Documente Academic

Documente Profesional

Documente Cultură

Excel PV 2016 Demo Version

Încărcat de

ahmadlieDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Excel PV 2016 Demo Version

Încărcat de

ahmadlieDrepturi de autor:

Formate disponibile

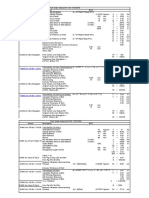

General Information

Excel

PV

Location:

Purchaser: Excel Design Softwares

Vessel Name:

Service:

40" ID Sample Tank

2016

P.O. Number:

Tag Number:

Designer: Irfan Shaikh

Design Conditions

Internal Pressure [psi] 480.00 Materials

Internal Temperature [ºF] 250.00 Shell Material SA 516 Gr.70

Test Temperature [ºF] 70.00 Head Material SA 516 Gr.70

Fluid Specific Gravity 1 Nozzle Material SA 516 Gr.70

Fluid Height [in.] 119.9635 Nozzle Pad Material SA 516 Gr.70

Head Type

Top ⁽ᴴᵉᵃᵈ ¹⁾ Elliptical

Dimensions Bottom ⁽ᴴᵉᵃᵈ ²⁾ Elliptical

Vessel Diameter [in.] 40.00

Shell Length [in.] 120.00 60

Inner Corrosion Allowance [in.] 0.0300 Elliptical Axes Ratio (1-3) 2

Outer Corrosion Allowance [in.] 0.0000 Straight Flange ⁽ᴴᵉᵃᵈ ¹⁾ [in.] 1.5

Min. Thickness ᵁᴳ⁻¹⁶⁽ᵇ⁾ [in.] Compressed Air/Steam/Water

Thinning Allowance [in.] 0.0300 60

Polishing Allowance [in.] Elliptical Axes Ratio (1-3) 2

Straight Flange ⁽ᴴᵉᵃᵈ ²⁾ [in.] 1.5

Radiography

Longitudinal (Shell) None UW-11(c) Type 1 Longitudinal (Head) Seamless No RT

Circumferential (Shell) None UW-11(c) Type 1 Circumferential (Head) None UW-11(c) Type 1

Shell Plate Thickness 0.75 [in.] EFE Acceptable Thickness

Head 1 Plate Thickness Demo [in.]

Head 2 Plate Thickness Demo [in.]

①

②

③

ASME Section VIII, Division 1, 2015 Edition Excel Design Softwares Excel PV 2016

Excel Design Softwares

Purchaser: Excel Design Softwares Vessel Name: 40" ID Sample Tank

Tag Number: 0 Mark Number: S1

Designer: Irfan Shaikh Date Printed: 5/23/2018

Cylindrical Shell Design Information

Design Pressure: 480.000 psi Design Temperature: 250 ºF

Static Head: 4.329 psi Long. Joint Efficiency: 70 %

Shell Material: SA 516 Gr.70

Shell Length: 120.0000 in. Stress at Design temperature: 20000 psi

Inside Diameter: 40.0000 in. Stress at 70 ºF temperature: 20000 psi

Inner Corrosion Allowance: 0.0300 in. Extreme Fiber Elongation: 1.84 %

Outer Corrosion Allowance: 0.0000 in. Minimum Thickness ᵁᴳ⁻¹⁶⁽ᵇ⁾: 0.12375 in.

Circ. Joint Efficiency: 70 %

Shell Estimated Volume: 652.80 US Gal.

Shell Surface Area: 106.03 ft² ShellEstimated Weight: 3260.67 lb

Cylindrical Shell Design Calculations

Required Thickness at 250 ºF:

tc(a) = P * R / (S * E - 0.6 * P) {Paragraph UG-27(c)(1)}

Demo Version o Version in.

tc(b) = P * R / (2 * S * E + 0.4 * P) {Paragraph UG-27(c)(2)}

Demo Version o Version in.

Demo Version Demo Version in.

Demo Version

Maximum Allowable Working Pressure, Corroded at 250 ºF:

Pc(a) = S * E * t / (R + 0.6 * t) {Paragraph UG-27(c)(1)}

Demo Version o Version psi

Pc(b) = 2 * S * E * t / (R - 0.4 * t) {Paragraph UG-27(c)(2)}

Demo Version o Version psi

Demo Version Demo Version psi

Maximum Allowable Pressure, New at 70 ºF: {Paragraph UG-27(c)(1)}

Pc = S * E * t / (R + 0.6 * t) MAP = Pc - Ps

Demo Version 0 Demo Version psi

Extreme Fiber Elongation: {Paragraphs UG-79}

EFE = 50 * (t / Rf) * (1 - Rf / Ro)

Demo Version o Version %

Demo Version

Nominal Shell Thickness Selected = 0.75 in.

Nominal Shell Thickness Selected = 0.75 in.

ASME Section VIII, Division 1, 2015 Edition Excel PV 2016

Excel Design Softwares

Purchaser: Excel Design Softwares Vessel Name: 40" ID Sample Tank

Tag Number: 0 Mark Number: H1

Designer: Irfan Shaikh Date Printed: 5/23/2018

Top Head Design Information

Design Pressure: psi Design Temperature: ºF

Static Head: psi Joint Efficiency: %

Head Material:

Stress at Design temperature: psi

Dish Type: Stress at 70 ºF temperature: psi

Inside Diameter: in. Minimum Thickness ᵁᴳ⁻¹⁶⁽ᵇ⁾: in.

Extreme Fiber Elongation: %

Inner Corrosion Allowance: in. ### in.

Outer Corrosion Allowance: in. K Factor=(1/6)*(2+(D/(2*h))²):

Thinning Allowance: in. K Factor(corroded):

Polishing Allowance: in. Skirt/Straight Flange Length: in.

Head Design Calculations

Required Thickness at 250 ºF:

###

###

###

###

###

###

###

Extreme Fiber Elongation:

###

###

###

###

###

###

###

S-ar putea să vă placă și

- External Pressure - Pressure Vessel EngineeringDocument15 paginiExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- Thickness Calculation of Pressure Vessel ShellDocument17 paginiThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Toriconical Head Ver 1.1Document4 paginiToriconical Head Ver 1.1Iqbal AhmadsÎncă nu există evaluări

- Weight Estimation of Vessels AppsDocument26 paginiWeight Estimation of Vessels Appsdhavalesh1Încă nu există evaluări

- ASME Pressure VesselsDocument41 paginiASME Pressure VesselsJawed Akhter100% (1)

- Nozzle Design CalculationDocument1 paginăNozzle Design CalculationSachin55860% (1)

- Pressure Vessel Design TemplateDocument3 paginiPressure Vessel Design TemplateRamachandran Venkatesh0% (1)

- SHELLDocument6 paginiSHELLSalz EngineeringÎncă nu există evaluări

- Ligament Efficiency and Thickness of The Support PlateDocument10 paginiLigament Efficiency and Thickness of The Support PlatePankajDhobleÎncă nu există evaluări

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 paginiLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleÎncă nu există evaluări

- ASME Pressure Vessel Design-ADocument190 paginiASME Pressure Vessel Design-AWidyAdityaÎncă nu există evaluări

- Reinf S1Document2 paginiReinf S1tasingenieriaÎncă nu există evaluări

- Hydro-Test CalculationDocument5 paginiHydro-Test CalculationRitu SinghÎncă nu există evaluări

- Super CalculationsDocument9 paginiSuper CalculationsNoé MarínÎncă nu există evaluări

- Design of Pressure VesselDocument227 paginiDesign of Pressure VesselLê Ngọc ThảoÎncă nu există evaluări

- ASME B31.3 CalculatorDocument144 paginiASME B31.3 CalculatorLeoÎncă nu există evaluări

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 paginăK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjÎncă nu există evaluări

- Deaera DesignDocument13 paginiDeaera DesignBhanu K PrakashÎncă nu există evaluări

- Engineering Example CalculationDocument78 paginiEngineering Example Calculationkae kaeÎncă nu există evaluări

- Manual Design Validation CalculationDocument21 paginiManual Design Validation CalculationToniÎncă nu există evaluări

- UG 45 Sample CalculationDocument1 paginăUG 45 Sample CalculationAris Purniawan100% (1)

- Cone DevelopmentDocument2 paginiCone DevelopmentpandiangvÎncă nu există evaluări

- Dish CalculationDocument2 paginiDish CalculationRyan Goh Chuang HongÎncă nu există evaluări

- Compress CalculationDocument106 paginiCompress CalculationKrupal Patel100% (1)

- Heat Treatment Requirement Heat Treatment Requirement: o o o oDocument2 paginiHeat Treatment Requirement Heat Treatment Requirement: o o o ofizanlaminÎncă nu există evaluări

- U Stamp - KK Form - SampleDocument5 paginiU Stamp - KK Form - SampleshazanÎncă nu există evaluări

- How To Calculate Filler MetalDocument3 paginiHow To Calculate Filler MetalEdgar Coavas PérezÎncă nu există evaluări

- Top Pipe MomentDocument2 paginiTop Pipe Momentrsubramani100% (1)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 paginiDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Încă nu există evaluări

- Joint Efficiency TutorialDocument47 paginiJoint Efficiency TutorialJignesh ShahÎncă nu există evaluări

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocument1 paginăF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcÎncă nu există evaluări

- Extreme Fiber Elongation Calcs - J.SDocument1 paginăExtreme Fiber Elongation Calcs - J.SJ.SIVIRA100% (1)

- 300 - F&D Head Design Tool Ver E4.01Document1 pagină300 - F&D Head Design Tool Ver E4.01Mo ZeroÎncă nu există evaluări

- Edr 01 Dec 2018Document21 paginiEdr 01 Dec 2018AMALENDU PAULÎncă nu există evaluări

- ASME 31 - 8mDocument1 paginăASME 31 - 8mMarcoAlbaÎncă nu există evaluări

- Design Procedure For Aes He PDFDocument30 paginiDesign Procedure For Aes He PDFRyan Goh Chuang HongÎncă nu există evaluări

- Shell and Tube HE CalculationDocument16 paginiShell and Tube HE CalculationPradip ShindeÎncă nu există evaluări

- Asme Viii CalcsDocument20 paginiAsme Viii CalcsSriram VjÎncă nu există evaluări

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 pagină2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- Calculation of Air Receiver TankDocument2 paginiCalculation of Air Receiver TankAdhe GedeÎncă nu există evaluări

- RTJ Flange Dimensions - Class 150 To Class 2500 PDFDocument13 paginiRTJ Flange Dimensions - Class 150 To Class 2500 PDFRommy RomanzaÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650Document21 paginiStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 paginiStorage Tank Design Calculation - Api 650: Close Floating RoofhgagÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 paginiStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012Încă nu există evaluări

- Best Tank Calculation SheetDocument88 paginiBest Tank Calculation Sheetchriscivil12Încă nu există evaluări

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument13 paginiStorage Tank Design Calculation - Api 650: Close Floating Roofanto3harrish3fdo100% (1)

- Mechanical Calculation Tanky 53 KLDocument4 paginiMechanical Calculation Tanky 53 KLm khaeronÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 paginiStorage Tank Design Calculation - Api 650: Close Floating Roofvicky ssÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650Document92 paginiStorage Tank Design Calculation - Api 650Abelardo ContrerasÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650: Close Cone-RoofDocument14 paginiStorage Tank Design Calculation - Api 650: Close Cone-RoofSalah JallaliÎncă nu există evaluări

- DatasheetDocument2 paginiDatasheetnirmalÎncă nu există evaluări

- Input EchoDocument6 paginiInput EchohgagÎncă nu există evaluări

- Api Tank 400M3 HCDocument10 paginiApi Tank 400M3 HCCharles DogneÎncă nu există evaluări

- Code Calcs Rev1Document11 paginiCode Calcs Rev1Tauqeer AhmedÎncă nu există evaluări

- Pv-Elite He 101 - Rev 7Document118 paginiPv-Elite He 101 - Rev 7Dwi Putra100% (1)

- E-2020 ANALISISDocument82 paginiE-2020 ANALISISElkin PabaÎncă nu există evaluări

- Welding Calculation ModulDocument5 paginiWelding Calculation ModulricardoÎncă nu există evaluări

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 paginiPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoÎncă nu există evaluări

- API 650 Storage Tank 2400Document34 paginiAPI 650 Storage Tank 2400PANOLI PROJECTÎncă nu există evaluări

- Walkway XlxsDocument16 paginiWalkway XlxshgagÎncă nu există evaluări

- API 571 Damage MechanismsDocument29 paginiAPI 571 Damage Mechanismsahmadlie100% (4)

- API 571 Study GuideDocument5 paginiAPI 571 Study GuideMiryam Teresa Torres AcevedoÎncă nu există evaluări

- Viii - Inspection Checklist 2Document13 paginiViii - Inspection Checklist 2ahmadlie100% (2)

- P 192.481 Visually Inspect For Atmospheric Corrosion RevisionsDocument2 paginiP 192.481 Visually Inspect For Atmospheric Corrosion RevisionsahmadlieÎncă nu există evaluări

- The Importance of Corrosion Monitoring in Oilfield SystemsDocument19 paginiThe Importance of Corrosion Monitoring in Oilfield Systemsahmadlie100% (1)

- Pre-Asses CO2 Corrosion RateDocument2 paginiPre-Asses CO2 Corrosion Rateahmadlie100% (1)

- PRV and PSVDocument1 paginăPRV and PSVahmadlieÎncă nu există evaluări

- Engineering Units ConverterDocument23 paginiEngineering Units ConverterahmadlieÎncă nu există evaluări

- CorrosionDocument5 paginiCorrosionahmadlieÎncă nu există evaluări

- PSV Test FrequencyDocument130 paginiPSV Test Frequencyahmadlie100% (2)

- VISIO 2010 Tips and Techniques HandoutsDocument82 paginiVISIO 2010 Tips and Techniques HandoutsJerzyCPÎncă nu există evaluări

- DM Api 571Document24 paginiDM Api 571ahmadlie100% (2)

- Pre-Asses CO2 Corrosion RateDocument2 paginiPre-Asses CO2 Corrosion Rateahmadlie100% (1)

- Tempil-Iron Carbon DiagramDocument1 paginăTempil-Iron Carbon DiagramcutefrenzyÎncă nu există evaluări

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Document3 paginiLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieÎncă nu există evaluări

- Assessment Record Descriptive Aspects: Descriptive Criterion Safety Report Refs CommentsDocument2 paginiAssessment Record Descriptive Aspects: Descriptive Criterion Safety Report Refs CommentsahmadlieÎncă nu există evaluări

- 8244CD Excel-Template Double-pipe-heat-exchanger-Design P1and2 Us UnitsDocument2 pagini8244CD Excel-Template Double-pipe-heat-exchanger-Design P1and2 Us UnitsahmadlieÎncă nu există evaluări

- Pressure Drop in Water Gas Shift Reactor (Jason Keith)Document6 paginiPressure Drop in Water Gas Shift Reactor (Jason Keith)ahmadlieÎncă nu există evaluări

- 510 Pre Study Guide June 2006 - 2Document50 pagini510 Pre Study Guide June 2006 - 2justbye75% (4)

- 002 API 510 Course Puspatri Apr 09Document185 pagini002 API 510 Course Puspatri Apr 09ahmadlie100% (5)

- FRP Repair of CorrosionDocument13 paginiFRP Repair of CorrosionahmadlieÎncă nu există evaluări

- CP Presentation (Compressed)Document34 paginiCP Presentation (Compressed)ahmadlieÎncă nu există evaluări

- Hitman Contracts PC ManualDocument14 paginiHitman Contracts PC ManualChernoll MendoncaÎncă nu există evaluări

- Electrical Load For Indoor UnitsDocument2 paginiElectrical Load For Indoor UnitsMD BILAL ASLAMÎncă nu există evaluări

- M403 DatasheetDocument2 paginiM403 DatasheetmichelerenatiÎncă nu există evaluări

- MSETCL - Approved Vendor ListDocument11 paginiMSETCL - Approved Vendor ListNavaneetha KrishnanÎncă nu există evaluări

- FE Yeet GUIDocument3 paginiFE Yeet GUINobodyÎncă nu există evaluări

- InfoWorks ICM Overview 60 Mins PDFDocument31 paginiInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- Mobile Robots and Autonomous VehiclesDocument2 paginiMobile Robots and Autonomous VehiclesAbel Varghese DavidÎncă nu există evaluări

- Manto: at Work For You at Work For You at Work For You at Work For YouDocument4 paginiManto: at Work For You at Work For You at Work For You at Work For YouHossam Eldin kamalÎncă nu există evaluări

- Heat ConductionDocument11 paginiHeat ConductionAlex Samuel SilvaÎncă nu există evaluări

- Community Building PDFDocument2 paginiCommunity Building PDFLauren100% (1)

- TG-5 Relay SettingDocument10 paginiTG-5 Relay Settingbasil100% (1)

- 990 Vibration Transmitter Datasheet-141612mDocument14 pagini990 Vibration Transmitter Datasheet-141612mloopkkÎncă nu există evaluări

- Yuli's PPT FloralDocument28 paginiYuli's PPT FloralYuli MyeshaÎncă nu există evaluări

- C/C++ Programming Language NotesDocument68 paginiC/C++ Programming Language Notesctf challengeÎncă nu există evaluări

- Switch v7LAB StudentDocument206 paginiSwitch v7LAB Studentkcf4scribdÎncă nu există evaluări

- Emmeskay MIL-SIL TutorialDocument52 paginiEmmeskay MIL-SIL TutorialNeacsu EugenÎncă nu există evaluări

- Applies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)Document5 paginiApplies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)apletonprinceÎncă nu există evaluări

- ABB Wireless Communications For Mining OperationsDocument38 paginiABB Wireless Communications For Mining OperationsAymanÎncă nu există evaluări

- Sapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsDocument19 paginiSapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsYashi FakeÎncă nu există evaluări

- Introduction To Surveying PDFDocument27 paginiIntroduction To Surveying PDFArseni MaximÎncă nu există evaluări

- Role of Technology in AdvertisementtDocument29 paginiRole of Technology in AdvertisementtShalini ChatterjeeÎncă nu există evaluări

- Current Volt Meter Ina219Document40 paginiCurrent Volt Meter Ina219sas999333Încă nu există evaluări

- Manual Ni Usrp 2920Document56 paginiManual Ni Usrp 2920Anghye Plata100% (1)

- Ms 95-2018 Solved AssignmentDocument15 paginiMs 95-2018 Solved AssignmentPramod ShawÎncă nu există evaluări

- ETL Specification Table of Contents: Change LogDocument3 paginiETL Specification Table of Contents: Change LogKarthik RaparthyÎncă nu există evaluări

- Hong Kong International Airport Instrument Approach ChartDocument21 paginiHong Kong International Airport Instrument Approach ChartThamaroj ChansawangÎncă nu există evaluări

- Gen Target-2017Document22 paginiGen Target-2017SundeepÎncă nu există evaluări

- Advant Controller 4050series eDocument124 paginiAdvant Controller 4050series eABVSAIÎncă nu există evaluări

- LAB 1 HandoutDocument2 paginiLAB 1 HandoutManuGearÎncă nu există evaluări

- Color Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Document14 paginiColor Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Adam Michael GreenÎncă nu există evaluări