Documente Academic

Documente Profesional

Documente Cultură

Seal Replacement Guide

Încărcat de

craigorio616Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Seal Replacement Guide

Încărcat de

craigorio616Drepturi de autor:

Formate disponibile

Document Number: 903132 Revision: A

Date: March 22, 2016

Description: Seal Replacement Instructions

Sheet: Page 1 of 5

REV CHANGE DESCRIPTION ECO # INITIALS DATE

A Release - SF 3/22/15

Overview

This procedure describes the proper installation and conditioning of seals for direct drive

pumps: Mini Series-I, Series-I, Series-I+, M1-Class and MX-Class.

SSI pumps require regular service, typically seal and check valve replacement. The spare

parts and procedures for replacing individual components are covered in other documentation.

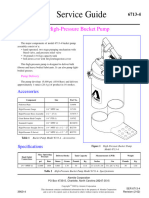

The head and self-flush should look similar to the following:

Document Number: 903132 Revision: A

Date: March 22, 2016

Description: Seal Replacement Instructions

Sheet: Page 2 of 5

Installation Procedure

Before removing the pump head, turn OFF the pump power, and disconnect the inlet and

outlet lines from the check valve housings.

Removing the Fasteners:

Remove the two pump head fasteners.

Step 1

Use a 3/16” hex key for recessed nuts. If

necessary, use pliers for thumb nuts.

Removing the Pump Head:

Carefully pull the pump head forward and

off the guide pins. Pull straight and slowly

to prevent damage to the piston.

Step 2

Note: The seal back-up washer may

remain on the piston. Remove the washer

from the piston if it did not stay in the

pump head.

Removing the Self-Flush:

Carefully separate the flush housing from

the pump. Pull straight and slowly to

prevent damage to the piston.

Step 3 Remove the self-flush diaphragm from the

piston by carefully grasping the sealing

flange on two sides and sliding it straight

out on the piston being careful not to exert

side pressure that may break the piston.

Removing the Seal:

Insert the flanged end of the seal

insertion/removal tool into the seal cavity

on the pump head. Tilt it slightly so that

Step 4 the flange is under the seal, and pull out

the seal.

Caution: Using any other “tool” will

scratch the finish of the sealing surface

and create a leak.

Document Number: 903132 Revision: A

Date: March 22, 2016

Description: Seal Replacement Instructions

Sheet: Page 3 of 5

Cleaning the Piston:

Use the scouring pad included in the seal

replacement kit to clean the piston. Gently

squeeze the piston within a folded section

of the pad and rub the pad along the

length of the piston. Rotate the piston

Step 5 frequently to assure the entire surface is

scrubbed. After scouring, use a lint-free

cloth, dampened with alcohol, to wipe the

piston clean.

Note: Do not exert pressure perpendicular

to the length of the piston, as this may

cause the piston to break.

Replacing the Seal:

Place a high pressure replacement seal on

the rod-shaped end of the seal

insertion/removal tool so that the spring

Step 6 (energizer) is visible when the seal is fully

seated on the tool. Insert the tool into the

pump head.

Note: Be careful to line up the seal with

the cavity while inserting.

Reinstalling the Self-Flush:

Gently place the new diaphragm onto

piston with center hub protruding towards

you. Push diaphragm all the way back

into recess and against metal base of

Step 7 piston. Carefully replace the self-flush

housing, making sure that the O-ring is

properly installed in the self-flush housing.

Caution: Do not exert pressure

perpendicular to the length of the piston,

as this may cause the piston to break.

Document Number: 903132 Revision: A

Date: March 22, 2016

Description: Seal Replacement Instructions

Sheet: Page 4 of 5

Reinstalling the Pump Head:

Place the seal back-up washer on the

piston. Replace the pump head. Make

sure that the inlet check valves are on the

bottom and the outlet check valves are on

Step 8 top.

Note: Push onto guide pins straight and

slowly to prevent damage to the piston.

Do not force the self-flush housing or

pump head into place.

Reinstalling the Fasteners:

Reinstall fasteners. As you tighten,

alternate side-to-side until snug. For

Step 9

recessed nuts, turn 1 flat past snug using

a 3/16” hex key. For thumb nuts, turn 1/6

rotation past snug; if necessary, use pliers.

Document Number: 903132 Revision: A

Date: March 22, 2016

Description: Seal Replacement Instructions

Sheet: Page 5 of 5

Condition the Seal(s)

New seals must be conditioned prior to use. Conditioning is the process of running the seals

wet under controlled conditions to allow surfaces to seat and break-in for proper function of the

seal.

Note: Use only pure solvents to condition new seals. Buffer solutions and salt solutions

should never be used to condition new seals. Recommended solvents are HPLC-grade

methanol, IPA and water, and mixtures of these liquids.

Suggested Conditioning Parameters: Using a restrictor coil or a suitable column, run the

pump with a 50:50 solution of IPA/Water or Methanol/Water for 30 minutes at the back

pressure and flow rate listed under PHASE 1 below, according to the pump head type. Then

run the pump for another 15 minutes under conditions for PHASE 2 below, according to head

type.

PHASE 1

Pump Type Pressure Flow Rate

24 ml/min or less pump 1,000 psi <3 mL/min

40 ml/min or higher pump 250 psi <3 mL/min

PHASE 2

Pump Type Pressure Flow Rate

24 ml/min or less pump 2,000 psi 3-4 mL/min

40 ml/min or higher pump 500 psi <6 mL/min

END OF DOCUMENT

S-ar putea să vă placă și

- Triplex Pump ManualDocument11 paginiTriplex Pump ManualDustin WhiteÎncă nu există evaluări

- Dive Scubapro D400 Maintenance ProcedureDocument5 paginiDive Scubapro D400 Maintenance ProceduremanonpomÎncă nu există evaluări

- Attention!: Lea Antes de Fijar La Manguera de AireDocument8 paginiAttention!: Lea Antes de Fijar La Manguera de AireOlier Muñoz GomezÎncă nu există evaluări

- Fristam Mainten Type FPH - 3542Document12 paginiFristam Mainten Type FPH - 3542Hafid NaufalÎncă nu există evaluări

- Wood's Powr-Grip Guide To Maintenance, Troubleshooting, and RepairDocument4 paginiWood's Powr-Grip Guide To Maintenance, Troubleshooting, and Repairkamikadze7Încă nu există evaluări

- Enerpac P-392 Service InstructionsDocument8 paginiEnerpac P-392 Service InstructionsSergio ReyesÎncă nu există evaluări

- Rainin PipetMan GuideDocument18 paginiRainin PipetMan GuideHector Duchens SilvaÎncă nu există evaluări

- 6801 DeVilbiss HVLP InstructionsDocument8 pagini6801 DeVilbiss HVLP Instructionschris2473Încă nu există evaluări

- Instructions and Parts List For Model 50H Hand-Operated Hydraulic PressDocument6 paginiInstructions and Parts List For Model 50H Hand-Operated Hydraulic PressWaqar DarÎncă nu există evaluări

- PistonDocument5 paginiPistonAna Paula Maia LimaÎncă nu există evaluări

- Fill Rite Series 5200 Piston Hand Pump OIPMDocument8 paginiFill Rite Series 5200 Piston Hand Pump OIPMElmeri Fidel Gomez AriasÎncă nu există evaluări

- 9E-A User Manuals and ServiceDocument10 pagini9E-A User Manuals and Servicerponce161276Încă nu există evaluări

- PTS-1028 Ra FC Operation ManualDocument32 paginiPTS-1028 Ra FC Operation ManualOrlando PWRÎncă nu există evaluări

- IH Type Standard Chemical Pump PDFDocument7 paginiIH Type Standard Chemical Pump PDFscribd birdÎncă nu există evaluări

- Maintenance Procedure MK 17Document5 paginiMaintenance Procedure MK 17HankÎncă nu există evaluări

- Dive Scubapro - Mk2+, Mk2 - Maintenance ProcedureDocument4 paginiDive Scubapro - Mk2+, Mk2 - Maintenance ProceduremanonpomÎncă nu există evaluări

- Pump Manual Update June 2018Document8 paginiPump Manual Update June 2018Abdallah AbdelrehimÎncă nu există evaluări

- DAKE Press Model 75 H - 907003Document6 paginiDAKE Press Model 75 H - 907003mark_dayÎncă nu există evaluări

- Service Guide: High-Pressure Bucket PumpDocument10 paginiService Guide: High-Pressure Bucket PumpRodrigoÎncă nu există evaluări

- Single Cylinder Air Compressor Repair ManualDocument13 paginiSingle Cylinder Air Compressor Repair ManualGLÎncă nu există evaluări

- EZClean Pressure Washer Surface Cleaner AttachmentDocument6 paginiEZClean Pressure Washer Surface Cleaner Attachmentmonkey44Încă nu există evaluări

- 1994 Volvo 850 Power Steering 2.4LDocument9 pagini1994 Volvo 850 Power Steering 2.4LKwkeatonÎncă nu există evaluări

- Circulation Pump A27-A30angDocument11 paginiCirculation Pump A27-A30angpavan3229100% (1)

- Owners' Manual PRO Sprayers 996P and 997P: Screw Cap WandDocument2 paginiOwners' Manual PRO Sprayers 996P and 997P: Screw Cap WandmbkÎncă nu există evaluări

- Manual Triplex PumpDocument45 paginiManual Triplex PumpSalineñoApasionado100% (1)

- Carburador Keihin CDKDocument2 paginiCarburador Keihin CDKRosana Espinola100% (1)

- BS-400 - Customer Maintenance Card - V3.0 - ENDocument2 paginiBS-400 - Customer Maintenance Card - V3.0 - ENEmilioPerezBallesterosÎncă nu există evaluări

- Handling and Maintenance of Spray EquipmentDocument34 paginiHandling and Maintenance of Spray EquipmentLuo MiyandaÎncă nu există evaluări

- Midland PumpDocument12 paginiMidland Pumppeters petersÎncă nu există evaluări

- 8359 BDDocument7 pagini8359 BDEduard KönigÎncă nu există evaluări

- Metering Pump Seal Replacement On The HP 1090 Liquid Chromatograph (LC)Document3 paginiMetering Pump Seal Replacement On The HP 1090 Liquid Chromatograph (LC)HamidReza ShahbaaziÎncă nu există evaluări

- Gate Valve Maintenance ManualDocument27 paginiGate Valve Maintenance ManualLeandro100% (1)

- 26850a002 d65 Series Reciprocating Pumps IomDocument16 pagini26850a002 d65 Series Reciprocating Pumps IomIslam ElhabsheÎncă nu există evaluări

- Adjusting Brake Clearance To SpecificationDocument5 paginiAdjusting Brake Clearance To SpecificationMarian Patnaan Rabang100% (1)

- Article Brakes Pad Rear ServiceDocument3 paginiArticle Brakes Pad Rear ServiceAlexander Amaru RuisÎncă nu există evaluări

- KX Free Piston ModDocument2 paginiKX Free Piston ModKidKawie100% (1)

- BR5100 Installation and TroubleshootingDocument2 paginiBR5100 Installation and TroubleshootingRégis OngolloÎncă nu există evaluări

- Udor Maintenance Trouble ShootingDocument4 paginiUdor Maintenance Trouble ShootingMONA100% (1)

- CAV Pintaux Injection Nozzle RebuildDocument6 paginiCAV Pintaux Injection Nozzle RebuildDanny DanÎncă nu există evaluări

- PCT PumpDocument29 paginiPCT PumpMuhammad Junaid AttaÎncă nu există evaluări

- 471 Part%205%20maintenance PDFDocument16 pagini471 Part%205%20maintenance PDFLê Thanh NgọcÎncă nu există evaluări

- SM Tm3989 Knott A4Document1 paginăSM Tm3989 Knott A4Marc GlebÎncă nu există evaluări

- Replace A Pool Motor Shaft SealDocument14 paginiReplace A Pool Motor Shaft SealBenjamin DoverÎncă nu există evaluări

- PG1203Document17 paginiPG1203heriberto8280Încă nu există evaluări

- AutoSparge Owners Manual-V3Document6 paginiAutoSparge Owners Manual-V3Arlex Ricardo Guillen PetitÎncă nu există evaluări

- Mini Jet Wine Filter InstructionsDocument2 paginiMini Jet Wine Filter InstructionsGerry CouturierÎncă nu există evaluări

- 5mL Pipettor Cleaning-CareDocument1 pagină5mL Pipettor Cleaning-CareNavi MoralesÎncă nu există evaluări

- API Gate Valve - WKM Maintenance ManualDocument8 paginiAPI Gate Valve - WKM Maintenance ManualsambhajiÎncă nu există evaluări

- Lab-Manual-BC-2 OriginalDocument32 paginiLab-Manual-BC-2 OriginalLê Thị Hiền100% (1)

- AK4562DDocument4 paginiAK4562DVENTAS PROINMARÎncă nu există evaluări

- LEIBINGER Dismantling and Cleaning The NozzleDocument3 paginiLEIBINGER Dismantling and Cleaning The NozzleRonald Franco Obando100% (1)

- N2 Triplex Pump-MaintenanceDocument14 paginiN2 Triplex Pump-MaintenanceIbrahim AhmedÎncă nu există evaluări

- Dive Scubapro BPI Maintenance ProcedureDocument4 paginiDive Scubapro BPI Maintenance ProceduremanonpomÎncă nu există evaluări

- Poly Transfer Operation ManualDocument12 paginiPoly Transfer Operation Manualab5951Încă nu există evaluări

- Wato 2Document103 paginiWato 2Soluciones Biomedicas de ColombiaÎncă nu există evaluări

- Reciprocating PumpDocument8 paginiReciprocating Pump123rahul456Încă nu există evaluări

- GEARTEK PUMP SERVICE INSTRUCTIONSDocument8 paginiGEARTEK PUMP SERVICE INSTRUCTIONSLorenzoÎncă nu există evaluări

- Two Cycle Carburetor and the Back Alley MechanicDe la EverandTwo Cycle Carburetor and the Back Alley MechanicEvaluare: 4.5 din 5 stele4.5/5 (2)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1De la EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Evaluare: 5 din 5 stele5/5 (2)

- Parenthood and Happiness A ReviewDocument36 paginiParenthood and Happiness A Reviewcraigorio616Încă nu există evaluări

- NE 9000 ManualDocument65 paginiNE 9000 Manualcraigorio616Încă nu există evaluări

- BAA 18 100 SOL 00003 - Amendment - 13 - 20200304 PDFDocument117 paginiBAA 18 100 SOL 00003 - Amendment - 13 - 20200304 PDFcraigorio616Încă nu există evaluări

- As 97064 FD-X C 611H53 Us 1059-3Document28 paginiAs 97064 FD-X C 611H53 Us 1059-3Ryan WilliamsÎncă nu există evaluări

- WS AutomaRules r5 LRDocument4 paginiWS AutomaRules r5 LRcraigorio616Încă nu există evaluări

- PictionaryDocument1 paginăPictionaryMagzi MaglenteÎncă nu există evaluări

- WS Scoresheet r2 PDFDocument1 paginăWS Scoresheet r2 PDFcraigorio616Încă nu există evaluări

- Wingspan - BonusCards - r4 - 26CardPack - JameyDocument6 paginiWingspan - BonusCards - r4 - 26CardPack - Jameycraigorio616Încă nu există evaluări

- Pictionary Words Hard 2 PDFDocument2 paginiPictionary Words Hard 2 PDFcraigorio616Încă nu există evaluări

- Antibodies 08 00011 v2Document31 paginiAntibodies 08 00011 v2craigorio616Încă nu există evaluări

- Man 4820 3601 LC Vanquish UHPLC Man48203601 ENDocument144 paginiMan 4820 3601 LC Vanquish UHPLC Man48203601 ENcraigorio616Încă nu există evaluări

- Controller 2 11 enDocument114 paginiController 2 11 encraigorio616Încă nu există evaluări

- Pictionary Words Really Hard PDFDocument1 paginăPictionary Words Really Hard PDFcraigorio616Încă nu există evaluări

- Pictionary Words EasyDocument1 paginăPictionary Words Easycontact 2 webÎncă nu există evaluări

- Pictionary Words HardDocument1 paginăPictionary Words HardAnonymous vkHLaXxOCLÎncă nu există evaluări

- Pictionary Words Idioms PDFDocument1 paginăPictionary Words Idioms PDFcraigorio616Încă nu există evaluări

- TV Software Update Guide v3 PDFDocument44 paginiTV Software Update Guide v3 PDFAnderson CapristanÎncă nu există evaluări

- Pictionary Words Medium 2 PDFDocument2 paginiPictionary Words Medium 2 PDFAnsdÎncă nu există evaluări

- Colibri SampleDocument26 paginiColibri SampleGergő Attila TóthÎncă nu există evaluări

- Pictionary Words Easy 2Document1 paginăPictionary Words Easy 2Sara SaavedraÎncă nu există evaluări

- Pictionary Words Medium PDFDocument1 paginăPictionary Words Medium PDFcraigorio616Încă nu există evaluări

- VIND Rulebook FINAL PRESS 190403 PDFDocument44 paginiVIND Rulebook FINAL PRESS 190403 PDFcraigorio616Încă nu există evaluări

- Cn32Pt, Cn16Pt, Cn16Ptd, Cn8Pt, Cn8Ptd, Cn8Ept: Temperature & Process ControllersDocument79 paginiCn32Pt, Cn16Pt, Cn16Ptd, Cn8Pt, Cn8Ptd, Cn8Ept: Temperature & Process Controllerscraigorio616Încă nu există evaluări

- Pictionary Words PeopleDocument1 paginăPictionary Words PeopletebugreenÎncă nu există evaluări

- Ugears Monowheel Assembly InstructionsDocument24 paginiUgears Monowheel Assembly Instructionscraigorio616Încă nu există evaluări

- Adaptable Reactor Technology - ChameleonDocument2 paginiAdaptable Reactor Technology - Chameleoncraigorio616Încă nu există evaluări

- Ugears Card Holder InstructionDocument16 paginiUgears Card Holder Instructioncraigorio616Încă nu există evaluări

- Jabra Speak 710 User Manual RevB enDocument25 paginiJabra Speak 710 User Manual RevB enkarthi_kuttyÎncă nu există evaluări

- Deep-Well Plates: BRAND. For Lab. For LifeDocument4 paginiDeep-Well Plates: BRAND. For Lab. For Lifecraigorio616Încă nu există evaluări

- In These Classrooms, Chemistry Is Part of A Larger WholeDocument12 paginiIn These Classrooms, Chemistry Is Part of A Larger Wholecraigorio616Încă nu există evaluări

- Study of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaDocument8 paginiStudy of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaPratikDedhia99Încă nu există evaluări

- Gas LiftDocument2 paginiGas LiftArmando O GarciaÎncă nu există evaluări

- AP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadDocument16 paginiAP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadpavaniÎncă nu există evaluări

- Lecture 1 SeriesDocument43 paginiLecture 1 SerieschetsÎncă nu există evaluări

- Factors affecting the rate of a chemical reactionDocument15 paginiFactors affecting the rate of a chemical reactionAvÎncă nu există evaluări

- 42 Mab 191Document5 pagini42 Mab 191false mailÎncă nu există evaluări

- Erosion Failure Analysis of CFBC Boiler Using CFDDocument5 paginiErosion Failure Analysis of CFBC Boiler Using CFDOscar DorantesÎncă nu există evaluări

- Re90220 01 - 2011 10Document6 paginiRe90220 01 - 2011 10Parmasamy SubramaniÎncă nu există evaluări

- Velocity For Gas in PipeDocument18 paginiVelocity For Gas in Pipeuche ekeÎncă nu există evaluări

- PDF en Funke Phe En-Gb PDFDocument12 paginiPDF en Funke Phe En-Gb PDFStoianovici CristianÎncă nu există evaluări

- Kul-24.3200 L01 Resistance 001 2015 AutumnDocument45 paginiKul-24.3200 L01 Resistance 001 2015 AutumnBraulyo PimentelÎncă nu există evaluări

- PSV Sizing Tool - API BasedDocument11 paginiPSV Sizing Tool - API BasedJoseph Paul Ilagan0% (1)

- Boling Point CurvesDocument28 paginiBoling Point CurvesMuhammad MohtashimÎncă nu există evaluări

- SPE-17170-PA Numerical Analysis of The Effects of Gravel Packing On Gas Well ProductivityDocument4 paginiSPE-17170-PA Numerical Analysis of The Effects of Gravel Packing On Gas Well ProductivityFerchoMedinaÎncă nu există evaluări

- HMT Answer 2 & 16 Marks HMTDocument85 paginiHMT Answer 2 & 16 Marks HMTChandra Sekar100% (3)

- P.J. Richards and R.P. Hoxey. Appropriate Boundary Conditions For Computational K-E Turbulence ModelDocument9 paginiP.J. Richards and R.P. Hoxey. Appropriate Boundary Conditions For Computational K-E Turbulence ModelOmprakash BhartiÎncă nu există evaluări

- Turbine Start Up ProcedureDocument2 paginiTurbine Start Up ProcedureyuvaduraiÎncă nu există evaluări

- Final 04 SolDocument6 paginiFinal 04 SolHungDo0% (1)

- Fluid Mechanics For Chemical Engineers - Noel de Nevers 2EDocument580 paginiFluid Mechanics For Chemical Engineers - Noel de Nevers 2EJulio Cesar Domingos80% (5)

- H M AravindDocument2 paginiH M AravindAdithya ShankarÎncă nu există evaluări

- Latest Price Lists for Pipes & TubesDocument13 paginiLatest Price Lists for Pipes & TubesDaks Parker40% (5)

- A Comprehensive Analysis of Direct Contact Condensation of Saturated Steam On Subcooled Liquid JetsDocument16 paginiA Comprehensive Analysis of Direct Contact Condensation of Saturated Steam On Subcooled Liquid JetsLuisÎncă nu există evaluări

- System Practices For Ammonia and Carbon Dioxide RefrigerantsDocument27 paginiSystem Practices For Ammonia and Carbon Dioxide Refrigerants1940LaSalleÎncă nu există evaluări

- Be Summer 2020Document2 paginiBe Summer 2020dhruvÎncă nu există evaluări

- 1954 19Document258 pagini1954 19w824rg2Încă nu există evaluări

- Design and Validation of Bellows As Per EJMA-FEA (White Paper) PDFDocument5 paginiDesign and Validation of Bellows As Per EJMA-FEA (White Paper) PDFJaveed A. KhanÎncă nu există evaluări

- SM CHDocument88 paginiSM CHRodel Edra100% (1)

- Netzsch-ARC en Web PDFDocument20 paginiNetzsch-ARC en Web PDFdarksideministryÎncă nu există evaluări

- Pool Filtration PDF Document Aqua Middle East FZCDocument22 paginiPool Filtration PDF Document Aqua Middle East FZCAdolfsmith69Încă nu există evaluări