Documente Academic

Documente Profesional

Documente Cultură

DPT Report MBBR U-A Rev 1

Încărcat de

Muhammad Fitransyah Syamsuar PutraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DPT Report MBBR U-A Rev 1

Încărcat de

Muhammad Fitransyah Syamsuar PutraDrepturi de autor:

Formate disponibile

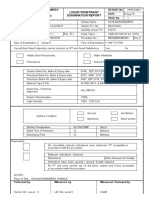

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-015A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 min

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 29˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 1141105 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

BOTTOM PLATE

WL P 2/3 W 09 / W 014 10 ACC ND

BOTTOM PLATE

TO ANNULAR W 08 / W 09 /

J1 W 014 10 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 23 /11/ 2016 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-033A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 31˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

SHELL

WLP 3/1 W 014 8 ACC ND

WLP 3/2 W 014 / W 011 8 ACC ND

WLP 3/3 W 09 8 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 18 /12 / 2016 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-027A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces :GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 31˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

CWL 3/4 W 016 / W 011 8 ACC ND

WLP 4/1 W 010 / W 011 8 ACC ND

WLP 4/2 W 010 / W 011 8 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 26/12/2016 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-048A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 31˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

Shell PN 04

WLP 4/3 W 010 / W 011 8 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 13/1/2017 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-036A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible √ solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : √ solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush √ Spray Dwei time : 5 min Temp : 29˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation √ As welded Machining Grinding Solvent

Time of examination √ After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

√ Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

Shell PN 4

CWL 4/5 W 010 / W 011 8 TO 6 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 25/1/2017 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-050A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. VAcceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 31˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

Shell PN 05

WLP 5/1 W 018/ W 011 6 ACC ND

WLP 5/2 W 018/ W 011 6 ACC ND

WLP 5/3 W 018/ W 011 6 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 15/2/2017 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-043A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 29˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

N3

WJ-04 W 014 6 ACC ND

WJ-05 W 014 6 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 2/3/2017 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-043A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 29˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

N1

WJ-14 W 014 7.11 TO 6 ACC ND

WJ-15 W 014 6 ACC ND

N4

WJ-10 W 016 7.11 TO 6 ACC ND

WJ-11 W 016 6 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 20/2/2017 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-028A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : GTAW+SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwel time : 5 min Temp : 30˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

Annulare Plate

WLP P1/2 W 14 / W 09 10 ACC ND

WLP P3/4 W 14 / W 08 10 ACC ND

WLP P5/6 W 09 / W 08 10 ACC ND

WLP P7/8 W 14 / W 09 10 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 24/11/2016 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-048A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 29˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

Nozzle Box

WJ-04 W 016 6 ACC ND

WJ-08 W 014 6 ACC ND

WJ-09 W 016 6 ACC ND

WJ-10 W 014 6 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 21/2/2017 Date : Date :

PENETRANT TEST REPORT

PT DEGREMONT

PENETRANT TEST REPORT

Customer : PT Degremont Drawing No : T 6486.06A Report No : U3-IR-ME-U1-049A

Client : PT IKPT Procedure No : QP-WLD-05 NCR Ref No :

Wo NO : 14122 Aplicable CODE : ASME Sect. V Acceptan Crit : API 650

Material Spec. : A 36 Welding Proces : SMAW

Penetrant Type/Method : visible solvent removable other

Brand's Name/type : Magnaflux Penetrant : Magnaflux SKL-SP 2

Methode pre-cleaning : solvent spray Drying after pre cleaning : 3 minutes

Penetrant Aplication : Brush Spray Dwei time : 5 min Temp : 29˚C

Light Intensity : Light Source :

Method Removing excess penetrant : Remove with cleaner

Drying after remove excess penetrant Developer App : Spray Developer Time : 10 min

Batch No of penetrant : 150605 Cleaner : 150606 Developer : 408396

Surface preparation As welded Machining Grinding Solvent

Time of examination After welding After hydro After PWHT

Scope of examination Base Metal Edge prep Back chipping

Weld Part Repair Weld Other

Result Types of

Part Name Weld No Thickness Remark

Accepted Rejected Distinuitis

N1 Inside W 014 6 ACC ND

N2 Inside W 016 6 ACC ND

N3 Inside Box W 014 6 ACC ND

N4 Inside Box W 016 6 ACC ND

N 2 Outside

WJ-02 W 016 6 ACC ND

WJ-03 W 016 6 ACC ND

Sketch (Ientifity discountinuity listed above ) if necessary

Examined by : PT Degremont PT IKPT PT Synthetic Rubber Indonesia

Name : Abdurahman wahid

NDE Level : II

Date : 1/3/2017 Date : Date :

S-ar putea să vă placă și

- DPT Report MBBR U-BDocument15 paginiDPT Report MBBR U-BMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Report PTDocument3 paginiReport PTGancie 26Încă nu există evaluări

- Procedure No.: Liquid Penetrant TestDocument4 paginiProcedure No.: Liquid Penetrant Testคุณพ่อน้อง บิ๊กบอสÎncă nu există evaluări

- 23-01-24. Comp MTA 6 Plant SignDocument4 pagini23-01-24. Comp MTA 6 Plant Signwahyudi140417Încă nu există evaluări

- Int-Aim-231887 PT 06-15-23Document2 paginiInt-Aim-231887 PT 06-15-23Joshua ClaytonÎncă nu există evaluări

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 paginiNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyÎncă nu există evaluări

- Advanced Oilfield Technology Company LLC: Liquid Penetrant Examination ReportDocument1 paginăAdvanced Oilfield Technology Company LLC: Liquid Penetrant Examination ReportAmal RajÎncă nu există evaluări

- Liquid PenetrantDocument2 paginiLiquid PenetrantabdiÎncă nu există evaluări

- Sharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportDocument2 paginiSharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportAmol KhatateÎncă nu există evaluări

- Oil Test-1Document2 paginiOil Test-1ForenTec Engineers RanchiÎncă nu există evaluări

- MT PipaDocument70 paginiMT PipaDani Madrid12Încă nu există evaluări

- Magnetic Examination Report: SketchDocument69 paginiMagnetic Examination Report: SketchSeret BroÎncă nu există evaluări

- 08-03-24. Water Injection Pump SambojaDocument1 pagină08-03-24. Water Injection Pump Sambojawahyudi140417Încă nu există evaluări

- Dye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuDocument4 paginiDye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuTWI CertificationÎncă nu există evaluări

- DPT of PropellerDocument3 paginiDPT of Propellersushanto.mtbdÎncă nu există evaluări

- RPE012Document2 paginiRPE012ireng potehÎncă nu există evaluări

- Int Aim 231787 PT 14 1302&03Document1 paginăInt Aim 231787 PT 14 1302&03Joshua ClaytonÎncă nu există evaluări

- NDT Report - Old.Turbine BearingsDocument3 paginiNDT Report - Old.Turbine BearingsOm Ar TanÎncă nu există evaluări

- MT-Lifting LugDocument4 paginiMT-Lifting Lugiksan_adityoÎncă nu există evaluări

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 pagină75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahÎncă nu există evaluări

- 56STLZ 1Document223 pagini56STLZ 1Dani Madrid12Încă nu există evaluări

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 paginiD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaÎncă nu există evaluări

- D.P. Test ReportDocument1 paginăD.P. Test Reportvirendra katkeÎncă nu există evaluări

- RPE001Document2 paginiRPE001ireng potehÎncă nu există evaluări

- Mpi CB, LBDocument7 paginiMpi CB, LBSuhari AriÎncă nu există evaluări

- RR3-3269 Eo1352Document2 paginiRR3-3269 Eo1352Deepak HoleÎncă nu există evaluări

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 paginiNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniÎncă nu există evaluări

- NDT Report - Dovetail WheelsDocument4 paginiNDT Report - Dovetail WheelsOm Ar TanÎncă nu există evaluări

- CB-043 Mpi Exp-02 Apr 2024Document1 paginăCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninÎncă nu există evaluări

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDocument2 pagini109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr Ddiman100% (1)

- Control Valves - Rev00Document12 paginiControl Valves - Rev00ocanhthuÎncă nu există evaluări

- Gpti Qicl J931 Mut 019Document3 paginiGpti Qicl J931 Mut 019uselessinstaid52Încă nu există evaluări

- IRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestDocument40 paginiIRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestAfzaalUmairÎncă nu există evaluări

- Installation of Padeyes Ad Load Test: Front CoverDocument40 paginiInstallation of Padeyes Ad Load Test: Front CoverAhmedA.HassanÎncă nu există evaluări

- PT02Document1 paginăPT02اسران احمدÎncă nu există evaluări

- BC MT 1688-0000Document84 paginiBC MT 1688-0000Tuấn ĐậuÎncă nu există evaluări

- MIghty Machine RejectDocument1 paginăMIghty Machine RejectMohammad Shanawaz MÎncă nu există evaluări

- Gpti Qicl J931 Mut 002Document2 paginiGpti Qicl J931 Mut 002uselessinstaid52Încă nu există evaluări

- A0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Document15 paginiA0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Madhan KannanÎncă nu există evaluări

- IVR-050212116123 - 22-1-Rev.0 - Enmas - True FabDocument6 paginiIVR-050212116123 - 22-1-Rev.0 - Enmas - True FabPavul RajÎncă nu există evaluări

- Gpti Qicl J931 Mut 041Document3 paginiGpti Qicl J931 Mut 041uselessinstaid52Încă nu există evaluări

- 0186 MOM DSP 025 062 0030 Valvulas de Control 2Document266 pagini0186 MOM DSP 025 062 0030 Valvulas de Control 2Lukas Ramírez SchiaffinoÎncă nu există evaluări

- REPORT-MT 21.10.2022 (Test)Document2 paginiREPORT-MT 21.10.2022 (Test)Nhien ManÎncă nu există evaluări

- REPORT-MT 21.10.2022 (Test)Document2 paginiREPORT-MT 21.10.2022 (Test)Nhien ManÎncă nu există evaluări

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 paginiProcedure Qualification Record (PQR) Khewari Development Projectsar sarÎncă nu există evaluări

- Example Report TOFD 2 INT-GP1186!09!70Document1 paginăExample Report TOFD 2 INT-GP1186!09!70EMTC EMTC100% (1)

- Example Report TOFD 2 INT-GP1186-09-70 PDFDocument1 paginăExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCÎncă nu există evaluări

- Coupler Plate DP TestDocument1 paginăCoupler Plate DP Testshindemitesh17Încă nu există evaluări

- CNT230045-6 C3 HRSG Blow Down Vessel - ReportDocument5 paginiCNT230045-6 C3 HRSG Blow Down Vessel - ReportDave CheungÎncă nu există evaluări

- 18-12-23. Gaslift Skid MTA M-23Document4 pagini18-12-23. Gaslift Skid MTA M-23Ferdie OSÎncă nu există evaluări

- Turbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1Document34 paginiTurbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1yuliantoÎncă nu există evaluări

- 106.8180.MPI - Pre.Unit.730395.Hydraulic TankDocument3 pagini106.8180.MPI - Pre.Unit.730395.Hydraulic TankHerr DdimanÎncă nu există evaluări

- Data Sheet For Special Piping Parts: (Strainer)Document2 paginiData Sheet For Special Piping Parts: (Strainer)dimas prasetyoÎncă nu există evaluări

- Ibop 101801720Document2 paginiIbop 101801720André da SilvaÎncă nu există evaluări

- L.P.T Reports.Document12 paginiL.P.T Reports.Shaikh AdilÎncă nu există evaluări

- DPT ReportDocument3 paginiDPT ReportMANIMARAN QCÎncă nu există evaluări

- MT02Document1 paginăMT02اسران احمدÎncă nu există evaluări

- United Caravan Trading and Contracting (Oil & Gas Division) : Initial Equipment Inspection ReportDocument1 paginăUnited Caravan Trading and Contracting (Oil & Gas Division) : Initial Equipment Inspection Reportfali2006Încă nu există evaluări

- Feuille Des Donnees Cables F&G: ProjetDocument6 paginiFeuille Des Donnees Cables F&G: ProjetAshraf Ammar100% (1)

- Program K3 2023Document2 paginiProgram K3 2023Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Tanda TerimaDocument2 paginiTanda TerimaMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Employee Hours Worked Last Three YearsDocument1 paginăEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Program K3 2023Document2 paginiProgram K3 2023Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Hydrostatic Water Filling Test ProcedureDocument1 paginăHydrostatic Water Filling Test ProcedureMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- III EngineeringDocument1 paginăIII EngineeringMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Vii CertificateDocument1 paginăVii CertificateMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Transmittal FormDocument90 paginiTransmittal FormMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PQR PT Bse WPS 07Document2 paginiPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Fit-Up Inspection ReportDocument1 paginăFit-Up Inspection ReportMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Transmittal FormDocument90 paginiTransmittal FormMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Laporan PiketDocument12 paginiLaporan PiketMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Manufacturing Data Record IndexDocument2 paginiManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT BridonDocument1 paginăPT BridonMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT BridonDocument1 paginăPT BridonMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Design Intermittent WeldingDocument5 paginiDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT DjabesmenDocument1 paginăPT DjabesmenMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PT PrysmianDocument1 paginăPT PrysmianMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Method Statement For Prediction Weld Shrinkage On StructuralDocument4 paginiMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- CSDCDocument2 paginiCSDCMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 paginiLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIDocument48 paginiDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadÎncă nu există evaluări

- ReliabilityDocument5 paginiReliabilityArmajaya Fajar SuhardimanÎncă nu există evaluări

- Pe 3 Syllabus - GymnasticsDocument7 paginiPe 3 Syllabus - GymnasticsLOUISE DOROTHY PARAISO100% (1)

- CONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlDocument109 paginiCONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlVss SantosÎncă nu există evaluări

- Inverter 1 KW ManualDocument44 paginiInverter 1 KW ManualLeonardoÎncă nu există evaluări

- Service Manual: Multifunction Electrical Tester CalibratorDocument106 paginiService Manual: Multifunction Electrical Tester CalibratorJuan Carlos Ferrer OrtizÎncă nu există evaluări

- SGT PDFDocument383 paginiSGT PDFDushyanthkumar DasariÎncă nu există evaluări

- AMS 48 - 2000-n - D0114354 - 055 - 00Document116 paginiAMS 48 - 2000-n - D0114354 - 055 - 00wanhall100% (1)

- Cultivation Vaderstad Manual 2017Document128 paginiCultivation Vaderstad Manual 2017deroryÎncă nu există evaluări

- Intershield803 MDSDocument4 paginiIntershield803 MDSSahanÎncă nu există evaluări

- Maxillofacial Notes DR - Mahmoud RamadanDocument83 paginiMaxillofacial Notes DR - Mahmoud Ramadanaziz200775% (4)

- Chapter 2 Unfinished RRLDocument22 paginiChapter 2 Unfinished RRLGM XylerÎncă nu există evaluări

- Biopolymers: Overview of Several Properties and Consequences On Their ApplicationsDocument10 paginiBiopolymers: Overview of Several Properties and Consequences On Their ApplicationsrafacpereiraÎncă nu există evaluări

- Thesis ProposalDocument19 paginiThesis Proposaldharmi subedi75% (4)

- Sav4747 PDFDocument49 paginiSav4747 PDFAndres Antonio Moreno CastroÎncă nu există evaluări

- NORSOK M-630 Edition 6 Draft For HearingDocument146 paginiNORSOK M-630 Edition 6 Draft For Hearingcaod1712100% (1)

- Tamilnadu Shop and Establishment ActDocument6 paginiTamilnadu Shop and Establishment ActShiny VargheesÎncă nu există evaluări

- Funding HR2 Coalition LetterDocument3 paginiFunding HR2 Coalition LetterFox NewsÎncă nu există evaluări

- Employment Offer: 1. Employer InformationDocument2 paginiEmployment Offer: 1. Employer InformationnavidÎncă nu există evaluări

- The Emom Manual: 25 Kettlebell Conditioning WorkoutsDocument14 paginiThe Emom Manual: 25 Kettlebell Conditioning WorkoutsguilleÎncă nu există evaluări

- Potato Storage and Processing Potato Storage and Processing: Lighting SolutionDocument4 paginiPotato Storage and Processing Potato Storage and Processing: Lighting SolutionSinisa SustavÎncă nu există evaluări

- Senior Project RiceberryDocument76 paginiSenior Project RiceberryIttisak PrommaÎncă nu există evaluări

- A Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaDocument32 paginiA Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaSonu PradhanÎncă nu există evaluări

- Drug-Nutrient Interaction in Prescriptions ForDocument7 paginiDrug-Nutrient Interaction in Prescriptions ForRafika DitaÎncă nu există evaluări

- METHOD STATEMENT FOR INSTALLATION OF Light FixturesDocument5 paginiMETHOD STATEMENT FOR INSTALLATION OF Light FixturesNaveenÎncă nu există evaluări

- Neopuff PDFDocument4 paginiNeopuff PDFoechimÎncă nu există evaluări

- Entitlement Cure SampleDocument34 paginiEntitlement Cure SampleZondervan100% (1)

- Rules For State Competitions and Iabf Approved TournamentsDocument56 paginiRules For State Competitions and Iabf Approved TournamentsQuality management systems documentsÎncă nu există evaluări

- DOWSIL™ 2-9034 Emulsion: Features & BenefitsDocument5 paginiDOWSIL™ 2-9034 Emulsion: Features & BenefitsLaban KantorÎncă nu există evaluări

- Class Two Summer Vacation AssignmentDocument1 paginăClass Two Summer Vacation AssignmentshahbazjamÎncă nu există evaluări