Documente Academic

Documente Profesional

Documente Cultură

Aatcc TM008

Încărcat de

Amir SajjadTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aatcc TM008

Încărcat de

Amir SajjadDrepturi de autor:

Formate disponibile

AATCC takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this test method. Users of this test method are expressly advised

that determination of the validity of any such patent rights, and the risk of infringement of

such rights, are entirely their own responsibility.

This test method is subject to revision at any time by the responsible technical committee

and must be reviewed every five years and if not revised, either reaffirmed or withdrawn.

Your comments are invited either for revision of this test method or for additional

procedures and should be addressed to the AATCC Technical Center. Your comments will

receive careful consideration at a meeting of the responsible technical committee, which

you may attend. If you feel that your comments have not received a fair hearing, you

should make your views known to Christopher S. Leonard, Technical Director, at the

address shown below.

This test method is copyrighted by AATCC, PO Box 12215, Research Triangle Park, NC

27709 USA. Individual reprints (single or multiple copies) of this method may be obtained by

contacting AATCC at the above address or tel: 919-549-3526; fax: 919-549-8933, or e-mail:

orders@aatcc.org.

AATCC License Agreement: This test method is copyrighted by the American Association

of Textile Chemists and Colorists (AATCC), PO Box 12215, 1 Davis Drive, Research

Triangle Park, NC USA. All rights reserved.

AATCC grants you a license as follows: The right to download one electronic file of this

AATCC test method for temporary storage on one computer for purposes of viewing, and/or

printing one copy of the AATCC test method for individual use. Neither the electronic file nor

the hard copy print may be reproduced in any way. In addition, the electronic file may not be

distributed elsewhere over computer networks or otherwise. The hard copy print may only be

distributed to other employees for their internal use within your organization.

This test method is not for resale.

Copyright © 2012 American Association of Textile Chemists and Colorists

AATCC Test Method 8-2007

Colorfastness to Crocking: Crockmeter Method

Developed in 1936 by AATCC Commit- for information purposes only. The pre- tant to avoid incorrect test results where

tee RA38; revised 1937, 1952, 1957, cautions are ancillary to the testing proce- abnormal crock images can result and in-

1961, 1969, 1972, 1985, 1988, 1996, dures and are not intended to be all inclu- fluence the rating process.

2004, 2005, 2007; reaffirmed 1945; sive. It is the user’s responsibility to use 6.2 Use the Crockmeter Verification

1989; editorially revised and reaffirmed safe and proper techniques in handling Cloth or in-house poor crocking fabric

1968, 1974, 1977, 1981, 1995, 2001; materials in this test method. Manufac- with known behavior and conduct three

editorially revised 1986, 2002, 2008 turers MUST be consulted for specific dry and wet crock tests.

(with title change), 2009, 2010, 2011. details such as material safety data sheets 6.2.1 A poor circular image with un-

Partly equivalent to ISO 105-X12. and other manufacturer’s recommenda- even dye pick-up may indicate the crock-

tions. All OSHA standards and rules ing finger needs resurfacing (see 13.7).

must also be consulted and followed. 6.2.2 A double, elongated image may

1. Purpose and Scope 4.1 Good laboratory practices should indicate a loose clip (see 13.7).

be followed. Wear safety glasses in all 6.2.3 A stretched and streaked crock

1.1 This test method is designed to de- laboratory areas. image may be due to mounting the crock

termine the amount of color transferred square diagonally.

from the surface of colored textile materi-

als to other surfaces by rubbing. It is ap-

5. Apparatus and Materials (see 13.1) 6.2.4 Scuff marks to the sides of the

plicable to textiles made from all fibers in specimen indicate the loops to the wire

5.1 Crockmeter (see 13.3, 13.4 and

the form of yarn or fabric whether dyed, clips are positioned downwards and are

Fig. 1).

printed or otherwise colored. It is not rec- not high enough to prevent rubbing the

5.2 Crockmeter Test Cloth, cut in 50

ommended for use for carpets or for specimen surface.

mm squares (see 13.5).

prints where the singling out of areas may 5.3 AATCC Chromatic Transference 6.2.5 A streak in the center of the crock

be too small using this method (see 13.2 Scale (see 13.6). cloth image and in the direction of rub-

and 13.3). 5.4 Gray Scale for Staining (see 13.6). bing may mean the top of the metal base

1.2 Test procedures employing white is warped and not flat. This will require a

5.5 White AATCC Textile Blotting

test cloth squares, both dry and wet with brace insert to square up the tester base.

Paper (see 13.6).

water, are given. 5.6 Specimen Holder for crockmeter 6.2.6 If specimen holders are used,

1.3 As washing, drycleaning, shrink- (see 13.4). place the holder over the specimen on the

age, ironing, finishing, etc., may affect 5.7 In-house poor crocking cloth. tester base. Move the crocking finger on

the degree of color transfer from a mate- 5.8 Crockmeter Verification Cloth. the crocking arm to the most forward po-

rial, the test may be made before, after, or This item may be used in lieu of an sition and observe whether it hits the in-

before and after any such treatment. in-house poor crocking cloth when such side edge of the holder. If this occurs,

poor in-house crocking cloth is not avail- move the holder slightly forward for all

able. tests. Without correction, this problem

2. Principle will cause a dark area on one side of the

2.1 A colored test specimen is rubbed crocking image.

6. Verification 6.2.7 Confirm the wet pick-up tech-

with white crock test cloth under con-

trolled conditions. 6.1 Verification checks on the opera- niques (see 9.2).

2.2 Color transferred to the white test tion of the test and the apparatus should 6.2.8 Replace the abrasive paper on the

cloth is assessed by a comparison with be made routinely and the results kept in tester base if it is smooth to the touch in

the Gray Scale for Staining or the Chro- a log. The following observations and the crocking area compared to the adja-

matic Transference Scale and a grade is corrective actions are extremely impor- cent area, or if slippage of the specimen

assigned. is noticed.

6.2.9 In routine testing, observe if mul-

3. Terminology tiple streaks are on the crocking image.

Position specimen normally with the long

3.1 colorfastness, n.—the resistance of dimension oblique to the warp and fill-

a material to change in any of its color ing. If the direction of rubbing falls along

characteristics, to transfer of its color- a twill line or surface pattern, etc., then

ant(s) to adjacent materials, or both, as a streaks may occur. If they do occur,

result of the exposure of the material to slightly adjust the angle for testing.

any environment that might be encoun-

tered during the processing, testing, stor- 7. Test Specimens

age or use of the material.

3.2 crocking, n.—a transfer of color- 7.1 Two specimens are used, one each

ant from the surface of a colored yarn or for the dry and the wet tests.

fabric to another surface or to an adjacent 7.1.1 Additional specimens may be

area of the same fabric principally by used to increase the precision of the aver-

rubbing. age (see 12.1).

7.2 Cut specimens at least 50 × 130 mm

4. Safety Precautions (2.0 × 5.1 in.) and position for testing pref-

erably with the long dimension oblique to

NOTE: These safety precautions are Fig. 1—Crockmeter. warp and filling or wales and courses.

AATCC Technical Manual/2012 TM 8-2007 21

Copyright © 2012 American Association of Textile Chemists and Colorists

7.2.1 Larger or full width lab samples matic pipetter, draw up water in mL to 11. Report

may be used without cutting individual 0.65 times weight of crocking square. If

specimens, when multiple tests are crocking square weight equals 0.24 gm, 11.1 State whether dry or wet crocking

needed and when using for production the mL used would be 0.24 × 0.65 = 0.16 test.

testing. mL. Lay crocking square on white plastic 11.2 Report the grade determined in 10.3.

7.3 Yarns. Knit a piece of fabric at least mesh over a dish. Apply water evenly 11.3 Report the grade determined in

50 × 130 mm, or wind yarn tightly on a over crocking square and weigh the wet 10.4 to the nearest 0.1 grade.

suitable form at least 50 × 130 mm with square. Calculate wet pickup according 11.4 State whether Gray Scale for

the yarn running in the long direction; or to instructions in this method and Method Staining (EP2), Chromatic Transference

otherwise stretched (see 13.8). 116, Colorfastness to Crocking: Rotary Scale (EP8) or Instrumental Assessment

Vertical Crockmeter Method. If needed, of Degree of Staining (EP12) was used

8. Conditioning adjust the amount of water used to wet for evaluating staining (see 13.6 and

the square and using a new crocking 13.9).

8.1 Prior to testing, precondition and square, repeat steps. When 65 ± 5% wet 11.5 If any pretreatment or aftertreat-

condition the test specimens and the ment was given to any specimens (see

pickup is achieved, record the amount of

crock squares for crock testing as di- 1.3) indicate method of treatment.

water used. Draw up the recorded amount

rected in ASTM D 1776, Conditioning

Textiles for Testing. Condition each spec- of water into the syringe tube, graduated

imen for at least 4 h in an atmosphere of pipette or automatic pipetter for each wet 12. Precision and Bias (see 13.15)

21 ± 1°C (70 ± 2°F) and 65 ± 2% RH by crocking performed during the current

day. Repeat this process each day. 12.1 Precision. An interlaboratory test

laying each test specimen or crock square was conducted in 1986 to establish the

separately on a screen or perforated shelf 9.2.3 Avoid evaporative reduction of precision of the test method. Testing was

of conditioning rack. the moisture content below the specified conducted under the normal atmospheric

level before the actual crock test is run. conditions of each laboratory and not

9. Procedures 9.2.4 Continue as directed in 9.1. necessarily under ASTM standard condi-

9.2.5 Air dry the white test square, then tions. Two operators at each of 12 labora-

9.1 Dry Crocking Test. tories evaluated 5 fabrics in 3 replications

9.1.1 Place a test specimen on the base condition (see 8.1) before evaluating. In

the case of napped, brushed or sanded by both dry and wet test method. Each of

of the crockmeter resting flat on the abra- 3 raters independently rated the stained

sive cloth with its long dimension in the material when loose fiber might interfere

with the rating, remove the extraneous crock squares using both the Gray Scale

direction of rubbing (see 13.7). for Staining and the Chromatic Transfer-

9.1.2 Place specimen holder over speci- fibrous material by pressing lightly on the

crock circle with the sticky side of cello- ence Scale. The original data is on file at

men as an added means to prevent the AATCC Technical Center.

slippage. phane tape before evaluating.

12.1.1 The components of variance as

9.1.3 Mount a white test cloth square,

standard deviations of the Gray Scale for

the weave parallel with the direction of

10. Evaluation Staining or Chromatic Transference Scale

rubbing, over the end of the finger which

rating units are given in Table I.

projects downward from the weighted

sliding arm. Use the special spiral wire 10.1 Rate the amount of color trans- 12.1.2 Critical differences are given in

clip to hold the test square in place. Posi- ferred from the specimen to the white test Table II.

tion the clip with loops upward. If the square under examination by means of the 12.1.3 Example for determining be-

loops point downward they can drag Chromatic Transference Scale or the Gray tween laboratory differences using one

against the test specimen. Scale for Staining (see 13.11 and 13.14). observer and the chromatic scale are

9.1.4 Lower the covered finger onto the 10.2 Back the test square with three given in Table III.

test specimen. Beginning with the finger layers of white test cloth while evaluating. Interpretation: For the dry crock test,

positioned at the front end, crank the since the difference between labs is less

10.3 Rate dry and wet crocking fast- than the critical differences in 12.1.2

meter handle 10 complete turns at the rate ness by means of the Gray Scale for

of one turn per second to slide the covered (0.82), the difference in results is not sig-

Staining (AATCC Evaluation Procedure nificant. For the wet crock test, since the

finger back and forth 20 times. Set and 2), or the AATCC 9-Step Chromatic

run the motorized tester for 10 complete difference between labs is greater than

Transference Scale (AATCC Evaluation the critical difference (1.53), the differ-

turns. Refer to individual specifications Procedure 8), or AATCC Evaluation Pro-

for any other required number of turns. ence in results is significant.

cedure 12, Instrumental Assessment of 12.2 Bias. The true value of colorfast-

9.1.5 Remove the white test cloth Degree of Staining, and record the nu-

square, condition (see 8.1) and evaluate ness to crocking can only be defined in

merical rating that corresponds to the ap- terms of a test method. Within this limita-

as directed in Section 10. In the case of propriate one on either of them.

napped, brushed or sanded material when tion, this test method has no known bias.

loose fiber might interfere with the rating, 10.4 Average individual results to the

remove the extraneous fibrous material nearest 0.1 grade when multiple speci- 13. Notes

by pressing lightly on the crock circle mens are tested or when a panel of evalu-

with the sticky side of cellophane tape ators rate color transfer. 13.1 For potential equipment information

before evaluating.

9.2 Wet Crocking Test.

9.2.1 Establish technique (see 13.10)

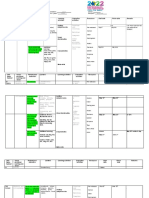

for preparing wet crock cloth squares by Table I—Components of Variance

weighing a conditioned square, then thor-

oughly wet out white testing square in Dry Wet

Test

distilled water. Prepare only one square at Scale Chromatic Gray Chromatic Gray

a time. Single Operator/Rater 0.20 0.20 0.24 0.25

9.2.2 Weigh dry crock square. Using a Within Laboratory 0.20 0.19 0.31 0.34

syringe tube, graduated pipette or auto- Between Laboratory 0.10 0.17 0.38 0.54

22 TM 8-2007 AATCC Technical Manual/2012

Copyright © 2012 American Association of Textile Chemists and Colorists

Table II—Critical Differences finger to dig into and push aside the yarns, or

slide off them and possibly give erroneous

For the components of variance in Table I, two averages of observed values should be considered results. This attachment is 25 mm in diameter

significantly different at the 95% probability level if the difference equals or exceeds the following critical by 51 mm long. Positioned on its side and held

differences. in place by the standard finger, it provides a

wider test area, and holds the white test square

Dry Wet by two spring loaded clips. For additional in-

Test No. of

Scale Observations Chromatic Gray Chromatic Gray formation on this development see the article

by C. R. Trommer, “Modification of the

Single Operator/Rater 1 0.55 0.54 0.68 0.70 AATCC Crockmeter for Yarn Testing,” Amer-

3 0.32 0.31 0.39 0.40 ican Dyestuff Reporter, Vol. 45, No. 12, p357,

5 0.24 0.24 0.30 0.31 June 4, 1956; also see articles by S. Korpanty

Within Laboratory 1 0.77 0.75 1.08 1.17 and C. R. Trommer, “An Improved Crock-

3 0.60 0.61 0.93 1.02 meter for Yarn Testing,” American Dyestuff

5 0.60 0.57 0.90 1.00 Reporter, Vol. 48, No. 6, p40, March 23, 1959.

Between Laboratory 1 0.82 0.89 1.53 1.90 13.9 It has been noted that different grades

3 0.69 0.77 1.43 1.81 may result depending upon whether the

5 0.66 0.74 1.41 1.79 Gray Scale for Staining or Chromatic Trans-

ference Scale is used for the evaluation. It is,

The critical differences were calculated using t = 1.96 which is based on infinite degrees of freedom. therefore, important to report which scale was

used.

13.10 Experienced operators do not have to

repeat this weighing procedure during a test

session once the technique is established.

Fiber 100% 10.3-16.8 mm combed

Table III—Crock Test Results cotton staple, desized, 13.11 For very critical evaluations and in

bleached, with no optical cases of arbitration, grades must be based on

Dry Wet brightener or finishing mate- the Gray Scale for Staining.

Lab A 4.5 3.5 rial present 13.12 For a discussion of crock testing, see

Lab B 4.0 1.5 Yarn 15 tex (40/1 cotton count), the article by J. Patton, “Crock Test Problems

Difference 0.5 2.0 5.9 turns/cm “z” can be Prevented,” Textile Chemist and Color-

Thread count 32 ± 5 warp ends/cm: 33 ± 5 ist, Vol. 21, No. 3, p13, March 1989; and “Test-

picks filling/cm ing for Crocking: Some Problems and Pitfalls”

Weave 1/1 plain by Allan E. Gore, Textile Chemists and Color-

pH 7 ± 0.5 ists, Vol. 21, No. 3, p17, March 1989.

pertaining to this test method, please visit

Mass/sq meter 100 ± 3 g finished 13.13 For prints where the singling out of

the online AATCC Buyer’s Guide at http://

Whiteness W = 78 ± 3 (Method 110) areas too small to test with the standard crock-

www.aatcc.org/bg. AATCC provides the pos-

meter is necessary (see AATCC Method 116,

sibility of listing equipment and materials sold 13.5.1 CAUTION: ISO crock cloth results Rotary Vertical Crockmeter Method). Speci-

by its Corporate members, but AATCC does may not be equivalent to AATCC crock cloth mens tested by both test methods may show

not qualify, or in any way approve, endorse or results/values based on crock cloth study. dissimilar results. There is no known correla-

certify that any of the listed equipment or 13.6 The Chromatic Transference Scale, tion between the two methods.

materials meets the requirements in its test Gray Scales for Staining and White AATCC

methods. 13.14 An automated electronic grading sys-

Textile Blotting Paper are available from tem may be used as long as the system has

13.2 For carpets, AATCC Method 165, Col- AATCC, P.O. Box 12215, Research Triangle

orfastness to Crocking: Carpets—Crockmeter been demonstrated to provide results that are

Park NC 27709; tel: 919/549-8141; fax: 919/ equal to and provide equal or better repeatabil-

Method, under the jurisdiction of Committee 549-8933; e-mail: orders@aatcc.org; web site:

RA57, Floor Covering Test Methods, should ity and reproducibility than an experienced

www.aatcc.org. grader performing visual evaluation.

be used. 13.7 Accidental damage to the rubbing fin-

13.3 The crockmeter provides a reciprocat- ger, spiral clip or abrasive paper should be 13.15 The precision of this test method is

ing rubbing motion simulating the action of a repaired as follows: neatly renew the abrasive dependent on the combined variability of the

human finger and forearm. paper; bend the clip further open or shut material being tested, the test method itself,

13.4 The crockmeter is so designed that the around a rod slightly smaller in diameter than and the evaluation procedure utilized.

16 ± 0.3 mm (0.625 ± 0.01 in.) diameter finger the crock peg; resurface the finger by move- 13.15.1 The precision statement in Section

moves back and forth, with each complete ment on an extra piece of fine emery cloth in a 12 was developed from results obtained by vi-

turn of the crank, in a straight line along a 104 manner simulating regular use. sual evaluation (EP 2 and EP 8).

± 3 mm track on the specimen, with a down- 13.8 For more convenient crock testing of 13.15.2 It is expected that the use of instru-

ward force of 9 N ± 10% (2 lb ± 10%). multiple strands of yarn or thread a dowel at- mental evaluation procedures (EP 12) will re-

13.5 Crockmeter Test Cloth should meet tachment is useful. This attachment was de- sult in greater precision than that obtained

the following specifications: veloped to avoid the tendency of the standard from visual evaluations.

AATCC Technical Manual/2012 TM 8-2007 23

Copyright © 2012 American Association of Textile Chemists and Colorists

S-ar putea să vă placă și

- 2018 AATCC Laundering MethodsDocument48 pagini2018 AATCC Laundering MethodsWarlie Suwarlie67% (3)

- AATCC 96-2004 Test Method For Commercial LaunderingDocument5 paginiAATCC 96-2004 Test Method For Commercial LaunderingBeatriz RaCancojÎncă nu există evaluări

- Abrasion Resistance MartindaleDocument3 paginiAbrasion Resistance MartindaleGreeshma100% (1)

- SGSTesting SoftlinesandHardlinesDocument0 paginiSGSTesting SoftlinesandHardlinesthanhuong122Încă nu există evaluări

- Parameter Description Remark: Test Name: Ici Pilling Test Method Name: BS EN ISO 12945-1/BS 5811Document2 paginiParameter Description Remark: Test Name: Ici Pilling Test Method Name: BS EN ISO 12945-1/BS 5811Md Masum100% (1)

- Finishes in Textiles: Identification Finishes in Textiles: IdentificationDocument7 paginiFinishes in Textiles: Identification Finishes in Textiles: IdentificationMilagros WieczorekÎncă nu există evaluări

- Technical AATccDocument48 paginiTechnical AATccomi sunÎncă nu există evaluări

- Wale and Course Count of Weft Knitted Fabrics: Standard Test Method ForDocument6 paginiWale and Course Count of Weft Knitted Fabrics: Standard Test Method ForjiandapaÎncă nu există evaluări

- Astm D 3107Document6 paginiAstm D 3107muthuganuÎncă nu există evaluări

- Pile Fabric Abrasion: Standard Test Method ForDocument6 paginiPile Fabric Abrasion: Standard Test Method ForEugene GudimaÎncă nu există evaluări

- Moisture ManagementDocument32 paginiMoisture ManagementSalome Kyatuheire100% (1)

- TestimgDocument32 paginiTestimgZulqarnain AwanÎncă nu există evaluări

- Pilling Resistance TestsDocument7 paginiPilling Resistance TestsTauqeer RazaÎncă nu există evaluări

- ALDI ManualDocument44 paginiALDI Manualleo100% (1)

- Point System For Evaluating Quality in TextilesDocument115 paginiPoint System For Evaluating Quality in TextilesBenjamin OchoaÎncă nu există evaluări

- International Standard: Textile Fabrics - Determination of Resistance To Surface Wetting (Spray Test)Document6 paginiInternational Standard: Textile Fabrics - Determination of Resistance To Surface Wetting (Spray Test)yok patchnakan100% (3)

- Textile Testing and Product EvaluationDocument64 paginiTextile Testing and Product EvaluationBhaswati PandaÎncă nu există evaluări

- AATCC Test Method 15Document2 paginiAATCC Test Method 15Tauqeer RazaÎncă nu există evaluări

- Astm D 4964 - 96Document5 paginiAstm D 4964 - 96Ziauddin QureshiÎncă nu există evaluări

- Astm D3512Document6 paginiAstm D3512sayeed hossen100% (2)

- Fabric Quality InspectionDocument37 paginiFabric Quality InspectionFaysal AhammadÎncă nu există evaluări

- On Textile TestingDocument17 paginiOn Textile TestingGourav Arora100% (2)

- Determining Fabric Quality: Prepared By: Riza Leigh I. FiguesDocument55 paginiDetermining Fabric Quality: Prepared By: Riza Leigh I. FiguesRizaLeighFiguesÎncă nu există evaluări

- Polymer Blends and Composites: Chemistry and TechnologyDe la EverandPolymer Blends and Composites: Chemistry and TechnologyÎncă nu există evaluări

- Fabric Defects: - Causes - Types - 4 Point System For MeasuringDocument8 paginiFabric Defects: - Causes - Types - 4 Point System For MeasuringTarang MathurÎncă nu există evaluări

- Textile Chemical Processing IDocument2 paginiTextile Chemical Processing IDebojyoti GangulyÎncă nu există evaluări

- Textile Nonwoven TestingDocument10 paginiTextile Nonwoven TestingSandeep Yadav100% (1)

- Aatcc195-2011 Liquid Moisture Management Properties of Textile FabricsDocument5 paginiAatcc195-2011 Liquid Moisture Management Properties of Textile Fabricsdr tamerÎncă nu există evaluări

- Astm D3512 PDFDocument2 paginiAstm D3512 PDFEDGAR IMANÎncă nu există evaluări

- ISO 12947-4 1998 Cor 1 2002 (E)Document1 paginăISO 12947-4 1998 Cor 1 2002 (E)saran7ranÎncă nu există evaluări

- Essential Fabric Quality Reports For Bulk Cutting Approval of Fabrics-12Oct20Document5 paginiEssential Fabric Quality Reports For Bulk Cutting Approval of Fabrics-12Oct20M. Harunur RashidÎncă nu există evaluări

- Zipper Testing Methods PDFDocument3 paginiZipper Testing Methods PDFRicardo Jose PirelaÎncă nu există evaluări

- AATCC Test Method 42 (Water Resistance: Impact Penetration Test)Document3 paginiAATCC Test Method 42 (Water Resistance: Impact Penetration Test)ADITI AWASTHIÎncă nu există evaluări

- Astm D3107-2007 (2011) - 3125Document3 paginiAstm D3107-2007 (2011) - 3125Ayman SebaeiÎncă nu există evaluări

- Air PermeabilityDocument2 paginiAir Permeabilityjyoti1234321Încă nu există evaluări

- Pilling of TextilesDocument16 paginiPilling of TextilesAthirah Mansor100% (2)

- 4pt, 10pt SystemDocument12 pagini4pt, 10pt SystemShaaban Noaman100% (1)

- BS en 14704-1 2005 Determination of The Elasticity of FabriDocument27 paginiBS en 14704-1 2005 Determination of The Elasticity of Fabritiagolobo0% (3)

- ISO Lab Test For Apparel FabricsDocument5 paginiISO Lab Test For Apparel FabricsMuhammad ImranÎncă nu există evaluări

- IS - ISO 16322-1 (2005) - Textiles - Determination of Spirality After Laundering, Part 1 - Percentage of Wale Spirality Change in Knitted GarmentsDocument11 paginiIS - ISO 16322-1 (2005) - Textiles - Determination of Spirality After Laundering, Part 1 - Percentage of Wale Spirality Change in Knitted GarmentsCella ChenÎncă nu există evaluări

- Textile Testing and Product EvaluationDocument64 paginiTextile Testing and Product EvaluationAnmol Jain100% (3)

- Testing Procedures For Fabrics and TrimsDocument48 paginiTesting Procedures For Fabrics and Trimsshivanift100% (1)

- Factors Affecting Yarn StrengthDocument11 paginiFactors Affecting Yarn StrengthAbhishek ThakurÎncă nu există evaluări

- Carr and Latham's Technology of Clothing ManufactureDe la EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerEvaluare: 4 din 5 stele4/5 (1)

- BS Quantitative Analysis of Fiber MixturesDocument34 paginiBS Quantitative Analysis of Fiber MixturesDonna Uldo100% (1)

- Color Fastness To Crocking AATCC 8-2005Document1 paginăColor Fastness To Crocking AATCC 8-2005Hung LeÎncă nu există evaluări

- Title: Textile Testing and Quality AssuranceDocument4 paginiTitle: Textile Testing and Quality AssuranceTauqeer Raza100% (2)

- Tensile Strength Test-Grab MethodDocument1 paginăTensile Strength Test-Grab MethodeducardxÎncă nu există evaluări

- Yarn TwistingDocument12 paginiYarn TwistingMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- List of Projects/Theses (Textile Chemistry)Document27 paginiList of Projects/Theses (Textile Chemistry)Md Majharul IslamÎncă nu există evaluări

- Fibers Properties Textile MaterialsDocument19 paginiFibers Properties Textile MaterialsGarmentLearner100% (1)

- AATCC 163-2002 Colorfastness - Dye Transfer in Storage-Fabric-to-FabricDocument2 paginiAATCC 163-2002 Colorfastness - Dye Transfer in Storage-Fabric-to-FabricMichael Chen50% (2)

- D3107 07 (Reapproved 2011)Document6 paginiD3107 07 (Reapproved 2011)Muhammad HugoÎncă nu există evaluări

- Assignment Base On: Study On Some Fabric Faults During Processing.Document5 paginiAssignment Base On: Study On Some Fabric Faults During Processing.MD Nazrul IslamÎncă nu există evaluări

- Modern Cotton Spinning Machinery, Its Principles and ConstructionDe la EverandModern Cotton Spinning Machinery, Its Principles and ConstructionÎncă nu există evaluări

- Textile Finishing: Recent Developments and Future TrendsDe la EverandTextile Finishing: Recent Developments and Future TrendsÎncă nu există evaluări

- SASO 369 1998 enDocument9 paginiSASO 369 1998 enAmir Sajjad0% (1)

- 첨부 1. Method Statement for Chemical Rebar Anchor - Draft (M3-AZ-MST-GCN00-C...Document33 pagini첨부 1. Method Statement for Chemical Rebar Anchor - Draft (M3-AZ-MST-GCN00-C...Amir SajjadÎncă nu există evaluări

- Luminaires: Part 1: General Requirements and Tests (IEC 60598-1, Ed. 7.0 (2008) MOD)Document17 paginiLuminaires: Part 1: General Requirements and Tests (IEC 60598-1, Ed. 7.0 (2008) MOD)Amir SajjadÎncă nu există evaluări

- 첨부 3. Reference Standard (ASTM E488)Document8 pagini첨부 3. Reference Standard (ASTM E488)Amir SajjadÎncă nu există evaluări

- 첨부 2. Calculation Report of HILTY Chemical Anchor (CASE-2)Document7 pagini첨부 2. Calculation Report of HILTY Chemical Anchor (CASE-2)Amir SajjadÎncă nu există evaluări

- NB-263 RCI-1 InquiriesDocument2 paginiNB-263 RCI-1 InquiriesAmir SajjadÎncă nu există evaluări

- 첨부 3. Reference Standard (ASTM E488)Document8 pagini첨부 3. Reference Standard (ASTM E488)Amir SajjadÎncă nu există evaluări

- NB-263 RCI-1 InquiriesDocument2 paginiNB-263 RCI-1 InquiriesAmir SajjadÎncă nu există evaluări

- Iec - 62722-2-1-2014Document22 paginiIec - 62722-2-1-2014Amir Sajjad0% (1)

- E1359 12Document8 paginiE1359 12Amir SajjadÎncă nu există evaluări

- NB-263 RCI-1 InquiriesDocument2 paginiNB-263 RCI-1 InquiriesAmir SajjadÎncă nu există evaluări

- SASO 765 (GS 416) Playground Equipment For Children Parks - Part 1: General Safety RequirementsDocument18 paginiSASO 765 (GS 416) Playground Equipment For Children Parks - Part 1: General Safety RequirementsAmir SajjadÎncă nu există evaluări

- Saso Astm F747 2011Document4 paginiSaso Astm F747 2011Amir SajjadÎncă nu există evaluări

- Saso 60598Document25 paginiSaso 60598Amir SajjadÎncă nu există evaluări

- 5817 PDFDocument18 pagini5817 PDFAmir SajjadÎncă nu există evaluări

- 0117e-Guide-Preparation Bend Testing of SpecimensDocument2 pagini0117e-Guide-Preparation Bend Testing of SpecimensİbrahimErenÎncă nu există evaluări

- 첨부 3. Reference Standard (ASTM E488)Document8 pagini첨부 3. Reference Standard (ASTM E488)Amir SajjadÎncă nu există evaluări

- Astm d1244Document5 paginiAstm d1244Amir SajjadÎncă nu există evaluări

- Jis G 03313 000 000 2010 e Ed10 I4Document60 paginiJis G 03313 000 000 2010 e Ed10 I4Amir SajjadÎncă nu există evaluări

- JIS Z 2201 StandardDocument18 paginiJIS Z 2201 StandardAmir Sajjad100% (2)

- Fashion History During:-1990s-Technology Era 2000s-Internet EraDocument29 paginiFashion History During:-1990s-Technology Era 2000s-Internet EradenisÎncă nu există evaluări

- A Report On The DevelopmentThe Design and Technical Development WorkshopDocument32 paginiA Report On The DevelopmentThe Design and Technical Development WorkshopsukhnagÎncă nu există evaluări

- 95 Pages Hi-Quality Tips and Techniques For ClayDocument94 pagini95 Pages Hi-Quality Tips and Techniques For Claymarshella100% (1)

- Beauty Care q3 Basic Pedicure 2 2Document55 paginiBeauty Care q3 Basic Pedicure 2 2Jairus Haro100% (2)

- Code 144 BookDocument38 paginiCode 144 BookVictor Vander0% (1)

- Transitions Paragraph and QuestionsDocument9 paginiTransitions Paragraph and QuestionsBlaise LacoursiereÎncă nu există evaluări

- Cartoon AnalysisDocument3 paginiCartoon AnalysisJELYN MAXINE HANAPONÎncă nu există evaluări

- Arabic SpeakingDocument196 paginiArabic SpeakingknopeÎncă nu există evaluări

- Classic Applique Embroidery: Project Needs & NotesDocument5 paginiClassic Applique Embroidery: Project Needs & Notesnomcebo dlaminiÎncă nu există evaluări

- 6000RUDocument80 pagini6000RUSamik MukherjeeÎncă nu există evaluări

- Jutti Keyword KeywordeverywhereDocument15 paginiJutti Keyword KeywordeverywhereRiya GupteÎncă nu există evaluări

- 1-Acción Didáctica 1er Grado Primaria Regular - Mayo, Junio y Julio 2022Document4 pagini1-Acción Didáctica 1er Grado Primaria Regular - Mayo, Junio y Julio 2022William JimenezÎncă nu există evaluări

- Pe Action PlanDocument8 paginiPe Action Planapi-217592309Încă nu există evaluări

- MSDS LaktosaDocument5 paginiMSDS LaktosaMuhammad FajarÎncă nu există evaluări

- Ideas by Gul Ahmed Final VersionDocument15 paginiIdeas by Gul Ahmed Final VersionIfrah NadeemÎncă nu există evaluări

- Design Inspiration Naturalism On ApparelsDocument9 paginiDesign Inspiration Naturalism On ApparelsSunil TalekarÎncă nu există evaluări

- Teen World Book Additional Sample PagesDocument2 paginiTeen World Book Additional Sample Pagesjoska222Încă nu există evaluări

- Msds Glutaraldehid 24%Document6 paginiMsds Glutaraldehid 24%febby diovanyÎncă nu există evaluări

- Courtship & Marriage of Asian CountryDocument11 paginiCourtship & Marriage of Asian Countrybaysiclyndon50% (2)

- I. Pass To Interrogative 1. She Is Walking The Dog Every DayDocument6 paginiI. Pass To Interrogative 1. She Is Walking The Dog Every DaydanielÎncă nu există evaluări

- Naruto Ultimate Ninja Storm ID SheetDocument41 paginiNaruto Ultimate Ninja Storm ID SheetThe StealistÎncă nu există evaluări

- American Gyration - Spec ScriptDocument16 paginiAmerican Gyration - Spec ScriptMichael WorthyÎncă nu există evaluări

- Business Statistics 3rd Edition Sharpe Solutions ManualDocument36 paginiBusiness Statistics 3rd Edition Sharpe Solutions Manualswellishhonorer.fem0dz100% (43)

- How To Draw Manga Vol. 28 - CouplesDocument131 paginiHow To Draw Manga Vol. 28 - Couplescirce_sorceress90% (29)

- Scene 1 Cinderella L6Document3 paginiScene 1 Cinderella L6aviewatsÎncă nu există evaluări

- Operation Breakdown and SAM of The Full Sleeve Formal Men's ShirtDocument56 paginiOperation Breakdown and SAM of The Full Sleeve Formal Men's ShirtKumera HaileyesusÎncă nu există evaluări

- AttachmentDocument116 paginiAttachmenttextile028Încă nu există evaluări

- MGMT 2 Integrated Management System: Tamondong Jake Veneracion Anth Krvin Obedoza Joshua Bongbonga Andrew Villarico JamesDocument16 paginiMGMT 2 Integrated Management System: Tamondong Jake Veneracion Anth Krvin Obedoza Joshua Bongbonga Andrew Villarico JamesalfaÎncă nu există evaluări

- Garment Worker Exploitation Fast FashionDocument10 paginiGarment Worker Exploitation Fast Fashionapi-565360584Încă nu există evaluări

- Kryx's HouserulesDocument157 paginiKryx's HouserulesEthan WhiteÎncă nu există evaluări