Documente Academic

Documente Profesional

Documente Cultură

Test Commissioning Plan Rev 1 Al Ri

Încărcat de

Adnan AttishDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Test Commissioning Plan Rev 1 Al Ri

Încărcat de

Adnan AttishDrepturi de autor:

Formate disponibile

T est in g & Co mmi ssi onin g Pl an

RTC/082/2013

Document No.:

M009 REI MEP PLN 00001 Revision 0.2

Document Type PLN - Plan

Reason for Issue 03 - Issued for Approval

T&C Manager Signature Date

Prepared by:

Burak Oral

Engineering Manager Signature Date

Checked by:

Tauqeer Ansari

QA/QC Manager Signature Date

Reviewed by:

Raul Go

Project Manager Signature Date

Approved by:

Wessam Alahmedy

Revision History

Rev. No. Description of Revision Date of Revision

0.1 First Issue 9 July 2017

0.2 Second Issue 4 Oct 2017

M009-REI-MEP-PLN-00001 Rev 0.2 Page 1 of 133

Testing & Commissioning Plan

Controlled copy Issue Log:

NB: This is only applicable to copies issued outside EDMS

This document has been issued in a controlled manner to the following recipients:

(In the event of a revision, the parties listed are to be issued with the updated version)

Copy No. Company Name Representative

M009-REI-MEP-PLN-00001 Rev 0.2 Page 2 of 133

Testing & Commissioning Plan

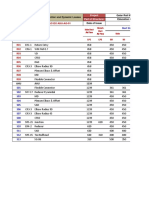

Table of Contents

1. INTRODUCTION ........................................................................................................... 6

1.1 Purpose .................................................................................................................. 6

1.2 Description .............................................................................................................. 6

1.3 Objectives ............................................................................................................... 6

1.4 References, Definitions & Abbreviation ................................................................... 7

1.4.1 References ...................................................................................................... 7

1.4.2 Definitions ........................................................................................................ 8

1.4.3 Abbreviations ................................................................................................. 12

1.4.4 Regulatory/Utilities Authorities ....................................................................... 13

2 SCOPE & LIST OF SYSTEMS ..................................................................................... 13

2.1 General ................................................................................................................. 13

2.2 Commission ability Assurance .............................................................................. 15

2.3 Commissioning Phase Scope ............................................................................... 16

3 COMMISSIONING RESPONSIBILITIES & OBLIGATIONS ......................................... 17

3.1 SPH Responsibilities ............................................................................................. 17

3.2 Commissioning Team ........................................................................................... 17

3.2.1 Members Appointed by MEP Sub-Contractor:................................................ 17

3.3 Responsibilities ..................................................................................................... 18

3.3.1 MEP Commissioning Authority Responsibilities: ............................................ 18

3.3.2 Manufacturer/Vendors/Specialist Responsibilities .......................................... 19

3.3.3 Planning and Scheduling FAT Activities ......................................................... 19

3.3.4 RAMS Demonstration Report ......................................................................... 19

3.3.5 FRACAS (Failure Reporting, Analysis & Corrective Action System) ............... 20

3.3.6 Change Management System ........................................................................ 20

3.4 Commissioning Management Process .................................................................. 21

3.5 Verification & Validation ........................................................................................ 22

3.6 Organizational Chart ............................................................................................. 24

3.7 RACI Matrix .......................................................................................................... 24

4 PROGRESS REPORTING .......................................................................................... 24

4.1 T&C Schedule....................................................................................................... 24

4.2 Commissioning Process Monitoring (CPM) Log .................................................... 25

4.3 Commissioning Inspection Monitoring (CIM) Log .................................................. 25

4.4 Commissioning Meeting’s ..................................................................................... 26

M009-REI-MEP-PLN-00001 Rev 0.2 Page 3 of 133

Testing & Commissioning Plan

4.5 Witnessing ............................................................................................................ 26

4.6 GSAS Requirement’s Validation ........................................................................... 26

5 OVERVIEW OF COMMISSIONING STRATEGY ......................................................... 28

5.1 Testing Strategy.................................................................................................... 28

5.2 Safety during T&C (Lock Out Tag Out & Permit to Work) ...................................... 28

5.3 Phases of the Project ............................................................................................ 29

5.4 Stages of the Project............................................................................................. 29

5.5 Test Before Completion ........................................................................................ 29

5.5.1 Design Stage: ................................................................................................ 29

5.5.2 Manufacture Stage – FAT Test (Stage 1):...................................................... 29

5.5.3 Installation Testing (IT) (Stage 2): .................................................................. 30

5.5.4 Partial Stand-Alone Test (PSAT) (Stage 3): ................................................... 30

5.5.5 Stand Alone Testing (SAT) (Stage 4) ............................................................. 30

5.6 Test on Completion ........................................................................................ 31

5.6.1 Integration Testing (Stage 5).......................................................................... 31

5.7 Test After Completion .................................................................................... 31

5.7.1 System Performance Testing (Stage 6) ......................................................... 31

6 DOCUMENTATION ..................................................................................................... 31

6.1 Test Procedures & Method of Statements for Tests: ............................................. 31

6.2 Check List & Test Sheet:....................................................................................... 32

6.3 Installation Test Reports: ...................................................................................... 33

6.4 Certificates: ........................................................................................................... 33

6.5 Test Pack: ............................................................................................................. 34

7 SYSTEM DESCRIPTIONS, TESTING & COMMISSIONING PROCEDURES,

STRATEGY, & INTERFACES. ............................................................................................ 35

7.1 HVAC System ...................................................................................................... 35

7.1.1 Installation Completion & Preparation ......................................................... 35

7.1.2 TAB Agency .................................................................................................. 35

7.1.3 References ................................................................................................... 36

7.1.4 Air Handling Units/Fresh Air Handling Units/Fan Coil Unit/Fans ..................... 36

7.1.5 Water Balancing ............................................................................................ 37

7.1.6 Air Balancing.................................................................................................. 37

7.1.7 Chemical Dosing Unit/Stream Filtration Unit .................................................. 37

7.1.8 Primary Chilled Water Pumps ........................................................................ 38

7.1.9 SRAC/CRAC Units......................................................................................... 38

7.1.10 Leakage Detection System for CHW Pre-insulated Pipe ................................ 39

7.1.11 Air Cooled Chiller ........................................................................................... 40

M009-REI-MEP-PLN-00001 Rev 0.2 Page 4 of 133

Testing & Commissioning Plan

7.2 Plumbing System .................................................................................................. 40

7.2.1 Installation Completion & Preparation ................................................................ 40

7.2.2 Booster Pump and Circulation Pumps......................................................... 41

7.2.3 Sump Pumps ................................................................................................ 41

7.2.4 Water Heater ................................................................................................ 42

7.2.5 Sand Filter .................................................................................................... 42

7.2.6 Chlorination of Portable Water System ....................................................... 42

7.2.7 Packaged Water Softener ............................................................................ 43

7.3 Fire Fighting System ............................................................................................. 43

7.3.1 Installation Completion & Preparation ................................................................ 43

7.3.2 Fire Pump ...................................................................................................... 44

7.3.3 Fire Hose Cabinets ........................................................................................ 44

7.3.4 Zone Control Valve & Sprinkler System ......................................................... 45

7.3.5 Clean Agent FM 200 System ......................................................................... 45

7.3.6 Fire Damper Drop Test .................................................................................. 45

7.4 Electrical System .................................................................................................. 46

7.4.1 Earthing ......................................................................................................... 46

7.4.2 MCC panels ................................................................................................... 47

7.4.3 Distribution boards ......................................................................................... 47

7.4.4 Variable Frequency Driver (VFD) ................................................................... 48

7.4.5 Automatic Transfer Switch (ATS) ................................................................... 49

7.4.6 Lightning Protection System .......................................................................... 49

7.4.7 Lighting System ............................................................................................. 50

7.4.8 Fire Alarm System ......................................................................................... 51

7.5 Interface Test ........................................................................................................ 52

7.5.1 Cause and Effect Testing ............................................................................... 52

7.5.2 Black-out Testing ........................................................................................... 53

8 CLIENT TRAINING ...................................................................................................... 53

9 FINAL DOCUMENTATION & HANDOVER .................................................................. 54

9.1 Equipment Data Sheets ............................................................................................... 55

9.2 O&M Manuals .............................................................................................................. 55

9.3 Manufacture Commissioning Report & Calibration Certificates .................................... 56

9.4 Drawings ...................................................................................................................... 56

10 ANNEXURE ................................................................................................................. 56

11 NFPA CODES and OTHER STANDARD REFRENCE............................................... 133

M009-REI-MEP-PLN-00001 Rev 0.2 Page 5 of 133

Testing & Commissioning Plan

1. INTRODUCTION

1.1 Purpose

This plan defines the method that will be used to ensure proper commissioning of the General

MEP Works of Qatar Rail, Green Line Elevated & At Grade Project. This plan reflects the

requirements of the Contract Documents and the obligation of the Qatar Rail Stations Green

Line Elevated and At Grade project team, the Design, the Consultants, the Commissioning

Authority, the relevant Main Contractors, MEP Contractors, and Supplier/Vendors as well as

a streamlined approach to allow for complete testing of the systems while maintaining the

necessary requirements associated with the works which is in the Employer’s requirement

,D+B Contractor, MEP Subcontractor and the Third Party T&C ( MECON) & TAB Agencies.

1.2 Description

Commissioning is the systematic process of ensuring all site and building components,

equipment, systems, and interfaces among systems perform in accordance with the design

intent, Employers Requirements and the contract documents. The commissioning process

encompasses and supplements the traditionally separate functions of system, equipment, and

component installation, checkout, startup, calibration, operational testing, adjustment and

balancing, functional performance testing, development of O&M manuals, development of

system manuals, development of as-constructed drawings, operation and maintenance

training, final acceptance testing, and deferred functional performance and seasonal testing.

1.3 Objectives

Ensure applicable equipment’s, systems, and components that are properly installed and

adequately checked out according to the manufacturer’s recommendations, industry

accepted standards, and the contract documents, prior to startup.

Ensure applicable equipment, systems, and components are started up, calibrated,

operationally tested (statically and dynamically), adjusted and balanced, and functionally

tested per the contract documents, prior to initiating operation and maintenance training

and final acceptance testing.

Ensure operation and maintenance manuals, system manuals, as-constructed drawings,

and other required documentation are developed, updated, and submitted in accordance

with the design intent and the contract documents.

Ensure Client operation and maintenance personnel are adequately train prior to

substantial completion of the work to provide routine operation and maintenance.

Ensure that the plan is developing document to attain score “1” and to achieve an overall

score of minimum “4” stars certification under GSAS (which shall be from 3rd party and

shall be as per latest revision 2010 and updated).

Ensure that T&C activities commenced according to the full complaint T&C plan and T&C

results shall validate this score.

GSAS provides direction for the commissioning process and ensure that commissioning

team should be fully aware and addressed during all phases of the building process from

pre-design to post-occupancy.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 6 of 133

Testing & Commissioning Plan

Ensure the T&C Plan is a “LIVE” document and such as will be subject to constant review

during the construction phase through the handover of Green Line Elevated & At Grade

project as the process of material approval and shop drawing production and

equipment/system installation continues.

A full commissioning management team shall be appointed to manage, co-ordinate,

monitor, witness, including system sign-off and verifying all the testing and commissioning

of station/tunnel engineering services.

The commissioning activities shall be undertaken and carried out by the commissioning

management team generated within Green Line Elevated & At Grade Project & by the

team of subcontractor (Redco).

The Green Line Elevated & At Grade Project MEP tests shall be carried out at all the

associated stations including their interconnecting tunnels, Trough, Cross passages,

Switch boxes, Emergency Exits etc.

1.4 References, Definitions & Abbreviation

1.4.1 References

The following other Contract Documents may contain requirements that relate to this

section of contract documents submittals:

INTERNATIONAL STANDARDS

UNI EN ISO 9001:2008 Quality Management system -Requirement

UNI EN ISO 9000:2005 Quality Management system -Fundamental and Vocabulary

UNI EN ISO 14001:2004 Environmental Management

OHSAS 18001:2007 Occupational Health and Safety Management System

BSI/BS British Standard Institute BS 7671

NFPA National Fire Protection Association

IEC International Electro Technical Commission

IEEE Institute of Electrical and Electronics Engineers

ANSI American National Standard Institute

NEMA National Electrical Manufacture Association

IES Illuminating Engineering Society

ASTM American Standards Testing and Materials

SMACNA Sheet Metal & Air Conditioning Contractor’s National Association

UL Underwriters Laboratory, Inc.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 7 of 133

Testing & Commissioning Plan

National Standards

QCS 2010 Qatar National Construction Standards

QCDD Qatar Civil Defense Standards

KAHRAMAA Qatar General Electricity and Water Corporation

BASE DOCUMENATION FOR TESTING AND COMMISSIONING PLAN

CMS Ref: TM-201-PP01, Rev- Qatar Rail Program Testing and Commissioning Management Plan

05,15/12/15 Rev-05

Volume 4: ER’s-General Section 17 T&C & Section 18 O&M Manuals (18.1)

Volume 5: ER’s-Particular Section 3 (3.7-3.8) and Section 4

Volume 6: ER’s-Design Spec Section 13 & Section 15

Volume 7: ER’s-Material’s and Appendix A -MEP Specifications addendum to QCS

Workmanship Specification

1.4.2 Definitions

A. Commissioning Lots (CmLot)

The Smallest functioning units are referred as commissioning Lots (CmLot). A

commissioning Lot is a basic geographical section of one or more sub systems or

functional units, which constitutes an independent, coherent, functional and isolated

assembly.

B. No Objection with Comments (NOWC)

For documents that have been reviewed in accordance with project review procedure

and have the status of No Objection with Comments. No Objection to use this

document, but the document is to be revised by incorporating the comments. Subject

to the comments, the document can be used.

C. Statement of No Objection (SONO)

For documents that have been reviewed in accordance with project review procedure

and

have the status of Statement of No Objection. The document can be used without

amendment.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 8 of 133

Testing & Commissioning Plan

D. Commissioning Plan:

An overall plan, developed during the construction that provides the structure,

schedule and coordination planning or the entire testing and commissioning process.

E. Pre-Commissioning Certificate (PCC):

PCC is a certificate issued by the MEP Contractor for Supervision Engineer approval

when a Commissioning Lot is completely tested.

F. Factory Acceptance Tests (FAT)

These tests are Qualification Tests and/or Routine Tests undertaken during Stage 1 of

Testing and Commissioning. Separate FAT Procedures shall be submitted for each

equipment.

G. Installation Release Notice (IRN)

IRN is the document formalizing the transfer of responsibility for part of a system

(Commissioning Lots) from the REDCO MEP Contractor installation team to the

REDCO MEP commissioning team.

H. Non-conformance

Non-conformance is a defect that may occur during the various setting up and testing

phases that may result in design changes. When a Non-conformance becomes

apparent, the nonconformance procedure is followed to ensure that the Defect is

properly remedied.

I. Non-conformance Report (NCR)

Non-conformance report is a report for recording the non-conformance.

J. Partial Acceptance Certificate (PAC)

Partial Acceptance Certificate is a certificate issued by the MEP Contractor and

supported by a Supervision Engineer approval when a sub-system or system is

completely tested.

K. Test Readiness Review (TRR) (Check list of Readiness)

Test Readiness Review is the permit to start stage 4 activities that are Stand Alone

Tests. The TRR assesses test objectives, test methods and procedures, scope of

tests, and safety and confirms that required test resources have been properly

identified and coordinated to support planned tests. The TRR verifies the traceability

of planned tests to program requirements and user needs.

L. Certificate of Completion (COC)

Certification that show all systems are commissioned and all system under MEP Scope

as per Subcontract works together as a whole and there are no interfaces or functional

issues between other disciplines.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 9 of 133

Testing & Commissioning Plan

M. Commissioning Process Monitoring (CPM) Log

Commissioning Process Monitoring Log includes all activity logs for the services,

equipment’s, and devices identified system by system divided into various test.

N. Commissioning Inspection Monitoring (CIM) Log

Commissioning Inspection Monitoring Log shows the status of inspections to reflect

the actual commissioning IRE status and approval.

O. Factory Acceptance Test Certificate (FATC)

Factory Acceptance Test Certificate (FATC) is a certification that show all FATs are

successfully performed.

P. Stages

1. Factory Acceptance Test (FAT) (Stage 1):

The FAT stage is defined as the testing of equipment and equipment components

during production in the factory or in similar conditions and it confirms that the

supply of individual components and equipment is according to the design and the

overall project requirements.

2. Installation Test (IT) Stage (Stage 2):

The Installation Test stage is the testing stage following the installation of civil

works, equipment or sub systems on site within the defined commissioning lot. The

goal of the IT is to demonstrate that the relevant equipment or sub systems have

been correctly installed. After successful Installation Test, an Installation Release

Note (IRN) is issued for the relevant CmLot. Equipment are visually inspected and

non-energized equipment are tested (air leakage testing, light test, pressure test

etc.)

3. Partial Stand-Alone Test (Stage 3):

Once an Installation Release Note (IRN) has been issued for the CmLot then a

third step of testing takes place on the defined CmLot, this time in an energized

state, to prove functionality of CmLot. If permanent power supply is not available

during any step of testing and commissioning activities, it is Redco responsibility

to provide details of power requirement to Design and Built (D+B) contractor

adequate parameters to allow T&C activities to be undertaken. Stage 3 tests shall

be completed by the issuance of Pre-Commissioning Certificates (PCC) to be

submitted to the Engineer for comment/review and acceptance.

4. Stand Alone Test (Stage 4):

A Test Readiness Review (TRR) shall be held prior to the start of the Stand-Alone

Tests. This test aims to prove that all MEP sub-systems can work independently in

autonomous mode. Continuity, isolation and grounding tests shall be done on all

electrical cables and wires in addition to the functional tests required following the

installation of such equipment for those items within contractor scope.

5. System Integration Testing (SIT) (Stage 5):

M009-REI-MEP-PLN-00001 Rev 0.2 Page 10 of 133

Testing & Commissioning Plan

This state shall demonstrate that all system works together as a whole and there

are no interfaces or functional issues between other disciplines. Improves various

stand – alone system into a coordinated set of integrated systems functioning

together with

other systems. During this phase, Integration Testing shall be conducted using

permanent power supply.

6. System Performance Test (SPT) (Stage 6):

This phase is to prove the overall inter-operability of all independent pre-

commissioned systems. This includes the proof of compliance with the overall

system specifications. At the end of the successful System Performance

Verification Test, Completion Certificate will be issued.

Q. Commissioning Handover Certificate (CHOC)

For each section is issued by the Engineer when all As-Built documentation,

operations manuals, punch lists of outstanding items and test reports are provided by

the contractor to the engineer after the successful completion of Phase 4 dynamic

testing.

R. Commissioning Logic

Is when the Commissioning test activities have been listed on Test data sheets and

linked together in a logical manner ensuring that the sequence and interdependences

of activities are recognized.

S. Commissioning Schedule

When the Commissioning Logic is established, each test activity is given an

estimated duration and is reviewed from the resource viewpoint. By analyzing the

results and carrying out a number of reconciliations to decide on the optimum

number of, inter alia, personnel, test sites, items of plant and materials, the

Commissioning Logic is converted into the Commissioning Schedule by the

Contractor.

T. Dynamic Testing

Are test requiring the use of Test trains and are carried out during the Phase 4 of

Testing and Commissioning.

U. Engineering Safety Case

Is a document produced by the MSI Contractor to demonstrate that the infrastructure

and system is acceptably safe .

V. Construction/Commissioning Railway Rule Book

Is the rulebook developed by the MSI Contractor to manage the transition from a

construction site into an integrated operating railway.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 11 of 133

Testing & Commissioning Plan

1.4.3 Abbreviations

ARCH Project Archive

AC Acceptance Certificate

BS British Standard

CCW Certificate of Completion of Works

CHOC Commissioning Handover Certificate

CCRRB Construction Commissioning Railway Rulebook

CmLOT Commissioning Lot

CWK Civil Works

CRAC Computer Room Air Conditioner

DVE Design Verification Engineer

E&M Electrical & Mechanical Equipment

EMC Electromagnetic Compatibility

FAT Factory Acceptance Tests

FATC Factory Acceptance Test Certificate

HVAC Heating, Ventilation & Air Conditioning

H&S Health, Safety

SDR Surveillance Deficiency Report

IAT Installation Acceptance Tests

ICD Interface Control Document

IRN Installation Release Note

IOR Internal Observation Report

ISA Independent Safety Assessor

IFC Issued for Construction

IT Information Technology

ITP Inspection and Test Plan

LV Low Voltage

MEP Mechanical, Electrical & Plumbing

MS Method Statement

MSI Main System Integrator

MSDS Material Safety Data Sheet

MTC Maintenance Certificate

NOWC No Objection with Comments

NCR Non-Conformance Report

OCC Operation Control Centre

O&M Operation & Maintenance

PCA Partial Acceptance Certificate

PM Project Manager

PMC Project Management Consultant

PPE Personal Protective Equipment

PSH Joint Venture of PORR, Saudi Binladin Group and HBK

QA / QC Quality Assurance / Quality Control

QCS Qatar Construction Specification

QMS Quality Management System

QND Qatar National Datum

RAMS Reliability, Availability, Maintainability and Safety

SCADA Supervision Control and Data Acquisition

SCIL Safety Critical Item List

SHA Safety Hazard Analysis

M009-REI-MEP-PLN-00001 Rev 0.2 Page 12 of 133

Testing & Commissioning Plan

SAT Site Acceptance Test

SIL Safety Integrity Level

SIT Static Integration Tests

SONO Statement of No Objection

SRAC Split Room Air Conditioner

T&C Testing & Commissioning

TAB Test Adjusting & Balancing

TRR Test Readiness Review

V&V Verification and Validation

WAD Work Authorization Document

TP Test Pack

RIL Redco International

1.4.4 Regulatory/Utilities Authorities

KAHRAMAA Qatar General Electricity & Water Corporation

Qatar Rail Client

QCDD Qatar Civil Defense Department

MOI Minister of interior

ASHGAL Public Works Authority of Qatar

2 SCOPE & LIST OF SYSTEMS

2.1 General

The Redco MEP T&C Team is responsible for the commissioning process and shall plan,

execute, and document the commissioning work specified herein.

Systems to be commissioned:

The scope of this Testing and Commissioning Plan covers all testing that shall be

performed during the installation and commissioning of the Mechanical, Electrical, Public

Health, and Firefighting/Fire suppression systems within the Green Line Elevated & At

Grade Metro Project. Systems, equipment, components, and the interface between the

systems specified in the following systems shall be Tested, Verified, Commissioned and

Demonstrated according to the contract.

Systems to be commissioned shall include:

A. Mechanical Systems

Air Cooled Chiller

Fans (Smoke extract, Pressurization, Supply and General Extract Fans)

Air Handling Units

Fan Coil Units

Chilled Water Pumps

SRAC Units

CRAC Units

M009-REI-MEP-PLN-00001 Rev 0.2 Page 13 of 133

Testing & Commissioning Plan

Duct accessories (Motorized Damper, Fire Damper & Volume control Damper)

Air Balancing of HVAC System

Flushing, Cleaning and Passivation of Chilled Water System

Water Balancing for Chilled Water System

Chemicals Dosing System

Chilled Water Pressurization Unit and Expansion Tank

CHW Pipework accessories

Air Distribution devices (Diffusers, Grilles, Nozzles, etc.)

B. Electrical Systems

LV Panels

LV Distribution Network (Cables and Final Circuits)

LV Motor Control Centers (MCCs)

Lighting Fixtures

Small Power and associated final DBs

Variable Frequency Drives and Motor Starters

Lighting Control System

Emergency Lighting System

Fire Alarm Functional Test

Panel Boards Functional Test

Earthing, Bonding and Lightning Protection

BACS Interfacing

C. Plumbing Systems

Water Storage Tanks

Booster Pumps

Sand Filter

Chlorination of water System

Electric Water Heaters

Thermostatic Mixing Valve

Sump Pumps (Drainage)

Drainage System Functionality (Sewage, Storm water and roof drainage and

water force main)

D. Fire Fighting System

Fire Pumps

Zone Control Valves Assembly

Wet Type Sprinkler System

Functional Tests

Fire Hydrant System

Fire Hose Cabinet and Fire Hose Station

FM 200 Gas Suppression System

Fire Extinguishers

M009-REI-MEP-PLN-00001 Rev 0.2 Page 14 of 133

Testing & Commissioning Plan

2.2 Commission ability Assurance

To enable a degree of services familiarization, Redco T&C Team will carry out a review of

all contract documentation such as drawings, specifications, design information, specialist

suppliers/manufacturers design & shop drawings to ensure all standards are adhered too

and that all commissioning requirement are incorporated.

Commission ability study for MEP commissioning works includes following but not limited

to, under project specification requirements:

a) Examine Contract Documents

Contract Documents are defined in the Conditions of the Contract.

Verify the equipment, such as gage cocks, thermometer wells, flow-control devices,

balancing valves and fittings, manual volume dampers, fire dampers, detectors,

sensors, isolators required by the Contract Documents. Verify that quantities and

locations of these equipment are accessible and appropriate for effective

commissioning and for efficient system and equipment operation.

b) Examine approved submittal data of systems and equipment.

c) Examine design data, including system descriptions, statements of design

assumptions for environmental conditions and system's output, and statements of

philosophies and assumptions about systems and equipment controls.

d) Examine equipment performance data, including fan and pump curves.

e) Examine system and equipment installations to verify that they are complete and that

testing, cleaning, adjusting, and commissioning specified in individual Specification

Sections have been performed.

f) Examine system and equipment test reports.

g) Examine systems for functional deficiencies that cannot be corrected by adjusting and

balancing.

h) Examine air-handling equipment to ensure clean filters have been installed, bearings

are greased, belts are aligned and tight, and equipment with functioning controls is

ready for operation.

i) Examine plenum ceilings, utilized for supply air, to verify that they are airtight.

j) Examine equipment for installation and for properly operating safety interlocks and

controls.

k) Examine noise and vibration mitigation.

l) Examine the sub-main distribution board(SMDB), distribution board (DB), Mechanical

Control Center (MCC), Variable frequency driver (VFD) etc. to ensure that all the

associated accessories/components are working properly and all the test which are

explained in the testing and commissioning method statements are performed and

are ready for operation.

m) Report deficiencies discovered before and during performance of testing, adjusting,

and balancing procedures.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 15 of 133

Testing & Commissioning Plan

2.3 Commissioning Phase Scope

Commissioning includes setting to work, testing & balancing and performance testing to

demonstrate adequacy of the system, and complete verification of performance of all the

systems and services. The process shall encompass all system documentation, start-up

and continuous (time period) testing, calibrations, testing & balancing, training and after

all results are accepted, inclusion into the final Operation and Maintenance Manuals.

Inspection, Testing & Commissioning

The process of inspection, testing and commissioning is divided in to various stages

as follows.

Stage 1 Factory Acceptance Test (FAT)

Stage 2 Installation Test (IT)

Stage 3 Partial Stand-Alone Test (PSAT)

Stage 4 Stand Alone Test (SAT)

Stage 5 MEP System Integration Test (SIT)

Stage 6 System Performance Test (SPT)

Testing & Commissioning Certificate

Stage 3 Partial Completion Certificate

Stage 4 Partial Acceptance Certificate

Stage 5 Acceptance Certificate

Stage 6 Certificate of Completion

Testing & Commissioning Handover Documentation

The sign off of individual test and commissioning activities / demonstrations will take

place on a Progressive / logic sequence basis during the construction of the project.

Redco will coordinate with SPH for archiving purposes.

Redco T&C team will prepare the test packs as a result of all relevant tests for every

equipment and will organize a general test pack for each sub-system including each

separate test packs. After the completion of all final commissioning documentation,

Redco T&C shall provide the test packs. These test packs will subsequently be

included within the Operation and Maintenance Manuals (O&M) for the project.

The following must be included as a minimum within each test pack;

• A project standard commissioning completion certificate.

• All relevant testing and commissioning documentation, each having been

individually signed by the relevant specialist, sub-contractor, Redco, SPH and Client

team to confirm that these works have been undertaken successfully.

• Appropriate calibration certification for the instrument used during the test and

commissioning process.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 16 of 133

Testing & Commissioning Plan

• Related installation IRN having been individually signed by the specialist/sub-

contractor, Redco, SPH and Client team to confirm that installation of the works has

been undertaken successfully.

3 COMMISSIONING RESPONSIBILITIES & OBLIGATIONS

3.1 SPH Responsibilities

SPH to co-ordinate a l l activities of the commissioning schedule, so that completion,

testing, and commissioning of the systems is carried out without hindrance and in a

safe and satisfactory manner by the appointed sub-contractors and also SPH to arrange

Power, Water and suitable temperature for any testing and commissioning activity.

3.2 Commissioning Team

3.2.1 Members Appointed by MEP Sub-Contractor:

Commissioning Manager and Commissioning Engineers from MECON as a third party

shall manage all the commissioning activities, coordinate and implement testing and

commissioning process. This consists of the following:

Commissioning Manager / Engineer

Foreman

Skilled Worker

Helper

Schedule of Key Personnel from QR, SPH and Redco (MEP Subcontractor)

Company Contact Name Contact Details

EMPLOYER PRIMARY CONTACT

QATAR RAIL TBC Mobile: Email:

ENGINEER ASSISTANT PRIMARY CONTACT/PSH COMMISSIONING MANAGER

SPH TBC Mobile: Email:

Sub-CONTRACTOR PRIMARY CONTACT/MECON COMMISSIONING MANAGER

REDCO Jaffer Ibrahim Mobile: 33194898 Email: jaffer@mepgljv.com

MECON Burak Oral Mobile: 31579429

Email: burak.oral@mecoyapi.com

The above schedule details are of the Main Commissioning Team Members. The

members representing each contractor, vendor, supplier, subcontractor, installer and specialist

required as a part of Commissioning team shall be detailed as below.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 17 of 133

Testing & Commissioning Plan

3.3 Responsibilities

3.3.1 MEP Commissioning Authority Responsibilities:

To manage and execute the commissioning activities in liaison with the specialist

vendors, and all related subcontractor.

Organize and lead the testing and commissioning teams.

Coordinate and update the commissioning programs.

Convene team meetings/workshops for the purpose of coordination, communication and

conflict resolution, discuss and report progress of the test and commissioning processes.

Responsibilities include the arranging for facilities, preparing agenda and attendance

lists, and notifying participants.

Prepare testing and commissioning procedure, which includes checklists, test reports and

risk assessment for all MEP related works.

Coordinate with HSE for necessary safety procedure implementation.

Identify the requirement of special agency for commissioning as per project specifications.

Identify testing and commissioning team member responsibilities, by name, firm, and

trade specialty, for performance of each testing and commissioning task.

Verify ensure the commission ability of the system and sub-system. Agree actions

required and follow action implementation on site.

Enable the permit to work system, implement safety signage & LOTO procedure to ensure

the safe operation coordination with HSE officer.

Schedule, direct, coordinate, execute, witness and document testing, commissioning,

inspections and other related activities.

Complete the test report duly signed by commissioning engineer, specialist of

vendors/manufacturers commissioning certificate, equipment data sheet, equipment

schedule and final drawings for the producing test pack, verify the test results and

necessary documentation prior to submission for consultant verification.

Prepare and maintain commissioning risk register to log and update the commissioning

risk, which may affect the system performance and non-compliance to the project

requirement/authority’s requirement.

Compile test and commissioning data, inspection reports, and include in the system

manual, commissioning reports and O&M manuals.

Certify date of test acceptance and commissioning for each item of equipment for start of

warranty periods.

Provide required information for O&M manual preparations.

Prepare and conduct operation and maintenance training including the formulation of

training programmed, all in accordance with the contract requirements.

Preparation of Test Packs upon completion of tests.

Prepare regular testing and commissioning reports, for each phase and segments

activities.

Assemble the final test and commissioning documents, test pack including the test and

commissioning reports and in collaboration with the entity responsible for

system/equipment supply/performance of corrective action.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 18 of 133

Testing & Commissioning Plan

Participate in the final review at acceptance meeting and review/approve final test and

commissioning documentation.

3.3.2 Manufacturer/Vendors/Specialist Responsibilities

As directed by MEP commissioning manager, assign representative with

expertise and authority to act on behalf of subcontractors and schedule them to

participate in and perform testing and commissioning team activities including,

but not limited to, the following:

Participate in maintenance orientation and inspections.

Participate in procedures meetings for testing and commissioning.

Verify test and commissioning activities for all system equipment as directed by MEP

commissioning managers and in accordance with test and commissioning procedures

and programed.

Participate in final review and acceptance meetings.

Preparation of test packs including test sheets, manufacturer’s recommendation, and

material submittal approvals, etc.

Give input to planning for operation and maintenance data submittals, equipment start-

up, and testing to contractor for incorporation into the O&M plan and documentation.

Participate in training sessions for Client’s operation and maintenance personnel.

Provide update project record documents to the Supervision Management.

Submit O&M manuals for all systems as specified in project contracts documents.

Provide technicians who are familiar with construction and operation of installed

systems. Develop specific test procedures and participate in testing and installed

systems, subsystems, and equipment.

3.3.3 Planning and Scheduling FAT Activities

FAT activities like procedure, FAT Test and record of FAT Test shall be carried as per

approved Methodology.

3.3.4 RAMS Demonstration Report

Upon commence of T&C a period of RAM requirements monitoring will be carried out

during (SPT with permanent power in place) in order to demonstrate that the RAM

targets are met.

The RAM demonstration process comprises of the following main stages

Preparation of a RAM Demonstration Report.

Collecting RAM performance failure data as part of a FRACAS system

Carrying out tests and demonstration during a RAM Demonstration Period.

Implementation of Corrective action for remedial measure for any identified deficiencies.

Analyzing the failure data to demonstrate that the Sub-system meets the RAM

performance targets, with extension of the RAM Demonstration Period, should RAM

performance targets not be achieved during this period.

RAM Demonstration report shall be forwarded by sub-contractor (Redco) and will be

part of T&C report (sub-construction package). During the T&C phase, every failure will

be registered, and in case of failure random will be ‘counted in the calculation of RAM

parameter.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 19 of 133

Testing & Commissioning Plan

3.3.5 FRACAS (Failure Reporting, Analysis & Corrective Action System)

If the failure is due to equipment failure, then FRACAS shall be applied.

FRACAS is applied to ensure all failures and incidents are accurately and consistently

categorized as to cause, significance, frequency and chargeability.

3.3.6 Change Management System

A systematic approach to proposing, evaluating, approving, implementing and

reviewing changes.

The scope of change management is much broader than change control, which was

typically applied to one change.

Change management includes the oversight and management of the entire portfolio

of changes and the change process, including all the components of change control.

An evaluation of the change should be undertaken after implementation to confirm

the change objectives were achieved.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 20 of 133

Testing & Commissioning Plan

3.4 Commissioning Management Process

MEP WORKS MANAGEMENT SYSTEM

Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6

Design Operations

Lifecycle Stages Manufacture Stage Installation Testing Partial Stan Alone Test Stand Alone Test Integration Testing System Performance Test

Sub System Static Testing of Non

Partial Testing for seperated sub- Integration with other

Factory Acceptance Testing Energized Equipment Systems Tests Operational testing and demonstretions Fracas - Warranty

systems Disciplines

Stage Discription (Leakage Testing & Etc.)

FAT then transfer to site

Construction Handover

Energisation

Performence Growth Taget

Completion of Shop Drawing

Permenent Energisation

Certificate of Complation

Sectional Completion

Safety Conditions Fulfilled

Design Issued for Construction

Signaling and Control Approval.

Milestone Stage

Completion of System Acceptance Start of

Modsafe Staging Sub-system Design Completion of Sub-system Installation Commertial Operation

Long Term Items Supply "

Responsibility for Safety of the

Other Contractor

Line

Other Contractor MEP Contractor / Other

Responsibility for MEP Works Qatar Rail Operator &

Contractor

Safety Management MEP Contractor Maintener

QR Rail Operator &

Factory Acceptance Certificate Installation Release Note (IRN) Pre Commissioning Certificate Partial Acceptance Certificate Acceptance Certificate Certificate of Copmletion

Maintener

System Gates Definitions

Safety Case Regime & Testing

FAT IRN PCC PAC AC CHOC, CofC Operational Safety Case

Certification

Defect Reports,

Snag List Snag List Snag List Snag List Snag List Snag List

In-Compliances Snag List Operation Issues Log

Project Management MEP Project Manager QR / PSH

Qatar Rail Operator &

MEP Contractor

Provision of Tecnical Support Maintener

Responsibility for Works MEP Contractor Defects Notification Period (DNP)

Involvement of O&M operational

staff

M009-REI-MEP-PLN-00001 Rev 0.2 Page 21 of 133

Testing & Commissioning Plan

3.5 Verification & Validation

T&C process objective is to carry out all the activities which are necessary in order to

ensure and to demonstrate the complete system and sub-system Integration Verification and

Validation.

There are five possible Verification methods which can be used on the project

a) Analysis

b) Inspection

c) Review

d) Test

e) Similarity

Each project requriement is verified according to one or more of the aformentioned methods.

* Figure 6 from 6.2.3 V&V Method section of Qatar Rail Program Test & Commissioning Management

NOTE: Test reports to be available and in coordination to the Engineering Safety Validation

Plan as part of the necessary validation criteria

M009-REI-MEP-PLN-00001 Rev 0.2 Page 22 of 133

Testing & Commissioning Plan

M009-REI-MEP-PLN-00001 Rev 0.2 Page 23 of 133

Testing & Commissioning Plan

3.6 Organizational Chart

The Organizational Chart applicable to this work is attached in Annexure G.

3.7 RACI Matrix

(Please refer to Appendix H For the whole process RACI Chart)

4 PROGRESS REPORTING

(Please refer to Appendix J for the 3 WLA and Progress report)

4.1 T&C Schedule

Redco T&C department will produce an integrated Commissioning Program for approval

incorporating all services, project sectors, segments and zone requirements, including device

and sub-system tests. The Program will show all key milestones together with all inter

relationships and all interface between systems and external services.

The schedule is to be programmed in a manner that includes all tests to be conducted on site

in every stage of commissioning plan. Every testing and commissioning activities shall be

identified on this schedule and will be tracked in the “T&C Process Tracker” such as;

FAT tests and planned schedules

Static test schedules

SAT tests and planned schedules

Testing equipment certification and availability

A three-week schedule updated weekly

Standalone test schedules

Dynamic Systems testing schedules

M009-REI-MEP-PLN-00001 Rev 0.2 Page 24 of 133

Testing & Commissioning Plan

T&C milestones are shown in the Contract Schedule

Expending the schedule with the discussion of relevant stakeholders for integrated

testing.

A. Production of T&C System Management Procedure

Redco T&C will produce or obtain commissioning system management procedure from

specialist/vendors for special systems and testing will review that procedure fully complies

with the project specification & client requirements this will include but not be limited to:

1. Scope

2. Purpose

3. Definitions

4. Resources

5. Testing and Commissioning Methodology

6. Risk Assessment

7. Job Safety Analysis

8. Attachments (Check List & Test Sheets)

4.2 Commissioning Process Monitoring (CPM) Log

Redco will prepare a Commissioning Process Monitoring Log, which includes all the services,

equipment’s, and devices identified system by system divided into various test with

predetermined weight-age. The same is to be updated on a weekly basis. Moreover, reported

to Supervision, Management on a weekly basis to track the actual process. CPM will report

on the status of testing and commissioning as system and subsystem. Redco will submit the

CPM tool skeleton review and approval. This CPM log will generate only the actual

percentage. The final plan percentage is to be matched from Commissioning Program, which

is being updated by Redco Planner / Commissioning team.

4.3 Commissioning Inspection Monitoring (CIM) Log

Redco will prepare an Inspection status-monitoring log to reflect the actual commissioning

documentation status and approval. Documents projection to be made system wise and status

of Submission, Approval and Rejection to be updated on daily basis.

CIM log will reflect the commissioning documents percentage system wise, as follows

Electrical Systems

HVAC System

Plumbing & Public Health System

Fire Fighting System

Fire Alarm System

M009-REI-MEP-PLN-00001 Rev 0.2 Page 25 of 133

Testing & Commissioning Plan

CIM log will highlight the Total Commissioning document system wise, Submitted, Approved,

Rejected and Under Review. Redco commissioning team will submit the CIM summary and

Graph on weekly basis.

4.4 Commissioning Meeting’s

Redco T&C will arrange and administer meetings to agree and submit all relevant

documentation for testing and commissioning and ensure meeting agenda covers all relevant

topics such as:

Health & Safety

Documentation Progress - Method statements and test procedure.

Production test pack.

Installation Progress affecting Commissioning.

Testing and Commissioning Progress (after commencement).

Coordination and interface

4.5 Witnessing

With the self-certification system, all tests are to be witness and signed-off as per T&C

procedure shown in Section 7.

Despite the self-certification, every test (Off-site) shall be formally notified to each of the

validating entities with sufficient time to let interested people planning their participation if

needed, independently of the fact they are willing to witness the test or not.

The test notification will identify the test purpose and various other information such as person

in charge of the test, the test procedure reference, the location of the test, etc.

The Redco shall perform all necessary testing and commissioning activities which takes place

on the defined CmLot, the smallest functioning units, in order to ensure satisfactory operation

of the completed works and compliance with the Contractor Requirements. Tests shall be

witnessed by the SE, the Contractor and Engineer’s Assistant as required and where identified

in the Inspection and Test Plan.

Tests are to be carried out following the below indicated stages and including the

documentation associated related to its witnessing as indicated in point 5.3:

4.6 GSAS Requirement’s Validation

Once the mentioned system commissioned, all system test packs shall be signed off by the

PMC, evidence to the GSAS Log (GSAS by 3rd Party) shall be forwarded to Sub contractor

Redco, who shall verify the accuracy and then forwarded to Sustainability team to validate that

the requirement is been met in terms of commissioning process.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 26 of 133

Testing & Commissioning Plan

Review

Activities Responsible Outcomes

Design Review Design Tracker WORK FLOW

Department

MEP Review MEP Department Material

Submittal Tracker

Equipment Installations

Activities Responsible Outcomes

- Material Submittal

FAT - Factory QA/QC - FAT Acceptance - FAT Procedures

Stage 1 - FAT - Contractual Requirements

Acceptance Test Procurement – T&C Certificate

- Installation Method Statements

Installations QA/QC IRN - Construction/non-energized Tests (Ductwork & Pipeline Leakage Test, Cable

Testing Department Stage 2 - IT Continuity Test Etc.)

- Visual Checks Test Before

Commissioning - As per CmLots Completion

Activities Responsible Outcomes - Commissioning Method Statement

- Energized State (Temporary / Permanent Power Supply)

PSAT – Partial Commissioning PCC Stage 3 - PSAT - Activities shall be performed as per related CmLots

Stand Alone Test Department - Test Packs shall be updated as per PCC

- Commissioning Method Statement

SAT –Stand Alone Commissioning PAC - Energized State (Temporary / Permanent Power Supply)

Test Department Stage 4 - SAT

- Test Packs shall be updated as per PAC

-

- Commissioning Method Statement

-

- Commissioning System Procedure

SIT – System Commissioning AC - Energized State (Permanent Power Supply) Test On

Integration Test Department Stage 5 - SIT - Adjusting and Balancing actions, cause & effect checks, black-out test and Completion

activities etc. shall be performed at this stage.

- Test Packs shall be updated as per AC

-

- Commissioning Method Statement

SPT – System Commissioning CofC

- Commissioning System Procedure

Performance Test Department

Stage 6 - SPT - Energized State (Permanent Power Supply) Test After

- O&M Manuals Completion

- Client Training

- Test Packs shall be finalised as per CofC

-

M009-REI-MEP-PLN-00001 Rev 0.2 Page 27 of 133

Testing & Commissioning Plan

5 OVERVIEW OF COMMISSIONING STRATEGY

5.1 Testing Strategy

The fundamental testing strategy is that during different phases of the work, such as

manufacturing, construction and commissioning, system requirements as detailed in the

technical specifications and in accordance to the validation plan, are verified by inspection,

test(s) or submission(s), which provide test analysis or product data to prove that a

specification requirement(s) have been met.

Use of Spare Parts during Testing and Commissioning

a) Suitable Testing and Commissioning spares shall be available in order to be

able to replace faulty equipment during Testing and Commissioning period.

Strategy for Test Failure

A test may fail due to number of reasons

a) The sub system works as designed but the Test Procedure was incorrect.

b) The Test Procedure was correct but the expected values (design values) were

not within tolerance or were inconsistent.

c) Most of the test passed but a specific part or component failed.

d) The equipment does not work as designed

If the failure is due to equipment failure, then FRACAS shall be applied.

FRACAS is applied to ensure all failures and incidents are accurately and consistently

categorized as to cause, significance, frequency and chargeability.

5.2 Safety during T&C (Lock Out Tag Out & Permit to Work)

Procedure M009-SPH-HMS-PLN-00009 & M009-SPH-QMS-PLN-00029 cover Redco

scope of works. This includes associated test equipment and temporary piping and power

installations.

This procedure is intended to provide authorize employees with a level of protection equal to

that, which would be afforded to them by the use of personal lock. The preferred method for

providing this type of protection involves the use of locks and key control as described

further in this procedure. When an energy-isolating device is not capable of being locked out,

the energy control program shall have utilized tag out (s). A personal sign-in/sign-out log or

permit is acceptable and considered a “personal tag out device” as long as (1) it identifies

each authorized employee being protected and (2) the person in charge can reliably account

for each individual authorized employee who is being protected.

This procedure Explains the procedures for Lockout I Tag out specified in the project H&S

plan: M009-SPH-HMS-PLN-00009 and also refers to doc. M009-SPH-QMS-PLN-00029

"Lock-out I Tag-out Procedure".

M009-REI-MEP-PLN-00001 Rev 0.2 Page 28 of 133

Testing & Commissioning Plan

5.3 Phases of the Project

MEP T&C testing activities are to be divided into the following main phases:

Test Before Completion

Test on Completion

Test After Completion

5.4 Stages of the Project

For the phases mentioned above, T&C activities and certification of the work will be

considered in 6 main stages.

Manufacture Stage – FAT Test (Stage 1)

Installation Testing Stage (Stage 2)

Partial Stand-Alone Stage (Stage 3)

Stand Alone Stage (Stage 4)

Integration Testing Stage (Stage 5)

System Performance Testing (Stage 6)

Detailed descriptions are outlined in the following sections.

5.5 Test Before Completion

5.5.1 Design Stage:

The milestone for starting the T&C activities shall be the design stage. Completion of sub-

system shop drawings will form a basis to T&C activities for preparing verification

documentation and in line to the validation criteria.

5.5.2 Manufacture Stage – FAT Test (Stage 1):

Manufacturing Stage mainly consists of Factory Acceptance Test (FAT). This Stage is

defined as the testing of equipment and equipment components during production in a

factory or testing laboratories. The aims of these tests are to confirm that the supplied

loadout complies with declared specifications and capacities on equipment data sheets. In

this stage verification of design and overall project, requirements are also considered.

FAT Tested equipment shall be stated as a list and a schedule for tests and dates will be

established and provided. In this list, it should also be remarked which equipment will be

fully tested or randomly tested for a portion of the total system. The engineer will be notified

with Factory Acceptance Tests. These will all be identified in the Testing and

Commissioning Schedule.

Before the FAT test in the factory a Testing Program including details of inspection and

testing shall be informed to the Engineer. The program shall include:

Agenda

FAT attendees contact details

FAT Procedure

M009-REI-MEP-PLN-00001 Rev 0.2 Page 29 of 133

Testing & Commissioning Plan

Responsibilities

Calibration test records of instruments

Sample test records

At the conclusion of the FAT test, a Factory Acceptance Test Certificate (FATC) will be

issued by the supplier indicating how the item have been rigorously tested. FAT will be

issued for review and approval to Engineer.

A Certificate of Conformity shall be required for propriety equipment, and a Certificate of

Compliance to ensure its compliance with the relevant standards.

5.5.3 Installation Testing (IT) (Stage 2):

The aim of installation testing stage is to demonstrate the equipment, or the sub-systems

have been installed correctly.

After successful installation tests; Installation Release Note (IRN) is to be issued for the

relevant CmLot. IRN is to be prepared by the QA/QC department and handed over to the

T&C Department. T&C department will only support to the QA/QC Team for this stage. IT

Tests will be considered as non-energized tests conducted in construction phase.

5.5.4 Partial Stand-Alone Test (PSAT) (Stage 3):

Once an (Installation Release Note) IRN has been issued for the identified/selected CmLot

then a third step of testing takes place, this time in an energized state, to prove the

functionality of CmLot. If permanent power supply is not available during any step of testing

and commissioning activities, it is SPH responsibility to provide details of power

requirement to Design and Built (D+B) contractor adequate parameters to allow T&C

activities to be undertaken.

The Partial Stand-Alone Test (PSAT) shall demonstrate that the MEP System or

installations works/were installed correctly as individual parts not as a whole system.

Equipment and installations will be tested part by part. Partial Stand-Alone Test will be

excluded from integration of other internal MEP sub-systems.

Stage 3 tests shall be completed by the issuance of Pre-Commissioning Certificates (PCC)

to be submitted to the Supervision Engineer for comment/review and acceptance.

5.5.5 Stand Alone Testing (SAT) (Stage 4)

Test Readiness Review is the permit to start stage 4 activities which are Stand Alone Tests.

The TRR assesses test objectives, test methods and procedures, scope of tests, and safety

and confirms that required test resources have been properly identified and coordinated to

support planned tests. The TRR verifies the traceability of planned tests to program

requirements and user needs.

This testing stage aims to prove that all MEP sub-systems can work independently in

autonomous mode with its all system components.

During testing of equipment’s and components, permanent power shall be provided for all

the testing activities in order to prevent any harm in the system.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 30 of 133

Testing & Commissioning Plan

After ensuring that all the necessary equipment has been tested and that the snag lists do

not contain any items that may invalidate the test, Partial Acceptance Certificates (PAC)

shall be issued.

5.6 Test on Completion

5.6.1 Integration Testing (Stage 5)

System integration tests demonstrate that the system works together as per design and

there are no interfaces or functional issues between the MEP, Civil, Track, Transit and

Operations.

During this phase, Integration Testing shall be conducted using permanent power supply,

only where applicable temporary power is to be used.

During this phase of the testing, a comprehensive set of integration testing shall be

conducted for station systems.

All Testing, Adjusting and Balancing actions, cause & effect checks, black-out test and

activities etc. shall be performed at this stage.

All specific integration testing will be the responsibility of Main Contractor. However, for

BACS and Railway System testing, MSI will take the lead on integration supported by

Redco.

At the end of each successful System Integration test, an Acceptance Certificate (AC) will

be issued.

5.7 Test After Completion

5.7.1 System Performance Testing (Stage 6)

Within this stage, construction phases are to be considered as finished, and studies for

proving that the system is suitable for operating with all independent pre-commissioned

systems. The stage includes performance testing to demonstrate that the integrated

equipment and systems meet contract performance requirements.

By the end of a successful System Performance Verification Test Completion Certificate

will be issued.

6 DOCUMENTATION

6.1 Test Procedures & Method of Statements for Tests:

Redco T&C will produce or obtain from manufacturer/vendor/specialist for their dedicated

commissioning method statements. Testing shall be performed according to approved test

methods.

Review and comment on the documents and assist where necessary in bringing

documents up to the required project standard and to ensure conformity to contract

documents.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 31 of 133

Testing & Commissioning Plan

Produce a comprehensive commissioning documentation structure so that all system

records can be easily field retrieved and reproduced.

All these procedures must be submitted to the Main Contractor in advance for approval. The

data will indicate that the test fully complies with the project specifications & client

requirements, which will include but not limited to:

Objective, Purpose, Scope

Definitions

Resources / Calibrated Devices

Testing and Commissioning Methodology

Initial and Final Conditions

Detailed Description

Results Expected

Format of Recording

Results Obtained on Site

Immediate on-site analysis

Immediate conclusions and actions to be taken

Pass/Fail Criteria

Risk Assessment

Job Safety Analysis

Attachment (Check List & Test Sheet)

In these procedures contractor will take into proper account the test procedures and

constraints of any other Interfacing Parties, the external railway networks, and the external

facility networks.

The test results conducted on site will be noted and reported with a specific procedure. These

reports are to be signed with the person in charge of testing, and those who have witnesses

the test as part of piece of Self Certification.

All procedures are to be consistent with the general arrangements defined in the document

above.

MSI is the Test Lead Contractor and is in charge of carrying out the tests such as Site

Integration & Dynamic Testing within the scope of MSI. Redco to provide support at this stage

ensuring that all its equipment works as per project specification.

6.2 Check List & Test Sheet:

For each test conducted on site, a test data sheet (checklist) shall be provided. This test has

to contain all necessary data for the test such as followings;

Title and the number of the test

Phase and sub-phase of Testing and Commissioning

M009-REI-MEP-PLN-00001 Rev 0.2 Page 32 of 133

Testing & Commissioning Plan

Brief description of the test

Objectives of the test

Location

Duration

Requirement regarding items such as equipment, staff, facilities

Requirements in the form of availability of other metro line assets

Satisfactory space, whether the test is passed or failed.

If the test fails, provide the criteria and the parameter of the failure

Space for any additional comments.

The data sheets will be available for every particular test and will be implemented with the

relevant test M&S.

6.3 Installation Test Reports:

For every result of each test conducted on site, it should be reported in its proper methods.

Results should be analyzed carefully and conclusions must be indicated properly.

The contractor is responsible for complying and submitting Test Reports in accordance with

the Contractor’s Test Procedure.

Partial test reports can be submitted in the continuum of project, but must be reported after

completion of a sub-system or full system test as a Test Pack. Same process will be necessary

for every type of equipment located to one specific architectural area (Station, Trough, and

Evacuation Shaft etc.) The Test Report shall contain as a minimum, the following:

Test Checklist or Test Sheet including;

o Date, time and location

o Description of the system/sub-system tested

o Test Configuration

o Measured Parameters

o The Pass/Fail Indication

o The Derivations (if any)

Drawing of system/sub-system tested

Material Submittal Approval Reference

QA/QC Installation Approval Reference

ITP (Inspection Test Plan)

HSE Assessment & Job Hazard Analysis

IRE (Inspection Request)

Calibration Certificates and Fit Reports for test equipment.

6.4 Certificates:

Certificates shall be used to confirm that equipment or sub-system meets requirements for

related Stage. Certificates are based on results from the test and the check sheets in the test

reports.

Each discipline requirements are outlined in further items.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 33 of 133

Testing & Commissioning Plan

MEP Certificate

*: Table 5 from 6.5.3 Certificate section of Qatar Rail Program Test & Commissioning

Management

6.5 Test Pack:

For every individual equipment, Redco will prepare type of a significant CmLot or a sub-system

a test pack. These Test Packs will be reported to Supervision Engineer. Results will be

analyzed carefully and conclusions will be indicated properly.

The Sub contractor is responsible for compiling and submitting Test Pack in accordance with

the Contractor’s Test Procedure.

Same process will be necessary for every type of equipment located or appeals to the one

specific architectural area (Station, Trough, Evacuation Shaft etc.)

The Test Pack shall contain as a minimum, the following:

MIR (Material Inspection Request)

Material Submittal Approval Reference (MAR)

FAT

IRE for Installation

Test Reports for Installation Stage

Installation Release Note (IRN)

PSAT and/or SAT Checklist including;

o Date, time and location

o Description of the system/sub-system tested

o Test Configuration

o Measured Parameters

o The Pass/Fail Indication

o The Derivations (If Any)

o ITP

M009-REI-MEP-PLN-00001 Rev 0.2 Page 34 of 133

Testing & Commissioning Plan

o HSE Assessment & Job Hazard Analysis

Drawing of system/sub-system tested

Equipment Data Sheet

Calibration Certificates and/or Fit Reports for test equipment’s

7 SYSTEM DESCRIPTIONS, TESTING & COMMISSIONING PROCEDURES, STRATEGY, &

INTERFACES.

Complete MEP system will be tested and commissioned by Redco T&C Specialist (MECON)

and functionality of the system performance will be verified prior to Supervision Engineer

verification. Stages of testing and inspection are defined below for clear understanding of

commissioning strategy and step-by- step procedures.

Detailed testing and commissioning procedure will be submitted for each system and sub-

system to detail the commissioning methodology including standards, codes and project

specification references.

7.1 HVAC System

7.1.1 Installation Completion & Preparation

Complete system readiness checks and prepare system readiness report. Verify the

following:

A. Installation of ductwork are completed.

B. Installation of piping completed.

C. Installation of equipment are completed.

D. Ductworks are cleaned out of dust.

E. Pipework leakage test are performed and passed according to related Method

Statement.

F. Isolation and control valves are installed.

G. IRN has issued.

H. Permanent electrical power wiring is complete.

I. Hydronic systems are filled, clean, and free of air.

J. Equipment and duct access doors are securely closed.

K. Balance, Motorized smoke, and fire dampers are open.

L. Isolating and balancing valves are open and control valves are operational.

M. Ceilings are installed in critical areas where air – pattern adjustments are required

and access to balancing devices is provided.

N. Windows and doors can be closed so design conditions for system operations can

be met.

7.1.2 TAB Agency

MECON is appointed T & C supervision and TAB Agency.

M009-REI-MEP-PLN-00001 Rev 0.2 Page 35 of 133

Testing & Commissioning Plan

7.1.3 References

HVAC system testing, adjusting and balancing will be performed according to the following

specification and standards.

Project specifications for Testing, Adjusting and Balancing of HVAC systems.

QCS 2010 for Testing, Adjusting and Balancing of HVAC systems.

Associated Air Balance Council (AABC) and National Environmental Balancing Bureau

- Standard Testing & Balancing (TAB) Procedures.

Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA).

7.1.4 Air Handling Units/Fresh Air Handling Units/Fan Coil Unit/Fans

A. Pre - Commissioning & Start up

The initial pre-commissioning, fan alignment and setting to work is to be carried out by

Redco T&C in liaison with the unit manufacturer/supplier prior to start-up.

Note: Equipment will not be started until the installation of mechanical and electrical is

signed off. Pre-commissioning will be carried out for the equipment, associated duct

works, dampers and control devices including air terminals.

B. Functional Test & TAB

Functionality including electrical performance, fan performance, terminal air balancing

and noise level measurement. Vibration test will be carried out for major equipment’s.

Redco T&C will verify and ensure test results then offer for Supervision Engineer

verification.

Note: Water balancing will be a separate inspection for complete secondary water

distribution network. It will not be a part of HVAC system functionality test.