Documente Academic

Documente Profesional

Documente Cultură

QR 07 Standard Tolerance Sheet Modified

Încărcat de

Muhammad Fitransyah Syamsuar PutraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QR 07 Standard Tolerance Sheet Modified

Încărcat de

Muhammad Fitransyah Syamsuar PutraDrepturi de autor:

Formate disponibile

5142 Evanston Ave.

Muskegon, MI 49442

Ph: 231-788-2351

Fax: 231-788-1162

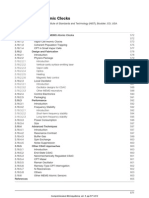

EAGLE ALLOY DIMENSIONAL TOLERANCE STANDARDS

The following are the normal tolerances that can be applied to as cast parts produced from each of

the available processes. Any deviation from these guidelines will be considered on a case by case basis.

Specific part geometry may require or allow an increase or decrease in tolerance from this standard.

Subsequent operations (e.g. grinding, pressing, machining, etc.) may improve tolerances on specific

dimensions. Tolerances based on experience and from STEEL CASTINGS HANDBOOK, Steel

Founders Society of America.

SHELL ISO 8062 (REF) AIRSET ISO 8062 (REF)

LINEAR DIMENSIONS - INCH (MM)

0” to 6” INCL (0 to 152 INCL) +/- 0.030” (0.75) CT8 +/- 0.063” (1.60) CT10

6” to 12” INCL (152 to 305 INCL) +/- 0.045” (1.15) CT9 +/- 0.094” (2.40) CT11

12” to 18” INCL (305 to 457 INCL) +/- 0.060” (1.50) CT9 +/- 0.125” (3.20) CT11

18” to 24” INCL (457 to 610 INCL) +/- 0.090” (2.30) CT10 +/- 0.188” (4.80) CT12

24” to 30” INCL (610 to 762 INCL) +/- 0.098” (2.50) CT10 +/- 0.251” (6.40) CT12

30” to 36” INCL (762 to 914 INCL) +/- 0.098” (2.50) CT10 +/- 0.314” (8.00) CT12

MISC CALLOUTS

ACROSS PARTING LINE-ADD to ABOVE 0.010” (.25) 0.030” (.75)

PATTERN to CORE DIMS-ADD to ABOVE 0.010” (.25) 0.030” (.75)

MISMATCH-COPE to DRAG +/- 0.020” (.50) +/- 0.063” (1.60)

GATE/RISER CONTACTS +/- 0.063” (1.60) +/- 0.063” (1.60)

RECOMMENDED MINIMUM RADIUS 0.031” (0.75) 0.063” (1.60)

ANGULAR DIMENSIONS (DEGREES)

ALL ANGLES +/- 1 ° +/- 1 °

*DO NOT PUT DATUM LOCATING POINTS ON PARTING LINE OR GATE/RISER CONTACTS.

SURFACE FINISHES

SHELL CAST SURFACE FINISH: 200 - 300 RMS (4.6 - 6.9 Ra)

AIRSET CAST SURFACE FINISH: 300 - 560 RMS (6.9 - 12.8 Ra)

P:\QUALITY RECORDS\QR 07 - Standard Tolerance Sheet.doc FORM 07 Updated 01/02/2015

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hydrostatic Water Filling Test ProcedureDocument1 paginăHydrostatic Water Filling Test ProcedureMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Employee Hours Worked Last Three YearsDocument1 paginăEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Program K3 2023Document2 paginiProgram K3 2023Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Program K3 2023Document2 paginiProgram K3 2023Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Vii CertificateDocument1 paginăVii CertificateMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Tanda TerimaDocument2 paginiTanda TerimaMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- PT BridonDocument1 paginăPT BridonMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Manufacturing Data Record IndexDocument2 paginiManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- III EngineeringDocument1 paginăIII EngineeringMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Transmittal FormDocument90 paginiTransmittal FormMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Laporan PiketDocument12 paginiLaporan PiketMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Fit-Up Inspection ReportDocument1 paginăFit-Up Inspection ReportMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- PT BridonDocument1 paginăPT BridonMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- PQR PT Bse WPS 07Document2 paginiPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Transmittal FormDocument90 paginiTransmittal FormMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT PrysmianDocument1 paginăPT PrysmianMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Method Statement For Prediction Weld Shrinkage On StructuralDocument4 paginiMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Design Intermittent WeldingDocument5 paginiDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- CSDCDocument2 paginiCSDCMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- V005t16a008 82 GT 277Document10 paginiV005t16a008 82 GT 277satstarÎncă nu există evaluări

- BEC701 - Fibre Optic Communication PDFDocument201 paginiBEC701 - Fibre Optic Communication PDFMax DurendÎncă nu există evaluări

- MECHANICAL CONCEPTS TestDocument19 paginiMECHANICAL CONCEPTS TestBob DehnkeÎncă nu există evaluări

- En Aw 6082 Rev 2 Final PDFDocument3 paginiEn Aw 6082 Rev 2 Final PDFtechspawÎncă nu există evaluări

- Nov 21st 2014 Friday: Products DetailsDocument1 paginăNov 21st 2014 Friday: Products DetailsXuân Giang NguyễnÎncă nu există evaluări

- Durafix Easyweld Flyer EnglishDocument2 paginiDurafix Easyweld Flyer EnglishDavid Assumpção da SilvaÎncă nu există evaluări

- TCR Arabia Company ProfileDocument120 paginiTCR Arabia Company Profilefatihkisa100% (1)

- Evidence of Plate Tectonic - 123715Document54 paginiEvidence of Plate Tectonic - 123715nicolas banlasanÎncă nu există evaluări

- ACTIVITY - Periodic Trends Properties WebQuest 2017 PDFDocument3 paginiACTIVITY - Periodic Trends Properties WebQuest 2017 PDFVasudev Pandey0% (1)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Fourier Transform Infrared (FT-IR) Spectrometers Coupled To Thermal AnalysisDocument24 paginiFourier Transform Infrared (FT-IR) Spectrometers Coupled To Thermal Analysisc_passerino6572Încă nu există evaluări

- Answers To Student Book Questions Rates of ReactionDocument3 paginiAnswers To Student Book Questions Rates of Reactionhamzaabdulhadi474Încă nu există evaluări

- Momentum - QDocument6 paginiMomentum - QZil HummaÎncă nu există evaluări

- Aplicatii Keyence - Digitalizari - Masuratori 2020 PDFDocument8 paginiAplicatii Keyence - Digitalizari - Masuratori 2020 PDFArjocan Emil DanÎncă nu există evaluări

- Chemistry and Association of Vanadium Compounds in Heavy Oil and Bitumen, and Implications For Their Selective RemovalDocument14 paginiChemistry and Association of Vanadium Compounds in Heavy Oil and Bitumen, and Implications For Their Selective RemovalMelÎncă nu există evaluări

- Solved Problems in PhysicsDocument22 paginiSolved Problems in Physicsvasudevan m.vÎncă nu există evaluări

- Pump Calcs PreDocument3 paginiPump Calcs PreaberraÎncă nu există evaluări

- Dose Calc - Practice ProblemsDocument3 paginiDose Calc - Practice Problemsapi-484630324Încă nu există evaluări

- Into 2 Mems ClocksDocument42 paginiInto 2 Mems ClocksjonwangÎncă nu există evaluări

- 2 - SANFIELD-Quality Manual For Elastomeric BearingsDocument34 pagini2 - SANFIELD-Quality Manual For Elastomeric Bearingsghaghra bridge100% (5)

- AIATS First Step JEE (Main & Advanced) 2022-24 - Group 1Document2 paginiAIATS First Step JEE (Main & Advanced) 2022-24 - Group 1Deepak LimbaÎncă nu există evaluări

- Colorado School of Mines CHEN403 Stirred Tank Heater Developing Transfer Functions From Heat & Material BalancesDocument8 paginiColorado School of Mines CHEN403 Stirred Tank Heater Developing Transfer Functions From Heat & Material BalancesSatria WijayaÎncă nu există evaluări

- ME 4131 Notes 4Document2 paginiME 4131 Notes 4jaz squaredÎncă nu există evaluări

- Benzene Hydrogenation Over Ni/Al O Catalysts Prepared by Conventional and Sol-Gel TechniquesDocument9 paginiBenzene Hydrogenation Over Ni/Al O Catalysts Prepared by Conventional and Sol-Gel TechniquesHarun AydınÎncă nu există evaluări

- Gizmo - Water CycleDocument3 paginiGizmo - Water CycleSparkly AudiosÎncă nu există evaluări

- Chemsheets GCSE 1365 The Electron Structure of IonsDocument2 paginiChemsheets GCSE 1365 The Electron Structure of IonsMorziqÎncă nu există evaluări

- Pamphlet 121 - Explosive Properties - Ed. 3 - 01-2009Document37 paginiPamphlet 121 - Explosive Properties - Ed. 3 - 01-2009sangoi87Încă nu există evaluări

- Observing Microorganisms Through A MicroscopeSV PDFDocument3 paginiObserving Microorganisms Through A MicroscopeSV PDFFelipe Andrés JorqueraÎncă nu există evaluări

- Lab Report Air ParticleDocument11 paginiLab Report Air ParticleSalmah AbasÎncă nu există evaluări