Documente Academic

Documente Profesional

Documente Cultură

Paint Shop PDF

Încărcat de

arunenggTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Paint Shop PDF

Încărcat de

arunenggDrepturi de autor:

Formate disponibile

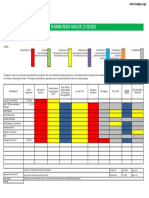

SWP No.

38

SAFE WORKING PROCEDURE Page: 1 of 1

Vehicle Paint Spraying

Date: July 2003

Personal Protective

Key Hazards Risks

Equipment

1. Pressure Systems 1. Fires/Explosions 1.

Disposable overalls (hooded)

2. Flammable Vapours 2. Hearing Damage 2.

Appropriate Respiratory

3. Solvents 3. Respiratory Damage Protection

4. Isocyanates 4. Eye Damage 3.

Gloves

5. Sensitisation 4.

Eye protection

6. Dermatitis

DO DO NOT

• Only use spraying equipment if trained and authorised • Spray paints without extraction systems

to do so operating

• Ensure that spray booth has negative pressure during • Never spray isocyanates without using

spraying operation extraction ventilation and air fed RPE

• Ensure that ventilation systems are maintained and • Never spray water based paints without the

thoroughly examined by a competent person at least use of extraction and suitable RPE

every 14 months • Do not eat, drink or smoke when using,

• Use HVLP equipment where possible to reduce mixing or pouring paints and thinners

overspray

• Do not spray isocyanate based paint unless

• Wear appropriate PPE

in the proprietary spray booth

• Visually inspect respiratory protective equipment

(RPE) for damage before use and replace filters

• Never use carbon type RPE when spraying

• Ensure that air fed RPE is maintained, compressed air isocyanate based paint

quality is tested and records kept, water/oil separator • Never take risks with vehicles with full fuel

traps emptied frequently tanks in low bake booths

• Use only air fed RPE when spraying isocyanate based • Do not use high pressure paint spraying

paints when spraying into ‘confined’ areas such as

• Keep paint storage to a minimum within the work area door shuts, etc

• Keep paints and thinners lidded at all times when not • Never use substances without first reading

in use the COSHH assessment

• Prevent spillages and accidental skin and eye contact

– wear appropriate PPE (gloves, eye protection, etc)

• Dispose of daily waste in a lidded metal bin Specific Training Requirements

• All waste paints, thinners, booth filters require careful

handling and disposal under the Special Waste • Use of paint spraying equipment

Regulations

• Maintenance of RPE and log keeping

• Store flammables in a flammables store/cabinet

• Ensure extraction ventilation is switched on when

pouring or mixing paints

• Ensure that all electrical items in rooms where paint is

stored, mixed or sprayed are intrinsically safe

• Attend regular health surveillance for lung function and References

skin checks • Special Waste Regulations

• Ensure that all fire escape routes are clear and free • SWP 59 Use of compressors & compressed air

from obstruction equipment

• Keep unauthorised personnel out of spraying rooms • Provision & Use of Work Equipment Regs

and paint mixing areas • PPE Regs

• Follow all COSHH control measures identified in the • Reporting Injuries Diseases and Dangerous

assessment Occurrences Regs [RIDDOR]

• Operators Handbook

S-ar putea să vă placă și

- Generator (Portable) PDFDocument1 paginăGenerator (Portable) PDFcityofdarwingisÎncă nu există evaluări

- Name: SignDocument1 paginăName: SignAdel AlKhedawyÎncă nu există evaluări

- Personal protective equipment Complete Self-Assessment GuideDe la EverandPersonal protective equipment Complete Self-Assessment GuideEvaluare: 5 din 5 stele5/5 (1)

- MSDS - Asada Threading Oiil Red - ENDocument7 paginiMSDS - Asada Threading Oiil Red - ENnghiaÎncă nu există evaluări

- 1.tech Pneumatic Tool Safety 20180207Document2 pagini1.tech Pneumatic Tool Safety 20180207Ku RatheeshÎncă nu există evaluări

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 paginiCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaÎncă nu există evaluări

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 paginiAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640Încă nu există evaluări

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 paginiAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferÎncă nu există evaluări

- RadiographyDocument1 paginăRadiographyNature BeautiesÎncă nu există evaluări

- Jsa Confined Space EntryDocument11 paginiJsa Confined Space EntryNii AshiiiÎncă nu există evaluări

- Dry Bulk Product Safety SOPDocument14 paginiDry Bulk Product Safety SOPWan Sek ChoonÎncă nu există evaluări

- Ramapo College Vehicle Fueling SOPDocument1 paginăRamapo College Vehicle Fueling SOPAnees EkÎncă nu există evaluări

- John Burke - Safe Work at HeightDocument32 paginiJohn Burke - Safe Work at HeightRoman DuranÎncă nu există evaluări

- Basic Safety AwarenessDocument12 paginiBasic Safety AwarenessAkuabataÎncă nu există evaluări

- Spill Kit HandlingDocument2 paginiSpill Kit HandlingHanan SarwarÎncă nu există evaluări

- TBT 30 HousekeepingDocument2 paginiTBT 30 HousekeepingfrancisÎncă nu există evaluări

- Cold weather safetyDocument11 paginiCold weather safetyotak04Încă nu există evaluări

- Bolt TorquingDocument2 paginiBolt TorquingREHAN IQBALÎncă nu există evaluări

- JSA - EDDY CURRENRT - AmendedDocument1 paginăJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemÎncă nu există evaluări

- Safe Working PracticesDocument7 paginiSafe Working PracticesDiana ParkerÎncă nu există evaluări

- Updated - COSHH Risk Assessment 1 - Sherwin Willams PrimerDocument2 paginiUpdated - COSHH Risk Assessment 1 - Sherwin Willams PrimerPaul McGahanÎncă nu există evaluări

- Welding PPE GuideDocument9 paginiWelding PPE Guidecyrelle rose jumentoÎncă nu există evaluări

- JSA CT Cement (Example)Document2 paginiJSA CT Cement (Example)aneshseÎncă nu există evaluări

- FUSHAN TECH SAFETY PROCEDUREDocument11 paginiFUSHAN TECH SAFETY PROCEDUREhoangmtbÎncă nu există evaluări

- Behavior Based Safety (BBS) : Emco QatarDocument29 paginiBehavior Based Safety (BBS) : Emco QatarparthaÎncă nu există evaluări

- HSE Emergency Response ChecklistDocument4 paginiHSE Emergency Response ChecklistMargaretta WijayantiÎncă nu există evaluări

- JHA GasesDocument2 paginiJHA GasesalokcÎncă nu există evaluări

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 paginiProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (2)

- Working at Height Rescue Plan: WHS-FM-008Document2 paginiWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoÎncă nu există evaluări

- Aerial Lift Inspection FormsDocument15 paginiAerial Lift Inspection FormsianÎncă nu există evaluări

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 paginiJSA For Rebar Works Includes Working in ScaffoldingMohammed Minhaj100% (1)

- JHA Maintenance Tech HVACDocument2 paginiJHA Maintenance Tech HVACMdavaÎncă nu există evaluări

- Surface Blasting Safety Procedures ManualDocument21 paginiSurface Blasting Safety Procedures ManualRajanbabu100% (1)

- PPE Hazard Assessment for Pharmacy TechsDocument6 paginiPPE Hazard Assessment for Pharmacy Techsgabguarse100% (2)

- JHA For Radiography TestDocument8 paginiJHA For Radiography TestM8Rskn6wcÎncă nu există evaluări

- Hot Work Program PDFDocument49 paginiHot Work Program PDFAnonymous wtK1AZBiÎncă nu există evaluări

- Toolbox Talk 9: Critical Risks - ExcavationsDocument2 paginiToolbox Talk 9: Critical Risks - ExcavationsPravin GowardunÎncă nu există evaluări

- JsaDocument10 paginiJsaTanzeel LiaqatÎncă nu există evaluări

- Explosive Safety EssentialsDocument40 paginiExplosive Safety EssentialsLolita Mamore-gandiaÎncă nu există evaluări

- Jsa CompressorDocument9 paginiJsa CompressorRavi thokalÎncă nu există evaluări

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 paginiJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteÎncă nu există evaluări

- Safe Operating Procedure: Pinch PointsDocument1 paginăSafe Operating Procedure: Pinch PointsAndri IrawanÎncă nu există evaluări

- Metal Chop Saw SopDocument2 paginiMetal Chop Saw SopkylealamangoÎncă nu există evaluări

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDocument37 paginiFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongÎncă nu există evaluări

- 0400E-CHB - Sulfuric AcidDocument1 pagină0400E-CHB - Sulfuric AcidVeralord De VeraÎncă nu există evaluări

- Scaffolds: 1926 Subpart LDocument59 paginiScaffolds: 1926 Subpart LVijayakumarVageesanÎncă nu există evaluări

- Hot Work at Height and From Scaffolding Presents Special Hazards. Additional Requirements Are NeededDocument2 paginiHot Work at Height and From Scaffolding Presents Special Hazards. Additional Requirements Are Neededテレブリコ ジェファーソンÎncă nu există evaluări

- Eye WashDocument21 paginiEye Washapi-273019508100% (1)

- JSEA FOR EARTH WORK (Alumina Silo Area)Document13 paginiJSEA FOR EARTH WORK (Alumina Silo Area)MD AbdullahÎncă nu există evaluări

- Activity 3.2.1 Training Needs Analysis (Document1 paginăActivity 3.2.1 Training Needs Analysis (Mahnoor MasroorÎncă nu există evaluări

- Confined Space Entry Safety AnalysisDocument2 paginiConfined Space Entry Safety AnalysisDheeraj Kapoor /QOGIL/QuippoworldÎncă nu există evaluări

- MWR 135Document20 paginiMWR 135Philip Bautista TotanesÎncă nu există evaluări

- Fan InstallationDocument2 paginiFan InstallationKrishna PatilÎncă nu există evaluări

- Jha Region7 GeoprobeDocument10 paginiJha Region7 Geoprobewasif ahmedÎncă nu există evaluări

- JSA Format Internal ReactorDocument13 paginiJSA Format Internal Reactorsakthi venkatÎncă nu există evaluări

- PPE EYE PROTECTIONDocument72 paginiPPE EYE PROTECTIONHaseeb AhsanÎncă nu există evaluări

- Manual Handling Safety TipsDocument1 paginăManual Handling Safety TipsNishadh NishÎncă nu există evaluări

- Field BusDocument25 paginiField BusarunenggÎncă nu există evaluări

- Ehs ProfileDocument22 paginiEhs ProfilearunenggÎncă nu există evaluări

- 19 III 1aDocument3 pagini19 III 1aarunenggÎncă nu există evaluări

- AAR Railroads Moving America SafelyDocument3 paginiAAR Railroads Moving America SafelyarunenggÎncă nu există evaluări

- Basics of Oil RefiningDocument6 paginiBasics of Oil RefiningarunenggÎncă nu există evaluări

- TS4000H Manual PDFDocument105 paginiTS4000H Manual PDFarunenggÎncă nu există evaluări

- DCSandPLC Cement PlantsDocument12 paginiDCSandPLC Cement PlantsWaqar Abdul GhaffarÎncă nu există evaluări

- Commercial DCSDocument30 paginiCommercial DCSarunenggÎncă nu există evaluări

- TS4000 Safety ManualDocument7 paginiTS4000 Safety ManualarunenggÎncă nu există evaluări

- Msds - Epoxy Paint PDFDocument4 paginiMsds - Epoxy Paint PDFarunenggÎncă nu există evaluări

- TS4000H Manual PDFDocument105 paginiTS4000H Manual PDFarunenggÎncă nu există evaluări

- TS4000H Data SheetDocument2 paginiTS4000H Data SheetarunenggÎncă nu există evaluări

- 2 - P K GoswamiDocument38 pagini2 - P K GoswamiarunenggÎncă nu există evaluări

- 1 - CS - Putting CSR On Top GearDocument3 pagini1 - CS - Putting CSR On Top GeararunenggÎncă nu există evaluări

- Paint Booth ChecklistDocument3 paginiPaint Booth ChecklistarunenggÎncă nu există evaluări

- Onboard Maintenance Paint Guide - tcm40 67407 PDFDocument9 paginiOnboard Maintenance Paint Guide - tcm40 67407 PDFPrince SadhotraÎncă nu există evaluări

- Painters SyndromeDocument4 paginiPainters SyndromearunenggÎncă nu există evaluări

- Safety Practices Oisd NormsDocument26 paginiSafety Practices Oisd NormsRaju100% (1)

- Lead Awareness Toolbox TalkDocument2 paginiLead Awareness Toolbox Talkarunengg100% (1)

- BE - EHS Instructions For Contractors - June 2015Document17 paginiBE - EHS Instructions For Contractors - June 2015arunenggÎncă nu există evaluări

- Eng - Jci Ehs Policy2017 FinalDocument1 paginăEng - Jci Ehs Policy2017 FinalarunenggÎncă nu există evaluări

- BE - EHS Instructions For Contractors - June 2015Document17 paginiBE - EHS Instructions For Contractors - June 2015arunenggÎncă nu există evaluări

- Natural Gas HighwayDocument7 paginiNatural Gas HighwayarunenggÎncă nu există evaluări

- BE - EHS Instructions For Contractors - June 2015Document17 paginiBE - EHS Instructions For Contractors - June 2015arunenggÎncă nu există evaluări

- Lessons Learned From Application of Risk Management in Shipment of LNGDocument19 paginiLessons Learned From Application of Risk Management in Shipment of LNGarunenggÎncă nu există evaluări

- Ship To Ship LNG Transfer TechnologyDocument54 paginiShip To Ship LNG Transfer Technologyarunengg100% (3)

- Intricacies of Designing Gas PipelinesDocument27 paginiIntricacies of Designing Gas PipelinesarunenggÎncă nu există evaluări

- Revised Guidelines On Industry Transport DisciplineDocument12 paginiRevised Guidelines On Industry Transport DisciplinearunenggÎncă nu există evaluări

- M 19Document18 paginiM 19Sunil Kumar100% (1)

- Sap Fi/Co: Transaction CodesDocument51 paginiSap Fi/Co: Transaction CodesReddaveni NagarajuÎncă nu există evaluări

- BIU and EU functions in 8086 microprocessorDocument12 paginiBIU and EU functions in 8086 microprocessorDaksh ShahÎncă nu există evaluări

- WM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersDocument4 paginiWM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersEdgar JimenezÎncă nu există evaluări

- Alexander Lee ResumeDocument2 paginiAlexander Lee Resumeapi-352375940Încă nu există evaluări

- ABN AMRO Holding N.V. 2009 Annual ReportDocument243 paginiABN AMRO Holding N.V. 2009 Annual ReportF.N. HeinsiusÎncă nu există evaluări

- SEEPZ Special Economic ZoneDocument2 paginiSEEPZ Special Economic ZonetarachandmaraÎncă nu există evaluări

- Analysis of Trend Following SystemsDocument52 paginiAnalysis of Trend Following SystemsClement Li100% (1)

- (EMERSON) Loop CheckingDocument29 pagini(EMERSON) Loop CheckingDavid Chagas80% (5)

- Tambunting Pawnshop Vs CIR Re VATDocument7 paginiTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureÎncă nu există evaluări

- Request Letter To EDC Used PE PipesDocument1 paginăRequest Letter To EDC Used PE PipesBLGU Lake DanaoÎncă nu există evaluări

- PDF Problemas Ishikawa - Free Download PDF - Reporte PDFDocument2 paginiPDF Problemas Ishikawa - Free Download PDF - Reporte PDFNewtoniXÎncă nu există evaluări

- Telangana Budget 2014-2015 Full TextDocument28 paginiTelangana Budget 2014-2015 Full TextRavi Krishna MettaÎncă nu există evaluări

- PaySlip ProjectDocument2 paginiPaySlip Projectharishgogula100% (1)

- What Role Can IS Play in The Pharmaceutical Industry?Document4 paginiWhat Role Can IS Play in The Pharmaceutical Industry?Đức NguyễnÎncă nu există evaluări

- OPIM101 4 UpdatedDocument61 paginiOPIM101 4 UpdatedJia YiÎncă nu există evaluări

- Instruction/Special Maintenance Instruction (IN/SMI)Document2 paginiInstruction/Special Maintenance Instruction (IN/SMI)ANURAJM44Încă nu există evaluări

- Cagayan Electric Company v. CIRDocument2 paginiCagayan Electric Company v. CIRCocoyPangilinanÎncă nu există evaluări

- Statement of PurposeDocument2 paginiStatement of Purposearmaan kaurÎncă nu există evaluări

- 10 Appendix RS Means Assemblies Cost EstimationDocument12 pagini10 Appendix RS Means Assemblies Cost Estimationshahbazi.amir15Încă nu există evaluări

- Modulus of Subgrade Reaction KsDocument1 paginăModulus of Subgrade Reaction KsmohamedabdelalÎncă nu există evaluări

- Parasim CADENCEDocument166 paginiParasim CADENCEvpsampathÎncă nu există evaluări

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDocument143 paginiAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieÎncă nu există evaluări

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnDocument122 paginiExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganÎncă nu există evaluări

- ProkonDocument57 paginiProkonSelvasatha0% (1)

- The Punjab Commission On The Status of Women Act 2014 PDFDocument7 paginiThe Punjab Commission On The Status of Women Act 2014 PDFPhdf MultanÎncă nu există evaluări

- Rejoinder To Adom Ochere's Misrepresentation - FinalDocument3 paginiRejoinder To Adom Ochere's Misrepresentation - FinalFuaad DodooÎncă nu există evaluări

- FZ16 9B 1KD2 (Patada) PDFDocument62 paginiFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- UBI1Document66 paginiUBI1Rudra SinghÎncă nu există evaluări

- SINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORDocument3 paginiSINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORElias EliasÎncă nu există evaluări

- Data SheetDocument14 paginiData SheetAnonymous R8ZXABkÎncă nu există evaluări