Documente Academic

Documente Profesional

Documente Cultură

Fatigue Life Analysis of Joint Bar of Insulated Rail Joint

Încărcat de

IJARP PublicationsDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fatigue Life Analysis of Joint Bar of Insulated Rail Joint

Încărcat de

IJARP PublicationsDrepturi de autor:

Formate disponibile

International Journal of Advanced Research and Publications

ISSN: 2456-9992

Fatigue Life Analysis Of Joint Bar Of Insulated Rail

Joint

Washimraja Sheikh, Piyush M. Sirsat, Nakul K. Mahalle

RTM Nagpur University, Priyadarshini College of Engineering, Assistant Professor, Department of Mechanical Engineering, Maharashtra,

India 440019. PH-09970465053

wasimsheikh7@gmail.com

RTM Nagpur University, Priyadarshini College of Engineering, Assistant Professor, Department of Mechanical Engineering, Maharashtra,

India 440019. PH-09890754116

piyush.sirsat51083@gmail.com

RTM Nagpur University, Priyadarshini College of Engineering, Assistant Professor , Department of Mechanical Engineering, Maharashtra,

India 440019. PH-9028514896

nakul.mahalle@gmail.com

Abstract: Rail joints are use for the purpose of joining the two rails. Traditionally, it was done by using bolted rail joint but due to large

number of drawbacks and for safety purpose the number of joints in mainline track has been minimized by the widespread use of

continuously welded rail (CWR) but for the track circuit there is no alternative for insulated rail joint. Insulated rail joint is use for signaling

purpose to allow a railway signaling system to locate trains by maintaining a shorting circuits system. The IRJ is however substantially

weaker than the rail and so is subjected to large stresses, causing failure. This paper is concern with to find the fatigue life of joint bar of IRJ

and to suggest the proper profile design which will help to improve its fatigue life.

Keywords: Insulated rail joint, joint bar, stresses, fatigue life, wheel rail contact, endpost.

1. Introduction

Failure of insulated rail joint leads to delay in train also

sometime may be responsible for train accident. Research

indicates that the mean service life of insulated rail joint is

only about 20% that of noninsulated joints including CWR

with short service life of 12-18 months. Generally the

Profile P1. Profile P2 Profile P3

bending stiffness of a rail joint is much smaller than that of

the rail. It is about one third. This is a major weakness of the

Figure1. Profiles of joint bars

IRJ. The bending stiffness of IRJ depends on several factors

such as bending stiffness of joint bars, the tightness of the 2. Objective

bolts and how well bars fit in rail ends. Another weakness is Objective of this work is to estimate and compare the fatigue

the failure of joint bar causing a support discontinuity during life of joint bar with the three different profiles to suggest the

passing of train wheel over it. This can cause a vertical best suited design.

acceleration of the moving wheel load and induce a dynamic

force and stresses in the track. Combining effects cause a 3. Component of Insulated Rail Joint

failure readily at the IRJ compared to elsewhere along a 1) Rail 2) Joint bar/fisher plates

continuous rail. Based on various worldwide designs of 2) Insulating End post 4) Nut and Bolts

IRJ’s, the following are the failure modes of IRJ: 5)Insulating material ( between rail and joint bar).

i. Bending stress ii. Thermal stress iii. Residual stress

iv. Shear stress v. Von misses stress

vi. Fatigue failure vii. Broken bolt

viii. Joint bar failure ix. Delamination of end post

x. Crushed end post and metal flow.

xi, Stresses due to static and Dynamic load

xii. Epoxy layer debonding from rail, joint bar or both

This work focuses on mainly fatigue life of joint bar which is

calculated in terms of million gross tons (MGT) which helps

to find the different stress developed and also the life

Figure 2 a) Dis assembly b) Assembly of IRJ

expectancy of joint bar. The following three profiles of joint

bars have considered for this work.

3.1.1 Rail: Rail is nothing but the continuous track which is

made from carbon steel and joint together by continuous arc

welding. In IRJ other part are fastened to rail and then it is

welded to other rail on track. 136RE is most common rail

type use in India.

Volume 1 Issue 5, November 2017 158

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

3.1.2 Joint bar: Joint bars are two carbon steel plates use to

support the IRJ laterally by fastening nut and bolt to IRJ.

3.1.3 Endpost: Endpost is working as an insulating material

between two rails for electrical signaling purpose. The

Endmost material can be inserted in between two ends of rail

perpendicular to longitudinal axis of rail. The thickness of

Endpost may vary from 5mm to 10mm. Material use for end

post is fiber glass.

3.1.4 Nut and Bolt: Nut and bolt are use for fastening Figure 3. a) 30 mm Joint Bar Profile b) Nut bolt dimension

purpose.

4. Methodology

i. Estimation of fatigue life ( in terms of MGT) of joint bar

using Miner’s law.

ii. Analyze the effect of changing length & cross sectional

area on life of Joint bar.

The fatigue life of various joint bar has calculated by

considering various lengths in addition to 36 inch joint bar, Figure 4. Joint Bar Hole Spacing.

which is generally used in Indian rail track and various cross

section area. Finally, comparing results Joint bar with 6. Dynamic Load Calculations

improved design has selected in order to increase the fatigue

life of Joint bar. 6.1 General Consideration: Insulated joints are subjected to

load from two main sources

5. Specification and Design Consideration 1) From rail imparting vertical forces to the joint through

the wheels.

5.1Specification of Joint bar: 2) From the thermal loads that occur longitudinally in the

Length of joint bar = 1.219 m (48 inches) joint.

= 0.9144 m (36 inches) Vertical load = Static load + Dynamic load

= 0.6096 m (24 in)

The vertical load imparted to the track does not simply come

A) For joint bar profile P1: from the static force (Po) of wheel pressing down on the rail.

Cross Sectional Area, AJ1 = 0.008 m2 (6.27 in2) Use of static load alone for analysis would only be sound

Moment of Inertia, IJ1 = 5.098 x 10-6 m4 (12.25 in4) only if it is assumed that rails and wheels are both smooth

Topmost distance from neutral axis, and free of defects. With actual wheels and rail, however,

CJ1 = 0.0388 m (1.53 inches) this is not the case and the presence of defects causes

additional dynamic loads (Pd) to be applied to the track. The

B) For joint bar profile P2: vertical load that is actually applied to the rail is super

Cross Sectional Area, AJ2 = 0.00759 m2 (5.89 inch2) position (Po) and the dynamic load (Pd).

Moment of Inertia, IJ2 = 6.714 x 10-6 m4 (16.14 inch4) The major factors that affect the magnitude of dynamic load

Topmost distance from neutral axis, components are:

CJ2 = 0.0612 m (2.41 inches) i. Speed of train ii. Static wheel load

iii. Wheel diameter iv. Vehicle unstrung mass

C) For joint bar profile P3: v. Condition of the vehicle vi. Condition of track

Cross Sectional Area, AJ3 = 0.00727 m2 (5.64 inch2) ii. Condition and type of ballets and sub ballast.

Moment of Inertia, IJ3 = 5.84 x 10-6 m4 (14.04 inch4)

Topmost distance from neutral axis, A) Dynamic load factor (DLF):

CJ3 = 0.0642 m (2.53 inches)

DLF = ( ) (1)

5.2 Design consideration

Joint bar is a rigid plate of steel which supports a joint bar Vmph -Train velocity in miles per hour.

laterally and use in various lengths and cross sectional area. D - Wheel diameter in inches

In India common length of joint bar is 48inch and 36inch. B) Calculation of dynamic force:

Pd = DLF x Po (2)

P TOT - Total vertical force; Po - Static wheel load.

But equation (1) is valid only for continuous track and not

for joint in track.

Volume 1 Issue 5, November 2017 159

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

C) Calculation of dynamic load when wheel impact at -Half length of joint bar; - Distance between rail ends

joint: at the joint.

When wheel impact a joint, the dynamic load consist of a

short time peak (P3) and delay peak (P4) as shown in fig.

. λ=4√ (8)

E - Modulus of elasticity of rail material; IR - Bending

moment of inertia. To calculate joint bar reaction load.

Q= ( 9)

- Joint efficiency factor; b - Half length of joint bar.

Joint efficiency factor is the fraction of the bending moment

that the joint bar carry in continues rail and various between

Figure 5. Variation of dynamic load at wheel- rail contact 0.6 to 0.8 for good joint. Theoretical maximum value for

joint efficiency factor = 4

P3 load is associated with rail end batter by the un sprung IJ - vertical bending inertia of joint bars

mass of the rail car. IR - vertical bending inertia of rail.

- It is shorter duration load.

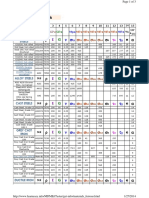

- This load is associated with the inertias of the rail and ties Table 1. Parameter use in dynamic load calculation.

and does not produce large track deformations.

S. No Parameter Value Value(SI)

P4 is smaller load and is applied over a longer time. 1 Mu 4.53 lb-s2/in 793.32Ns2/m

- This load is associated with rail bending and produces 2 Kr 3.3x105lb/in 57.79 x106 N/m

track deformations that are transmitted to the ballast. 3 Kv 3000 psi 20.684 x106 N/m2

4 R 18 in 0.4572 m

5 R 40 mph 18.22 m/ sec

∑ 30 x106 psi 2.068 x 1011 N/m2

Pd = Po + [ √ ] (3) 6 E

7 IR 94.2 in4 3.92 x10/ -5 m4

8 IJ 32.38 in4 1.34 x 10-5m4

9 ∆T 41º F 5 0c

Mu - unsprung mass; Kr -Rail stiffness; V - Train speed;

10 ∆ 0.25 in 0.00635 m

R -Wheel radius; - Effective joint dip angle. 11 B 18 in 0.4572 m

Effective joint dip angle is made up of four different ports. 12 AJ 11.78 in2 0.00759m

13 Po 19000 lb 84.55x103N

∑ = α1 + α2 + α3 +α4 14 CJ 2.42 in 0.0614 m

2

15 So 32000 lb/ in 220.0632x106 N/m2

α1 - part of dip angle that would occur in the continuous rail. 16 SU 130,000 lb/in2 890.318x106 N/m2

17 AR 12.95 in2 0.008354 m

18 αth 6.5 x 10-6 /0F 117 x10 -7/0c

λ1 = √ (4)

α4 - Related to deformation of rail ends due to batter. This

α2 - Related to the wheel dropping into the gap between the batter is characterized by its depth and length.

rail end and can be calculated .

α4 = (10)

α2 = (5)

d - Depth of deformation due to rail end batter

= Distance between rail ends at the joint. l - Length of deformation due to rail end batter.

α3 = Bending of rail end at joint and con be calculated.

D) Calculation for Dynamic load, Pd:

α3 = , [ ] (6) Pd = Po + [√ ]

α=

This is from semi – infinite beam on elastic foundation

theory. α1 = √

P - Applied wheel load; Q - Joint bar reaction load

= x

=b- (7) [ ]

√

α1 = 0.049

α2 = = = 0.00694

α3= 2, [ ]-

=b- = 0.4572 – ( ) = 0.454 m

Volume 1 Issue 5, November 2017 160

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

MR (0)

λ= √ =√ = 0.89

β max = 0.7 (Considering β=0.7) Joint bars are also assumed to behave as beams in bending

Q= = 36362.64 N/m and are assumed to carry only a fraction of moment in a

continuous rail. This fraction is called the joint efficiency

= 2,( ) ( )- . factor, P

* [ ]+

=2{ [ ] = β max = ( ) max = √ (3)

0.00458

α = where IJ and IR are the vertical bending inertias for the joint

bars and rail respectively, the bending moment carried by the

In the calculation of the vertical loads of the joint, it has been joint bars (MJ) is assumed to be.

assumed that there was no deformation of the rail end due to

rail end batter. Therefore, α4 neglected here. MJ = β M o = β (4)

α= = 0.049 + 0.00694 + 0.00458 = 0.06

The maximum bending stress at the top of the joint bar is

Pd = Po + [√ ] compressive when the wheel is located at the joint and is

equal to:

= 84.55 x

= (5)

( ) [√ ( ) ]

Pd = 130.29 x N CJ = Distance from the joint bar neutral axis to the top of the

Static load, Po = 84.55 x N joint bar as shown in fig.

It come from an average wheel load from 150 trains moving IJ = moment of inertia of joint bar pair.

over 12 wheel impact load detector (WILD) sites that were When wheel moves away from the joint location, the

samples three times in a 12 month period. moment distribution evolves and the rail is subjected to

Formula for dynamic load factor (DLF) reverse bending. The maximum reverse bending stress at the

top of the joint bar is tensile and occurs when the wheel is at

DLF = 1 + =1 + * + = 1 + 0.167 = 1.167 a distance xrb from the joint, which is determined by

PTOT = Po x DLF = 19000 x 1.167 differtiating equation the moment at this location is

PTOT = 22173 = 98.66 x N determined by applying equation with P = P TOT The

stress in the joint bar is related to the moment at this location

Table 2. Value of Respective Loads and is equal to the moment at this location and is equal to

S. No Load Value = (6)

1 Po 84.55 x 103 N

2 Pd 130.29 x N The fatigue life of joint bars is adversely affected by stress

imposed by rail thermal expansion when the ambient

3 PTOT 98.66 x N temperature is below the rail neutral temperature. The

thermal load in rail, Pth is equal to

7. Fatigue Life Calculation

P = AR E αth = 117 x / oC (7)

7.1 Engineering Estimation of Stresses in joint bars

AR = Rail cross- sectional area;

For this study, 132 RE rail and its companion 36 inch joint

αth = Coefficient of thermal expansion

bar shown in fig, have been chosen to illustrate the method.

The longitudinal bending moment distribution in a

continuous rail is calculated from the equations for an Sth = (8)

infinite beam on elastic foundation, and is equation.

AJ = Joint bar cross sectional area; T = 5o C The rail fatigue

MR (x) = [ ] (1) properties used in the present calculations were derived from

experiments conducted by Jensen The calculations for the

Where, Pd is the dynamic load fatigue life of Joint bars are carried out using Miner’s law

expressed as

√ (2)

N = No * + (9)

Kv = Rail foundation modulus; E = modulus of elasticity

IR = Rail bending inertia = 94.2 in4

N = Fatigue life in cycles;

The bending moment is maximum at the point of application

No = Represents infinite life (in cycles)

of the load (x = 0 ) where

So = Endurance limit; SU = Ultimate strength

Volume 1 Issue 5, November 2017 161

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

SM = mean stress; SA = Alternating stress 7.2 Fatigue life calculation of P2:

The Jensen fatigue properties for rail steel are incorporated Given data:

into this equation by assuming the following values: IR = 3.92 x ; IJ = 6.714 x

No = cycles; K = 0.14 CJ = 0.0612m; rb = 1.143m; AR = 0.008354m

So = 220.0632 x N/ ; Su = 896.318 x N/ AJ = 0.00759; αth = 117x /oC

Mean stress, Po = 84.55 x N; Pd = 130.29 x N

SM = PTOT = 98.66 x N; λ = 0.89

Smax = maximum stress SJ- =

Smax = + Sth

Smin = minimum stress MJ = = = 25.61 x N.m

Smin = + Sth SJ- = = -234.20 x N/

Alternating stress

SJ+ =

SA =

The fatigue life ( in cycles ) can be expressed in terms of

million gross Tons (MGT) of traffic by, A)Calculation of :

MGT = MR = [ ]

MR (45) =

7.2 Fatigue life calculation for P1: [ [

Given data:

]]

IR = 3.92 x ; IJ = 5.0984 x

CJ = 0.0388m; rb = 1.143m = 27.71x [ ]= 27.71x [ ]

AR = 0.008354 m ; AJ = 0.008 MR (45) = 9.82 x N.m

αth = 117x /oC SJ+ = = 62.86x N/

Po = 84.55 x N; Pd = 130.29 x N Pth = AR. E. αth. T

PTOT = 98.66 x N; λ = 0.89 = 0.008354x 2.068 x = 1.01x

SJ- = N/

Sth = = = 12.09 x N/

MJ = = = 25.61 x N.m

Smin = SJ- + Sth = (-234.20 x ) + (12.09 x )

SJ- = = -194.89 x N/

Smin = -222.11x N/

SJ+ = Smax = SJ+ + Sth = (62.86x

= 75.763 x N/

To calculate :-

SM =

MR = [ ]

= [ ]

MR (45) =

SM = -73.118x N/

[ [

SA = = [ (75.763 x ) + (222.11x )]

]]

SA = 297.872x N/

= 27.71x [ ] = 27.71x [ ]

MR (45) = 9.82 x N.m N = No * +

SJ+ = = 52.31x N/ ( )[ ]

=107* +

Pth = AR. E. αth. T 1/0.14

= 0.008354x 2.068 x Pth = 1.01x N= x (0.79) = 0.202x cycles

N/ MGT = = 84.45

Sth = = = 12.62 x N/

7.3 Fatigue life calculation for P3:

Smin = SJ- + Sth = (-194.89 x ) + (12.62 x ) Given data:

Smin = -182.27x N/ IR = 3.92 x ; IJ = 5.84 x

Smax = SJ+ + Sth CJ = 0.0642m; rb = 1.143m

Smax = (52.31x = 64.93x N/ AR = 0.008354m; AJ = 0.00727

SM = = [ ] αth = 117x /oC; Po = 84.55 x N

SM = -58.67x N/ Pd = 130.29 x N; PTOT = 98.66 x N

SA = = [( )+( )] λ = 0.89; SJ- = ; SJ+ =

SA = 247.2x N/

MJ = = = 25.61 x N.m

N = No * +

SJ- = = -281.53 x N/

7 ( )[ ]

=10 * +

N= x (0.94) 1/0.14

= 0.642x cycles A)Calculation of :

MR = [ ]

MGT = = 271.73

Volume 1 Issue 5, November 2017 162

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

MR (45) = 9.82 x N.m Q= β (Considering β=0.7)

SJ+ = = 75.56 x N/

Q= = 36362.64 N/m

Pth = AR. E. αth. T = 1.01x N/

= 2,( ) ( )- . *

Sth = =

[ ]+

Sth = 13.89x N/

Smin = SJ- + Sth = -267.64x N/ =2{ [ ] =

Smax = SJ+ + Sth 0.00458

Smax = (75.56x = 89.45 x N/ α= = 0.049 + 0.00694 + 0.00458 α = 0.06

SM = = -89.09x N/ Pd = Po + [√ ]

SA = - = 357.09x N/

= 84.55 x

N = No * + = 0.063x cycles

( ) [√ ( ) ]

MGT = = 26.63

Pd = 130.39 x N

Table 3. Fatigue life of joint with different profiles.

8.3 Case III:

S. No Profile MGT When L = 0.6096 m (24 in)

1 P1 271.73 α1 = 0.049 m; α2 =0.00694m

2 P2 84.45

3 P3 26.63

α3 = , [ ]

=b- = 0.3 - ( ) = 0.296 m

8. Effect of Change in Length on Fatigue Life of

Joint Bar Q=β = = 55.41 N/m3

From equation of dynamic load calculation it is clear that the = 2,( ) ( )- .

length use only in the calculation of dip angle.

*

α3 = , [ ] (1)

[ ]+

Ʃα = α1 + α2 + α3 + α4 (2) α3 = 0.00447

Ʃα = α1 + α2 + α3 + α4 = 0.049 + 0.00694 + 0.00447

∑ = 0.06

Pd = Po + [ √ ] (3)

∑

Pd = Po + [ √ ]

8.1 Case I: = 84.55

When L = 1.219 m (48in) x

α1 = 0.049 m; α2 =0.00694m

( ) [√ ( ) ]

α3 = , [ ]

= 130.29x N = 130.29x N.

=b- = 0.6095-( ) = 0.6 m

Q=β = = 27.28 N/m3 Table 4. Comparison between L, α and Pd

= 2,( ) ( )- .

S. No L (m) α ( °) Pd (N)

* [ ]+

1 1.219 0.06066 130.63 x

α3 = 0.35

Ʃα = α1 + α2 + α3 + α4 = 0.6066

2 0.9144 0.00458 130.39 x

∑

Pd = Po + [ √ ]

3 0.6096 0.06 130.29 x

= 84.55 x

( ) [√ ( ) ] From above table it is clear that, there is no change in

dynamic load whether the length of joint bar is increases or

= 130.63x N. decreases.

8.2 Case II: 9. Graphical Analysis

When L = 0.9144 m (36in) Graphical analysis is use her to compare the relation of

α1 = 0.049 m; α2 =0.00694m various input on final result.

α3= 2, [ ]-

= b - = 0.4572 – ( ) = 0.454 m

λ=0.89;

Volume 1 Issue 5, November 2017 163

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

Table 5. Profiles with A, IJ and CJ From above graph, it is clear that

1. As the distance from neutral axis reduces, fatigue life of

P1 P2 P3 joint bar is increases.

AJ1 2. Profile P1 has lowest value of CJ and highest value of

IJ1 CJ1 AJ2 IJ2 CJ2 AJ3 IJ3 CJ3 MGT.

(m

2 (m4) (m) (m2) (m4) (m) (m2) (m4) (m)

)

10. Result

5.09

0.0 1.53 0.00 6.714 0.0072 5.84x

84x 2.42 2.53

08 759 x10-6 7 10-6 I) Analytical Method:

10-6

From table 3, it is clear that profile P1 (MGT = 271.73) has

the highest MGT among the other profiles. Also, the value

9.1 Graphical Representation of Area and MGT of MGT is depends on following three factors:

i. Cross sectional area

ii. Moment of Inertia

iii. Neutral axis distance of joint bar from top of rail.

10.2) Graphical Method:

From figures 6, 7 & 8, it is clear that for profile P1:

i. As cross sectional area increases, MGT increases.

ii. As moment of inertia increases, in general MGT increases

Area in (10-6m2) .iii. As distance of neutral axis from top reduces, MGT

increases.

Figure 6. Graph – Area Vs MGT

11. Conclusion

From above graph it is clear that Proper design of joint bar helps to improve fatigue life which

1. As the cross sectional area increase, fatigue life of joint ultimately leads to improve the service life of Insulated Rail

bar is increases. Joint. On the basis of analytical and graphical results, it has

2. Profile P1 has highest value of MGT. concluded that fatigue life is mainly depend on the cross-

sectional area, moment of inertia and distance of neutral axis

9.2 Graphical representation of Moment of Inertia and from the top. For better service life, cross-sectional area,

MGT moment of inertia should be more and distance of neutral

axis from top should be less.

12. References

[1] Nirmal Kumar Mandal and Brendan Peach, “An

engineering analysis of insulated rail joints”,

International Journal of Engineering Science and

Technology, Volume 2, Issue 8, 2010, pp. 3964-3988.

[2] Brandon Talamini, David Y Jeong, JeffGordon,.

Moment of Inertia in (10 m )-6 2 “Estimation of fatigue life of railroad joint bars,”

ASME/IEEE joint rail conference and internal

Figure 7. Graph – Area Vs Moment of Inertia combustion Engine Spring Technical Conference,

Colorado, US, March 13-16, 2007.

From above graph, it is clear that

1. For profile P1 I J is less and then it increasing for other [3] Zefeng Wen, Xuesong Jin and Weihua Zhange, “Contact

profiles. Impact Stress Analysis of Rail Joint Region Using the

2. Though Profile P1 has less moment of inertia as compare Dynamic Finite Element Method” ,Wear 258, 2005,

to other profile, it has highest value in MGT. pp.1301-1309.

9.3 Graph representation of Distance, CJ and MGT [4] Muhammad Akter. “Revenue service evaluation of

advanced design insulated joints”, Transportation

Technology Center, Inc. Tomo Conner, BNSF Railway

Company Technology, May 2007.

[5] Jemil Degife, “Fatigue analysis of aalrt bolted rail joint’,

A Research paper submitted to the Addis Ababa

Institute of Technology, School of Graduate Studies,

Addis Ababa University for partial fulfillment of the

requirements for master of science in rolling stock

engineering.

Figure 8. Graph – CJ Vs MGT [6] www.jointbartypes.com

Volume 1 Issue 5, November 2017 164

www.ijarp.org

S-ar putea să vă placă și

- Static Structural and Fatigue Analysis of SpannerDocument17 paginiStatic Structural and Fatigue Analysis of Spannerprashant kottalagiÎncă nu există evaluări

- We Were "I" Before Apple®: A Complete Guide To Using Ifeatures, Iparts, and Iassemblies in Inventor®Document22 paginiWe Were "I" Before Apple®: A Complete Guide To Using Ifeatures, Iparts, and Iassemblies in Inventor®linuskotteÎncă nu există evaluări

- Ballast Less Track DesignDocument8 paginiBallast Less Track DesignSanjoy SanyalÎncă nu există evaluări

- Special Cables Catalogue - El Sewedy CablesDocument126 paginiSpecial Cables Catalogue - El Sewedy CablesSherif Eltoukhi100% (1)

- Electrode Selection Excel SheetDocument1 paginăElectrode Selection Excel Sheetchandrakit047Încă nu există evaluări

- BOSCH Motronic Blazer 2.4Document1 paginăBOSCH Motronic Blazer 2.4sereno100% (1)

- Kel Industrial Training ReportDocument21 paginiKel Industrial Training ReportVineet JobÎncă nu există evaluări

- Selecting Your Spanco Gantry Crane: Motorized Option AvailableDocument10 paginiSelecting Your Spanco Gantry Crane: Motorized Option AvailablewessamalexÎncă nu există evaluări

- Solidworks Simulation BasicsDocument28 paginiSolidworks Simulation BasicsvinunfÎncă nu există evaluări

- Monorails 4ed Bk180Document12 paginiMonorails 4ed Bk180harishram123456Încă nu există evaluări

- Deflection RatioDocument7 paginiDeflection RatioKamlesh DalavadiÎncă nu există evaluări

- Materials FerrousDocument3 paginiMaterials Ferrousjohnson_regoÎncă nu există evaluări

- HandbookDocument80 paginiHandbookVocem LuxÎncă nu există evaluări

- 10-06 SolidWorks API DemystifiedDocument37 pagini10-06 SolidWorks API DemystifiedOARIASCOÎncă nu există evaluări

- Fatigue Analysis of A Shaft On AnsysDocument28 paginiFatigue Analysis of A Shaft On AnsysSatheesh SekarÎncă nu există evaluări

- SMath StudioDocument19 paginiSMath StudiosamirsilvasalibaÎncă nu există evaluări

- 2020 R1 Mechanical Overview PresentationDocument60 pagini2020 R1 Mechanical Overview PresentationEmre ATAYÎncă nu există evaluări

- Design and Finite Element Analysis of Ai PDFDocument7 paginiDesign and Finite Element Analysis of Ai PDFRaja Sekhar BattuÎncă nu există evaluări

- Portal Frame Footings and Slab - 4ed - bk180Document12 paginiPortal Frame Footings and Slab - 4ed - bk180NivarÎncă nu există evaluări

- Weld SymbolsDocument5 paginiWeld SymbolsArya KamiÎncă nu există evaluări

- Guide For DoggersDocument49 paginiGuide For DoggersEliecer DarbyÎncă nu există evaluări

- Hooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsDocument34 paginiHooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsRafaelMallquiAntialonÎncă nu există evaluări

- Eot Crane During SeismicDocument12 paginiEot Crane During SeismicboyzesÎncă nu există evaluări

- Crib Sheet For SMath Studio v0.95Document10 paginiCrib Sheet For SMath Studio v0.95Anonymous Re62LKaACÎncă nu există evaluări

- Seismic Analysis of Overhead Cranes - Kine CranesDocument23 paginiSeismic Analysis of Overhead Cranes - Kine CraneshathamphanÎncă nu există evaluări

- Stresses in Machine MemberDocument18 paginiStresses in Machine MemberK ULAGANATHANÎncă nu există evaluări

- Designing Parametric Bevel ...Document10 paginiDesigning Parametric Bevel ...ankit kumarÎncă nu există evaluări

- Goodco Z Tech Spherical BearingsDocument20 paginiGoodco Z Tech Spherical BearingsRusandi NoorÎncă nu există evaluări

- Partial Fixity BaseDocument24 paginiPartial Fixity Basekhemindra narain100% (1)

- APDL HelpDocument220 paginiAPDL HelpFaisal Naveed SiddiquiÎncă nu există evaluări

- Modeling of Welded Connections in SolidWDocument5 paginiModeling of Welded Connections in SolidWCleyton L. AlvesÎncă nu există evaluări

- CalculationDocument2 paginiCalculationMunir RasheedÎncă nu există evaluări

- BeltDocument180 paginiBeltHectorHugoRamirezÎncă nu există evaluări

- What Is Meant by Solidity Ratio in Structural Engineering - QuoraDocument3 paginiWhat Is Meant by Solidity Ratio in Structural Engineering - Quoramn_sundaraamÎncă nu există evaluări

- Strand7 R246 Verification Manual TOC PDFDocument20 paginiStrand7 R246 Verification Manual TOC PDFAbel BerhanmeskelÎncă nu există evaluări

- Lecture 14.4: Crane Runway Girders: Objective/ScopeDocument22 paginiLecture 14.4: Crane Runway Girders: Objective/ScopeScooby DooÎncă nu există evaluări

- Elastomeric Bearing Pads and Strips Brochure 2010Document4 paginiElastomeric Bearing Pads and Strips Brochure 2010Anton Husen PurboyoÎncă nu există evaluări

- Rotating Axle Application - 115326-18-1100Document16 paginiRotating Axle Application - 115326-18-1100Erc Nunez VÎncă nu există evaluări

- Con 1302Document12 paginiCon 1302Sanket Arun More100% (1)

- Steel Desing To Eurocode 3Document2 paginiSteel Desing To Eurocode 3Jonp4ul_MiddletonÎncă nu există evaluări

- Ansys Analysis-Trolley Beam 3T1Document13 paginiAnsys Analysis-Trolley Beam 3T1Ye Wint ThuÎncă nu există evaluări

- Catalog ChinaDocument61 paginiCatalog Chinaa.muhammadÎncă nu există evaluări

- Graitec Com en Ad Steel Connection Design ASPDocument7 paginiGraitec Com en Ad Steel Connection Design ASPpatrickNX9420Încă nu există evaluări

- Structural Design Calculations For A New Lean-To Timber Framed CarportDocument18 paginiStructural Design Calculations For A New Lean-To Timber Framed Carportali381Încă nu există evaluări

- Solidworks 2003 ManualDocument95 paginiSolidworks 2003 ManualPhạm Văn ĐảngÎncă nu există evaluări

- ANSYS Mechanical APDL Advanced Analysis Guide PDFDocument414 paginiANSYS Mechanical APDL Advanced Analysis Guide PDFMustafa Demir100% (1)

- Design of Crane Girder - Workshop Cum Office BuildingDocument3 paginiDesign of Crane Girder - Workshop Cum Office BuildingMuhammad HasanÎncă nu există evaluări

- Bolted Connections: 2.1 TerminologyDocument14 paginiBolted Connections: 2.1 TerminologyjohnsonregoÎncă nu există evaluări

- Coefficient of Friction Equation and Table ChartDocument3 paginiCoefficient of Friction Equation and Table Chartspamalstublieft1832Încă nu există evaluări

- Metric FastenersDocument26 paginiMetric FastenersvijayjaghanÎncă nu există evaluări

- Advanced Design TechniquesDocument23 paginiAdvanced Design Techniquesapi-3748063Încă nu există evaluări

- 7-Bolted Connections PDFDocument18 pagini7-Bolted Connections PDFKellen BrumbaughÎncă nu există evaluări

- DS Prestress HBDocument28 paginiDS Prestress HBBrian James MarzanÎncă nu există evaluări

- U C Jindal PDFDocument1.043 paginiU C Jindal PDFRaja Sekhar Battu100% (1)

- Column SpliceDocument1 paginăColumn SpliceBun KunÎncă nu există evaluări

- 07 Fatigue Failure IDocument33 pagini07 Fatigue Failure Iforemar100% (1)

- Solidworks Hardware Guide - 2018Document16 paginiSolidworks Hardware Guide - 2018MANJUNATH SHARMAÎncă nu există evaluări

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsDe la EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsÎncă nu există evaluări

- Ijest10 02 08 13Document26 paginiIjest10 02 08 13slamdunkelevenÎncă nu există evaluări

- Failure Analysis of Primary Suspension Spring of Rail Road VehicleDocument15 paginiFailure Analysis of Primary Suspension Spring of Rail Road Vehicle012 ANMOL RATANÎncă nu există evaluări

- Fatigue Analysis of Rail Joint Using Finite Element Method: Sunil Patel, Veerendra Kumar, Raji NareliyaDocument5 paginiFatigue Analysis of Rail Joint Using Finite Element Method: Sunil Patel, Veerendra Kumar, Raji NareliyaAnonymous tKjZMWnoÎncă nu există evaluări

- 1-S-Failure Analysis of Primary Suspension Spring of Rail Road VehicleDocument16 pagini1-S-Failure Analysis of Primary Suspension Spring of Rail Road VehicleDeepak BhopeÎncă nu există evaluări

- Curved BridgesDocument43 paginiCurved BridgesRam Nepali75% (4)

- Finite Element Analysis of Steel CordDocument6 paginiFinite Element Analysis of Steel CordSanjiv Kumar SinghÎncă nu există evaluări

- Coronary Diseases Modeling of Some Risk Factors Using Artificial Intelligence TechniquesDocument5 paginiCoronary Diseases Modeling of Some Risk Factors Using Artificial Intelligence TechniquesIJARP PublicationsÎncă nu există evaluări

- Clotting and Gel Separator Property of Extract From The Roots of Damong Maria Artemisia Vulgaris With Oryza SativaDocument9 paginiClotting and Gel Separator Property of Extract From The Roots of Damong Maria Artemisia Vulgaris With Oryza SativaIJARP PublicationsÎncă nu există evaluări

- Construction of Incomplete Counterbalancing For Immediate Sequential Effects Crossover DesignDocument3 paginiConstruction of Incomplete Counterbalancing For Immediate Sequential Effects Crossover DesignIJARP PublicationsÎncă nu există evaluări

- Deforestation Forest Scarcity and Adaptation Stategy in Sapele Delta State NigeriaDocument9 paginiDeforestation Forest Scarcity and Adaptation Stategy in Sapele Delta State NigeriaIJARP PublicationsÎncă nu există evaluări

- Comparative Effectiveness of Modelling Technology of Instructional Media On The Junior Secondary Students Creative Arts in Abuja NigeriaDocument6 paginiComparative Effectiveness of Modelling Technology of Instructional Media On The Junior Secondary Students Creative Arts in Abuja NigeriaIJARP PublicationsÎncă nu există evaluări

- Design and Construction of Moveable Solar Energy Street Light For Use in Nigerian Institute of Leather and Science TechnologyDocument3 paginiDesign and Construction of Moveable Solar Energy Street Light For Use in Nigerian Institute of Leather and Science TechnologyIJARP Publications100% (1)

- Teachers Career Performance in Secondary Education Case Study of Teachers Psychology Ethics Moral and Values in Dodoma M TanzaniaDocument8 paginiTeachers Career Performance in Secondary Education Case Study of Teachers Psychology Ethics Moral and Values in Dodoma M TanzaniaIJARP PublicationsÎncă nu există evaluări

- Variation in Topsoil Electrcial Resistivity With Chromium ConcentrationDocument5 paginiVariation in Topsoil Electrcial Resistivity With Chromium ConcentrationIJARP PublicationsÎncă nu există evaluări

- Control of Weed Threshold Using Artificial Neural NetworksDocument4 paginiControl of Weed Threshold Using Artificial Neural NetworksIJARP PublicationsÎncă nu există evaluări

- Training Needs Assessment of Health Personnel On The Management of Diabetes Mellitus in The West Region of CameroonDocument6 paginiTraining Needs Assessment of Health Personnel On The Management of Diabetes Mellitus in The West Region of CameroonIJARP PublicationsÎncă nu există evaluări

- Aerobic Fitness Levels Among Undergraduate Students of A Nigerian University Using Coopers 12 Minute Walk TestDocument3 paginiAerobic Fitness Levels Among Undergraduate Students of A Nigerian University Using Coopers 12 Minute Walk TestIJARP PublicationsÎncă nu există evaluări

- Evaluation of Proximate Chemical Components Nutritional Value Antinutritional and Antioxidant Properties in Yellow Mustard SeedsDocument7 paginiEvaluation of Proximate Chemical Components Nutritional Value Antinutritional and Antioxidant Properties in Yellow Mustard SeedsIJARP PublicationsÎncă nu există evaluări

- Comparative Analysis On The Factors Affecting Employee Turnover Between Supervisors and Frontline Employees in The Bpo IndustryDocument6 paginiComparative Analysis On The Factors Affecting Employee Turnover Between Supervisors and Frontline Employees in The Bpo IndustryIJARP PublicationsÎncă nu există evaluări

- The Analysis of Instagram Buzzer Accounts For Maximizing Promotional ActivityDocument6 paginiThe Analysis of Instagram Buzzer Accounts For Maximizing Promotional ActivityIJARP PublicationsÎncă nu există evaluări

- Reclamation of Heavy Metal Contaminated Soil by Using Biochar As Soil ConditionerDocument5 paginiReclamation of Heavy Metal Contaminated Soil by Using Biochar As Soil ConditionerIJARP Publications100% (1)

- The Entry Level Nursing Competencies and The Gaps Between Nursing Education and PracticeDocument6 paginiThe Entry Level Nursing Competencies and The Gaps Between Nursing Education and PracticeIJARP PublicationsÎncă nu există evaluări

- Preparation of Zeolite Membrane and Modeling Dehydration of Organic Compounds On The Pilot Scale With The Help of Artificial Neural NetworkDocument7 paginiPreparation of Zeolite Membrane and Modeling Dehydration of Organic Compounds On The Pilot Scale With The Help of Artificial Neural NetworkIJARP PublicationsÎncă nu există evaluări

- Modeling of Adsorption Process in Wastewater Treatment Using Artificial Neural NetworkDocument5 paginiModeling of Adsorption Process in Wastewater Treatment Using Artificial Neural NetworkIJARP PublicationsÎncă nu există evaluări

- Investment in Bursa Malaysia Between Returns and RisksDocument8 paginiInvestment in Bursa Malaysia Between Returns and RisksIJARP PublicationsÎncă nu există evaluări

- The Vat and The Importance of Its Application in IraqDocument4 paginiThe Vat and The Importance of Its Application in IraqIJARP PublicationsÎncă nu există evaluări

- Peacekeeping Action Team in Crime Prevention of Selected Villages in Cebu City PhilippinesDocument9 paginiPeacekeeping Action Team in Crime Prevention of Selected Villages in Cebu City PhilippinesIJARP Publications100% (1)

- Optimality Boundary Conditions For Stochastic Elliptic System Involving Higher Order OperatorDocument4 paginiOptimality Boundary Conditions For Stochastic Elliptic System Involving Higher Order OperatorIJARP PublicationsÎncă nu există evaluări

- Evaluation of Heavy Traffic Vehicular Exhausts Roads Side Polluted Guinea Grass Paniaum Maximum On Health Performance and Pathological Responses of Guinea Pigs in Humans As The Consumer of Its MeatDocument4 paginiEvaluation of Heavy Traffic Vehicular Exhausts Roads Side Polluted Guinea Grass Paniaum Maximum On Health Performance and Pathological Responses of Guinea Pigs in Humans As The Consumer of Its MeatIJARP PublicationsÎncă nu există evaluări

- Print Media and The Challenges of Social MediaDocument6 paginiPrint Media and The Challenges of Social MediaIJARP Publications100% (1)

- Prevalence of Nematode Contracaecum and Cestode Ligula Intestinalis Parasites Infection in Two Fish Species at Lake TanaDocument8 paginiPrevalence of Nematode Contracaecum and Cestode Ligula Intestinalis Parasites Infection in Two Fish Species at Lake TanaIJARP PublicationsÎncă nu există evaluări

- Evaluating The Resource Supply Thresholds That Trigger Livestock Movement Leading To Grazing Conflicts in Northern KenyaDocument6 paginiEvaluating The Resource Supply Thresholds That Trigger Livestock Movement Leading To Grazing Conflicts in Northern KenyaIJARP PublicationsÎncă nu există evaluări

- Hivaids Related Knowledge Attitude Risk Perception and Sexual BehaviorDocument5 paginiHivaids Related Knowledge Attitude Risk Perception and Sexual BehaviorIJARP PublicationsÎncă nu există evaluări

- Efficiency of Proportional Allocation Procedure Over Other Allocation Procedures in Stratified Random SamplingDocument3 paginiEfficiency of Proportional Allocation Procedure Over Other Allocation Procedures in Stratified Random SamplingIJARP PublicationsÎncă nu există evaluări

- Factors Related To The Maritime Pre Apprenticeship Phase of A UniversityDocument7 paginiFactors Related To The Maritime Pre Apprenticeship Phase of A UniversityIJARP PublicationsÎncă nu există evaluări

- Evaluation of Recombinant Inbred Lines Derived From Bulk Population Method of Selection in Rice Oryza Sativa LDocument7 paginiEvaluation of Recombinant Inbred Lines Derived From Bulk Population Method of Selection in Rice Oryza Sativa LIJARP PublicationsÎncă nu există evaluări

- Wegusta Caststeel CastironDocument3 paginiWegusta Caststeel CastironPandurang KadamÎncă nu există evaluări

- Puente GruaDocument1.133 paginiPuente GruaLuis Fernando Bravo0% (1)

- AISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFDocument24 paginiAISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFhoustonhimselfÎncă nu există evaluări

- General Characteristics: Power DefinitionDocument6 paginiGeneral Characteristics: Power Definitionzekson1Încă nu există evaluări

- Ammonia Injection SystemDocument21 paginiAmmonia Injection SystemTutti Ganti A PezziÎncă nu există evaluări

- Navistar 2017.03Document48 paginiNavistar 2017.03alxsscabalÎncă nu există evaluări

- Energy Epp0500 PowerCableAccessories SouthEastEurope PDFDocument140 paginiEnergy Epp0500 PowerCableAccessories SouthEastEurope PDFElafanÎncă nu există evaluări

- 14.Cttc Bhuvaneshwar Admma QualfileDocument24 pagini14.Cttc Bhuvaneshwar Admma QualfileGold SmithÎncă nu există evaluări

- COMAU Arc-Tin Kem en ManualDocument84 paginiCOMAU Arc-Tin Kem en ManualcabecavilÎncă nu există evaluări

- Aci Method of Mix DesignDocument19 paginiAci Method of Mix DesignJuel Rahaman100% (1)

- ClassificationWorkshop FHWA13Document148 paginiClassificationWorkshop FHWA13Nasher Andi AriasthaÎncă nu există evaluări

- Repol® H100eyDocument2 paginiRepol® H100eyXuân Giang NguyễnÎncă nu există evaluări

- Tata Indigo Petrol ManualDocument141 paginiTata Indigo Petrol Manualxtemp100% (3)

- Caase18 Preliminary Agenda Mar20 v1Document277 paginiCaase18 Preliminary Agenda Mar20 v1Anonymous oTrMzaÎncă nu există evaluări

- Dyna Blend MixerDocument12 paginiDyna Blend MixeramirmughalÎncă nu există evaluări

- Quiz Oil & Gas EngineeringDocument110 paginiQuiz Oil & Gas EngineeringLisa Malone100% (1)

- IMO Ship Waste Delivery Receipt Mepc - Circ - 645Document1 paginăIMO Ship Waste Delivery Receipt Mepc - Circ - 645wisnukerÎncă nu există evaluări

- The Flexible ImpellerDocument134 paginiThe Flexible ImpellerenlateÎncă nu există evaluări

- Panya Kaew 2011Document8 paginiPanya Kaew 2011fahmyÎncă nu există evaluări

- Rel 003Document0 paginiRel 003Bence M ZoltanÎncă nu există evaluări

- DVR User ManualDocument17 paginiDVR User Manualashok7Încă nu există evaluări

- Kiln Inlet Lamella Seal FLSDocument2 paginiKiln Inlet Lamella Seal FLSamir100% (3)

- Organic Chemical TechnologyDocument5 paginiOrganic Chemical TechnologykayeÎncă nu există evaluări

- Procedure TextDocument8 paginiProcedure TextRista Nya DendiÎncă nu există evaluări

- Pengembangan Transportasi Berkelanjutan Di Kota Semarang: Jl. Jatiwangi No. 4R, SemarangDocument14 paginiPengembangan Transportasi Berkelanjutan Di Kota Semarang: Jl. Jatiwangi No. 4R, SemarangWardanÎncă nu există evaluări