ft Head Press. 125’ 17RCB 1.60 lb/ft Head Press. 125’

3/8" 1/4” ID & 11/16" OD USBR 3/8" 5/16” ID & 7/8" OD CH2M HILL

3/16" 6.4mm ID & 17.5mm OD 3/8" 5/16” ID & 5/8" OD 7.9mm ID & 22.2mm OD MWH

4.8mm 9.5mm 1/4" 9.5mm 7.9mm ID & 15.9mm OD

9.5mm Black & Veatch

6.4mm

1/8" 1/8"

3.2mm 1/8"

6" 6" 3.2mm 6" 3.2mm

152.4mm 152.4mm

152.4mm

19RCB 1.66 lb/ft Head Press. 175’ 21RCB 1.19 lb/ft Head Press. 100’ 22RCB 1.45 lb/ft Head Press. 125’

Ontario 1/4” ID & 1/2" OD 1/4” ID & 5/8" OD 9” Mass.

9/32" 13/32" 3/16” ID & 5/8" OD Hydro 3/16" 3/16"

4.8mm ID & 15.9mm OD 6.4mm ID & 12.7mm OD 4.8mm 1/4" 6.4mm ID & 15.9mm OD

7.1mm 10.3mm 4.8mm 6.4mm

3/4"

19.1mm

6" 9" 9"

152.4mm 228.6mm 228.6mm

23RCB 1.63 lb/ft Head Press. 175’ 24RCB 2.10 lb/ft Head Press. 175’ 18RCB 2.45 lb/ft Head Press. 175’

1/4” ID & 3/4" OD 1/4"

3/4” ID & 1 1/4" OD CH2M HILL

3/16" 3/8" 6.4mm ID & 19.1mm OD 1/8" 3/8" 19.1mm ID & 31.9mm OD 1/8" 1/8" 1/2” ID & 1" OD

6.4mm 3.2mm 3.2mm 3/8" 12.7mm ID & 25.4mm OD MWH

4.8mm 9.5mm 3.2mm 9.5mm 9.5mm Black & Veatch

9" 9" 9"

228.6mm 228.6mm 228.6mm

20RCB 2.85 lb/ft Head Press. 200’ 25RCB 2.65 lb/ft Head Press. 175’ 26RCB 3.60 lb/ft Head Press. 225’

3/8" 1/4” ID & 3/4" OD Ontario 7/8” ID & 1 1/2" OD USBR 7/8” ID & 1 1/2" OD

7/8" Hydro 3/16" 22.2mm ID & 38.1mm OD 1/4" C.O.E. 1/4" 3/16"

9.5mm 6.4mm ID & 19.1mm OD

22.2mm 4.8mm 6.4mm 6.4mm 1/2" 22.2mm ID & 38.1mm OD 4.8mm

12.7mm

1/2" 3/8"

9" 9.5mm 9" 12”

12.7mm 228.8mm 304.8mm

228.6mm

30RCB 1.06 lb/ft Head Press. 75’ 31RCB 1.78 lb/ft Head Press. 150’

EYELET 17.0mm ID 3.0mm

20.0mm EYELET 13.0mm ID 4.5mm 7.0mm 3.5mm

4.0mm 6.0mm 3.0mm 25.0mm

50.0mm 55.0mm

150.0mm 250.0mm

Sika® Southern Metal WATERSTOPS

8 Concrete Accessories

DESIGN AND SIZES

RIBBED / SPECIAL

93SP 1.28 lb/ft 94SP .92 lb/ft Head Press. 100’

5/8” ID & 1" OD New York B

1/4" 15.9mm ID & 25.4mm OD 1/8" 3/16" 5/16” ID & 9/16" OD New York A

6.4mm 3.2mm 4.8mm 7.9mm ID & 14.3mm OD

1/8"

3.2mm

7" 6"

177.8mm 152.4mm

TEAR WEB

71TW .78 lb/ft Head Press. 65’ 72TW 1.00 lb/ft Head Press. 100’ 73TW 3.78 lb/ft Head Press. 150’

1 1/8"

28.7mm

5/8" 3/8" 3/8"

15.9mm 9.5mm 5/8" 9.5mm

3/8" 1/8" 15.9mm 3/8" 2 1/2"

1/8" 9.5mm 3.2mm 9.5mm 3/8" 63.5mm 3/4"

3.2mm 9.5mm 19.1mm

6" 9"

152.4mm 228.6mm

9"

228.6mm

FLAT RIBBED

13 FR .43 lb/ft Head Press. 65’ 12FR .84 lb/ft Head Press. 75’ 15FR 1.39 lb/ft Head Press. 125’

3/32" 3/16" 1/8" 1/8" 3/16" 7/16" 1/8" 3/8" 1/4"

2.4mm 4.8mm 3.2mm 3.2mm 4.8mm 11.1mm 3.2mm 9.5mm 6.4mm

4" 6" 6"

101.6mm 152.4mm 152.4mm

17 FR 1.50 lb/ft Head Press. 125’ 21FR 1.22 lb/ft Head Press. 100’ 18FR 2.37 lb/ft Head Press. 175’

1/8" 3/8" MWH 3/16" 1/8" 1/8" 3/8" 5/8" MWH

3.2mm Black & Veatch 3.2mm 3.2mm 9.5mm 15.9mm Black & Veatch

9.5mm 4.8mm

5/8"

15.9mm 9"

6" 9"

228.6mm 228.6mm

152.4mm

22FR 2.40 lb/ft Head Press. 175’ 41FR 2.07 lb/ft Head Press. 175’ 47FR 1.71 lb/ft Head Press. 125’

1/8" 3/8" 1/2" 3/8" 1/4" 3/8"

9.5mm 1/8" 1/8"

9.5mm 1/2"

3.2mm 12.7mm 3.2mm 9.5mm 6.4mm 3.2mm

12.7mm

9" 6"

9" 152.4mm

228.6mm 228.6mm

23FR 1.32 lb/ft Head Press. 125’ 24FR 1.75 lb/ft Head Press. 150’

EYELET 25.0mm

6.0mm 4.0mm 3.0mm EYELET 4.5mm 7.0mm 3.0mm

20.0mm

SHAPES ARE DRAWN

250.0mm

200.0mm TO VARYING SCALES

Sika® Southern Metal WATERSTOPS

Concrete Accessories 9

DESIGN AND SIZES

DUMBBELL CENTERBULB

54DBCB 1.20 lb/ft Head Press. 100’ 28DBCB 1.41 lb/ft Head Press. 100’ 53DBCB 2.06 lb/ft Head Press. 125’

1/4" 3/4” ID & 1 1/8" OD 1/4" 3/4” ID & 1 1/8" OD 1/2" 3/8" 3/8” ID & 3/4" OD

19.1mm ID & 28.6mm OD

6.4mm 6.4mm 19.1mm ID & 28.6mm OD 12.7mm 9.5mm 9.5mm ID & 19.1mm OD

3/8" 5/8"

9.5mm 15.9mm

6" 6" 9"

152.4mm 152.4mm 228.6mm

23DBCB 3.10 lb/ft Head Press. 150’ 27DBCB 3.70 lb/ft Head Press. 150’

2” ID & 2 3/4" OD C.O.E.

1" 3/4” ID & 1 1/2" OD C.O.E. 15/16" 3/8" 50.8mm ID & 69.9mm OD

3/8" 19.1mm ID & 38.1mm OD

25.4mm 9.5mm 23.8mm 9.5mm

9"

228.6mm 9"

228.6mm

DUMBBELL

13DB .47 lb/ft Head Press. 65 12DB .63 lb/ft Head Press. 65’ 14DB .87 lb/ft Head Press. 75’

3/16" 3/8" 3/16" 15/32" 3/16"

4.8mm 9.5mm 4.8mm 11.9mm 4.8mm

5/8"

4" 5" 6" 15.9mm

101.6mm 127.2mm 152.4mm

29DB .71 lb/ft Head Press. 75’ 28DB 1.20 lb/ft Head Press. 100’ 15DB 1.51 lb/ft Head Press. 125’

3/16" 1/4" 5/8" 3/8" 3/4"

4.8mm 6.4mm 15.9mm 9.5mm 19.1mm

3/8"

9.5mm

6" 6" 6"

152.4mm 152.4mm 152.4mm

21DB 1.18 lb/ft Head Press. 100’ 23DB 2.18 lb/ft Head Press. 150’

3/16" 9/16" 3/8" 3/4"

4.8mm 14.3mm 9.5mm 19.1mm

9" 9"

228.6mm 228.6mm

Sika® Southern Metal WATERSTOPS

10 Concrete Accessories

DESIGN AND SIZES

SPLIT RIBBED W/CTRBULB

13SR .50 lb/ft Head Press. 65’ 14SR .76 lb/ft Head Press. 100’ 23SR 1.90 lb/ft Head Press. 150’

5/16” ID & 7/16" OD 3/16" 1/2” ID & 5/8" OD 3/16" 3/8"

3/8” ID & 3/4" OD 1/8"

3/16" 7.9mm ID & 11.4mm OD 4.8mm 12.7mm ID & 15.9mm OD 4.8mm

9.5mm ID & 19.1mm OD 3.2mm

4.8mm 3/32" 3/32" 9.5mm

2.4mm 2.4mm

4" 6" 9"

101.4mm 152.4mm 228.6mm

15SR 1.54 lb/ft Head Press. 125’

3/8" 3.8” ID & 5/8" OD

9.5mm ID & 15.9mm OD

9.5mm

3/16"

4.8mm

6"

152.4mm

DUMBBELL - SPLIT

15DBS 1.49 lb/ft Head Press. 125’ 23DBS 2.20 lb/ft Head Press. 150’

3/4"

3/8" 19.1mm 3/8"

9.5mm 9.5mm

3/4"

19.1mm

6" 9"

152.4mm 228.6mm

BASE SEAL

41BS 1.53 lb/ft Head Press. 100’ 42BS 1.85 lb/ft Head Press. 100’ 43BS .79 lb/ft Head Press. 75’

5/32" 9/16" 3/4" Texas Hwy

2" 9/16" 14.3mm 5/32" 19.1mm 2" Type A 7/16" 7/16" Texas Hwy

14.3mm 4.0mm 4.0mm 11.1mm 11.1mm

50.8mm 50.8mm

3/4"

1/8" Type B

3/4" 3.2mm

19.1mm 19.1mm

9" 9" 7"

228.6mm 228.6mm

177.8mm

44BS .83 lb/ft Head Press. 100’ 45BS 1.21 lb/ft Head Press. 100’

9/16" 1 1/8" 1/2" New York D 1/2" 3/4" 1 1/4" New York E

14.3mm 28.6mm 12.7mm 12.7mm 19.1mm 31.8mm

1/8"

3.2mm 9/16"

1/8"

3.2mm 14.3mm

6" 7"

152.4mm 177.8mm SHAPES ARE DRAWN TO

VARYING SCALES

Sika® Southern Metal WATERSTOPS

Concrete Accessories 11

DESIGN AND SIZES

MULTI-RIBBED

51MR .84 lb/ft Head Press. 25’ 52MR 1.24 lb/ft Head Press. 50’ 53MR 1.81 lb/ft Head Press. 50’

1 3/16" 1 3/16"

30.2mm 1/4"

30.2mm 1/4" 6.4mm

6.4mm

1 5/8" 1 5/8"

1 5/8" 3/16" 41.3mm 41.3mm

3/16" 41.3mm 4.8mm

4.8mm 6 1/4"

4 7/16" 158.8mm

3 1/4" 112.7mm

82.6mm

A NOTE ABOUT HEAD PRESSURE RATINGS:

Head Pressure Ratings are based on parameters published in the

Corps of Engineers document, Waterstops and Other Preformed

Joint Materials for Civil Works Structures EM 1110-2-2101, dated

30 September 1995. Sample testing conducted by Sika® Southern

Metal on select profiles has indicated a conservative tendency

in these ratings. That said, the published Head Pressure Ratings

should be considered to be ultimate values. An appropriate safety

factor should be applied to these values. Contact a Sika Canada

representative for more information.

RETROFIT WATERSTOP SYSTEMS

Retrofit waterstops seal joints where new construction meets

an existing structure and can be suitable for working joints.

Systems include waterstop profile, stainless steel batten bars

and anchor bolts. Epoxy 7300 is sold separately.

Sika® Southern Metal WATERSTOPS

12 Concrete Accessories

SPECIALTY SHAPES

These shapes have been developed to meet U-550 1.10 lb/ft

unique requirements of clients or other W1-2 Calif.

specifying groups. Consult a Sika Canada 1/8"

3.2mm 2"

representative for more information or for 50.8mm 3 1/8"

1/8"

special applications. 3.2mm 79.4mm

2 1/4"

57.1mm

5 1/4"

133.4mm

43RET 2.92 lb/ft with hardware 912RET 8.27 lb/ft with hardware

NEW CONCRETE NEW CONCRETE S.S. BATTEN BAR

S.S. BATTEN BAR 7/8"

S.S. ANCHOR BOLT 1/2"

S.S. ANCHOR BOLT

3 3/16" 6 3/8"

11/16"

EXISTING 3/8"

CONCRETE

EPOXY 7300 EXISTING EPOXY

7300

6" CONCRETE

9"

49SCP 1.38 lb/ft with hardware Head Press. 125’ 56SP 1.51 lb/ft Head Press. 125’

3"

NEW EXISTING

CONCRETE CONCRETE 1 1/2" 5” Mass.

38.1mm

3/32"

2.4mm

EPOXY 3/16"

7/16" 7300 4.8mm 5"

3"

127.0mm

S.S. ANCHOR BOLT

S.S. BATTEN BAR

SHAPES ARE DRAWN TO

VARYING SCALES

Sika® Southern Metal WATERSTOPS

Concrete Accessories 13

FABRICATIONS/SPLICING IRONS

TYPICAL PVC FABRICATIONS

Sika strongly recommends factory fabricated transitions and intersections. Typical fabrications for the most common shapes

are inventoried by Sika and available to meet construction schedules. Sika can provide customized fabrications to suit unusual

configurations or a convergence of differing profiles.

Vertical L, T, and Cross Fabrications Flat L, T, and Cross Fabrications

SPLICING IRONS FOR FIELD WELDING No. 213

As noted, a quality waterstop installation requires quality 4 ½" x 14" Plate

welds. Sika Splicing Irons are specifically designed for

welding thermoplastic waterstop and are constructed

of the highest quality components for superior and long

lasting performance. No other means or methods can be

used.

Temperature controls are adjustable for various conditions

and products. Irons are typically 120V operation, but 240V

is available for the 213 and 214 irons. No. 215

The 213 and 215 irons have an integral thermometer to 9" x 9" Plate

display the iron temperature for accurate welding. The

splicing iron should be large enough to melt the enire cross-

section of the waterstop profile. All irons are supplied with No. 214

a teflon coated cover necessary for welding. Replacement 2" x 14" Plate

covers are available for purchase.

CHEMICAL RESISTANT WATERSTOP

Sika® Southern Metal’s companion brand, Westec®, offers waterstop solutions for secondary containment

in petrochemical and industrial applications. Westec® Envirostop™ TPE-R (Thermoplastic Elastomeric

Rubber) Waterstops resist a wide range of oils, solvents, and aggressive chemicals. Alcohols, ketones,

glycols, esters and aqueous solutions of acids, bases, and salts have little effect on Westec®

Envirostop™ TPE-R Waterstop. TPE-R has excellent ozone resistance, low temperature flexibility,

excellent high temperature (up to 120 °C [250 °F]) performance and is heat weldable. Westec®

Envirostop™ TPE-R Waterstop can also be defined as a Thermoplastic Vulcanizate, TPV.

Westec® Envirostop™ TPE-R Waterstop is certified to NSF/ANSI

Standard 61 for Drinking Water System Components.

Contact a Sika Canada representative or visit www.Chemstop.

com for more information.

Sika® Southern Metal WATERSTOPS

14 Concrete Accessories

STRIP-APPLIED WATERSTOPS AND

INJECTION HOSE SYSTEMS

Hydrotite is a world renowned hydrophilic SikaSwell®-A (formerly Duroseal Gasket) Sika® Swellstop® is a flexible butyl

waterstop. Composed of modified is a water-swelling acrylate-ester that rubber and swellable clay waterproofing

chloroprene rubber protected with a expands upon contact with water to compound that expands upon contact

special delay coating, Hydrotite expands form a compression seal in nonmoving with water to form a compression seal in

when exposed to water, creating an concrete joints. SikaSwell®-A is a nonmoving concrete joints. Swellstop® is

effective compression seal within joints available in three sizes and is adhered available in two sizes and must be used

where limited movement will occur. to varying substrates with Sika® MK in conjunction with Swellstop Primer

Adhesive or Quellpaste Type E. Adhesive to create a watertight bond.

Hydrotite is used extensively in sealing

concrete construction joints, pipe AS WITH ALL HYDROPHILIC WATERSTOPS,

penetrations, precast concrete segments,

tunnel lining segments and for repair of HYDROTITE, SIKASWELL A AND SWELLSTOP

existing joints or retrofit applications. ARE SUGGESTED FOR APPLICATIONS WHERE

Several shapes and sizes are available.

EXPOSURE TO MOISTURE IS CONSTANT.

Sika offers SikaFuko® VT injection hose, the

world's number one injection hose system.

SikaFuko® VT systems are available in two

sizes and can deliver Portland cement,

microfine cement, or a variety of resins

to seal cracks or voids in the joint area.

SikaFuko® VT has a unique "re-injectable"

design, which allows the hose to be cleaned.

This key feature allows for a complete

maintenance program if leaks appear and

future re-injections are required.

Lockstop is a single component and self- SikaFuko® Eco 1 (formerly Duroject) is an

sealing mastic waterstop which bonds injection hose for delivering cements or

to concrete to prevent moisture from resins for planned sealing of construction

penetrating nonmoving joints. Lockstop joints. It is for single injection applications.

must be used in conjunction with Lockstop Sika offers a variety of injection materials

Primer Adhesive to create a watertight for SikaFuko® VT injection hose systems.

bond.

MOST STRIP-APPLIED WATERSTOPS AND INJECTION HOSE SYSTEMS ARE

SUITABLE FOR NONWORKING JOINTS ONLY.

Sika® Southern Metal WATERSTOPS

Concrete Accessories 15

SIKA SOLUTIONS FROM ROOF TO FOUNDATIONS

Roofing Systems Concrete Production Joint Sealing

Sarnafil® Sika® ViscoCrete® Sikaflex®

Sikaplan® SikaRapid® Sikasil®

Sikalastic® Sika® Air Sikadur® Combiflex

Grouting and Anchoring Concrete Repair & Protection Structural Strengthening

SikaGrout® Sika® MonoTop® Sikadur®, Sika® CarboDur®

Sikadur® SikaTop®, SikaRepair® SikaWrap®

Sika AnchorFix® Sikagard® Sika® CarboShear

Sika Canada Inc., a member of the Sika Group,

Floor & Wall Systems Waterproofing Systems is a leader in the field of speciality chemicals,

for construction and manufacturing industries.

Our product lines feature high quality roofing

systems, concrete admixtures, mortars and resins,

sealants and adhesives, structural strengthening

components, industrial and decorative flooring,

as well as protective coatings and waterproofing

systems. Our expertise is borne out of a global

presence and served by strong, local support. Sika

Sikafloor® SikaProof®, SikaFuko® has earned the trust of our industries for over

Sikagard® Sika® Greenstreak® 100 years, by delivering the highest standards of

Sikagard® Duroplast commitment and partnership.

SikaSwell®, SikaFix®

Also Available:

© Sika Canada Inc./Sika® Southern Metal waterstops/08.2015/ar

WATERPROOFING

SikaFuko® INJECTION

HOSE SYSTEMS

UNIQUE WATERPROOFING SOLUTIONS FOR CONSTRUCTION JOINTS

SikaProof® A

Waterproofing Membrane System

Greenstreak

The information, and in particular, the recommendations relating to the application and end-use of Sika products, are given in

good faith based on Sika’s current knowledge and experience of the products when properly stored, handled and applied under

normal conditions, within their shelf life. In practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal

relationship whatsoever, can be inferred either from this information, or from any recommendations, or from any other advice

offered. The proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and

delivery. Users should always refer to the most recent issue of the Product Data Sheet for the product concerned, copies of which

will be supplied on request or can be accessed in the Internet under www.sika.ca.

SIKA CANADA INC.

Head Office Other locations

601, avenue Delmar Toronto

Pointe-Claire, Quebec Edmonton 1-800-933-SIKA An ISO 9001 certified company

H9R 4A9 Vancouver www.sika.ca Pointe-Claire: ISO 14001 certified EMS

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Ait 225Document2 paginiAit 225Oscar I. ValenzuelaÎncă nu există evaluări

- QP 101Document7 paginiQP 101mdd omanÎncă nu există evaluări

- RWDocument29 paginiRWPramod DhaigudeÎncă nu există evaluări

- DEM Theory Attainment SY-A - 2022-23Document30 paginiDEM Theory Attainment SY-A - 2022-23shital jadhavÎncă nu există evaluări

- List of Long Lead Items Rev C 11 Oct 2016Document2 paginiList of Long Lead Items Rev C 11 Oct 2016Shafiullah KhanÎncă nu există evaluări

- Robert Bosch Written Placement Exam Paper - 2008Document2 paginiRobert Bosch Written Placement Exam Paper - 2008Shiv PrakashÎncă nu există evaluări

- Introducing of P&Id For Undergraduate StudentDocument8 paginiIntroducing of P&Id For Undergraduate StudenttyoÎncă nu există evaluări

- Internship ReportDocument37 paginiInternship ReportLemi Chala Beyene0% (1)

- Architectural Working DrawingsDocument62 paginiArchitectural Working DrawingsDondie Porcil CorduwaÎncă nu există evaluări

- Flyer - PCS-902 Line Distance RelayDocument3 paginiFlyer - PCS-902 Line Distance RelayAyeshazahidhussainÎncă nu există evaluări

- BS in Archi Comparative CurriculumDocument2 paginiBS in Archi Comparative CurriculumRoldan SuazoÎncă nu există evaluări

- Roving WASH CoordinatorDocument6 paginiRoving WASH CoordinatorHaftamu TekleÎncă nu există evaluări

- Military Standard: WL-S 2155 (A@Document17 paginiMilitary Standard: WL-S 2155 (A@luisÎncă nu există evaluări

- British Columbia Ministry of Transportation and InfrastructureDocument5 paginiBritish Columbia Ministry of Transportation and InfrastructureFarhanÎncă nu există evaluări

- CV Halit VatanseverDocument2 paginiCV Halit Vatanseverhalit vatanseverÎncă nu există evaluări

- Design Deliverable Documents ListDocument2 paginiDesign Deliverable Documents ListLai HuynhÎncă nu există evaluări

- Course Index: College of Nursing, Midwifery and HealthcareDocument121 paginiCourse Index: College of Nursing, Midwifery and HealthcareImran TermezyÎncă nu există evaluări

- MVA Method 3-Winding TransformerDocument9 paginiMVA Method 3-Winding TransformerraqueebÎncă nu există evaluări

- BSI Little Book of BIM 2018 UK enDocument32 paginiBSI Little Book of BIM 2018 UK enjasminetso100% (1)

- Belgaon Volume 2 RevisedDocument247 paginiBelgaon Volume 2 RevisedSeshu kvÎncă nu există evaluări

- Assignment 7221 MD-IIIDocument2 paginiAssignment 7221 MD-IIIkalikaÎncă nu există evaluări

- ProVent IPC Comparison Manual LetterDocument12 paginiProVent IPC Comparison Manual Letterjack j100% (1)

- C 1145073314Document2 paginiC 1145073314steam100deg8229Încă nu există evaluări

- Vikas Singh Curriculam Vitae: B.Tech. (ECE)Document2 paginiVikas Singh Curriculam Vitae: B.Tech. (ECE)sheb2004Încă nu există evaluări

- Design ReportDocument55 paginiDesign Reportزين ال عابدينÎncă nu există evaluări

- EM - 1110!2!3006-HEPP Electric DesignDocument118 paginiEM - 1110!2!3006-HEPP Electric DesignekaamfÎncă nu există evaluări

- 2022-10-11T005751.688Document1 pagină2022-10-11T005751.688Mohamed FahadÎncă nu există evaluări

- CVEN 345 - Lecture 1Document2 paginiCVEN 345 - Lecture 1Moh SalÎncă nu există evaluări

- Faculties and Departments PDFDocument3 paginiFaculties and Departments PDFGreat OghenemarohÎncă nu există evaluări

- Module 1 Engineering Design ProcessDocument16 paginiModule 1 Engineering Design ProcessvivekÎncă nu există evaluări