Documente Academic

Documente Profesional

Documente Cultură

Assignment 1 (B.i, II) CEV544.Vsd

Încărcat de

Faradilah Binti Ajma'inTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Assignment 1 (B.i, II) CEV544.Vsd

Încărcat de

Faradilah Binti Ajma'inDrepturi de autor:

Formate disponibile

QUESTION B (i)

Figure 2: Installation of PID controller in liquid level at the bottom of absorber

The contact with glycol obtained with several equilibrium stages in counter flow with the gas

leads to the dehydration of the latter as it exits the top of the column. The stream of TEG, diluted

by the water which it has absorbed (rich TEG), is discharged from the bottom of the column. As

the rich TEG flow in the bottom, the level controller is used to monitor and control its level using

the control valve in order to make it steady as well as the desired optimum production rate is

achieved. So, this type of control system is known as feedback control system. The feedback

control system can do a corrective action if the liquid level at the bottom has inconsistent flow of

the output that vary from their desired output. Besides, feedback controller also requires minimal

knowledge of the process to be controlled. Since glycol contactor (the absorber) is most

common places in the dehydration system where about 90% of glycol loss occurs. High gas

velocity through the glycol contactor will cause carryover of glycol into the pipeline. Hence, it is

necessary for feedback control system to be used in liquid level at the bottom to control the level.

QUESTION B (ii)

Water reflux into the stripper

Manipulated variable : The flow of wet/rich glycol leaves from absorber

Control variable : The temperature outlet from the reboiler

Disturbance variable : The flow of water inlet

The general operating problems in water reflux are glycol loss from the system. When the wet or

rich glycol leaves the absorber it will flows through a coil in the stripper where it is preheated by

hot lean glycol. The coil at top of the stripper provides a water reflux at the top of the stripper. In

this system, the temperature must control to ensure that the water leaving does not carry over

excess glycol and cause glycol loss. Glycol loss occurs when the reboiler temperature is too

high. In order to achieve the desired product, the temperature at the top of stripping column

should be maintain by manipulating the flow of rich glycol to a reflux generating, cooling coil

located at top of the stripping column. If the temperature drops too much, water vapour

condensation becomes excessive, which may flood the column, overfill the reboiler, increase

column pressure, and blow liquids out the top vent. Glycol losses may increase if the

temperature increase. In stripping system, the manipulated variable (MV) in this system is the

flow of wet/rich glycol leaves from absorber, the control variable (CV) is the temperature outlet

from the reboiler and the load disturbance variable is the flow of water inlet. The purpose design

control system in order to achieve optimum production rate of dehydrated natural gas is by using

ratio controller. Ratio controller located at the outlet stream of reboiler. The reboiler temperature

is controlled by a ratio control system in the hot oil outlet from the reboiler. The reboiler is

constructed with an internal weir which maintains the glycol level above the hot oil tubes giving

the required residence time for maximum heat transfer rates and prevent overheating of the unit.

Ratio control loop system used because it allows to measure two streams to produce and

maintain a ratio between the streams. It also simple to use and does not require a complex

model.

S-ar putea să vă placă și

- Practical Chemical Thermodynamics for GeoscientistsDe la EverandPractical Chemical Thermodynamics for GeoscientistsÎncă nu există evaluări

- Assigment 1-b CompleteDocument12 paginiAssigment 1-b CompleteFaradilah Binti Ajma'inÎncă nu există evaluări

- Sanitary Engineer II: Passbooks Study GuideDe la EverandSanitary Engineer II: Passbooks Study GuideÎncă nu există evaluări

- Salman PDFDocument263 paginiSalman PDFRoger FernandezÎncă nu există evaluări

- Maintain Liquid Levels Using Feedback ControlDocument6 paginiMaintain Liquid Levels Using Feedback ControlNadia RefaiÎncă nu există evaluări

- (Project Eco) Latest Semifull Half Without Part RogerDocument35 pagini(Project Eco) Latest Semifull Half Without Part RogerRoger FernandezÎncă nu există evaluări

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocument24 paginiCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- Dislocations and Interfacial Defects in MaterialsDocument1 paginăDislocations and Interfacial Defects in MaterialsbabeÎncă nu există evaluări

- S-Lab Manual Exp 3 - Air Flow Process ControlDocument12 paginiS-Lab Manual Exp 3 - Air Flow Process Controlarif arifinÎncă nu există evaluări

- FYP Extended Proposal First DraftDocument33 paginiFYP Extended Proposal First DraftEeHuey ChooÎncă nu există evaluări

- CPE680 Ethics EssayDocument2 paginiCPE680 Ethics EssayAeyrul KhairulÎncă nu există evaluări

- School of Chemical Engineering - 20Document372 paginiSchool of Chemical Engineering - 20biroutiÎncă nu există evaluări

- Process Control & Instrumentations CEV 544 PrelabDocument9 paginiProcess Control & Instrumentations CEV 544 PrelabFaradilah Binti Ajma'inÎncă nu există evaluări

- CEV633 - ASGN 1 - Mar2018 - QuestionDocument2 paginiCEV633 - ASGN 1 - Mar2018 - Questionbotakmbg6035Încă nu există evaluări

- Level Flow ControlDocument6 paginiLevel Flow Controlarpit gargÎncă nu există evaluări

- Process Control & Instrumentation Lab BKF 4791 Title of Experiment: Measurement and Control Air Flow System Lecturer's Name Group of Member: Name IDDocument12 paginiProcess Control & Instrumentation Lab BKF 4791 Title of Experiment: Measurement and Control Air Flow System Lecturer's Name Group of Member: Name IDTan Yong ChaiÎncă nu există evaluări

- Assignment 5: Optimization: (PO3, CO2)Document3 paginiAssignment 5: Optimization: (PO3, CO2)MohamedFittri0% (1)

- Climbing Film GanganDocument20 paginiClimbing Film GanganAdeniran Joshua50% (2)

- CED 30403-Air Pollution Control Technology Experiment 4Document11 paginiCED 30403-Air Pollution Control Technology Experiment 4mirza farhanÎncă nu există evaluări

- Boiling Heat Transfer ExpDocument22 paginiBoiling Heat Transfer ExpMahesh Vp0% (1)

- Assignment 1 (Part A and Part B)Document8 paginiAssignment 1 (Part A and Part B)botakmbg6035Încă nu există evaluări

- Level Process Control SystemDocument10 paginiLevel Process Control SystemnajihahÎncă nu există evaluări

- Che244 Exp 1Document6 paginiChe244 Exp 1NABILA AFIEQAH NASRUDINÎncă nu există evaluări

- Oil Distillation ReportDocument10 paginiOil Distillation ReportnisasoberiÎncă nu există evaluări

- Bioproduct Exp4 g1Document20 paginiBioproduct Exp4 g1JivashiniBalasupurManiamÎncă nu există evaluări

- Exp 2 (Air Pressure Process Control)Document16 paginiExp 2 (Air Pressure Process Control)shafiqah wong100% (1)

- Plant LocationDocument8 paginiPlant LocationEeHuey ChooÎncă nu există evaluări

- CH142L – Chemical Engineering Lab: Reverse Osmosis Process OptimizationDocument4 paginiCH142L – Chemical Engineering Lab: Reverse Osmosis Process OptimizationChua RhickÎncă nu există evaluări

- Control Lab ReportDocument11 paginiControl Lab ReportMariamMunirAhmad100% (1)

- Exp 4 Batch Evaporative Crystallization PDFDocument9 paginiExp 4 Batch Evaporative Crystallization PDFmirza farhanÎncă nu există evaluări

- AFPT921 Air Flow Pressure Temperature Control TrainingDocument2 paginiAFPT921 Air Flow Pressure Temperature Control TrainingKamalanathen ChlvnÎncă nu există evaluări

- Pre-Lab PM10 Sampling in FoodCourtDocument8 paginiPre-Lab PM10 Sampling in FoodCourtAjlaa RahimÎncă nu există evaluări

- Liquid Level Control SystemDocument0 paginiLiquid Level Control SystemNajiRihaniÎncă nu există evaluări

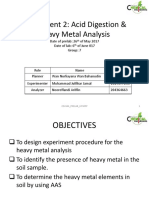

- Heavy Metal Soil AnalysisDocument10 paginiHeavy Metal Soil AnalysisSolehah OmarÎncă nu există evaluări

- Lab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFDocument7 paginiLab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFJaymacÎncă nu există evaluări

- Level Control Trainer FinalDocument6 paginiLevel Control Trainer FinalSiddhartha SharmaÎncă nu există evaluări

- CDB 3082 Chemical Engineering Lab Iv: - Flame PropagationDocument8 paginiCDB 3082 Chemical Engineering Lab Iv: - Flame PropagationBhinitha ChandrasagaranÎncă nu există evaluări

- Rotary Evaporator ExperimentDocument5 paginiRotary Evaporator ExperimentanujaÎncă nu există evaluări

- A Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketDocument3 paginiA Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketpalliÎncă nu există evaluări

- Water SamplingDocument5 paginiWater SamplingroldskiÎncă nu există evaluări

- Suggestions For The Optimum Process Conditions That Should Be Adopted To Improve The Process DesignDocument2 paginiSuggestions For The Optimum Process Conditions That Should Be Adopted To Improve The Process DesignAddison JuttieÎncă nu există evaluări

- Methanol From GlycerinDocument5 paginiMethanol From GlycerinaudreysosoÎncă nu există evaluări

- Experiment 6 - Level Flow Trainer (Wlf922)Document11 paginiExperiment 6 - Level Flow Trainer (Wlf922)Abdul AzimÎncă nu există evaluări

- Cooling Tower ReportDocument11 paginiCooling Tower Reportbae zazÎncă nu există evaluări

- CPB 40002 Engineering Technologist in Society UniKL MICET Assignment 1 (Individual) : Codes of Engineering EthicsDocument10 paginiCPB 40002 Engineering Technologist in Society UniKL MICET Assignment 1 (Individual) : Codes of Engineering EthicsSiti Hajar MohamedÎncă nu există evaluări

- Influence of Air Velocity on Drying Rate of Wet SandDocument3 paginiInfluence of Air Velocity on Drying Rate of Wet SandJohanÎncă nu există evaluări

- Refrigeration Unit (DONE)Document33 paginiRefrigeration Unit (DONE)Eimint Mansor Applez100% (1)

- Batch ReactorDocument4 paginiBatch ReactorFoo Xiao BingÎncă nu există evaluări

- Complete Lab Report 6Document7 paginiComplete Lab Report 6Azuan SofianÎncă nu există evaluări

- Evaporation: Kevin A. OlegarioDocument6 paginiEvaporation: Kevin A. OlegarioKitty VÎncă nu există evaluări

- Fication and Concentration of Pomegranate Juice (Punica Granatum L.)Document8 paginiFication and Concentration of Pomegranate Juice (Punica Granatum L.)Helton SilvaÎncă nu există evaluări

- Dynamic Simulation of A Crude Oil DistillationDocument14 paginiDynamic Simulation of A Crude Oil DistillationAL-JABERI SADEQ AMEEN ABDO / UPMÎncă nu există evaluări

- CHE545 MASS TRANSFER ASSIGNMENTDocument3 paginiCHE545 MASS TRANSFER ASSIGNMENTsoapÎncă nu există evaluări

- Water Jar TestDocument8 paginiWater Jar TestNurin Adlina100% (1)

- CELCHA2 Study GuidesDocument7 paginiCELCHA2 Study GuidesEsther100% (1)

- Experiment 1 Optimization of Flow Rate and Column Temperature (Method Development)Document7 paginiExperiment 1 Optimization of Flow Rate and Column Temperature (Method Development)NUR IZZATI OTHMAN BASRIÎncă nu există evaluări

- Glycol Dehydration Instrumentation and ControlsDocument3 paginiGlycol Dehydration Instrumentation and ControlsdndudcÎncă nu există evaluări

- Working Principle of TEG RegenerationDocument3 paginiWorking Principle of TEG RegenerationAzhar AhmadÎncă nu există evaluări

- Chapter 02Document58 paginiChapter 02MJ LagradaÎncă nu există evaluări

- Rubric For Assg 1Document3 paginiRubric For Assg 1Faradilah Binti Ajma'inÎncă nu există evaluări

- ASSIGNMENT 1 - EIA Dila (AutoRecovered)Document10 paginiASSIGNMENT 1 - EIA Dila (AutoRecovered)Faradilah Binti Ajma'inÎncă nu există evaluări

- Method To Prevent CorrosionDocument4 paginiMethod To Prevent CorrosionFaradilah Binti Ajma'inÎncă nu există evaluări

- Natural gas dehydration PID control systemDocument4 paginiNatural gas dehydration PID control systemFaradilah Binti Ajma'inÎncă nu există evaluări

- ASSIGNMENT 1 - EIA Dila (AutoRecovered)Document5 paginiASSIGNMENT 1 - EIA Dila (AutoRecovered)Faradilah Binti Ajma'inÎncă nu există evaluări

- Assignment 2 DilaDocument6 paginiAssignment 2 DilaFaradilah Binti Ajma'inÎncă nu există evaluări

- ASSIGNMENT 1 - EIA Dila (AutoRecovered)Document5 paginiASSIGNMENT 1 - EIA Dila (AutoRecovered)Faradilah Binti Ajma'inÎncă nu există evaluări

- Acid DigestionDocument2 paginiAcid DigestionFaradilah Binti Ajma'inÎncă nu există evaluări

- Green SolutionDocument5 paginiGreen SolutionFaradilah Binti Ajma'inÎncă nu există evaluări

- Oxalic Acid E11a BDocument52 paginiOxalic Acid E11a BFaradilah Binti Ajma'inÎncă nu există evaluări

- Process Control & Instrumentations CEV 544 PrelabDocument9 paginiProcess Control & Instrumentations CEV 544 PrelabFaradilah Binti Ajma'inÎncă nu există evaluări

- Recommendation & ImprovementDocument3 paginiRecommendation & ImprovementFaradilah Binti Ajma'inÎncă nu există evaluări

- Fully Report Vs-Group 5Document25 paginiFully Report Vs-Group 5Faradilah Binti Ajma'inÎncă nu există evaluări

- Environmentl EthicsDocument16 paginiEnvironmentl EthicsFaradilah Binti Ajma'inÎncă nu există evaluări

- Microsoft Word - Cev420 Course Outline (Mac - July 2016)Document10 paginiMicrosoft Word - Cev420 Course Outline (Mac - July 2016)Faradilah Binti Ajma'inÎncă nu există evaluări

- Group presentation on environmental issuesDocument4 paginiGroup presentation on environmental issuesFaradilah Binti Ajma'inÎncă nu există evaluări

- How Human Activities Affect Water QualityDocument2 paginiHow Human Activities Affect Water QualityFaradilah Binti Ajma'inÎncă nu există evaluări

- HC 1300002Document11 paginiHC 1300002imranÎncă nu există evaluări

- SevesoDocument7 paginiSevesoFaradilah Binti Ajma'inÎncă nu există evaluări

- T2 12222016 0000Document6 paginiT2 12222016 0000Faradilah Binti Ajma'inÎncă nu există evaluări

- Pressure Control P&IDDocument1 paginăPressure Control P&IDFaradilah Binti Ajma'inÎncă nu există evaluări

- Product Design and Development (Che227) Mini Project 3 EH110Document1 paginăProduct Design and Development (Che227) Mini Project 3 EH110Faradilah Binti Ajma'inÎncă nu există evaluări

- Arab Roleplay FinalDocument3 paginiArab Roleplay FinalFaradilah Binti Ajma'inÎncă nu există evaluări

- Ir 08Document18 paginiIr 08HeseSareGoblogÎncă nu există evaluări

- The Effects of Sleep Deprivation On Your BodyDocument21 paginiThe Effects of Sleep Deprivation On Your BodyFaradilah Binti Ajma'inÎncă nu există evaluări

- Outline PS DilaDocument7 paginiOutline PS DilaFaradilah Binti Ajma'inÎncă nu există evaluări

- Assignment 1Document2 paginiAssignment 1Faradilah Binti Ajma'inÎncă nu există evaluări

- 00 Rubric Jsub Eh224 - Cev503 - Assignment 4-5Document1 pagină00 Rubric Jsub Eh224 - Cev503 - Assignment 4-5Faradilah Binti Ajma'inÎncă nu există evaluări

- Compressed Air Operated Vacuum Waste Removal: Systems and ComponentsDocument20 paginiCompressed Air Operated Vacuum Waste Removal: Systems and ComponentsDaniel RukawaÎncă nu există evaluări

- AP Calculus BC Study GuideDocument4 paginiAP Calculus BC Study GuideHarshil SahaiÎncă nu există evaluări

- Mathematics Class 10 CBSE (NCERT)Document369 paginiMathematics Class 10 CBSE (NCERT)LinoÎncă nu există evaluări

- Evaluation of Lathyrus SativusDocument16 paginiEvaluation of Lathyrus SativusSAMI DHAOUIÎncă nu există evaluări

- XI-Opt. Syllabus (2023-24)Document29 paginiXI-Opt. Syllabus (2023-24)INDERDEEPÎncă nu există evaluări

- Physics Assignment 1Document4 paginiPhysics Assignment 1Trí Võ PhạmÎncă nu există evaluări

- No.1 PrestressedDocument10 paginiNo.1 PrestressedKristin ArgosinoÎncă nu există evaluări

- 16 RMM Spring Edition 2020 Solutions CompressedDocument83 pagini16 RMM Spring Edition 2020 Solutions CompressedKhokon GayenÎncă nu există evaluări

- Calentador Catalitico de TuberíasDocument2 paginiCalentador Catalitico de TuberíasDavid RomeroÎncă nu există evaluări

- Work MeasurementDocument15 paginiWork MeasurementBalaji BabuÎncă nu există evaluări

- Welding Machine CatalogueDocument12 paginiWelding Machine CatalogueRodney LanagÎncă nu există evaluări

- UMTS Chap6Document33 paginiUMTS Chap6NguyenDucTaiÎncă nu există evaluări

- VeEX OTN Quick Reference GuideDocument12 paginiVeEX OTN Quick Reference GuideDewan H S SalehinÎncă nu există evaluări

- Chapter 1Document11 paginiChapter 1bekemaÎncă nu există evaluări

- Water Pinch PresentationDocument14 paginiWater Pinch PresentationDafiMaboÎncă nu există evaluări

- ASME - Performance Test CodesDocument1 paginăASME - Performance Test CodesanoopkntpcÎncă nu există evaluări

- DS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1Document52 paginiDS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1AlexandreÎncă nu există evaluări

- Dental Material Final ReportDocument7 paginiDental Material Final ReportAbdullah Muhammed khaleel HassanÎncă nu există evaluări

- Timer Counter ArduinoDocument8 paginiTimer Counter ArduinoKietDangÎncă nu există evaluări

- Lubricants For Cement ProductionDocument21 paginiLubricants For Cement Productiongrameshkreddy2013100% (1)

- Brake SystemDocument19 paginiBrake SystemSudarshan NepalÎncă nu există evaluări

- Dimensional Analysis AND Similarity: Chapter-5. (Frank White)Document46 paginiDimensional Analysis AND Similarity: Chapter-5. (Frank White)ShujaAmjadÎncă nu există evaluări

- Order Change Management (OCM)Document19 paginiOrder Change Management (OCM)Debasish BeheraÎncă nu există evaluări

- Seminar ReportDocument45 paginiSeminar Reportmanaskollam0% (1)

- JefimenkoDocument10 paginiJefimenkoBilly M. SpragueÎncă nu există evaluări

- Research BulletsDocument18 paginiResearch BulletsVong Albios DogomeoÎncă nu există evaluări

- Prepare and Interpret Technical DrawingDocument5 paginiPrepare and Interpret Technical DrawingDwin Rosco75% (4)

- Post GreeDocument15 paginiPost GreeDwi PraptiÎncă nu există evaluări

- Plasma CuttingDocument12 paginiPlasma Cuttingpavi32Încă nu există evaluări

- DL-H61M-VG4: Motherboard User ManualDocument52 paginiDL-H61M-VG4: Motherboard User ManualSutripti Bardhan100% (1)

- Sully: The Untold Story Behind the Miracle on the HudsonDe la EverandSully: The Untold Story Behind the Miracle on the HudsonEvaluare: 4 din 5 stele4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldDe la EverandThe Fabric of Civilization: How Textiles Made the WorldEvaluare: 4.5 din 5 stele4.5/5 (57)

- Packing for Mars: The Curious Science of Life in the VoidDe la EverandPacking for Mars: The Curious Science of Life in the VoidEvaluare: 4 din 5 stele4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDe la EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaÎncă nu există evaluări

- The Weather Machine: A Journey Inside the ForecastDe la EverandThe Weather Machine: A Journey Inside the ForecastEvaluare: 3.5 din 5 stele3.5/5 (31)

- Highest Duty: My Search for What Really MattersDe la EverandHighest Duty: My Search for What Really MattersÎncă nu există evaluări

- Hero Found: The Greatest POW Escape of the Vietnam WarDe la EverandHero Found: The Greatest POW Escape of the Vietnam WarEvaluare: 4 din 5 stele4/5 (19)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDe la EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellEvaluare: 4.5 din 5 stele4.5/5 (80)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980De la Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Evaluare: 4 din 5 stele4/5 (21)

- A-level Biology Revision: Cheeky Revision ShortcutsDe la EverandA-level Biology Revision: Cheeky Revision ShortcutsEvaluare: 5 din 5 stele5/5 (5)

- The Future of Geography: How the Competition in Space Will Change Our WorldDe la EverandThe Future of Geography: How the Competition in Space Will Change Our WorldEvaluare: 4.5 din 5 stele4.5/5 (4)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDe la EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureEvaluare: 5 din 5 stele5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceDe la EverandPale Blue Dot: A Vision of the Human Future in SpaceEvaluare: 4.5 din 5 stele4.5/5 (586)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (241)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsDe la EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsÎncă nu există evaluări

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDe la EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationEvaluare: 4.5 din 5 stele4.5/5 (46)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDe la EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseEvaluare: 3.5 din 5 stele3.5/5 (12)

- The Path Between the Seas: The Creation of the Panama Canal, 1870-1914De la EverandThe Path Between the Seas: The Creation of the Panama Canal, 1870-1914Evaluare: 4.5 din 5 stele4.5/5 (124)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe la EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseEvaluare: 4.5 din 5 stele4.5/5 (50)

- Artificial Intelligence: A Guide for Thinking HumansDe la EverandArtificial Intelligence: A Guide for Thinking HumansEvaluare: 4.5 din 5 stele4.5/5 (30)

- Reality+: Virtual Worlds and the Problems of PhilosophyDe la EverandReality+: Virtual Worlds and the Problems of PhilosophyEvaluare: 4 din 5 stele4/5 (24)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesDe la EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesÎncă nu există evaluări

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări