Documente Academic

Documente Profesional

Documente Cultură

LTS CVG SCG 3082 001 B0

Încărcat de

Alhad PanwalkarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LTS CVG SCG 3082 001 B0

Încărcat de

Alhad PanwalkarDrepturi de autor:

Formate disponibile

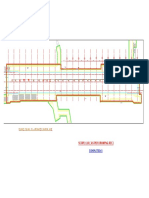

12 11 10 9 8 7 6 5 4 3 2 1

SUPPORTING ISMC 125 ISMC 125

1200 1200 ARRANGEMENT LACINGS (TYP.) BILL OF QUANTITES

LACINGS (TYP.) 12THK GUSSET PLATE

273 273 SUPPORTING 273 273 FOR MAIN BEAM 250Ø

ARRANGEMENT (REFER SEPARATE DRAWING) 12Thk. GUSSET ITEM LENGTH NOS. WEIGHT IN KG. No. OF WT. OF ALL

NB PIPE (H) (TYP) DESCRIPTION

A PLATE (TYP) NOS. (IN MM) REQD. UNIT WT. TOTAL WT. WT.PER MK.ER. MK.

FOR MAIN BEAM (TYP)

100

(REFER SEPARATE (TYP)

(TYP) 1 NB 250 PIPE (H) 30400 4 38.90 4730.24

DRAWING) COMPOSITE COLUMN

H (TYP) 250Ø NB PIPE (H) H

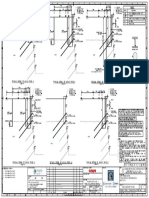

ISA 90x90x6THK 8THK GUSSET PLATE 38

20THK 2 ISA 90x90x6THK 887 8.20 276.38

LACINGS FILLED WITH FREE

(TYP) (TYP) TIE PLT

FLOWING CONCRETE

1200

(TYP.) (TYP) 3 195X8 THK. GUSSET. PLATE 400 2 62.80 9.79

(TYP) (M40) (TYP)

8Thk. GUSSET 4 135X8 THK. GUSSET. PLATE 160 2 62.80 2.71

PLATE (TYP) LACINGS

ISA 90X90X6THK 5 ISA 90x90x6THK 1164 34 8.20 324.52

(TYP)

1200

6 195X8 THK. GUSSET. PLATE 660 32 62.80 258.63

(TYP)

(TYP)

Y COMPOSITE COLUMN ITEM NO.11

250Ø NB PIPE (H) 7 160X8 THK. GUSSET. PLATE 175 36 62.80 63.30

X

(TYP) ISMC 125 FILLED WITH FREE

SECTION 4-4 LACINGS

SECTION 2-2 SECTION 3-3 FLOWING CONCRETE

8 195X8 THK. GUSSET. PLATE 700 2 62.80 17.14

1200

(TYP.) (M40)(TYP) 2

9 ISA 90x90x6THK 1258 8.20 20.63

ISA 90x90x6THK COMPOSITE COLUMN

LACINGS 250Ø NB PIPE (H) 10 190X8 THK. GUSSET. PLATE 415 2 62.80 9.90

(TYP.) STRUT-1 FILLED WITH FREE

STRUT-2 (TYP)

ISMC 125 FLOWING CONCRETE

1200

ISA 90x90x8Thk. 11 927X20 THK. TIE. PLT 1200 4 157.00 349.29

ISA 90x90x8Thk. (TYP.) (M40)(TYP)

G LACINGS (TYP.) G

LACINGS (TYP.) 12 NOT USED - - - -

(TYP) (TYP) BASE SLAB

10Thk. GUSSET

10Thk. GUSSET BOTTOM LVL 13 ISA 90x90x8THK 887 38 10.80 364.02

PLATE (TYP) TIE PLT

1200

PLATE (TYP) 0 0

ISA 90x90x8Thk. 20mm 1 4 P) 20mm 1 4 P) 14 220X12 THK. GUSSET. PLATE 395 2 94.20 16.37

Y Y

LACINGS (TYP.) ISA 90x90x8Thk. GAP (T GAP (T

LACINGS (TYP.) 15 170X12 THK. GUSSET. PLATE 180 2 94.20 5.76

10Thk. GUSSET PLUNGE

10Thk. GUSSET COLUMN

PLATE (TYP) ° 0. 5 4 16 ISMC 125 1129 34 13.10 502.85

PLATE (TYP)

1200

(TYP) 6

(TYP)

45 ° 6 17 230X12 THK. GUSSET. PLATE 720 32 94.20 499.18

ISA 90x90x6THK

LACINGS ISMC 125 18 175X12 THK. GUSSET. PLATE 180 34 94.20 100.88

(TYP.) (TYP.)

(TYP) SECTION5-5 CANTILEVER (TYP) 19 200X8 THK. BATTEN PLATE 1200 2 62.80 30.14

1200

SECTION 6-6 CANTILEVER

BRACKET

BRACKET 20 230X12 THK. GUSSET. PLATE 755 2 94.20 32.71

21 ISMC 125 1217 2 13.10 31.88

DETAIL-B DETAIL-C

TYPICAL DETAIL OF

1200

F ISMB 100 F

22 225X12 THK. GUSSET. PLATE 475 2 94.20 20.13

5THK STIFF PLATE

(TYP) CONCRETE BORE 23

(TYP) 170X12 THK. GUSSET. PLATE 180 2 94.20 5.76

120Ø HOLE FOR

C 4MPA UCS VALUE IS CONSIDERED BELOW ISA 90x90x8THK 1381

STRUT FILLING CONCRETE 24 2 10.80 29.82

1200

BASE SLAB LEVEL BASED ON BORE LOG

TOP PLATE CG-BH-04 FOR LD CALCULATION 25 ISA 90x90x8THK 583 4 10.80 25.18

ISMB 100

ISMC 125

LACINGS 12Ø REBAR 26 ISA 90x90x8THK 683 2 10.80 14.75

(TYP.) (TYP)

1200

23400

(TYP) 27 224X10 THK. GUSSET. PLATE 400 2 78.50 14.06

CL OF STRUT (TYP) 28 140X10 THK. GUSSET. PLATE 160 8 78.50 14.06

TOP PLATE

(TYP)

29 ISMB 150 850 4 15.00 51.00

1200

(TYP)

(TYP) 30 35X5 THK. STIFF PLATE 150 10 39.25 2.06

ISMB 150 (TYP)

31 ISMB 100 662 4 11.40 30.18

E (TYP) E

372 ISMB 100 658

Ø 32 4 11.40 30.01

1200

(TYP)

250NB PIPE

5THK STIFF PLATE 33 23x5 THK. STIFF PLATE 100 10 39.25 0.90

(TYP) 250NB PIPE

12Ø REBAR (TYP) 34 ISMC 100 901 4 9.56 34.45

(TYP)

DETAIL-A (TYP)

CONNECTION DETAIL OF

1200

35 ISA 45x45x6THK 1363 4 4.50 36.80

ISMC 100 TYPICAL ARRANGEMENT AT PC & ITEM 29,32,34

TOP OF PLUNGE COLUMN

120Ø HOLE FOR SECTION 7-7 36 350X20 THK. PLATE 450 4 157.00 98.91

FILLING CONCRETE

(TYP) 37 125X12 THK. PLATE 125 16 94.20 23.55

1200

TYPICAL STRUT HOLDING DETAIL CONCRETE INSIDE THIS PORTION SHALL BE 486 87 38 75X12 THK. PLATE 125 8 94.20 7.07 8085.01 8 64680.08

311 120

CHIPPED OFF & TOP PLATE WELDED WITH

TOTAL WT IN Kgs = 64680.08

ANCHOR BARS SHALL BE PLACED OVER THE

ISA 90x90x8THK NB PIPE & AGAIN REFILLED WITH REQUIRED

195

50

1200

160

LACINGS GRADE OF CONCRETE TILL THE TOP OF PLATE.

195

108

108

STRUT

(TYP.) ISMB 100

105

D COMPOSITE COLUMN D

ISMB 100 250Ø NB PIPE (H) ISMC 125 135 660

(TYP) 400

(TYP) FILLED WITH FREE

1200

FLOWING CONCRETE ISA 45x45x6THK

(TYP)

(TYP) 1. GROUTING SHALL BE CARRIED OUT BY 100mm

2. GROUT SPECIFICATION

(I) MAX AGGREGATE SIZE = 7mm

1200

(II) WATER CEMENT RATIO = 0.45

(III) SLUMP = 150±25mm

(IV) CONSISTENCY = PUMPABLE

3. GROUT SHALL BE PUMPED AT MINIMUM OF 1ATM

120 28 PRESSURE AND MAX OF 5ATM PRESSURE.

(TYP) 4. THE GROUT SHALL BE FREE FROM SEGREGATION,

SLUMPING & BLEEDING.

1400

5. APPROPRIATE NON SHRINK ADMIXTURES SHALL BE

50

50

USED FOR THE GROUT CONSISTENCY.

160

300

20THK TIE PLT

175

ENSURE THAT CONCRETE SHALL BE FILLED

(TYP)

C OUTSIDE THE NB PIPE THROUGHOUT THE C

ITEM NO.10

1200

BASE SLAB

ISA 45x45x6THK

ITEM NO.07 ITEM NO.08 EMBEDMENT LENGTH TILL THE BASE SLAB BOTTOM.

BOTTOM LVL

CONCRETING SHALL BE DONE AS PER APPROVED

(TYP) METHODOLOGY TO ENSURE THE QUALITY OF

400

CONCRETE INSIDE NB PIPE FOR COMPOSITE ACTION

ISA 45x45x6THK ISMB 150

245 155

52

54

(TYP) SECTION 9-9 ENSURE THAT CONCRETE SHALL BE OF FREE FLOWING

EMBEDMENT LENGTH

ISMC 100 ISMB 150

99 TYPE & THERE SHALL NOT BE ANY VOIDS INSIDE THE PIPE.

SECTION 8-8

120

224

120

5500

283 180 109 534

109 501

155 246

50

180

52

50

50

475

ITEM NO.27

120

220

230

367

230

170

28 120

175

340 340

121

108

121

121

170

99

120

PLUNGE COLUMN PC1 395 50

720 50 755

B ALONG X-X AXIS 180 B

225

SPECIAL HOLES SHALL BE PROVIDED AT SIDES

OF NB PIPE AT BOTTOM EMBEDMENT LENGTH ITEM NO.14 ITEM NO.15 ITEM NO.17 ITEM NO.18 ITEM NO.20 ITEM NO.22 ITEM NO.23

PORTION FOR SPREADING OF GROUT

1. ALL DIMENSIONS ARE IN MILLIMETRES. MUMBAI METRO RAIL CORPORATION LTD.

2.ALL NB PIPES SHALL CONFIRM TO IS 1161-1998 AND OF GRADE YSt310.

3.ALL WELDS ARE 5mm FILLET WELDS UNLESS OTHERWISE SPECIFIED

4. THE CUT LENGTH OF MEMBERS AND THE Nos. REQUIRED SHALL BE

DETERMINED AT SITE BY FULL SCALE LAYOUT.

5. GRADE OF STRUCTURAL STEEL SHALL BE E250(FE410W) GRADE A (OR) B

& SHALL BE IN ACCORDANCE WITH IS 2062.

CHURCHGATE STATION

6.THIS DRAWING SHALL BE READ IN CONJUNCTION WITH OUR LATEST

DRAWING NO: LTS-CVG-SCP-2083-001

FABRICATION DETAIL OF

7.GRADE OF INFILL CONCRETE FOR PIPE SHALL BE M40 AS MENTIONED IN PLUNGE COLUMN PC1 FOR

SPECIFIED LOCATION

8. TOLERANCE FOR PLUNGE COLUMN 1:200 (OR) 75mm WHICHEVER IS LESS

Mumbai Metro Line - 3 SUPPORTING TRAFFIC DECKING

A 9. EMBEDMENT LENGTH IS CALCULATED BASED ON BORE LOG CGBH-04 A

PARAMETERS AVAILABLE IN GEOFACTURAL REPORT

10. ALL WELDS SHALL BE TESTED BY DYE PENETRATION TEST LTS-CVG-SCG-3082-001 B0 D

11.TO ACHIEVE REQUIRED HEIGHT OF PIPE NB PIPE SHALL BE B0 04.09.17 REVISED AS PER SITE REQUIREMENT L&T – STEC JV MUMBAI

CONNECTED BY FULL PENETRATION BUTT WELD, SPLICE JOINT OF EACH D.LINGESH ARAVIND ASHOK A VIJAYAKUMAR T

PIPE IN A GROUP SHALL BE STAGGERED AND AT ANY CASE SPLICE OF A 12.07.17 DBRN FOR APPROVAL DLH ARD TVK

MORE THAN ONE PIPE SHALL NOT COME IN A PLANE

1:50 BASKARAN D 12.07.2017 LTS-CVG-SCG-3082-001

12 11 10 9 8 7 6 5 4 3 2 1

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Churchgate Station Mumbai Metro Rail Grid DetailsDocument1 paginăChurchgate Station Mumbai Metro Rail Grid DetailsAlhad PanwalkarÎncă nu există evaluări

- UGC-01-CAC-SCG-3XXX-XX2: Churchgate Station Temporary Secant Pile Wall Elevation Sheet 2 of 3Document1 paginăUGC-01-CAC-SCG-3XXX-XX2: Churchgate Station Temporary Secant Pile Wall Elevation Sheet 2 of 3Alhad PanwalkarÎncă nu există evaluări

- 2017-06-28 MMRC Presentation - Column Options-2017-06-28 - LatestDocument49 pagini2017-06-28 MMRC Presentation - Column Options-2017-06-28 - LatestAlhad PanwalkarÎncă nu există evaluări

- List of Drawings: LTS-CAC-SCG-3920-001Document1 paginăList of Drawings: LTS-CAC-SCG-3920-001Alhad PanwalkarÎncă nu există evaluări

- Churchgate Station Temporary Secant Pile Wall Elevation Sheet 1 of 3Document1 paginăChurchgate Station Temporary Secant Pile Wall Elevation Sheet 1 of 3Alhad PanwalkarÎncă nu există evaluări

- Plunge Col Progress SCG PrésentationDocument1 paginăPlunge Col Progress SCG PrésentationAlhad PanwalkarÎncă nu există evaluări

- Churchgate Station Mumbai Metro Rail Grid DetailsDocument1 paginăChurchgate Station Mumbai Metro Rail Grid DetailsAlhad PanwalkarÎncă nu există evaluări

- Churchgate Station Mumbai Metro Rail Grid DetailsDocument1 paginăChurchgate Station Mumbai Metro Rail Grid DetailsAlhad PanwalkarÎncă nu există evaluări

- UGC-01-CAC-SCG-3XXX-001: Churchgate Station GRID 02 - 14, LVL-5 Sheet 1 of 2Document1 paginăUGC-01-CAC-SCG-3XXX-001: Churchgate Station GRID 02 - 14, LVL-5 Sheet 1 of 2Alhad PanwalkarÎncă nu există evaluări

- UGC-01-CAC-SCG-3XXX-001: Churchgate Station GRID 02 - 14, LVL-5 Sheet 1 of 2Document1 paginăUGC-01-CAC-SCG-3XXX-001: Churchgate Station GRID 02 - 14, LVL-5 Sheet 1 of 2Alhad PanwalkarÎncă nu există evaluări

- 2017-06-28 MMRC Presentation - Column Options-2017!06!28 - LatestDocument49 pagini2017-06-28 MMRC Presentation - Column Options-2017!06!28 - LatestAlhad PanwalkarÎncă nu există evaluări

- TTA 465 C0U 1102001 A Geotechnical Interpretative ReportDocument81 paginiTTA 465 C0U 1102001 A Geotechnical Interpretative ReportAlhad PanwalkarÎncă nu există evaluări

- Pile Progress CG PrésentationDocument1 paginăPile Progress CG PrésentationAlhad PanwalkarÎncă nu există evaluări

- Pile Progress CG PrésentationDocument1 paginăPile Progress CG PrésentationAlhad PanwalkarÎncă nu există evaluări

- LTS Geo SCG 17 2301 ADocument135 paginiLTS Geo SCG 17 2301 AAlhad PanwalkarÎncă nu există evaluări

- Churchgate Station Corners StabilityDocument13 paginiChurchgate Station Corners StabilityAlhad PanwalkarÎncă nu există evaluări

- Geological Profile With GridsDocument1 paginăGeological Profile With GridsAlhad PanwalkarÎncă nu există evaluări

- Pile Progress CG PrésentationDocument1 paginăPile Progress CG PrésentationAlhad PanwalkarÎncă nu există evaluări

- Geological Profile With Grid No SCGDocument1 paginăGeological Profile With Grid No SCGAlhad PanwalkarÎncă nu există evaluări

- BOQ Hutatma Chowk Secant Pile R1Document1 paginăBOQ Hutatma Chowk Secant Pile R1Alhad PanwalkarÎncă nu există evaluări

- Cuffe Parade Cuffe Parade: UGC-01-GEO-SCP-1101-002Document1 paginăCuffe Parade Cuffe Parade: UGC-01-GEO-SCP-1101-002Alhad PanwalkarÎncă nu există evaluări

- Mumbai Metro Rail Project Line - 3 Colaba-Bandra-SeepzDocument1 paginăMumbai Metro Rail Project Line - 3 Colaba-Bandra-SeepzAlhad PanwalkarÎncă nu există evaluări

- Ugc 01 Geo SCP 1100 001 ADocument1 paginăUgc 01 Geo SCP 1100 001 AAlhad PanwalkarÎncă nu există evaluări

- Ugc 01 Geo SCP 1101 005 ADocument1 paginăUgc 01 Geo SCP 1101 005 AAlhad PanwalkarÎncă nu există evaluări

- UGC-01-GEO-SCP-1101-001: Cuffe Parade Station Anticipated Settlement Contour PlanDocument1 paginăUGC-01-GEO-SCP-1101-001: Cuffe Parade Station Anticipated Settlement Contour PlanAlhad PanwalkarÎncă nu există evaluări

- LTS Cac SCG 3902 001 B PDFDocument1 paginăLTS Cac SCG 3902 001 B PDFAlhad PanwalkarÎncă nu există evaluări

- UGC-01-GEO-SCP-1101-003: Cuffe Parade Station Typical Arrays of InstrumentationDocument1 paginăUGC-01-GEO-SCP-1101-003: Cuffe Parade Station Typical Arrays of InstrumentationAlhad PanwalkarÎncă nu există evaluări

- Ugc 01 Geo SCP 1100 002 ADocument1 paginăUgc 01 Geo SCP 1100 002 AAlhad PanwalkarÎncă nu există evaluări

- SCG - Soldier Pile - Sketch 1Document1 paginăSCG - Soldier Pile - Sketch 1Alhad PanwalkarÎncă nu există evaluări

- SCG - Strut Forces SummaryDocument25 paginiSCG - Strut Forces SummaryAlhad PanwalkarÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Masteringphys 14Document20 paginiMasteringphys 14CarlosGomez0% (3)

- USDA Guide To CanningDocument7 paginiUSDA Guide To CanningWindage and Elevation0% (1)

- Dermatology Study Guide 2023-IvDocument7 paginiDermatology Study Guide 2023-IvUnknown ManÎncă nu există evaluări

- There Is There Are Exercise 1Document3 paginiThere Is There Are Exercise 1Chindy AriestaÎncă nu există evaluări

- 2010 HD Part Cat. LBBDocument466 pagini2010 HD Part Cat. LBBBuddy ButlerÎncă nu există evaluări

- Easa Management System Assessment ToolDocument40 paginiEasa Management System Assessment ToolAdam Tudor-danielÎncă nu există evaluări

- Ansible Playbook for BeginnersDocument101 paginiAnsible Playbook for BeginnersFelix Andres Baquero Cubillos100% (1)

- How To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Document31 paginiHow To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Myster HighÎncă nu există evaluări

- ERIKS Dynamic SealsDocument28 paginiERIKS Dynamic Sealsdd82ddÎncă nu există evaluări

- EXPERIMENT 4 FlowchartDocument3 paginiEXPERIMENT 4 FlowchartTRISHA PACLEBÎncă nu există evaluări

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocument564 paginiPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuÎncă nu există evaluări

- IQ CommandDocument6 paginiIQ CommandkuoliusÎncă nu există evaluări

- SolBridge Application 2012Document14 paginiSolBridge Application 2012Corissa WandmacherÎncă nu există evaluări

- Kaydon Dry Gas SealDocument12 paginiKaydon Dry Gas Sealxsi666Încă nu există evaluări

- Strategies For StartupDocument16 paginiStrategies For StartupRoshankumar BalasubramanianÎncă nu există evaluări

- Beauty ProductDocument12 paginiBeauty ProductSrishti SoniÎncă nu există evaluări

- LIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEDocument126 paginiLIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEBASIT Ali KhanÎncă nu există evaluări

- The Service Marketing Plan On " Expert Personalized Chef": Presented byDocument27 paginiThe Service Marketing Plan On " Expert Personalized Chef": Presented byA.S. ShuvoÎncă nu există evaluări

- Bad DayDocument3 paginiBad DayLink YouÎncă nu există evaluări

- Corporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Document18 paginiCorporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Lia asnamÎncă nu există evaluări

- Basic Features of The Microcredit Regulatory Authority Act, 2006Document10 paginiBasic Features of The Microcredit Regulatory Authority Act, 2006Asif Hasan DhimanÎncă nu există evaluări

- SBI Sample PaperDocument283 paginiSBI Sample Paperbeintouch1430% (1)

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDocument24 pagini4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloÎncă nu există evaluări

- A Reconfigurable Wing For Biomimetic AircraftDocument12 paginiA Reconfigurable Wing For Biomimetic AircraftMoses DevaprasannaÎncă nu există evaluări

- Checklist of Requirements For OIC-EW Licensure ExamDocument2 paginiChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- DBMS Architecture FeaturesDocument30 paginiDBMS Architecture FeaturesFred BloggsÎncă nu există evaluări

- Assignment Gen PsyDocument3 paginiAssignment Gen PsyHelenÎncă nu există evaluări

- NLP Business Practitioner Certification Course OutlineDocument11 paginiNLP Business Practitioner Certification Course OutlineabobeedoÎncă nu există evaluări

- NABARD road inspection report formatDocument24 paginiNABARD road inspection report formatSrinivas PÎncă nu există evaluări

- Assembly ModelingDocument222 paginiAssembly ModelingjdfdfererÎncă nu există evaluări