Documente Academic

Documente Profesional

Documente Cultură

Commisioning of RLNG-II Contingency Plan

Încărcat de

Mirza Aatir SalmanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Commisioning of RLNG-II Contingency Plan

Încărcat de

Mirza Aatir SalmanDrepturi de autor:

Formate disponibile

SUI SOUTHERN GAS COMPANY LIMITED, KARACHI TERMINAL

ARRANGEMENT TO TAKE 2ND TERMINAL RLNG GAS AT CTS BIN-QASIM

JOB DESCRIPTION

Procedure to take gas from 2nd LNG Terminal which covers the pressurizing and commissioning

of 42” dia pipeline from MVA Pakland to MVA SMS Kotri, MVA Massu to MVA Lundo and

the other contingency arrangements at different places to ensure and meet the best engineering

practice we follow, as per following procedure to transport the RLNG gas from CTS Bin-Qasim

and to deliver SNGPL at exit point Sawan.

Commencement of Job is subjected to availability of Gas for pressurizing the system.

1. PERSONNEL

Executives.

i) Site Incharge : Mr. Naushad Hizb-CE (Ops) HQ3/

: Mr. Khalil Khawaja-DCE (Ops) I/C Section-IV

: Mr. Najeeb Shafique –SE (MPLI)

: Mr. Mumtaz Memon- CE (Ops) HQ2

with team of Operation & Instrument Engineers

ii) Operational Incharge : Mr. Saeed Alam- CE (MPLI)

2. Subordinate Staff.

i) MRM : 03

ii) Helpers : 08

3. RESPONSIBILITIES.

3.1 MR. KHALIL KHAWAJA-DCE (Ops) I/C Section-IV

MR NAJEEB SHAFIQUE SE-(MPLI)

Area of responsibility: CTS Bin-Qasim to MVA RS-4

MR. NAUSHAD HIZB-CE (OPS) I/C HQ3

MR. ATIF KHAN DCE-(OPS) HQ3

MR. SHAKEEL AHMED-SE(Ops) HQ3

Area of responsibility: MVA RS-4 to MVA Massu

MR. MUMTAZ HUSSAIN MEMON- CE(Ops) I/C HQ2

MR. MUNEER PITAFI –ENGINEER (Ops) HQ2

Area of responsibility: MVA RS3 to MVA Lundo

They will be responsible for all activities and shall be In-charge of entire activity

of valve operation required for pressurizing and commissioning in their respective

sections. Will be directly responsible for safe execution of entire operation in

accordance with the laid down procedures.

Will be responsible to depute Engineers and staff at locations for valve operation

during the entire job.

Will be responsible to coordinate with the team members for valve operation at

site in close liaison with Operation Incharge / Gas Control.

PTW will be issued by In-charge Section-IV and HQ-3 for work to start at their

respective sections.

Arrange proper lubrication of all valves of above segment.

Arrange firefighting equipment, explosive meter and other facilities at work site,

duly checked for proper working.

3.2 MR. SAEED ALAM - CE (MPL-I)

Will coordinate with team at site to carry out the subject job.

Will give clearance at all stages for work to start from gas control KT after

communicating with work site and ensuring status of pipeline network

according to gas supply and demand condition.

Will ensure valve operation according to the laid down procedure.

Will arrange instrument Mechanic with requisite tools at Site.

Will arrange explosive meter at site during operation.

Will depute MPLI personnel for valve operation before starting the job.

Will arrange for pressurizing & commissioning the system.

4. SAFETY MEASURES:

Following safety arrangements must be available at the work site and PTW issuing

authority and HSE department shall be responsible to ensure the same.

a. Arrange portable Fire Extinguishers in sufficient numbers at Site

b. Personal Safety Equipment, such as helmets, hand gloves, goggles etc. should be

make available at Site.

c. First Aid Box to be ready at Site.

d. Gas Explosive meter in working condition to be available at site.

e. Ensure issuance of P.T.W prior to start the job.

f. Safety gadget must be wear at all times during operations at Main Valve

assemblies:

• Safety helmet

• Safety boots

• Safety glasses

• Safety gloves

• Ear defenders / Muff

g. Safety Precautions should be observed /followed by field teams during the

operation:

a. Ensure that PTW is filled and signed by Section In-charge and Site in-charge prior

to start work.

b. Ensure that Safety sign boards are erected at the work site.

c. Ensure that once the work is completed all tools and equipment have been kept at

the proper place.

d. Never smoke at work site.

e. Mobile cell should be off during blowing & purging of the Gas.

f. No naked lights are allowed near to site during blow down and purging activities.

g. All vehicle will remain switched off during blow down and purging activities.

h. Ensure all relevant safety equipment is operational.

i. All members of team must receive brief safety instructions prior to start work at

launcher & receiver sites.

j. Ensure that personnel not involved in operation do not enter within barriers during

operations at valve assemblies.

k. Firefighting measures should be taken at sites prior to start opening blow-off

valves. CO2 fire extinguisher must be kept available at all sites. Firefighting teams

should be trained how to extinguish fire and how to protect themselves.

l. First aid kits must be available at work sites.

m. No idle person should stand near to the purging site.

n. In case of gas / condensate leakage urgent measures should be taken to assist

MPL-I personnel to eliminate the leakage as quickly as possible.

o. After completion of operation work site to be cleared properly.

SEQUENCE OF OPERATION

(Drawings are attached for reference)

Ensure that the mobile communication between different work site and Gas Control room

KT is working properly.

CTS BIN QASIM SECTION-IV (refer Annexure-I)

Hold Pre-Job meeting and assign duties to all officers & Staff participating in the

Operation. A Toolbox Talk (safety meeting) is to be arranged that focuses on safety

topics related to the job, such as workplace hazards and safe work practices. Explain

safety precautions to be taken during the operation to all team members.

Segregate work area & erect safety signage at site.

Arrange portable fire extinguishers, personal protective equipment (PPEs) & First Aid

Box (To be arranged by concerned section in-charge).

Before starting activity ensures that the gas injection from FOTCO gas terminal is

within 100 MMCFD during the entire activity.

Seek permission from Gas Control KT to start job. At the commencement of RLNG gas

injection from second terminal vent valve at upstream of 30” dia valve “A” to be opened

for purging and it is to ensure that clean gas is coming out of the vent.

When 100% clean gas is coming out of the vent close the vent and gradually open 30” dia

ball valve “A” at CTS Bin-Qasim to allow RLNG injection from FOTCO re-gasification

system into SSGCL 42” dia RLNG-II pipeline.

MVA PAKLAND SECTION-IV (refer Annexure-II)

Ensure that all the 42” dia main valves at MVA RS-5, Thatta & RS-4 are open.

In close coordination with Gas Control KT open 42” dia ball valve “B”, “C” and “D” at

MVA Pakland and allow gas by opening meter skid by-pass pipeline valves to

pressurize the 42” dia RLNG-II Pipeline from MVA Pakland to MVA SMS Kotri.

(Keeping in view gas supply and demand condition of the system).

MVA SMS KOTRI HQ-3 SECTION (refer Annexure-III)

When the pressure of 42” dia RLNG-II pipeline and 24” dia SNG-KYC pipeline

equalizes then first close 24” dia main valve “E” and open 42” dia interconnection valve

and 24” dia interconnection valve at MVA SMS Kotri as shown in detail A-A of drawing

SMS Kotri.

Make sure that interconnection valve between 16” dia ILBP pipeline and 18” Badin

pipeline is closed. Open interconnection valve “R” of 24” dia SNG-KYC pipeline and

18” dia Badin Pipeline at MVA SMS Kotri.

Open interconnection valve “p”, interconnecting 20” dia Kadanwari pipeline and 24” dia

SNG-KYC pipeline located at upstream of 24” dia main pipeline valve, which allow

indigenous gas flow towards Karachi through 20” & 24” dia pipelines.

MVA SIND UNIVERSITY HQ-3 SECTION (refer Annexure-IV)

It is to ensure that interconnection valves of 30” dia pipeline with 20” dia Kadanwari

pipeline 16” dia ILBP pipeline at MVA Sind University are closed.

Open 02 nos. 12” dia valves of interconnection of 30” dia pipeline and 18” dia Badine

Gas pipeline at MVA Sindh University. (make sure that interconnection valves with 20”

dia Kadanwari pipeline and 16” dia ILBP pipeline are closed). This will allow RLNG-II

Gas from 24” dia SNG-KYC pipeline and Badin Gas pipeline through 30” dia ILBP by-

pass pipeline to HQ-3.

HEADQUARTER HQ-3 (refer Annexure-V)

Close 24” dia newly installed compressor suction isolation valve “H”. When the pressure

equalizes across valve “I”,

Open 24” dia Massu-HQ3 pipeline interconnection valve “I” then “J” gradually (make

sure that 20” dia Kadanwari pipeline interconnection valve is closed). This will allow to

flow RLNG gas towards MVA Massu.

MVA MASSU BHURGARI & MVA LUNDO HQ-3 SECTION (refer Annexure-VI)

Open 42” dia valve “m” fully.

Before opening 24” dia interconnection valve “K” at MVA Massu the interconnection to

RLNG-II pipeline, the 42” dia RLNG-II pipeline section between MVA Massu and MVA

Lundo will first pressurized by opening 16” dia sacrificial valve at MVA Lundu

gradually (keeping in view that the supply to HQ2 compressor station should not

drop below the required pressure limit).

When pressure of 42” dia RLNG-II pipeline equalizes across the 42” dia valve then open

42” dia main valve at MVA Lundo.

Open 24” dia interconnection valve “K” gradually at MVA Massu to allow RLNG Gas

flow through 42” dia pipeline from MVA Massu to Compressor Station HQ-2.

UTILIZING 20” DIA KADANWARI PIPELINE FOR RLNG-II GAS.

SEQUENCE OF OPERATION

(Drawings are attached for reference)

HEADQUARTER HQ-3 (refer Annexure-V)

Close 20” dia Kadanwari main pipeline valve “a” and ensure that pig receiver neck

valve “b” is closed, then open Kadanwari pipeline Interconnection valve “L” to allow

RLNG-II to 20” dia Kadanwari pipeline.

MVA MASSU BHURGARI (Kosar Gas diversion) (refer Annexure-VI)

Open 12" dia Kosar Gas diversion pipeline valves "c" & “d” and close valves “f” &

“e”, which allow Kosar Field Gas flow towards HQ2. Simultaneously open 20" dia

RLNG-II interconnection valves “g” & “h”, which allow RLNG-II gas from 20” dia

Kadanwari pipeline to 42” dia RNLG-II pipeline.

MVA SMS KOTRI HQ-3 SECTION (refer Annexure-III)

OVERALL IN-CHARGE.

Mr. Syed Mahmood Jeelani DGM (GD) will be over-all In- charge of entire operation.

Date: 17-11-2017

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- P1 Chp12 DifferentiationDocument56 paginiP1 Chp12 DifferentiationbobÎncă nu există evaluări

- MOS - Steel StructureDocument15 paginiMOS - Steel StructuredennisÎncă nu există evaluări

- Parts Manual: Generator SetDocument118 paginiParts Manual: Generator SetAhmed Kamal100% (2)

- Flip The Coin - EbookDocument306 paginiFlip The Coin - EbookAjesh Shah100% (1)

- Barista Skills Foundation Curriculum enDocument4 paginiBarista Skills Foundation Curriculum enCezara CarteșÎncă nu există evaluări

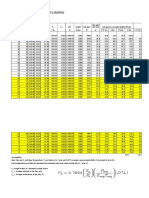

- Minimum Maximum LPG Energy Content (Btu/f)Document5 paginiMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanÎncă nu există evaluări

- KGM Working 18 01 12Document3 paginiKGM Working 18 01 12Mirza Aatir SalmanÎncă nu există evaluări

- Book Review: The Year 2100 by Dr. Michio KakuDocument2 paginiBook Review: The Year 2100 by Dr. Michio KakuMirza Aatir SalmanÎncă nu există evaluări

- Memo GM (HR) Format ABDocument1 paginăMemo GM (HR) Format ABMirza Aatir SalmanÎncă nu există evaluări

- Report On Data CNGDocument2 paginiReport On Data CNGMirza Aatir SalmanÎncă nu există evaluări

- Sui Southern Gas Company Limited Internal Audit Department: Avg Avg Avg 3 3Document15 paginiSui Southern Gas Company Limited Internal Audit Department: Avg Avg Avg 3 3Mirza Aatir Salman0% (1)

- Regas Rates Till Feb, 2017Document1 paginăRegas Rates Till Feb, 2017Mirza Aatir SalmanÎncă nu există evaluări

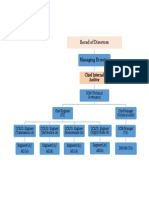

- Borad of Directors: Chief Internal AuditorDocument1 paginăBorad of Directors: Chief Internal AuditorMirza Aatir SalmanÎncă nu există evaluări

- (If Known) : Appendix - "A"Document21 pagini(If Known) : Appendix - "A"Mirza Aatir SalmanÎncă nu există evaluări

- LPG Air Mix/Sng Plant Operations - Communique # 1 Functional Re-Organization at Head Office and Other Directives About State of Affairs at PlantsDocument3 paginiLPG Air Mix/Sng Plant Operations - Communique # 1 Functional Re-Organization at Head Office and Other Directives About State of Affairs at PlantsMirza Aatir SalmanÎncă nu există evaluări

- Discussion Held On September 14Document9 paginiDiscussion Held On September 14Mirza Aatir SalmanÎncă nu există evaluări

- Heart Rate Variability Threshold As An Alternative.25Document6 paginiHeart Rate Variability Threshold As An Alternative.25Wasly SilvaÎncă nu există evaluări

- Ice 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisDocument15 paginiIce 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisBipin KrishnaÎncă nu există evaluări

- Helipal Tbs Powercube ManualDocument29 paginiHelipal Tbs Powercube Manualoualid zouggarÎncă nu există evaluări

- Personal Narrative RevisedDocument3 paginiPersonal Narrative Revisedapi-549224109Încă nu există evaluări

- SAED90DR Rev1 2 21.01.2011Document24 paginiSAED90DR Rev1 2 21.01.2011Cherry AbhiÎncă nu există evaluări

- Physico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegDocument9 paginiPhysico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegZyuha AiniiÎncă nu există evaluări

- User ManualDocument96 paginiUser ManualSherifÎncă nu există evaluări

- What Is Product Management?Document37 paginiWhat Is Product Management?Jeffrey De VeraÎncă nu există evaluări

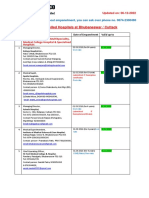

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Document19 paginiEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uÎncă nu există evaluări

- Assignment RoadDocument14 paginiAssignment RoadEsya ImanÎncă nu există evaluări

- Jurnal Vol. IV No.1 JANUARI 2013 - SupanjiDocument11 paginiJurnal Vol. IV No.1 JANUARI 2013 - SupanjiIchsan SetiadiÎncă nu există evaluări

- Ward 7Document14 paginiWard 7Financial NeedsÎncă nu există evaluări

- Forces L2 Measuring Forces WSDocument4 paginiForces L2 Measuring Forces WSAarav KapoorÎncă nu există evaluări

- Ged 102 Mathematics in The Modern WorldDocument84 paginiGed 102 Mathematics in The Modern WorldKier FormelozaÎncă nu există evaluări

- SAP HR - Legacy System Migration Workbench (LSMW)Document5 paginiSAP HR - Legacy System Migration Workbench (LSMW)Bharathk KldÎncă nu există evaluări

- Exam First Grading 2nd Semester - ReadingDocument3 paginiExam First Grading 2nd Semester - ReadingArleneRamosÎncă nu există evaluări

- Controlador DanfossDocument2 paginiControlador Danfossfrank.marcondes2416Încă nu există evaluări

- Bulletin PDFDocument2 paginiBulletin PDFEric LitkeÎncă nu există evaluări

- Comparitive Study of Fifty Cases of Open Pyelolithotomy and Ureterolithotomy With or Without Double J Stent InsertionDocument4 paginiComparitive Study of Fifty Cases of Open Pyelolithotomy and Ureterolithotomy With or Without Double J Stent InsertionSuril VithalaniÎncă nu există evaluări

- CL200 PLCDocument158 paginiCL200 PLCJavierRuizThorrensÎncă nu există evaluări

- Energy-Roles-In-Ecosystems-Notes-7 12bDocument10 paginiEnergy-Roles-In-Ecosystems-Notes-7 12bapi-218158367Încă nu există evaluări

- HPCL CSR Social Audit ReportDocument56 paginiHPCL CSR Social Audit Reportllr_ka_happaÎncă nu există evaluări

- Paper II - Guidelines On The Use of DuctlessDocument51 paginiPaper II - Guidelines On The Use of DuctlessMohd Khairul Md DinÎncă nu există evaluări

- VLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkDocument27 paginiVLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkSamir SabicÎncă nu există evaluări

- Reading Stressful Jobs 1 4Document4 paginiReading Stressful Jobs 1 4Ivana C. AgudoÎncă nu există evaluări