Documente Academic

Documente Profesional

Documente Cultură

Weldhelp Matrix

Încărcat de

Joel BrasilBorgesDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Weldhelp Matrix

Încărcat de

Joel BrasilBorgesDrepturi de autor:

Formate disponibile

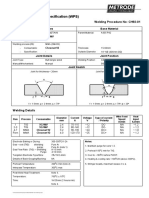

Welding Issue and Cause Matrix

Issues

Mislocated or

Missing Weld

Weld Quality

Relationships

Inconsistent

Poor Class A

Appearance

Sheet Metal

Indentation

Brittle Weld

Extra Welds

Non-Round

Edge Welds

Undersized

Separation

Stuck Weld

Sticking or

Expulsion/

Distortion

Interfacial

Stuck Tips

and Holes

Burn Thru

Excessive

between issues and

Cracks

Weld

Weld

causes:

S = Strong

W = Weak

Weld Current Low S S S S

Weld Current High S S S S S

Weld Force Low W S W S

Weld Force High S S S S

Weld Time Short S S W S

Weld Time Long S W W W

Squeeze Time Short W S W

Hold Time Short W S W S S

Hold Time Long S S W

Wrong Tips S S W W W S W S W S

Inc. Tip Alignment S W W S W S S

Electrode Wear W S S W S W

Electrode Skidding S W W W S S W

Inc. Tip Dressing W W W W W S W W S S W

Wrong Shank W W W W W W W W W W

Insufficient Cooling S W S W W

Poor Mech. Connect S W W W S W

Causes

Inc. Air/Hydraulics S W W W S W W

Incorrect Cylinder S W W W W W W S W

Incorrect Hoses W W W W W

Poor Elec. Connect S S W S S

Wrong Transformer W W W W W W W W W W

Wrong Cables/Shunts W W W W W S W W W

Poor Weld Access S W S S S

Shunting Guns/Parts S W S S S

Incorrect Material S W W W W W W S

Dirty Material S W W W S S S

Excessive Sealer S S W S S W S S W

Poor Part Fit-Up W S W S S W S S S S S

Damaged Part S W W W S W W S

Weld Flange Small S W S

Welds Mislocated S W W S S S S S

Tips Not Parallel S S W W S S S

Inc. Gun Equalization W S S

Incorrect Tests W S W W W W W S S W S

Incorrect Workpiece S W W W W W S S S W W W W W W

Poor Tip Follow-Up W S S W S W

S-ar putea să vă placă și

- Module 9.qualification 1.welding PerformanceDocument6 paginiModule 9.qualification 1.welding PerformanceMohd NizamÎncă nu există evaluări

- GTAW and Power SourcesDocument18 paginiGTAW and Power SourcesRavi Kumar SinghÎncă nu există evaluări

- Matrix Schedule Wps Bekapai - 3 Project: DescriptionDocument3 paginiMatrix Schedule Wps Bekapai - 3 Project: DescriptionFerdie OSÎncă nu există evaluări

- Asme 9 DatosDocument47 paginiAsme 9 Datosvichu_villamarÎncă nu există evaluări

- Simufact Welding PDFDocument8 paginiSimufact Welding PDFDele TedÎncă nu există evaluări

- Stud Bolts 2hex Nuts Weight Imperial SizesDocument12 paginiStud Bolts 2hex Nuts Weight Imperial SizesBryan Mauricio Diaz Avila100% (1)

- Welding in Pipelines - PV - StructureDocument6 paginiWelding in Pipelines - PV - StructureanshumanÎncă nu există evaluări

- Material Receiving Inspection Report: Project TitleDocument2 paginiMaterial Receiving Inspection Report: Project TitleGomathyselviÎncă nu există evaluări

- BPQ REV. 0 Interactive FormDocument2 paginiBPQ REV. 0 Interactive FormcosmicbunnyÎncă nu există evaluări

- PreheatDocument2 paginiPreheatScott TrainorÎncă nu există evaluări

- Get Compliant Welding with Kemppi's Universal WPS PackagesDocument6 paginiGet Compliant Welding with Kemppi's Universal WPS PackagesMarija IvanovskaÎncă nu există evaluări

- Welding Procedure Qualification of A36 Steel Plates Using The GTADocument33 paginiWelding Procedure Qualification of A36 Steel Plates Using The GTAKYAW SOEÎncă nu există evaluări

- Review of GTAW Welding ParametersDocument14 paginiReview of GTAW Welding Parameterskervyn SáenzÎncă nu există evaluări

- Technical 03of05 35Document6 paginiTechnical 03of05 35JITENDER KUMARÎncă nu există evaluări

- ERW pipe defects and issues explainedDocument2 paginiERW pipe defects and issues explainedkaveh-bahiraee100% (1)

- Wps FormatDocument2 paginiWps FormatMeghan GhoneÎncă nu există evaluări

- Erw Welding PDFDocument2 paginiErw Welding PDFChristineÎncă nu există evaluări

- Part2 Notice 1Document21 paginiPart2 Notice 1Danem Halas100% (1)

- Tol Geom Ansi y 14.5Document33 paginiTol Geom Ansi y 14.5Rebecca TurnerÎncă nu există evaluări

- Difference Between API 5L 44th & 45th EditionDocument7 paginiDifference Between API 5L 44th & 45th EditionPankaj ShrivastvaÎncă nu există evaluări

- Lloyd S Register Sec IX 2017 Edition Key ChangesDocument38 paginiLloyd S Register Sec IX 2017 Edition Key ChangesDilip Varadharajan100% (1)

- Welding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareDocument2 paginiWelding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareStoian ValentinÎncă nu există evaluări

- Specification of ElectrodeDocument28 paginiSpecification of ElectrodeAnonymous nKOyHbÎncă nu există evaluări

- P Q R - 005Document2 paginiP Q R - 005Courtney DukeÎncă nu există evaluări

- Book - Vol.1&2 - BasicsAndQuality - 22junDocument82 paginiBook - Vol.1&2 - BasicsAndQuality - 22junlth770310Încă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument2 paginiSaudi Aramco Inspection ChecklistRijwan MohammadÎncă nu există evaluări

- ButtWelding Is 11790 1986Document11 paginiButtWelding Is 11790 1986kathir1965Încă nu există evaluări

- 350xt Data Sheet EnglishDocument1 pagină350xt Data Sheet Englishanon_726020506Încă nu există evaluări

- Hose Quotation List: Description Quantity SpecificationDocument1 paginăHose Quotation List: Description Quantity SpecificationLegend AnbuÎncă nu există evaluări

- Welding Procedure Specification (WPS)Document3 paginiWelding Procedure Specification (WPS)Jignasa ShahÎncă nu există evaluări

- QW 381Document1 paginăQW 381Waqas WaqasÎncă nu există evaluări

- Feritescope MP30 TrainingDocument20 paginiFeritescope MP30 Trainingafnene1Încă nu există evaluări

- Fdocuments - in 23368109 04 Wis5 Mechanicaltesting 2006Document114 paginiFdocuments - in 23368109 04 Wis5 Mechanicaltesting 2006kaelcorbettÎncă nu există evaluări

- Auditing Oof Welding Under ASME Section IXDocument21 paginiAuditing Oof Welding Under ASME Section IXsabahiraqÎncă nu există evaluări

- Guide For AWS D1.1 2020 Visual Weld Inspection 1Document6 paginiGuide For AWS D1.1 2020 Visual Weld Inspection 1Nima SharifiÎncă nu există evaluări

- American Institute of Steel ConstructionDocument7 paginiAmerican Institute of Steel ConstructionsojeckÎncă nu există evaluări

- Wps PQRDocument7 paginiWps PQRsobariÎncă nu există evaluări

- Implications of NORSOK M-650 Standard in The OffshoreDocument27 paginiImplications of NORSOK M-650 Standard in The OffshoreJoherÎncă nu există evaluări

- RSW WOPQ REV. 2010a Interactive FormDocument1 paginăRSW WOPQ REV. 2010a Interactive FormcosmicbunnyÎncă nu există evaluări

- STAINLESS Filler Selector Guide PDFDocument1 paginăSTAINLESS Filler Selector Guide PDFArul Edwin VijayÎncă nu există evaluări

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 paginiTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Exercise 9 Welding SymbolsDocument5 paginiExercise 9 Welding SymbolsFord KatimÎncă nu există evaluări

- WPSPQRDocument11 paginiWPSPQR0502raviÎncă nu există evaluări

- TC VerificationDocument33 paginiTC VerificationmaheshÎncă nu există evaluări

- What is InspectionDocument6 paginiWhat is InspectionRathnakrajaÎncă nu există evaluări

- Bend TestDocument2 paginiBend TestFsÎncă nu există evaluări

- Shielded Metal Arc WeldingDocument39 paginiShielded Metal Arc Weldingعزت عبد المنعم100% (1)

- BohlerThyssen PDFDocument386 paginiBohlerThyssen PDFElMacheteDelHuesoÎncă nu există evaluări

- As 5066-2002 Tolerances For ISO Metric Bolts Screws Studs and Nuts - Product Grades A B and CDocument8 paginiAs 5066-2002 Tolerances For ISO Metric Bolts Screws Studs and Nuts - Product Grades A B and CSAI Global - APACÎncă nu există evaluări

- Duqm Refinery Project EPC Package 2 Utilities and Offsites Contract No CNT-1100-1000-007 INSPECTION RELEASE NOTEDocument2 paginiDuqm Refinery Project EPC Package 2 Utilities and Offsites Contract No CNT-1100-1000-007 INSPECTION RELEASE NOTEDadaso Baburao JamdarÎncă nu există evaluări

- Gmaw STTDocument4 paginiGmaw STTAnonymous 0rt9KWmNÎncă nu există evaluări

- BS 1724 (Bronze Welding by Gas)Document24 paginiBS 1724 (Bronze Welding by Gas)nandi_scrÎncă nu există evaluări

- Handle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsDocument1 paginăHandle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsSAKTHIVEL AÎncă nu există evaluări

- PQR Editable SampleDocument2 paginiPQR Editable SampleKoya ThangalÎncă nu există evaluări

- The Complete Guide to Telephone Interview Questions and AnswersDe la EverandThe Complete Guide to Telephone Interview Questions and AnswersÎncă nu există evaluări

- TSWR Sling Inspection ReportDocument1 paginăTSWR Sling Inspection ReportWalter TrajadaÎncă nu există evaluări

- Cast Iron Turning Insert Selection GuideDocument4 paginiCast Iron Turning Insert Selection GuideDominick JosephÎncă nu există evaluări

- Le Bidas - Bearing Failure Mode 2017 PDFDocument1 paginăLe Bidas - Bearing Failure Mode 2017 PDFWilfried BarrosÎncă nu există evaluări

- PHB 5 PDFDocument22 paginiPHB 5 PDFestephan82Încă nu există evaluări

- WeldingDocument16 paginiWeldinghadeÎncă nu există evaluări

- Resistance WeldingDocument5 paginiResistance WeldingJoel BrasilBorgesÎncă nu există evaluări

- Pei Wu PHDDocument171 paginiPei Wu PHDJoel BrasilBorgesÎncă nu există evaluări

- WT1 IntroDocument3 paginiWT1 IntroJoel BrasilBorgesÎncă nu există evaluări

- AWS Standards Complete List 0503Document4 paginiAWS Standards Complete List 0503Ron GoolsbyÎncă nu există evaluări

- Motoman XRC 2001 Control With Auto AxcessDocument24 paginiMotoman XRC 2001 Control With Auto AxcessEduardo Castillo ZuñigaÎncă nu există evaluări

- Microstructure and Mechanical Properties of Resistance Spot Welded Advanced High Strength SteelsDocument9 paginiMicrostructure and Mechanical Properties of Resistance Spot Welded Advanced High Strength SteelsJoel BrasilBorgesÎncă nu există evaluări

- Electrode Material SelectionDocument1 paginăElectrode Material SelectionJoel BrasilBorgesÎncă nu există evaluări

- Microtip Minimizing Weld SplashDocument2 paginiMicrotip Minimizing Weld SplashJoel BrasilBorgesÎncă nu există evaluări

- S PDFDocument32 paginiS PDFJoel BrasilBorgesÎncă nu există evaluări

- WeldingDocument16 paginiWeldinghadeÎncă nu există evaluări

- Welding NormsDocument14 paginiWelding NormsimupathanÎncă nu există evaluări

- Far Son 2003Document8 paginiFar Son 2003Joel BrasilBorgesÎncă nu există evaluări

- Design Guidelines - Spot Welding ChapterDocument11 paginiDesign Guidelines - Spot Welding ChapterJoel BrasilBorgesÎncă nu există evaluări

- Pod Raj 2008Document11 paginiPod Raj 2008Joel BrasilBorgesÎncă nu există evaluări

- F 201504271430187023Document4 paginiF 201504271430187023Joel BrasilBorgesÎncă nu există evaluări

- Miller SSW Spot WelderDocument4 paginiMiller SSW Spot WelderJoel BrasilBorgesÎncă nu există evaluări

- Pod Raj 2008Document11 paginiPod Raj 2008Joel BrasilBorgesÎncă nu există evaluări

- Spot Weld Tensile Testing MachineDocument3 paginiSpot Weld Tensile Testing MachineJoel BrasilBorgesÎncă nu există evaluări

- WeldingDocument16 paginiWeldinghadeÎncă nu există evaluări

- Projection Design & EquipmentDocument11 paginiProjection Design & EquipmentJoel BrasilBorgesÎncă nu există evaluări

- Welding NormsDocument14 paginiWelding NormsimupathanÎncă nu există evaluări

- Resistance WeldingDocument5 paginiResistance WeldingJoel BrasilBorgesÎncă nu există evaluări

- Resistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IDocument12 paginiResistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IJoel BrasilBorgesÎncă nu există evaluări

- Application Data SheetDocument4 paginiApplication Data SheetJoel BrasilBorgesÎncă nu există evaluări

- Numerical Study of Electrode Geometry Effects On Resistance Spot WeldingDocument10 paginiNumerical Study of Electrode Geometry Effects On Resistance Spot WeldingJoel BrasilBorgesÎncă nu există evaluări

- Projection Welding - Balance Heat and Extend Electrode LifeDocument4 paginiProjection Welding - Balance Heat and Extend Electrode LifeJoel BrasilBorgesÎncă nu există evaluări

- Resistance Welding - Amada Miyachi CoDocument5 paginiResistance Welding - Amada Miyachi CoJoel BrasilBorgesÎncă nu există evaluări

- Remedy Shortcut Keys: Home Solutions & Services Products Partners Support Education ConnectDocument2 paginiRemedy Shortcut Keys: Home Solutions & Services Products Partners Support Education Connectaert5683Încă nu există evaluări

- E No Ad Release NotesDocument6 paginiE No Ad Release NotesKostyantinBondarenkoÎncă nu există evaluări

- 71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldDocument2 pagini71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldicantakeyouupÎncă nu există evaluări

- Cs 2032 Data Warehousing and Data Mining Question Bank by GopiDocument6 paginiCs 2032 Data Warehousing and Data Mining Question Bank by Gopiapi-292373744Încă nu există evaluări

- Concepts in Enterprise Resource Planning: Chapter Six Human Resources Processes With ERPDocument39 paginiConcepts in Enterprise Resource Planning: Chapter Six Human Resources Processes With ERPasadnawazÎncă nu există evaluări

- Expressing Interest in NIBAV LiftsDocument9 paginiExpressing Interest in NIBAV LiftsSetiawan RustandiÎncă nu există evaluări

- Final Slip2Document30 paginiFinal Slip2rohan pawarÎncă nu există evaluări

- List of Family Outing EpisodesDocument7 paginiList of Family Outing EpisodesFanny KesumaliaÎncă nu există evaluări

- Service Level ManagementDocument8 paginiService Level Managementrashmib1980Încă nu există evaluări

- Chapter 9 PowerPointDocument33 paginiChapter 9 PowerPointYusrah JberÎncă nu există evaluări

- Wills and Succession ReviewerDocument85 paginiWills and Succession ReviewerYoshimata Maki100% (1)

- Vissim 11 - ManualDocument1.219 paginiVissim 11 - Manualmauricionsantos60% (5)

- QSK60 G6 PDFDocument2 paginiQSK60 G6 PDFShahzad Ali100% (2)

- Flygt 3202 PDFDocument137 paginiFlygt 3202 PDFEduardo50% (2)

- A Review of Bharat Nirman ProgrammeDocument3 paginiA Review of Bharat Nirman Programmevivek559Încă nu există evaluări

- QUIZ - FinalsDocument5 paginiQUIZ - FinalsFelsie Jane PenasoÎncă nu există evaluări

- Προσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςDocument20 paginiΠροσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςARISTEIDIS VIKETOSÎncă nu există evaluări

- 2 - Brief Report On Logistics Workforce 2019Document39 pagini2 - Brief Report On Logistics Workforce 2019mohammadÎncă nu există evaluări

- MAINTENANCE AND RELIABILITY ENGINEERING - Lecture 1Document24 paginiMAINTENANCE AND RELIABILITY ENGINEERING - Lecture 1K ULAGANATHANÎncă nu există evaluări

- Why The Bollard Pull Calculation Method For A Barge Won't Work For A Ship - TheNavalArchDocument17 paginiWhy The Bollard Pull Calculation Method For A Barge Won't Work For A Ship - TheNavalArchFederico BabichÎncă nu există evaluări

- Real Estate Merger Motives PDFDocument13 paginiReal Estate Merger Motives PDFadonisghlÎncă nu există evaluări

- Company Profile 2016 PDFDocument81 paginiCompany Profile 2016 PDFabioduncityÎncă nu există evaluări

- Andhra Pradesh Land Reforms (Ceiling On Agricultural Holdings) (Amendment) Act, 2009Document3 paginiAndhra Pradesh Land Reforms (Ceiling On Agricultural Holdings) (Amendment) Act, 2009Latest Laws TeamÎncă nu există evaluări

- Product Bulletin VHP7104GSI S5Document2 paginiProduct Bulletin VHP7104GSI S5Wiliam SeguraÎncă nu există evaluări

- Identifying Social Engineering Attacks - Read World ScenarioDocument4 paginiIdentifying Social Engineering Attacks - Read World Scenarioceleste jonesÎncă nu există evaluări

- Ceramic Disc Brakes: Haneesh James S ME8 Roll No: 20Document23 paginiCeramic Disc Brakes: Haneesh James S ME8 Roll No: 20Anil GöwđaÎncă nu există evaluări

- Brushed Axial Fans: VA85-A101-96A Performance DiagramDocument3 paginiBrushed Axial Fans: VA85-A101-96A Performance DiagramJaskaran SinghÎncă nu există evaluări

- Gmail - MOM For Plumeria Garden Estate - MyGateDocument1 paginăGmail - MOM For Plumeria Garden Estate - MyGateAjit KumarÎncă nu există evaluări

- Improving Network Quality Through RTPO 2.0 InitiativesDocument21 paginiImproving Network Quality Through RTPO 2.0 InitiativesArgya HarishÎncă nu există evaluări

- 09 e 4150 C 0305 CB 1 A 37000000Document217 pagini09 e 4150 C 0305 CB 1 A 37000000Dani GarnidaÎncă nu există evaluări