Documente Academic

Documente Profesional

Documente Cultură

WCE 2015 Proceedings Analyze Steel-Encased Composite Columns Using ANNs

Încărcat de

احمد حسينDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WCE 2015 Proceedings Analyze Steel-Encased Composite Columns Using ANNs

Încărcat de

احمد حسينDrepturi de autor:

Formate disponibile

Proceedings of the World Congress on Engineering 2015 Vol I

WCE 2015, July 1 - 3, 2015, London, U.K.

Analysis of Steel-Encased Composite Columns

Subjected to Concentric Axial Load Using

Artificial Neural Networks

Óscar Martínez-Ramos, David Hernández-Figueirido, and Ana Piquer

documents are Eurocode 4 [1] and AISC360 [2] (to be

Abstract—Composite steel-concrete members offer the referred as EC4 and AISC in this paper). The former is the

advantages of the best properties of each material. Different European unified design standard for composite structures

structural design codes have appeared around the world, but and the latter is the American code for steel structures.

Eurocode 4 and AISC360 are the reference guides. In this

paper, an experimental database on Steel Reinforced Concrete

The objectives of this paper are threefold: firstly, a

columns has been compiled and accuracy on predictions from historical review of experimental tests of concentrically

both codes has been checked. Based on Artificial Neural loaded SRC columns is shown; secondly, an assessment of

Networks, new expressions for predicting the ultimate load of the ability of EC4 and AISC to predict the behavior of such

compact and slender Steel Reinforced Concrete columns have columns, and finally a proposal of a neural-network-based

been developed. method to improve the prediction of the ultimate load is

given.

Index Terms—AISC360, Composite Columns, Eurocode 4,

Neural Networks, SRC, Steel Reinforced Concrete.

II. REVIEW OF EC4 AND AISC PROVISIONS

In this section, the way in which EC4 and AISC predict

I. INTRODUCTION the ultimate load is exposed. It should be noted that both

C OMPOSITE steel-concrete members can be made by a codes methods are based in Euler’s critical buckling load.

wide variety of cross-sections, but the most commonly Also, they are only applicable within a enclosed range of

used are concrete-encased I-shape steel (also called Steel parameters, such as material strengths and geometrical

Reinforced Concrete column, SRC) and concrete-filled steel considerations, which in some cases are overpassed by

tubes. available test specimens.

Although composite steel-concrete constructions have When comparing design calculations with the result of

been used for more than a century, all their advantages were experimental tests, the material safety factors specified in all

not fully understood at first; in the early twentieth century the design codes were set to unity.

concrete was used as a fire protection material for the steel A. Eurocode 4

profile, but the performance improvement produced by the

The simplified method offered by EC4 will be taken into

encasement was not yet considered. Nowadays, it is well

account in the analysis of this standard, since all specimens

known that these structural members exploit the synergistic

in the database have doubly symmetrical and uniform cross-

action of both materials; steel provides strength, ductility,

section.

light weight and fast erection, whereas concrete provides

stiffness, good performance at high temperatures and it is an

Resistance of cross-sections

economical material.

The plastic resistance to compression of a composite

In recent years, this type of composite members is being

cross-section is

increasingly used in a wide range of applications, such as

high-rise buildings, bridge piers and earthquake-resistant

N pl , Rk Aa · f y 0.85·Ac · f c As · f s . (1)

construction.

Many codes have been developed from experimental tests

Where:

results and later numerical analysis in order to stablish the

- Aa, Ac and As are the cross-sectional area of structural

design criteria of composite elements. Two of the guidance

steel shape, concrete and reinforcement, respectively.

- fy, fc and fs are the nominal value of the yield strength

Manuscript received March 5, 2015; revised March 31, 2015. of structural steel, the characteristic value of the 150x300

Óscar Martínez-Ramos is with Mechanical Engineering and mm cylinder compressive strength of concrete at 28 days

Construction Department, Universitat Jaume I, Castellón, Spain

(corresponding author, phone: +34-964728005; fax: +34-964728106; e-

and the characteristic value of the yield strength of

mail: omartine@uji.es). reinforcing steel, respectively.

David Hernández-Figueirido is with Mechanical Engineering and The slenderness ratio used in EC4 to evaluate instability

Construction Department, Universitat Jaume I, Castellón, Spain (e-mail: effects due to compression (buckling) is called relative

hernandd@uji.es).

Ana Piquer is with Department of Mechanical Engineering and slenderness (λ).

Construction, Universitat Jaume I, Castellón, Spain (e-mail:

ana.piquer@uji.es).

ISBN: 978-988-19253-4-3 WCE 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2015 Vol I

WCE 2015, July 1 - 3, 2015, London, U.K.

( N pl , Rk / N cr ) 0.5 (2) Where:

- χ is the reduction factor for the relevant buckling mode

given in EN 1993-1-1, 6.3.1.2 [4] in terms of the relevant

Where:

- Ncr is the elastic critical normal force. relative slenderness .

1

N cr 2 ( E·I )eff / L2 (3) (11)

2

2

- L is the effective buckling length of the column. 0.5·[1 ·( 0.2) 2 ] (12)

- (E·I)eff is the effective flexural stiffness.

Where:

( E·I ) eff E a ·I a 0 .6·E cm ·I c E s ·I s (4) - is an imperfection factor which depends on the

buckling axis. For strong axis buckling, =0.34 (curve b)

- Ia, Ic and Is are the second moment of inertia of the and for weak axis buckling, =0.49 (curve c).

structural steel section, the un-cracked concrete section and

the steel reinforcement, respectively. B. AISC

- The modulus of elasticity for structural and reinforced The compressive strength (NAISC) of doubly symmetric

steel is: Ea=Es=210 GPa. For concrete, there is a reference axially loaded SRC members is determined for the limit

to Eurocode 2 [3], table 3.1, where the secant modulus of state of flexural buckling based on member slenderness as

elasticity is defined as: follows:

Ecm 22( f c / 10) 0.3 (GPa) (5) N AISC Pno ·[0.658( Pno / Pe ) ] if Pno / Pe 2.25 (13)

N AISC 0.877·Pe if Pno / Pe 2.25 (14)

For member verification, a second order lineal analysis is

used. The design value for effective flexural stiffness Where:

(E·I)eff,II is determined from the following expression: - Pno has the same meaning as Npl,Rk defined in (1).

- Pe is the elastic critical buckling load and has the same

( E·I ) eff , II 0.9·( Ea ·I a 0.5·Ecm ·I c E s ·I s ) (6) expression that (3). Although the expression is the Euler’s

formula, there is a difference in the definition of the

The influence of geometrical imperfections is taken into effective stiffness of composite section:

account by an equivalent geometrical imperfection of

e0=L/200 for the strong axis and e0=L/150 for the weak axis. ( E·I ) eff E a ·I a C1·Ecm ·I c 0.5·E s ·I s (15)

Second order effects are evaluated by multiplying the C1 0.1 2·As / Ac As 0.3 (16)

greatest first order bending moment MEd by a factor k.

In this code, the slenderness ratio can be assumed to be

M Ed N Ed ·(e·k e0·k0 ) (7)

AISC ( Pno / Pe )0.5. (17)

Where:

- e is the eccentricity related to the considered axis.

III. REVIEW OF HISTORICAL EXPERIMENTAL TESTS

k / (1 N Ed / N cr,eff ) 1.00 (8) This section briefly explains the history of use and

0.66 0.44·r (9) research of SRC-based composite constructions and presents

an up-to-date database of experimental tests made with

steel-encased composite columns

- Ncr,eff is the critical nominal force for the relevant axis

and corresponding to the effective flexural stiffness given in A. Early times

(6), with the effective length taken as the column length. Composite elements appeared because of the need to

- β is an equivalent moment factor. protect steel members against fire, but the increase of

- r is the ratio between the end moments. According to resistance was not considered. For that reason, no

the way in which the forces are applied, this equals a ratio reinforcement bars were used in those first applications. In

between eccentricities at both ends. some cases, only a small amount of steel reinforcement was

- k0 has the same expression as (8), assuming β=1. employed to avoid concrete spalling due to fire.

After the big Kanto (Japan) earthquake in 1910, the

Resistance of members in axial compression excellent behavior of composite columns in seismic

The simplified method is used for members in axial conditions was reported and some studies were carried out

compression. The predicted axial force (NEC4) is calculated to better understand the joint performance of steel and

according to concrete.

For several decades, neither usage nor investigations were

N EC 4 ·N pl , Rk . (10) focused on composite construction. In 1965, Stevens [5] was

one of the firsts authors who carried on with investigations.

ISBN: 978-988-19253-4-3 WCE 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2015 Vol I

WCE 2015, July 1 - 3, 2015, London, U.K.

He tested a series of encased wide flange steel columns, during the tests.

concentrically loaded and with eccentricity on the minor

axis. Stevens reported that the reinforcement did not provide

further additional strength to the columns tested.

B. Historical efforts

Several researchers have made compilations of

experimental tests on composite columns. The first

experimental database was carried by SSRC Task Group, in

1979 [6] where 30 concentrically loaded and 44

eccentrically loaded SRC were reported. Some other authors

[7], [8], [9] and [10] have completed and expanded the

database.

C. Database review

The last database was elaborated in 2001, so there was a Fig. 1. Number of available tests of SRC columns subjected to concentric

need to review and complete it with the latest researches. A axial load according to the strength of the materials and the presence of

reinforcement.

new compilation of a significant amount of SRC columns

has been carried out, and is presented in this paper. The In Fig. 2, curve c from EC4 and AISC buckling curve

starting point for it was those mentioned above. The original have also been plotted, assuming that columns should fail

sources were checked, some tests were removed due to the about their weak axis. The EC4 prediction is plotted using

lack of information and some recent tests were included. (11) and (12) equations. The AISC curve is defined as:

A total of 164 tests were compiled, 48 with plain concrete

and 116 with steel reinforcement bars. Although modern

AISC N AISC / Pno , (19)

applications always include reinforcement, plain concrete

tests have also been included in this analysis.

using (13) and (14) for calculating NAISC, with relative

Materials slenderness according to AISC (17). In Fig. 2, relative

The main materials in SRC columns are the steel used in slenderness according to EC4 has been used in x-axis for

profiles and the concrete in covers. Steel is classified by the both curves.

yield strength (fy) and concrete is classified by the

compressive strength resistance that is measured in

cylindrical tests of 150 x 300 mm (fc). High strength

concrete is considered when fc>50 MPa and high strength

steel when fy>360 MPa. Normal strength materials are

considered when fc50 MPa and fy360 MPa.

Slenderness

Columns have been divided into compact and slender

columns. The slenderness ratio used in this paper is the

relative slenderness (λ), defined in (2).

The relative slenderness range considered in this study is

between 0.1 and 2.12. As stated in EC4, columns with

λ ≤ 0.2 are classified as compact, and its behavior is

governed by its cross-section strength; columns with λ > 0.2

are assumed to be slender. These columns are governed by

stability and fail by either elastic or inelastic column

buckling. Fig. 2. Experimental ratio of the tests according to material strengths and

The amount of available tests according to their buckling curves for EC4 and AISC.

slenderness and the strength of the materials is shown in Fig.

1. As can be seen in this figure, high strength materials have Both codes show a conservative prediction for most of

scarcely been used in research tests. Only 7.93% of normal strength material columns, as points lay well above

available tests were built with both high strength materials, both curves. In columns with normal strength concrete and

whereas 69.51% of tests have both normal materials. high strength steel, some points are close to the EC4 curve,

In order to compare test results with code predictions, in which means an accurate prediction, but others are above or

Fig. 2, experimental reduction factor (χEXP) has been plotted below the curve. Analyzing high strength concrete columns,

against the relative slenderness, calculated as defined in both columns with normal and high strength steel show a

EC4: behavior that differs from that predicted by EC4 and AISC.

Due to the small amount of available tests for these

EXP N EXP / N pl , Rk (18)

combinations, it would be advisable to conduct newer

experimental tests with high strength materials and evaluate

Where NEXP is the experimental failure load of the column the convenience of a new buckling curve.

ISBN: 978-988-19253-4-3 WCE 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2015 Vol I

WCE 2015, July 1 - 3, 2015, London, U.K.

IV. ANALYSIS WITH ARTIFICIAL NEURAL NETWORKS Oj f Ej (21)

Artificial Neural Networks (ANN) are arranged The output layer neurons receive these outputs affected

collections of simple processing units or nodes which are by another weights (wiS) and a bias (θS and applies a

able to solve highly nonlinear problems by learning from transfer function φ, which can be the same or different than

previous experience. that used before.

The basic unit of an ANN is called artificial neuron and

processes several weighted inputs through a given function

S O j ·w Sj S

N

(22)

to provide an output (Fig. 3). j 1

Purelin transfer function has been chosen as output

transfer function in every analysis. This function provides an

output proportional to the input.

N

S O j ·w Sj S (23)

j 1

The process through which the network becomes able to

Fig. 3. Basic structure of an Artificial Neuron. provide an accurate output is known as training. Back-

propagation is a supervised learning algorithm that is used

Neurons are arranged in layers and connected to other for training the net. The ANN is presented a set of training

neurons so every neuron’s output becomes another neuron’s data with known output values called targets. The initial

input. Connections are set between neurons in different weights are randomly set and the network output is

layers. There are no connections within the same layer. In a compared with the targets for every data in the training set.

feedforward multilayer perceptron there are three kinds of Subsequently the weights are adjusted. There is a number of

layers, namely one input layer, one or more hidden layers variations on the basic algorithm that are based on other

and one output layer (Fig. 4). standard optimization techniques. In this study, the

Levenberg-Marquardt algorithm is employed. The method

calculates the gradient of a performance function and adjusts

the weights in the steepest descent direction, in an attempt to

minimize this function. Every time performance has been

evaluated, an epoch is completed. This is an iterative

process that finishes when certain convergence criteria is

reached.

The performance function used in this study is the mean

Fig. 4. Basic structure of a feedforward multilayer perceptron. square error (mse), calculated for each item (k) of the

training data as:

The input and output layers have as many neurons as the

number of parameters considered to be the inputs and

P

mse ( k ) 0.5· ( sk tk ) 2 (24)

outputs of the problem. In this research, the inputs are k 1

assumed to be the axial capacity of each material acting

separately (Aa·fy, Ac·fc, As·fs) and the relative slenderness (λ). Where sk is each output value of the network and tk is the

The output is the failure load of the column. Thus, four target value for every item. P is the number of data in the

inputs and one output have been considered. pattern.

When designing an ANN, the number of hidden layers A. Compact columns

and the number of neurons per layer must be set in advance.

According to EC4, compact columns (λ≤0.2) are assumed

There is no specific rule about how to determine the number

to have a sectional behavior, independent of the slenderness

of hidden layers and neurons. In practical engineering

ratio. However, AISC takes into consideration slenderness

problems, a single hidden layer is considered to be sufficient

for every column.

[11]. In this paper, one hidden layer has been used in every

For stub columns, where both EC4 and AISC curves are

analysis, with a different number of neurons, as appropriate.

substantially horizontal, a linear behavior can be assumed

The output of every hidden layer neuron (Oj ;1 ≤ j ≤ N) is

for the ultimate load. When this occurs, a purelin transfer

the result of applying a transfer function f to the result of the

function with a single neuron in the hidden layer is the better

input function (Ej), a linear combination of the inputs

option.

(yi ;1 ≤ i ≤ n) affected by previously defined weights (wij) and

A total of 34 columns were presented to the net for the

an independent coefficient known as bias (θj) used to model training process. The ANN has been trained several times,

the threshold. The transfer function has been chosen and the network with the highest performance has been

differently for compact and slender columns. chosen. The performance is evaluated by the regression

coefficient (R). When comparing the real (NEXP) with the

n

Ej y i ·wij j (20) predicted (NANN) ultimate loads, the best regression

i 1

coefficient achieved was R = 0.988.

ISBN: 978-988-19253-4-3 WCE 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2015 Vol I

WCE 2015, July 1 - 3, 2015, London, U.K.

A design equation can be derived from the predictions of of predictions are over 1.1. In contrast, mean value for the

the trained network. For our best results of ANN, the Ratio obtained from the ANN is near to the unit and the

predicting equation (NANN) is: standard deviation is smaller than those obtained from the

codes.

N ANN 1 .095 Aa · f y 1.036 Ac · f c 1 .709 As · f s Nevertheless, ANN predictions lay on both sides of the

(25)

- 8856804 + 1228677 1:1 line, which could mean that some tests have been

underpredicted.

Where the cross-sectional area is expressed in mm2, the

TABLE I

material strengths in MPa and the load is obtained in N. STATISTICAL VALUES FOR COMPACT COLUMNS

B. Slender columns Ratio-EC4 Ratio-AISC Ratio-ANN

Slender columns (λ > 0.2) have a non-linear behavior. In Mean value 1.132 1.169 1.001

Standard deviation 0.134 0.136 0.096

this case, one of the most widely used transfer functions is

Ratio > 1.1 58.82% 70.59% 11.76%

chosen: the log-sigmoid transfer function. Thus, (21)

1 < Ratio ≤ 1.1 23.53% 20.59% 41.18%

becomes

0.9 < Ratio ≤ 1 17.65% 8.82% 29.41%

Ratio ≤ 0.9 0.00% 0.00% 17.65%

1

Oj . (26)

1 exp( E j )

Fig. 5 shows a plot of strength ratios for both codes and

the neural network. It can be seen that more accuracy and

For training the ANN, 130 columns have been used, with less scatter is achieved by ANN, since most of the points

relative slenderness ranging between 0.21 and 2.12. (70.59%) are within the 10% strip, in front of EC4

Different numbers of neurons in the hidden layer have predictions, that have 41.18% in this strip and AISC

been used to train the network, but no improvement has predictions, with a 29.41% in it.

been found when more than two neurons were implemented.

The best ANN found has R = 0.979, and as above, an

equation is derived:

1 .502 ·10 7 2 .238 ·10 7

N ANN 3 .111·10 5 (27)

1 exp( E1 ) 1 exp( E 2 )

Where:

E1 -4.555·10 -7 Aa · f y 8.040·10 8 Ac · f c

(28)

8.553·10 7 As · f s - 1.216 - 0.506

E 2 -9.167·10 -10 Aa · f y 1.195·10 7 Ac · f c

(29)

5.257·10 7 As · f s - 0.935 - 1

As before, when the cross-sectional area is expressed in

mm2 and the material strengths are in MPa, the load is

obtained in N.

V. COMPARISON BETWEEN ANN AND CODES PREDICTIONS Fig. 5. Strength ratios for compact columns.

In this section, the accuracy of the ANN predicting the

ultimate load is compared with EC4 and AISC standards. B. Slender columns

For that purpose, strength ratios are defined as Table II is equivalent to Table I, but related to slender

columns. It shows a bigger scatter of code predictions,

Ratio = NEXP / NPRED, (30) especially AISC predictions, with a high standard deviation.

where NPRED is the predicted load by ANN, EC4 and TABLE II

AISC. STATISTICAL VALUES FOR SLENDER COLUMNS

In order to better reflect the deviations of the predictions EC4 AISC ANN

from the experimental results, the -10% and +10% error Mean value 1.243 1.656 1.006

bounds are provided in Fig. 5 and Fig. 6. Standard deviation 0.299 0.909 0.170

Ratio > 1.1 64.62% 81.54% 31.54%

A. Compact columns 1 < Ratio ≤ 1.1 16.15% 6.15% 18.46%

Table I shows some statistical data about Ratios obtained 0.9 < Ratio ≤ 1 12.31% 7.69% 27.69%

from the three predictions. Ratio ≤ 0.9 6.92% 4.62% 22.31%

EC4 and AISC predictions are rather conservative: all of

the Ratios are above 0.9, and in both cases, more than half Both codes are still conservative, but some of predictions

ISBN: 978-988-19253-4-3 WCE 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2015 Vol I

WCE 2015, July 1 - 3, 2015, London, U.K.

are below Ratio 0.9. ANN predictions are nearly 50% on tests with compact and slender columns.

each side of Ratio=1, although more dispersion is found. Main design codes for composite construction, EC4 and

Fig. 6 a) shows that the higher the slenderness, the more AISC have been analyzed. Predictions from these standards

conservative the predictions are. In particular, AISC for SRC columns subjected to concentric axial load are

predictions are several times higher than experimental tests compared with experimental ultimate loads obtained from

for high slenderness. With regard to the results obtained tests. It has been found that both codes are rather

with the network, some of them lay in the unsafe zone conservative.

(22.31%). Subsequently, a new approach to predict ultimate loads

Fig. 6 b) is a zoom view of the dashed line square for concentrically loaded SRC columns is developed, based

highlighted in Fig. 6 a). In this area the most ANN on artificial neuron networks.

predictions are found around 1:1 line. The ANN prediction An artificial neuron network has been trained for each

fall on this line more than the standards predictions. It can type. From these networks, two equations have been derived

be seen that in general, AISC remains more conservative in after the training. The first one is a linear expression, since

this zone too. the behavior of compact columns is assumed to be linear.

Current regulations for composite construction are based The second one is based on log-sigmoid transfer functions,

on those developed for steel or concrete. Even when some due to the non-linear behavior of slender columns.

modifications to the original methods have been made, Performance of these networks and its associated

based on experimental studies, results differ markedly from expressions has been tested. Mean values for strength ratios

those obtained by tests. are very close to the unit and the standard deviation is

smaller than that obtained from the codes.

Future research will be aimed to improve design methods,

using artificial intelligence tools and to try to incorporate

them to the current codes.

REFERENCES

[1] European Committee for Standardization, “EN 1994-1-1:2004:

Eurocode 4. Design of composite steel and concrete structures – Part

1-1: General rules and rules for buildings.” Brussels (Belgium), 2004.

[2] American Institute of Steel Construction, “AISC 360:2010:

Specification for Structural Steel Buildings.” American Institute of

Steel Construction, Inc., Chicago, Illinois, 2010.

[3] European Committee for Standardization, “EN 1992-1-1:2004:

Eurocode 2: Design of concrete structures - Part 1-1: General rules

and rules for buildings.” Brussels (Belgium), 2004.

[4] European Committee for Standardization, “EN 1993-1-1: Eurocode 3:

Design of steel structures - Part 1-1: General rules and rules for

buildings.” Brussels (Belgium), 2005.

[5] R. F. Stevens, “Encased stanchions,” Struct. Eng., vol. 43, no. 2, pp.

59–66, 1965.

[6] Structural Stability Research Council (SSRC) - Task Group 20, “A

Specification for the Design of Steel-Concrete Composite Columns,”

Eng. J. AISC, vol. 101, no. 45, 1979.

[7] M. F. Aho, “A database for encased and concrete-filled columns.

M.Sc. Thesis,” School of Civil and Environmental Engineering,

Georgia Institute of Technology, Atlanta, Georgia, 1996.

[8] E. A. Lacroix, “Comparative study of strength design methods for

rectangular reinforced concrete and composite steel-concrete

columns. M.Sc. Thesis,” Department of Civil Engineering, University

of Manitoba, Winnipeg, Manitoba (Canada), 1998.

[9] R. T. Leon and M. F. Aho, “Towards new design provisions for

composite columns,” Compos. Constr. Steel Concr. IV, pp. 518–527,

2002.

[10] D. K. Kim, “A database for composite columns. M.Sc. Thesis,”

School of Civil and Environmental Engineering, Georgia Institute of

Technology, Atlanta, Georgia, 2005.

[11] M. Y. Rafiq, G. Bugmann, and D. J. Easterbrook, “Neural network

design for engineering applications,” Comput. Struct., vol. 79, no. 17,

pp. 1541–1552, Jul. 2001.

Fig. 6. Strength ratios for slender columns.

VI. CONCLUSION

In this paper, a database for experimental tests of SRC

columns subjected to axial load has been compiled and

analyzed. Available tests have been divided into two groups;

ISBN: 978-988-19253-4-3 WCE 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

S-ar putea să vă placă și

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- Article Shear Pier Hollow Core Circular SectionDocument11 paginiArticle Shear Pier Hollow Core Circular SectiontarekhocineÎncă nu există evaluări

- Load and Resistance Factors For Concrete Design: Aci Journal Technical PaperDocument9 paginiLoad and Resistance Factors For Concrete Design: Aci Journal Technical PaperHasanain AlmusawiÎncă nu există evaluări

- Experimental testing of joints for seismic design of lightweight structuresDocument14 paginiExperimental testing of joints for seismic design of lightweight structuresMikeÎncă nu există evaluări

- Damage PlasticityDocument12 paginiDamage PlasticityVibhanshu Mishra100% (1)

- Steel-Concrete Composite Members Using High-StrengDocument7 paginiSteel-Concrete Composite Members Using High-StrengAlbert FaragÎncă nu există evaluări

- Buckling of Rectangular Isolated R.C. Columns Closed-Form ApproximaDocument9 paginiBuckling of Rectangular Isolated R.C. Columns Closed-Form ApproximaAhmed MohammedÎncă nu există evaluări

- Comparative Analysis of Code-Based Approaches For Seismic Assessment of Existing Steel Moment Resisting Frames - 2021Document18 paginiComparative Analysis of Code-Based Approaches For Seismic Assessment of Existing Steel Moment Resisting Frames - 2021jcarlosgomez546Încă nu există evaluări

- Casafont - 1Document15 paginiCasafont - 1ma.shaheÎncă nu există evaluări

- 1 s2.0 S0950061816308893 MainDocument11 pagini1 s2.0 S0950061816308893 MainLeonardoÎncă nu există evaluări

- Nimiya Rose JoshuvaDocument9 paginiNimiya Rose JoshuvaVishnu P SudhakaranÎncă nu există evaluări

- 1 s2.0 S0167473022000261 MainDocument15 pagini1 s2.0 S0167473022000261 MaincarlhadrianlimÎncă nu există evaluări

- 10 1016@j Engstruct 2012 04 009Document32 pagini10 1016@j Engstruct 2012 04 009maximo.adhavÎncă nu există evaluări

- Computer Models For Nonlinear Analysis of Reinforced and Prestressed Concrete StructuresDocument20 paginiComputer Models For Nonlinear Analysis of Reinforced and Prestressed Concrete StructuresLavinia DamianÎncă nu există evaluări

- Chapter 6Document27 paginiChapter 6EDWARD T CHENJERAIÎncă nu există evaluări

- 02-Lignos EtAl-11NCEE ATC PaperRev1Document12 pagini02-Lignos EtAl-11NCEE ATC PaperRev1faisaladeÎncă nu există evaluări

- Dokumen - Tips - Tince2016 Steel Concrete Modules in Civil Work Design of Future Nuclear PowerDocument12 paginiDokumen - Tips - Tince2016 Steel Concrete Modules in Civil Work Design of Future Nuclear Power김현우Încă nu există evaluări

- Strengthening of Reinforced Concrete Columns by Steel Jacketing: A State of ReviewDocument10 paginiStrengthening of Reinforced Concrete Columns by Steel Jacketing: A State of Reviewsefatwrdk21Încă nu există evaluări

- Lightweight Steel Systems - Proposal and Validation of Seismic Design Rules For Second Generation of Eurocode 8Document15 paginiLightweight Steel Systems - Proposal and Validation of Seismic Design Rules For Second Generation of Eurocode 8n0188741wÎncă nu există evaluări

- Development of Research in Design of Segmental Box Type Superstructure in India A REVIEWDocument3 paginiDevelopment of Research in Design of Segmental Box Type Superstructure in India A REVIEWHardik TrivediÎncă nu există evaluări

- Comparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsDocument7 paginiComparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsEphrata MussieÎncă nu există evaluări

- A Study of Power Transmission PolesDocument22 paginiA Study of Power Transmission PolesVioleta LeonÎncă nu există evaluări

- Numerical and Analytical Investigations of Flextural Behaviour of ECC LWC Encased Steel BeamsDocument27 paginiNumerical and Analytical Investigations of Flextural Behaviour of ECC LWC Encased Steel BeamsCường NguyễnÎncă nu există evaluări

- Metal2021 Polat MetalDocument6 paginiMetal2021 Polat Metalrajiv jainÎncă nu există evaluări

- Journal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia MonacoDocument15 paginiJournal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia MonacoRami Alraof AlaydiÎncă nu există evaluări

- Engineering Structures: J.G. Ruiz-Pinilla, F.J. Pallarés, E. Gimenez, P.A. CalderónDocument13 paginiEngineering Structures: J.G. Ruiz-Pinilla, F.J. Pallarés, E. Gimenez, P.A. CalderónPaul KohanÎncă nu există evaluări

- Behaviour Factor of Code-Designed Steel Moment-Resisting FramesDocument12 paginiBehaviour Factor of Code-Designed Steel Moment-Resisting FramesWimpsÎncă nu există evaluări

- Investigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshDocument10 paginiInvestigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshIJRASETPublicationsÎncă nu există evaluări

- Simplified Assessment of Bending Moment CapacityDocument12 paginiSimplified Assessment of Bending Moment CapacityAlem LoajnerÎncă nu există evaluări

- Article 59794Document21 paginiArticle 59794BaNếpÎncă nu există evaluări

- Comparision IS VS EURO PDFDocument7 paginiComparision IS VS EURO PDFRadhaKrishnanTÎncă nu există evaluări

- Finite Element Analysis of R.C Beams Using Steel Scraps Under Cyclic Loading Using ETABSDocument5 paginiFinite Element Analysis of R.C Beams Using Steel Scraps Under Cyclic Loading Using ETABSjuan carlosÎncă nu există evaluări

- Bending Tests of Aluminium Alloy Cross-SectionsDocument12 paginiBending Tests of Aluminium Alloy Cross-SectionsRui MatiasÎncă nu există evaluări

- Study On Design of Steel Building in Earthquake ZonesDocument202 paginiStudy On Design of Steel Building in Earthquake ZonesAndreea CrisanÎncă nu există evaluări

- Steel Orthotropic Decks: Developments in The 1990sDocument8 paginiSteel Orthotropic Decks: Developments in The 1990sMARIOÎncă nu există evaluări

- Strong Column-Weak Beam Concept and Stiffness Factor Study For Moment Ressisting FramesDocument9 paginiStrong Column-Weak Beam Concept and Stiffness Factor Study For Moment Ressisting FramesInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- 4D Analysis of Segmental Cable Stayed Bridges PDFDocument10 pagini4D Analysis of Segmental Cable Stayed Bridges PDFHesham Nour EldeenÎncă nu există evaluări

- Analytica Prediction of Availabel Rotation Capacity of Cold Formed RHS and SHS BeamsDocument12 paginiAnalytica Prediction of Availabel Rotation Capacity of Cold Formed RHS and SHS BeamsganeshÎncă nu există evaluări

- Finite Element Analysis ofDocument23 paginiFinite Element Analysis ofDr. Shwan H. Said د. شوان حسين سعيدÎncă nu există evaluări

- Anchor BoltDocument20 paginiAnchor Boltsyed AffanÎncă nu există evaluări

- Article Exe2Document7 paginiArticle Exe2PUI DE GAMINGÎncă nu există evaluări

- Thin-Walled Structures: Khaled M. El-Sawy, Amr M.I. Sweedan, Mohamed I. MartiniDocument10 paginiThin-Walled Structures: Khaled M. El-Sawy, Amr M.I. Sweedan, Mohamed I. MartinialbertoxinaÎncă nu există evaluări

- Design Comprasion of Encased Composite Column Under Bi Axial Loading As Per Eurocode-4 and Aisc - LRFD CodeDocument12 paginiDesign Comprasion of Encased Composite Column Under Bi Axial Loading As Per Eurocode-4 and Aisc - LRFD CodeRonakShahÎncă nu există evaluări

- Simplifying Eurocode 8 Ductile Detailing Rules For Reinforced Concrete StructuresDocument12 paginiSimplifying Eurocode 8 Ductile Detailing Rules For Reinforced Concrete StructuressongkkÎncă nu există evaluări

- Abhrjul Aug 84 89435 Durack PDFDocument6 paginiAbhrjul Aug 84 89435 Durack PDFyanickdouce5408Încă nu există evaluări

- A Study of Reinforced Concrete Bridge Columns RetrDocument11 paginiA Study of Reinforced Concrete Bridge Columns Retrnattanai kuangmiaÎncă nu există evaluări

- Post Tension SlabsDocument15 paginiPost Tension SlabsHayman AhmedÎncă nu există evaluări

- Concrete Columns PDFDocument9 paginiConcrete Columns PDFAnne Karollynne CastroÎncă nu există evaluări

- Experimental Investigation of Existing Non Conforming RC Shear Walls - 2017Document13 paginiExperimental Investigation of Existing Non Conforming RC Shear Walls - 2017John ChivÎncă nu există evaluări

- EuroCode 4 - Lecture 2Document9 paginiEuroCode 4 - Lecture 2Tấn Đạt PhanÎncă nu există evaluări

- Resistance of Steel Connections To Low-Cycle FatigDocument12 paginiResistance of Steel Connections To Low-Cycle FatigjoseÎncă nu există evaluări

- Progressive Collapse 3Document23 paginiProgressive Collapse 3KIA190705 STUDENTÎncă nu există evaluări

- Final Book Word DocumentDocument209 paginiFinal Book Word DocumentNasreen KhanamÎncă nu există evaluări

- Structural Safety: Adil Emre Özel, Esra Mete GüneyisiDocument14 paginiStructural Safety: Adil Emre Özel, Esra Mete GüneyisibhargavisattarÎncă nu există evaluări

- A Monotonic Smeared Truss Model To Predict The Envelope Shear Stress-Shear Strain Curve For Reinforced Concrete Panel Elements Under Cyclic ShearDocument21 paginiA Monotonic Smeared Truss Model To Predict The Envelope Shear Stress-Shear Strain Curve For Reinforced Concrete Panel Elements Under Cyclic ShearGonzalo TorrisiÎncă nu există evaluări

- Simplifying Eurocode 8 Ductile Detailing Rules for RC StructuresDocument12 paginiSimplifying Eurocode 8 Ductile Detailing Rules for RC StructuresMÎncă nu există evaluări

- A Study of Power Transmission Poles PDFDocument22 paginiA Study of Power Transmission Poles PDFanup waghmareÎncă nu există evaluări

- Cumbia. Theory and GuideDocument44 paginiCumbia. Theory and GuideElias RojanoÎncă nu există evaluări

- Merchant-Rankine Approach For The Design of SteelDocument24 paginiMerchant-Rankine Approach For The Design of Steelel000011Încă nu există evaluări

- ETABS & STAAD ComparisonDocument70 paginiETABS & STAAD Comparisonpido290% (1)

- المدونة العراقية للخرسانة الإنشائية-304-2011Document182 paginiالمدونة العراقية للخرسانة الإنشائية-304-2011mmalani0967% (6)

- Staircase DesignDocument28 paginiStaircase DesignIbnuyusoff77Încă nu există evaluări

- Staircase DesignDocument28 paginiStaircase DesignIbnuyusoff77Încă nu există evaluări

- SFPE Heat Transfer Verification Cases SolutionsDocument45 paginiSFPE Heat Transfer Verification Cases Solutionsاحمد حسينÎncă nu există evaluări

- Staircase DesignDocument28 paginiStaircase DesignIbnuyusoff77Încă nu există evaluări

- 04 Chapter 4Document31 pagini04 Chapter 4lysotheaÎncă nu există evaluări

- Staircase DesignDocument28 paginiStaircase DesignIbnuyusoff77Încă nu există evaluări

- Staircase DesignDocument28 paginiStaircase DesignIbnuyusoff77Încă nu există evaluări

- Cai 2003Document17 paginiCai 2003احمد حسينÎncă nu există evaluări

- Behaviour of Composite Floor Slabs Under Fire Conditions: M. M. Florides & K. A. CashellDocument8 paginiBehaviour of Composite Floor Slabs Under Fire Conditions: M. M. Florides & K. A. Cashellاحمد حسينÎncă nu există evaluări

- SlabDocument3 paginiSlabاحمد حسينÎncă nu există evaluări

- Design of Concrete Structures Interpretation of EbookDocument2 paginiDesign of Concrete Structures Interpretation of Ebookاحمد حسينÎncă nu există evaluări

- BirtelDocument14 paginiBirtelkrishnanunniÎncă nu există evaluări

- Indian Standard: Code of Practice For Composite Construction in Structural Steel and ConcreteDocument1 paginăIndian Standard: Code of Practice For Composite Construction in Structural Steel and Concreteاحمد حسينÎncă nu există evaluări

- Nakamura 2010Document1 paginăNakamura 2010احمد حسينÎncă nu există evaluări

- An Iterative Finite Difference Scheme For Buckling of Graphene Beam Subject To Axial Compressive LoadDocument4 paginiAn Iterative Finite Difference Scheme For Buckling of Graphene Beam Subject To Axial Compressive Loadاحمد حسينÎncă nu există evaluări

- Steel Concrete Composite Structures IntroductionDocument2 paginiSteel Concrete Composite Structures Introductionاحمد حسينÎncă nu există evaluări

- Steel Concrete Composite Structures IntroductionDocument2 paginiSteel Concrete Composite Structures Introductionاحمد حسينÎncă nu există evaluări

- Wang 2005Document17 paginiWang 2005احمد حسينÎncă nu există evaluări

- الدليل الموحد لمساعدة الباحثين العراقينDocument17 paginiالدليل الموحد لمساعدة الباحثين العراقينkjsdvnÎncă nu există evaluări

- Weld CheckDocument6 paginiWeld CheckArnold c ElverÎncă nu există evaluări

- Class 9 Sample Paper 2020-21Document3 paginiClass 9 Sample Paper 2020-21sasta jiÎncă nu există evaluări

- 12.6 Perform An Activity - Measuring The Critical Angle For Various MediaDocument2 pagini12.6 Perform An Activity - Measuring The Critical Angle For Various MediaRajeshri SoniÎncă nu există evaluări

- D Lucky Labeling of Graphs PDFDocument6 paginiD Lucky Labeling of Graphs PDFtony augustineÎncă nu există evaluări

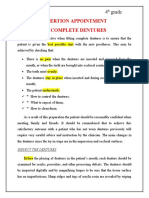

- Insertion Appointment of Complete Dentures: Lec 17 4 GradeDocument15 paginiInsertion Appointment of Complete Dentures: Lec 17 4 GradeSaif Hashim100% (1)

- OMC 140 Operator Manual v1.08Document38 paginiOMC 140 Operator Manual v1.08Anderson DuarteÎncă nu există evaluări

- Cics Class 05Document18 paginiCics Class 05HarithaÎncă nu există evaluări

- Machine DesignDocument69 paginiMachine DesignSushant TiwariÎncă nu există evaluări

- IMS2 Manual EngDocument61 paginiIMS2 Manual EngJhonatan BuenoÎncă nu există evaluări

- Connective TissueDocument6 paginiConnective TissuecrtgyhujikÎncă nu există evaluări

- State Standards: Common CoreDocument24 paginiState Standards: Common CoreEddy R. VélezÎncă nu există evaluări

- Gas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 ADocument33 paginiGas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 APélagie DAH SERETENONÎncă nu există evaluări

- Eng Grammar Book 8Document77 paginiEng Grammar Book 8ЖАНСАЯ Сейдахмет50% (2)

- EWDLEWML Servo Motor DriverDocument14 paginiEWDLEWML Servo Motor DriverWaleed LemsilkhiÎncă nu există evaluări

- CH 3Document19 paginiCH 3Abhishek GiriÎncă nu există evaluări

- PSD60-2R: Operation ManualDocument22 paginiPSD60-2R: Operation ManualOscar SantanaÎncă nu există evaluări

- Diffusion Weber and MorrisDocument12 paginiDiffusion Weber and MorrisFarah El ShahawyÎncă nu există evaluări

- Etap Help PDFDocument2 paginiEtap Help PDFRebeccaÎncă nu există evaluări

- A Framework For Transforming Artifacts From Data Flow Diagrams ToDocument7 paginiA Framework For Transforming Artifacts From Data Flow Diagrams Tow_mahmudÎncă nu există evaluări

- JefimenkoDocument10 paginiJefimenkoBilly M. SpragueÎncă nu există evaluări

- TRL External CommunicationDocument3 paginiTRL External CommunicationAyushGargÎncă nu există evaluări

- 01238-00-AD TY96 Installation ManualDocument42 pagini01238-00-AD TY96 Installation ManualJohan SwanepoelÎncă nu există evaluări

- 3-Lecture 03 Translational Mechanical System3-SDocument23 pagini3-Lecture 03 Translational Mechanical System3-SHamza KhanÎncă nu există evaluări

- Earth and Life Science Test ReviewDocument3 paginiEarth and Life Science Test Reviewmerlyn m romerov100% (1)

- Chapter 1Document11 paginiChapter 1bekemaÎncă nu există evaluări

- Mammography View ChapterDocument60 paginiMammography View ChapterSehar GulÎncă nu există evaluări

- The World of Chemistry Video Guide SetDocument10 paginiThe World of Chemistry Video Guide SetrkvÎncă nu există evaluări

- Si™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Document23 paginiSi™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Agenor CarvalhoÎncă nu există evaluări

- AminesDocument31 paginiAminesJoseph YayenÎncă nu există evaluări

- Chapter 1: Introduction: 1.1 Background TheoryDocument36 paginiChapter 1: Introduction: 1.1 Background TheoryBe-fit Be-strongÎncă nu există evaluări