Documente Academic

Documente Profesional

Documente Cultură

Experimental Study On M-Sand With Addition of Sugar As Admixture in Concrete

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Experimental Study On M-Sand With Addition of Sugar As Admixture in Concrete

Drepturi de autor:

Formate disponibile

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

Experimental Study On M-Sand With

Addition Of Sugar As Admixture In Concrete

T.Subramani1, M.Senthilkumar2, V.Ashok Kumar3, Pawan Kumar Singh4, R.Silambarasan5

1

Professor & Dean, Department of Civil Engineering, VMKV Engineering College, Vinayaka Mission’s Research Foundation

(Deemed to be University), Salem, TamilNadu, India.

2

Assistant Professor, Department of Civil Engineering, VMKV Engineering College, Vinayaka Mission’s Research Foundation

(Deemed to be University), Salem, TamilNadu, India.

3,4,5

UG Students,Department of Civil Engineering, VMKV Engineering College, Vinayaka Mission’s Research Foundation

(Deemed to be University), Salem, TamilNadu, India.

Abstract: The Concrete is a composite construction material time of concrete. Retarder and Accelerator are used to

plays a vital role in the construction of the nation’s increase and decrease the initial setting time of concrete

infrastructure. One of the important ingredients of conventional specially in winter sessions and summer sessions

concrete is natural sand or river sand. The issue of respectively.

environmental degradation and expensive nature of the river When water is added to cement, it sets and hardens

sand make us to switch on to the alternative sources. Lots of

gradually under normal climatic conditions. But in some

researches has been done to replace the sand, in this project we

study the effect of Sugar and replace the river sand by M-Sand countries, including Pakistan, higher summer temperatures,

with 50% and 100%. Its micro-filling effect reduces pores in low relative humidity and hot wind blowing cause rapid

concretes and provides better moisture resistivity and thus evaporation of water from the fresh concrete surface.

durability. M40 grade of concrete was used and the specimens Consequently concrete sets earlier and no proper time is left

were tested at 7, 14 and 28 days. Effective use for waste material available for concreting operations. For example, it has

and thus cost effective and performs as well as naturally been reported that, when the temperature of cement mortar

occurring sand. Different percentages of admixtures as Sugar with a water/cement (w/c) ratio of 0.6 is increased from

are selected in the evaluation as 0.25 % and 0.5% by weight of 27.80C to45.50C both the initial and final setting times are

cement. The experimental work mainly concluded after

nearly halved.

evaluation workability and concentrates with compressive

strength and split tensile strength and acid attack test on

concrete enhanced when admixtures like Sugar added into the Concrete has its superior properties like binding, strength

concrete Mix. and durability, but it cannot be used in all places due to

Keywords:M-Sand, Addition, Sugar, Admixture, Concrete different weather conditions in different countries.

Variation in weather condition and sessions causes changes

1. INTRODUCTION in the initial setting time of concrete. Retarder and

Concrete is an inevitable material in the human being’s life, Accelerator are used to increase and decrease the initial

because of its superior characteristics like strength and setting time of concrete especially in winter sessions and

durability, but in certain situations it can’t be used in all summer sessions respectively. With the help of different

places because setting time of concrete. Retarders are used type of admixture used such as Retarder- sugar and gypsum

in the concrete composition to improve the setting time and etc. and Accelerator- calcium chloride (cacl2) etc. By going

also to increase the temperature of the composition with through studying to various review papers and research

different type of admixtures. Concrete is most widely used papers sugar is good admixture to increasing the initial

man made construction material in the world and obtain by setting time. Sugar is a carbohydrate, a composition of

mixing cement, sand, aggregates and water, and sometime carbon, oxygen and hydrogen. It can be useful when

admixtures is required in suitable proportions. The strength, concreting used in hot weather conditions, when the normal

durability and other characteristics of concrete depends up setting time of concrete is shortened by the higher

on the properties of its ingredients, on the proportion of surrounding temperature such as Gujarat, Rajasthan states

mix, the method of compaction and other control during etc. Very small dosage of the order of 0.05 to 0.1 per cent

placing, compaction and curing. Concrete block has its of the mass of the concrete is enough. 0.05 per cent of

superior properties like binding, strength and durability, but sugar can delay initial setting time by about 3 hours.

it cannot be used in all places due to different weather Usually three different percentage of sugar admixtures were

conditions in different countries. Variation in weather taken as by weight of cement. Hence in order to maintain

condition and sessions causes changes in the initial setting the standard condition, admixtures are used. Retarders are

Volume 7, Issue 2, March – April 2018 Page 100

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

admixture that extend the hydration induction period, it sets as it dries and reacts with carbon dioxide in the air. It

thereby lengthening the setting times(Lea).Sugar, is resistant to attack by chemicals after setting.

carbohydrate derivatives , soluble zinc salts ,soluble borates

exhibits retarding action.Lea,1988-Sugar falls under the 3.2 Coarse Aggregate

category of ‘coating ‘ admixture ;in the presence of water a Aggregates are inert granular materials such as sand,

cement particle sends out a swarm of calcium ions into the gravel, or crushed stone that, along with water and Portland

surrounding water and any substance capable of cement, are an essential ingredient in concrete. For a good

immobilizing or delaying this surge will also slowdown the concrete mix, aggregates need to be clean, hard, strong

interchanges between the water and the particle, thus particles free of absorbed chemicals or coatings of clay and

retarding the hydration process. other fine materials that could cause the deterioration of

concrete.

2.METHODOLOGY

Figure 1. Shows the methodology adopted in this study 3.3 Fine Aggregate

Fine aggregates generally consist of natural sand or crushed

stone with most particles passing through a 9.5mm sieve.

3.4 Sugar

Sugar was used in the concrete production. A white

crystalline solid easily soluble in water and easily available

in market and used in the experimental works. Sugar, using

sugar-based ingredients that are used as additives to the

concrete.

Figure 2Sugar as Admixture

It shows that the effect of adding sugar-based materials in

the form of sucrose, sugar, and sugar cane in concrete

mixture is very significant, that is accelerate or slow the

time of hardening of concrete, and increase the compressive

Figure 1 Methodology strength of concrete. It should be noted that bagasse

contains 30-50% cellulose and 20-24% lignin. Cane plant is

known as the main ingredient of sugar production in my

3.MATERIAL COLLECTION country (Indonesia). In general, cooking cane rods contain

3.1 Cement 67-75% water, 8-16%, and 8-16% sucrose, 0.5-20%

A cement is a binder, a substance used for construction that reducing sugar, 0.5-1% organic material, 0.2-0.6%

sets, hardens and adheres to other materials, binding them inorganic compounds, 0.5-1% compounds nitrogenic, 0.3-

together. Cement is seldom used on its own, but rather to 0.8% ash, and 10-16% fibre. Cane also contains 30-50%

bind sand and gravel (aggregate) together. Cement is used cellulose and 20-24% lignin. The presence of lignin in the

with fine aggregate to produce mortar for masonry, or with bagasse and its juice is indicated to contribute the

sand and gravel aggregates to produce concrete. Cements attachment, when the sugarcane solution is mixed into the

used in construction are usually inorganic, often lime or concrete mixture. The sugar-based added ingredients in the

calcium silicate based, and can be characterized as being concrete mixture enhances the C-S-H bond so that it will

either hydraulic or non-hydraulic, depending upon the increase the value of the compressive strength of the

ability of the cement to set in the presence of water (see concrete over time until the optimal value of the

hydraulic and non-hydraulic lime plaster).Non-hydraulic compressive strength is achieved. At certain doses, sugars

cement will not set in wet conditions or underwater; rather, can accelerate or slow down the time of binding of cement

Volume 7, Issue 2, March – April 2018 Page 101

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

and hardening of concrete and improve the performance of

compressive strength of mortar and concrete. Sugar-based 4. MATERIAL PROPERTIES

concrete increased strength at a dose of 0.03% and 0.3% of

the weight of cement. 4.1 Cement

Cement, a popular binding material, is a very important

3.5 M-Sand civil engineering material. This article concerns the

Manufactured sand (M-Sand) is a substitute of river sand physical and chemical properties of cement, as well as the

for concrete construction. Manufactured sand is produced methods to test cement properties.

from hard granite stone by crushing. Manufactured sand is

an alternative for river sand. Due to fast growing 4.1.1Properties of Good Cement

construction industry, the demand for sand has increased It is always desirable to use the best cement in

tremendously, causing deficiency of suitable river sand in constructions. Therefore, the properties of a cement must

most part of the word. Due to the depletion of good quality be investigated. Although desirable cement properties may

river sand for the use of construction, the use of vary depending on the type of construction, generally a

manufactured sand has been increased. Another reason for good cement possesses following properties (which depend

use of M-Sand is its availability and transportation cost. upon its composition, thoroughness of burning and fineness

Since manufactured sand can be crushed from hard granite of grinding).

rocks, it can be readily available at the nearby place,

Provides strength to masonry.

reducing the cost of transportation from far-off river sand

Stiffens or hardens early.

bed. Figure.3 shows M-sand and sand.

Possesses good plasticity.

An excellent building material.

Easily workable.

Good moisture-resistant.

4.2 Properties of Coarse Aggregate

Concrete is a mixture of cementious material, aggregate,

and water. Aggregate is commonly considered inert filler,

which accounts for 60 to 80 percent of the volume and 70

to 85 percent of the weight of concrete. Although aggregate

is considered inert filler, it is a necessary component that

defines the concrete’s thermal and elastic properties and

Figure 3 M-sand and sand dimensional stability. Aggregate is classified as two

different types, coarse and fine. Coarse aggregate is usually

3.5.1 Advantages of Manufactured Sand (M-Sand) greater than 4.75 mm (retained on a No. 4 sieve), while fine

aggregate is less than 4.75 mm (passing the No. 4 sieve).

It is well graded in the required proportion. The compressive aggregate strength is an important factor

in the selection of aggregate. When determining the

It does not contain organic and soluble compound

strength of normal concrete, most concrete aggregates are

that affects the setting time and properties of

several times stronger than the other components in

cement, thus the required strength of concrete can

concrete and therefore not a factor in the strength of normal

be maintained.

strength concrete. Lightweight aggregate concrete may be

It does not have the presence of impurities such as

more influenced by the compressive strength of the

clay, dust and silt coatings, increase water

aggregates. Other physical and mineralogical properties of

requirement as in the case of river sand which

aggregate must be known before mixing concrete to obtain

impair bond between cement paste and aggregate.

a desirable mixture. These properties include shape and

Thus, increased quality and durability of concrete.

texture, size gradation, moisture content, specific gravity,

M-Sand is obtained from specific hard rock reactivity, soundness and bulk unit weight.

(granite) using the state-of-the-art International

technology, thus the required property of sand is 4.3 Fine Aggregate

obtained. 4.3.1 Basic Properties of Aggregates Used In Concrete

Composition

3.6 Water Aggregates consisting of materials that can react with

The amount of water in concrete controls many fresh and alkalies in cement and cause excessive expansion, cracking

hardened properties in concrete including workability, and deterioration of concrete mix should never be used.

compressive strengths, permeability and water tightness, Therefore it is required to test aggregates to know whether

durability and weathering, drying shrinkage and potential

for cracking.

Volume 7, Issue 2, March – April 2018 Page 102

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

there is presence of any such constituents in aggregate or Mix Proportion shown in Table.1

not.

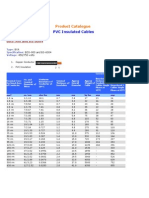

Table 1.Mixproportion

4.3.2 Size and shape

The size and shape of the aggregate particles greatly

influence the quantity of cement required in concrete mix

and hence ultimately economy of concrete. For the

preparation of economical concrete mix on should use

largest coarse aggregates feasible for the structure. IS-456

suggests following recommendation to decide the

maximum size of coarse aggregate to be used in P.C.C &

R.C.C mix. 6. TEST PROCEDURE

4.3.3 Porosity and absorption 6.1 Slump Test

The minute holes formed in rocks during solidification of Concrete slump test is to determine the workability or

the molten magma, due to air bubbles, are known as pores. consistency of concrete mix prepared at the laboratory or

Rocks containing pores are called porous rocks. Water the construction site during the progress of the work.

absorption may be defined as the difference between the Concrete slump test is carried out from batch to batch to

weight of very dry aggregates and the weight of the check the uniform quality of concrete during construction.

saturated aggregates with surface dry conditions. Generally concrete slump value is used to find the

Depending upon the amount of moisture content in workability, which indicates water-cement ratio, but there

aggregates, it can exist in any of the 4 conditions. are various factors including properties of materials, mixing

Very dry aggregate (having no moisture) methods, dosage, admixtures etc. also affect the concrete

Dry aggregate (contain some moisture in its pores) slump value.

Saturated surface dry aggregate (pores completely

filled with moisture but no moisture on surface) 6.2 Workability

Moist or wet aggregates (pores are filled with Workability of concrete has been measured by

moisture and also having moisture on surface) performing slump cone tests. Mix the material of

concrete properly on a water tight plat form and

4.4 Properties of Sugar as Admixture measure the slump cone value as stated in the

4.4.1 Physical and Chemical Properties above section 5.1 and record the values, tabulated

Pure sucrose is most often prepared as a fine, colourless, properly.

odourless crystalline powder with a pleasing, sweet taste. During the testing of slump value, it was clearly

Large crystals are sometimes precipitated from water observed that collapse of slump.

solutions of sucrose onto a string (or other nucleation Addition of Sugar to the concrete greatly

surface) to form rock candy, a confection. Like other influenced the setting property and clear collapse

carbohydrates, sucrose has hydrogen to oxygen ratio of 2:1. of slump witnessed during the experimentation.

It consists of two monosaccharides, α-glucose and Setting of cubes specimen after 24 hrs is difficult.

fructose, joined by a glycosidic bond between carbon atom During the de-moulding after 24 hrs. Cube

1 of the glucose unit and carbon atom 2 of the fructose unit. specimens are found cracks.

What is notable about sucrose is that unlike most

polysaccharides, the glycosidic bond is formed between the

reducing ends of both glucose and fructose, and not 6.3 Compressive Strength Test

between the reducing end of one and the non-reducing end Cube specimens of each percentage (0, 0.05, 0.1, 0.15, 0.2

of the other. and 0.25%) are casted according to the nominal mix

proportion and the size of cube specimen was 150 mm x

150 mm x 150 mm. According to the IS: 10086-1982, cube

5. MIX DESIGN moulds are used for experimental work. Specimens are

casted in cube mould and filled with concrete in three

Design Stipulations layers. Hand compaction is done with tamping rod and de-

Grade Designation M-40 moulded after 24 hrs. Specimens are marked with marker

Type of cement O.P.C-53grade and allowed to dry for some time and immersed in the

Fine Aggregate Zone-I curing tank. De-moulding of cube specimen is difficult

Sp. Gravity Cement 3.15 after 24 hrs. For specimens casted with admixture of 0.05%

Sp. Gravity Fine Aggregate 2.85 and 0.1% because of extension of setting time. Specimens

Sp. Gravity Coarse Aggregate 2.66 casted with 0.05% and 0.1% admixture were de-moulded

after 48 hrs and for 0.15, 0.2 and 0.25% after 72 hrs. The

5.1 Mix proportion specimens are kept into the curing tank for curing @ temp

27±2° for a period of 28days. After completion of curing

Volume 7, Issue 2, March – April 2018 Page 103

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

period, specimens are removed from curing tank, kept for Table 2Compressive strength test Result

drying and tested in UTM. Fig: 3 show the casted cube

specimens. During the experimentation of casting, it is

clearly observed lower ranking of bleeding and segregation.

6.4Acid Attack Test

The concrete cube specimens of various concrete mixtures

of size 150 mm were cast and after 28 days of water curing,

the specimens were removed from the curing tank and

allowed to dry for one day. The weights of concrete cube

specimen were taken. The acid attack test on concrete cube

was conducted by immersing the cubes in the acid water

for90 days after 28 days of curing. Hydrochloric acid

(HCL) with pH of about 2 at 5% weight of water was added

to water in which the concrete cubes were stored. The pH

was maintained throughout the period of 90 days. After 90

days of immersion, the concrete cubes were taken out of

acid water. Then, the specimens were tested for

compressive strength. The resistance of concrete to acid

attack was found by the % loss of weight of specimen and

the % loss of compressive strength on immersing concrete

cubes in acid water.

6.5 Alkaline Attack Test

To determine the resistance of various concrete mixtures to

alkaline attack, the residual compressive strength of Figure4 Compression Test Graph Result

concrete mixtures of cubes immersed in alkaline water

having 5% of sodium hydroxide (NaOH) by weight of 7.3 Split Tensile Test for Cylinder

water was found. The concrete cubes which were cured in

water for 28 days were removed from the curing tank and Table 3 shows Split Tensile Test Result and Figure 5 shows

allowed to dry for one day. The weights of concrete cube Split Tensile Graph Result

specimen were taken. Then the cubes were immersed in

alkaline water continuously for 90days. The alkalinity of Table 3Split Tensile Test Result

water was maintained same throughout the test period.

After 90 days of immersion, the concrete cubes were taken

out of alkaline water. Then, the specimens were tested for

compressive strength. The resistance of concrete to alkaline

attack was found by the % loss of weight of specimen and

the % loss of compressive strength on immersion of

concrete cubes in alkaline water.

7.TESTING RESULT

7.1 Ratios for Special Concrete (Extra Ingredients)

Ratio –I

Sugar Adding 0.25 % of Water

Sand Replacing 50 % of M-Sand

Ratio - II

Sand Replacing 100 % of M-Sand

Sugar Adding 0.5 % of Water

7.2 Compressive Strength of Cube

Compressive strength test Results shown in Table.2 and

Figure.4 shows Compression Test Graph Result.

Figure5 Split Tensile Graph Result

Volume 7, Issue 2, March – April 2018 Page 104

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

7.4 Workability of Concrete

Table 4 shows Workability of concrete results. Figure 6

Graph shows the workability results Figure 7 shows Slump

test results

Table 4Workability of concrete results

Figure 13 Graphs shows acid attack test results

8.CONCLUSION

The test carried out at 3 days, 7 days, 14 days and 28 days,

the comparison is made between the varying proportions

0.25%,0.5% addition and 50 %,100% replacement of M-

sand for Fine aggregate sugars in concrete mix for Setting

time ,Workability & Compressive strength.

Workability increased when the Ratio I compared to

conventional concrete.

Figure 6Graph shows the workability results

The setting time of concrete increase sugar with

increase the percentage of sugar.

Both split tensile &compressive strength increases as

the percentage of 0.25% sugar with 50% replacement

of M-sand increases45.33N/mm2 attained at 28 days

compared to conventional concrete 43.36N/mm2.

Strength of the concrete improved with little extra

cost and utility in specified situations.

Segregation and bleeding was very less due to the

usage of these admixtures.

References

[1]. T.Subramani., S.Krishnan. S.K.Ganesan.,

G.Nagarajan ”Investigation of Mechanical Properties

in Polyester and Phenyl-ester Composites Reinforced

Figure7Slump test results With Chicken Feather Fiber” International Journal of

Engineering Research and Applications Vol. 4, Issue

7.5 Acid Attack Test 12(Version 4), pp.93-104, 2014.

Table 5 shows Acid attack test results. Figure 8 shows [2]. T.Subramani, J.Jayalakshmi , " Analytical

Graphs shows acid attack test results Investigation Of Bonded Glass Fibre Reinforced

Polymer Sheets With Reinforced Concrete Beam

Table 5 Acid attack test results Using Ansys" , International Journal of Application or

Innovation in Engineering & Management (IJAIEM) ,

Volume 4, Issue 5, pp. 105-112 , 2015

[3]. T.Subramani, D.Latha , " Experimental Study On

Recycled Industrial Waste Used In Concrete" ,

International Journal of Application or Innovation in

Engineering & Management (IJAIEM) , Volume 4,

Issue 5, pp. 113-122 , 2015

[4]. T.Subramani, V.Angappan , " Experimental

Investigation Of Papercrete Concrete" , International

Volume 7, Issue 2, March – April 2018 Page 105

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

Journal of Application or Innovation in Engineering Engineering & Management (IJAIEM), Volume 5,

& Management (IJAIEM) , Volume 4, Issue 5, pp. Issue 5, pp. 228-238 , 2016

134-143 , 2015 [16]. T.Subramani, A.Anbuchezian , " Experimental Study

[5]. T.Subramani, V.K.Pugal , " Experimental Study On Of Palm Oil Fuel Ash As Cement Replacement Of

Plastic Waste As A Coarse Aggregate For Structural Concrete " , International Journal of Application or

Concrete" , International Journal of Application or Innovation in Engineering & Management (IJAIEM),

Innovation in Engineering & Management (IJAIEM) , Volume 6, Issue 3, March 2017 , pp. 001-005 , ISSN

Volume 4, Issue 5, pp.144-152 2015 2319 - 4847.

[6]. T.Subramani, B.Suresh , " Experimental Investigation [17]. T.Subramani, A.Anbuchezian , " Experimental Study

Of Using Ceramic Waste As A Coarse Aggregate Of Mineral Admixture Of Self Compacting Concrete

Making A Light Weight Concrete " , International " , International Journal of Application or Innovation

Journal of Application or Innovation in Engineering in Engineering & Management (IJAIEM), Volume 6,

& Management (IJAIEM) , Volume 4, Issue 5, pp. Issue 3, March 2017 , pp. 006-010 , ISSN 2319 -

153-162 , 2015 4847.

[7]. T.Subramani, M.Prabhakaran , " Experimental Study [18]. T.Subramani, A.Anbuchezian , " Experimental Test

On Bagasse Ash In Concrete" , International Journal On Bitumen With Addition Of 35% Of Plastic Fibre "

of Application or Innovation in Engineering & , International Journal of Application or Innovation in

Management (IJAIEM) , Volume 4, Issue 5, pp. 163- Engineering & Management (IJAIEM), Volume 6,

172 , 2015 Issue 3, March 2017 , pp. 017-022 , ISSN 2319 -

[8]. T.Subramani, A.Mumtaj , " Experimental 4847.

Investigation Of Partial Replacement Of Sand With [19]. T.Subramani, A.Anbuchezian , " Stabilization Of

Glass Fibre" , International Journal of Application or M30 Concrete Pavement By Partially Replacing

Innovation in Engineering & Management (IJAIEM) , Cement By 20% Of Flyash And Sodium Silicate " ,

Volume 4, Issue 5, pp. 254-263 , 2015 International Journal of Application or Innovation in

[9]. T.Subramani, S.B.Sankar Ram Experimental Study Engineering & Management (IJAIEM), Volume 6,

on Concrete Using Cement With Glass Issue 3, March 2017 , pp. 023-031 , ISSN 2319 -

Powder,IOSR Journal of Engineering,Volume 5 , 4847.

Issue 5, Version 3, pp43-53, 2015 [20]. T.Subramani, A.Anbuchezian , " Experimental

[10]. T.Subramani, S.Kumaran , " Experimental Investigation On Flexural Behavior Of Folded Ferro

Investigation Of Using Concrete Waste And Brick Cement Panels " , International Journal of Application

Waste As A Coarse Aggregate " , International or Innovation in Engineering & Management

Journal of Application or Innovation in Engineering (IJAIEM), Volume 6, Issue 3, March 2017 , pp. 045-

& Management (IJAIEM) , Volume 4, Issue 5, pp. 049 , ISSN 2319 - 4847.

294-303 , 2015 [21]. T.Subramani, A.Anbuchezian , " Experimental Study

[11]. T.Subramani, G.Ravi, “Experimental Investigation On Replacement Of Concrete Material By Water

Of Coarse Aggregate With Steel Slag In Concrete”, Treatment Plant Waste Sewage " , International

IOSR Journal of Engineering, Volume 5,Issue 5, Journal of Application or Innovation in Engineering

Version 3, pp64-73, 2015 & Management (IJAIEM), Volume 6, Issue 3, March

[12]. T.Subramani, K.S.Ramesh , " Experimental Study On 2017 , pp. 050-057 , ISSN 2319 - 4847.

Partial Replacement Of Cement With Fly Ash And [22]. T.Subramani, A. Fizoor Rahman , " An Experimental

Complete Replacement Of Sand With M sand" , Study On The Properties Of Pet Fibre Reinforced

International Journal of Application or Innovation in Concrete " , International Journal of Application or

Engineering & Management (IJAIEM) , Volume 4, Innovation in Engineering & Management (IJAIEM),

Issue 5 , pp. 313-322 , 2015 Volume 6, Issue 3, March 2017 , pp. 058-066 , ISSN

[13]. T.Subramani, G.Shanmugam , " Experimental 2319 - 4847.

Investigation Of Using Papercrete And Recycled [23]. T.Subramani, M.Meganathan, S.Priyanka , "

Aggregate As A Coarse Aggregate " , International Experimental Study On Strength Properties Of

Journal of Application or Innovation in Engineering Diaphanous Concrete With Vermiculite " ,

& Management (IJAIEM) , Volume 4, Issue 5, pp. International Journal of Application or Innovation in

323-332 , May 2015 Engineering & Management (IJAIEM), Volume 6,

[14]. T.Subramani, P.Sakthivel , " Experimental Issue 5, May 2017 , pp. 229-238 , ISSN 2319 - 4847.

Investigation On Flyash Based Geopolymer Bricks" , [24]. T.Subramani, T.Anandavel, S.Priyanka , "

International Journal of Application or Innovation in Experimental Investigation Of Waste Plastic Fiber In

Engineering & Management (IJAIEM) , Volume 5, Reinforced Cement Concrete Using Recycled Coarse

Issue 5, pp. 216-227 , 2016 . Aggregate " , International Journal of Application or

[15]. T.Subramani, R.Siva, “Experimental Study On Innovation in Engineering & Management (IJAIEM),

Flexural And Impact Behavior Of Ferrocement Slabs” Volume 6, Issue 5, May 2017 , pp. 239-250 , ISSN

International Journal of Application or Innovation in 2319 - 4847.

Volume 7, Issue 2, March – April 2018 Page 106

International Journal of Emerging Trends & Technology in Computer Science (IJETTCS)

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 7, Issue 2, March - April 2018 ISSN 2278-6856

[25]. T.Subramani, S.Priyanka , " Experimental Test On in Hand Ball Competition and also participated the All India Meet

Carbon Nano Powder On The Properties Of Concrete in Athletics during the year of 2018.

" , International Journal of Application or Innovation

in Engineering & Management (IJAIEM), Volume 6, Mr. Pavan Kumar Sing is pursuing B.E Under

graduate in the branch of Civil Engineering at

Issue 5, May 2017 , pp. 294-303 , ISSN 2319 - 4847.

Vinayaka Missions KirupanandaVariyar

[26]. T.Subramani, P.Babu, S.Priyanka , " Strength Study Engineering College, Vinayaka Missions

On Fibre Reinforced Concrete Using Palmyra Palm Research Foundation, Salem. He has well

Fibre Using Fem Software " , International Journal of knowledge in AUTOCAD drawing. His hobbies

Emerging Trends & Technology in Computer Science are playing Basketball, Hockey and Cricket.

(IJETTCS), Volume 6, Issue 3, May - June 2017 , pp.

198-207 , ISSN 2278-6856. Mr.R.Silambarasan is pursuing B.E Under

[27]. T.Subramani, G.Unni Krishnan, R.Arumugam, graduate in the branch of Civil Engineering at

A.Godwyn Michael Cornelies, H.Gopu , " Vinayaka Missions KirupanandaVariyar

Engineering College, Vinayaka missions University

Experimental Study Of Quarry Sand And Rice Husk

, Salem. He did the additional qualification in

Replacing In Concrete " , International Journal of Professional in Building Design.

Application or Innovation in Engineering

&Management (IJAIEM), Volume 6, Issue 5, May

2017 , pp. 312-319 , ISSN 2319 - 4847.

[28]. T.Subramani, R.Sengottaiyan, K.Roop Kumar,

V.Arun Kumar , S.S.ShanjaySundaraSood , " An

Expremental Investigation On Mineral Admixture For

High Perfomence Of Concrete " , International

Journal of Application or Innovation in Engineering

& Management (IJAIEM), Volume 6, Issue 5, May

2017 , pp. 320-326 , ISSN 2319 - 4847.

AUTHOR

Prof.Dr.T.Subramani Working as a Professor

and Dean of Civil Engineering in VMKV

Engineering College, Vinayaka Missions Research

Foundation (Deemed to be

University),Salem,TamilNadu, India. Having more

than 28 years of Teaching experience in Various

Engineering Colleges. He is a Chartered Civil Engineer and

Approved Valuer for many banks. Chairman and Member in

Board of Studies of Civil Engineering branch. Question paper

setter and Valuer for UG and PG Courses of Civil Engineering in

number of Universities. Life Fellow in Institution of Engineers

(India) and Institution of Valuers. Life member in number of

Technical Societies and Educational bodies. Guided more than

420 students in UG projects and 300 students in PG projects. He

is a reviewer for number of International Journals and published

201 International Journal Publications and presented more than

55 papers in International Conferences. Also presented more than

45 papers in National conferences and published 4 books.

Mr.M.Senthilkumar is currently working as a

Assistant Professor in the Department of Civil

Engineering, VMKV Engineering College,

Tamilnadu, India and having Industrial Experience

and Teaching Experience. Guided more UG

projects and some PG projects. He is Licensed

Building Surveyor in Idappadi Municipality, Tamilnadu, India and

Consulting Civil & Structural Engineer for many Companies. Life

member in number of Technical Societies and Educational bodies.

Mr.V.Ashok Kumar is pursuing B.E Under

graduate in the branch of Civil Engineering at

Vinayaka Missions KirupanandaVariyar

Engineering College, Vinayaka Missions Research

Foundation, Salem. He is very much interested in

sports. He was participated the “SouthZone 2017”

Volume 7, Issue 2, March – April 2018 Page 107

S-ar putea să vă placă și

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 paginiDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 paginiStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 paginiTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 paginiAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 paginiThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 paginiAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Soil Stabilization of Road by Using Spent WashDocument7 paginiSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Performance of Short Transmission Line Using Mathematical MethodDocument8 paginiPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 paginiDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 paginiStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 paginiA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 paginiA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 paginiSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 paginiImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Ijaiem 2021 01 28 6Document9 paginiIjaiem 2021 01 28 6International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Design and Manufacturing of 6V 120ah Battery Container Mould For Train Lighting ApplicationDocument13 paginiDesign and Manufacturing of 6V 120ah Battery Container Mould For Train Lighting ApplicationInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Swot Analysis of Backwater Tourism With Special Reference To Alappuzha DistrictDocument5 paginiSwot Analysis of Backwater Tourism With Special Reference To Alappuzha DistrictInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 paginiAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- The Effect of Work Involvement and Work Stress On Employee Performance: A Case Study of Forged Wheel Plant, IndiaDocument5 paginiThe Effect of Work Involvement and Work Stress On Employee Performance: A Case Study of Forged Wheel Plant, IndiaInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Annexure - I BOQ For General Civil Works-1 PDFDocument5 paginiAnnexure - I BOQ For General Civil Works-1 PDFA. K. RoyÎncă nu există evaluări

- Effect of Lithium Disilicate Veneers of Different Thickness On The Degree of Conversion and Microhardness of A Light-Curing and A Dual-Curing Cement.Document5 paginiEffect of Lithium Disilicate Veneers of Different Thickness On The Degree of Conversion and Microhardness of A Light-Curing and A Dual-Curing Cement.Danny Eduardo RomeroÎncă nu există evaluări

- Pure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchDocument27 paginiPure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchhelenÎncă nu există evaluări

- Dense Graded Bitumen Mixes For PavementsDocument4 paginiDense Graded Bitumen Mixes For PavementsPamirÎncă nu există evaluări

- Advanced Ceramic Materials For Composite Armor Protection Systems General LiteratureDocument4 paginiAdvanced Ceramic Materials For Composite Armor Protection Systems General Literatureibrahim100% (1)

- Hall - Petch Effect Carlton 2007Document8 paginiHall - Petch Effect Carlton 2007Jorge MatarÎncă nu există evaluări

- 02-21 GS TDSDocument2 pagini02-21 GS TDSUrgent HiringÎncă nu există evaluări

- ACI 330R-08 - Design & Construction Guidlines PDFDocument83 paginiACI 330R-08 - Design & Construction Guidlines PDFlyricmpÎncă nu există evaluări

- Practical Rock Spall Prediction in TunnelsDocument8 paginiPractical Rock Spall Prediction in Tunnelsengr_usman04Încă nu există evaluări

- TPG Acsr As 450Document1 paginăTPG Acsr As 450donlot onliÎncă nu există evaluări

- CSR-2014 Kohistan KPKDocument11 paginiCSR-2014 Kohistan KPKdiamer bashaÎncă nu există evaluări

- File 2Document12 paginiFile 2Irshad mohammedÎncă nu există evaluări

- CVX4446 SynopsisDocument3 paginiCVX4446 SynopsisHansika RuwanthiÎncă nu există evaluări

- SRI-ITP-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22146R0Document8 paginiSRI-ITP-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22146R0Dito NarendraÎncă nu există evaluări

- BRB Cables PVCDocument30 paginiBRB Cables PVCMorsed Al Mamun75% (40)

- EagleBurgmann - Statotherm R Profile Rings R901 - B.. - ENDocument1 paginăEagleBurgmann - Statotherm R Profile Rings R901 - B.. - ENЮляÎncă nu există evaluări

- Alloy: Live GraphDocument13 paginiAlloy: Live GraphKasia MazurÎncă nu există evaluări

- SiconDocument32 paginiSiconAnthony LoñezÎncă nu există evaluări

- GFRP Rebars 3Document12 paginiGFRP Rebars 3Vandhana PVÎncă nu există evaluări

- Application Guide Jotamastic 90: Areas For Immersed ExposureDocument1 paginăApplication Guide Jotamastic 90: Areas For Immersed ExposureTamerTamerÎncă nu există evaluări

- Specs CodeDocument4 paginiSpecs Codemelinda bulosÎncă nu există evaluări

- The Al-Si Phase Diagram: Microsc Microanal 15 (Suppl 2), 2009 60 Doi: 10.1017/S1431927609092642Document2 paginiThe Al-Si Phase Diagram: Microsc Microanal 15 (Suppl 2), 2009 60 Doi: 10.1017/S1431927609092642divyanshÎncă nu există evaluări

- Material Schedule For Housing Development at Barnawa KadunaDocument5 paginiMaterial Schedule For Housing Development at Barnawa KadunaAliyu Shehu100% (2)

- HW D 1104 SilGG JuntaDocument1 paginăHW D 1104 SilGG JuntaLibardoÎncă nu există evaluări

- 260543D01 - D08, Underground Electrical Manhole and Duct Bank Const. DetailDocument8 pagini260543D01 - D08, Underground Electrical Manhole and Duct Bank Const. DetailomarqasimÎncă nu există evaluări

- ULTIMATE STRENGTH DESIGN - StudentDocument4 paginiULTIMATE STRENGTH DESIGN - StudentMr. Mark B.Încă nu există evaluări

- Monolithic Isolating Joint Failure in Cathodic Protection SystemDocument5 paginiMonolithic Isolating Joint Failure in Cathodic Protection Systemعبدالرزاق سالمÎncă nu există evaluări

- Protective TextilesDocument36 paginiProtective TextilesDewan Ajuad Hossain Rifat100% (1)

- Bignozzi 2015Document8 paginiBignozzi 2015eclerÎncă nu există evaluări

- CHE421Document1 paginăCHE421Eko SuherÎncă nu există evaluări