Documente Academic

Documente Profesional

Documente Cultură

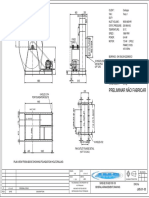

Note 1: Design Code: Pd5500 Cat Ii 2015

Încărcat de

Edo FaiZal CandraWinataTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Note 1: Design Code: Pd5500 Cat Ii 2015

Încărcat de

Edo FaiZal CandraWinataDrepturi de autor:

Formate disponibile

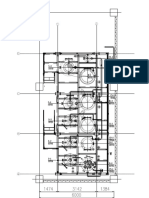

A1 8999

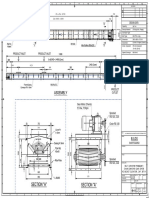

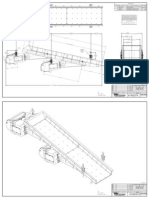

DO NOT SCALE. IF IN DOUBT, ASK. No.

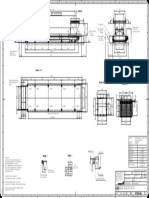

N1 INLET (P1-1422BX)

SERVICE SIZE

22" ASME B16.5

RATING

150#

FACE

F/F

SCH/THK

15mm

OVERALL

N2 OUTLET N/A N/A F/F 15mm

461 7844 694 N3 INSPECTION 14" ASME B16.5 150# F/F 15mm

SCREW ASSEMBLY N4 CASING DRAIN (SAMPLE POINT) 4" ASME B16.5 150# SOW R/F 40

(APPROX WEIGHT: 1490 KGS) 165 LH 474 275 6655 275 N5a/b/c/d STEAM INLET 3/4" ASME B16.5 150# SOW R/F SCH 40/2.87

(15mm) (15mm) (RH PITCH 8mm THK) (15mm) N6a/b CONDENSATE OUTLET 3/4" ASME B16.5 150# SOW R/F SCH 40/2.87

15 PTFE ALL WELDS POLISHED, GROUND & SMOOTHED CRACK & CREVICE FREE 400 GRIT. N7 INERT GAS DE LANTERN RING 3/4" ASME B16.5 150# SOW R/F SCH 40/2.87

550 15 PTFE

WEARSTRIP SCREW CENTRE TUBE (NATURAL) MILL FINISH. N8 INERT GAS NDE LANTERN RING 3/4" ASME B16.5 150# SOW R/F SCH 40/2.87

WEARSTRIP 150 (h6)

150 (h6) N9 NITROGEN PURGE 1/2" ASME B16.5 150# SOW R/F SCH 40

N10 INLET (CENTRIFUGE M1-1421A) N/A N/A F/F 15mm

N7 & N8

FLOWRATE: 2 NM³/hr

PRESSURE: 0.3 - 0.5 barG ABOVE CONVEYOR INTERNAL PRESSURE.

160 (h6)

550

WEARSLEEVE SS316 MIN WELD THROAT THICKNESS, FLIGHT TO CENTRE TUBE

10mm RADIAL CLEARANCE WILL NOT BE LESS THAN FLIGHT THICKNESS I.E 8mm FILLET. NOTE 1

BETWEEN TROUGH & FLIGHT

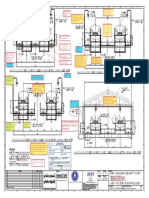

PRESSURE THRUST LOAD FOR UNRESTRAINED EXPANSION JOINT IS AS FOLLOWS:

1.) RECTANGULAR EJ: ~ 31 kN.

2.) CIRCULAR EJ: ~ 9 kN.

THESE SHALL BE CONSIDERED IN DESIGN OF EQUIPMENT, NOZZLES, SUPPORTS ETC.

10710

OVERALL

471 1044 986 1944 1488 1488 1044

(REMOVEABLE COVER) (REMOVEABLE COVER) (REMOVEABLE COVER) (REMOVEABLE COVER) (REMOVEABLE COVER) (REMOVEABLE COVER)

ROTATION SENSOR 371 N10 672 N7

TERMINAL BOX N8 N3 N5d N5b N1

ROTATION SENSOR

(SEZ-2529)

384

538 INSIDE

STEAM TRACING

924

LAYOUT

(SS316)

768

N9

C.O.G

373

1574 INSIDE N5c N5a 550 INSIDE

346

DRIVE COUPLING

NOZZLE 9 DETAILS

82 PRESSURE THRUST~ 31 kN PRESSURE THRUST~ 9 kN

1/2" ASME B16.5

(SEE NOTE 1) (SEE NOTE 1) 255

N6b N6a

1/4" NPT SOCKET 546 7894 2269.5

(BETWEEN ENDPLATES)

7000 CTRS SECTION A-A

SECTION B-B SCREW ROTATION

447 2500 CTRS 4500 447

N3

570 I/S C SIEMENS Z129-K4-160 N1

N3

100

367 N10 2651 C.O.G A N1

B 15 KW GEARBOX & MOTOR

(APPROX 376 KGS)

(INLET HEIGHT)

N9 N9

475

N5bN5d

N8

360

N5c N5a

P1-1422AX

N8

CL EL 109.435

1213

250

75

360

50

450

C.O.G

743

720

720

672

NAMEPLATE

EARTH BOSSES N6b

N5c N5a N6a

550 I/S (SEE DETAIL)

N2

428 500 I/S FLOOR EL 108.715

C 384 384 44

220 = 440 =

220 A

SECTION C-C

B N10 538 I/S

FOOTPLATE DETAILS

INLET HEIGHT)

(CENTRIFUGE

550 3225 3225 CTRS 1547

550

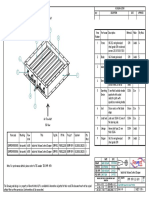

SLIDER PAD DETAILS DRIVE SLIDER PAD DETAILS 1950

25mm THK PTFE 25mm THK PTFE

SCALE 1:10 SCALE 1:10

200 175

36

130 18

535 CTRS

852 CTRS

OUTLET CL (FIXED) 1200 KGS CENTRIFUGE CL (SLIDER) 1200 KGS (SLIDER) 1200 KGS (SLIDER) 1200 KGS

720

22 (THERMAL EXPANSION

300 KGS PER BOLT (THERMAL EXPANSION +1.992mm)

300 KGS PER BOLT 600 KGS PER BOLT 600 KGS PER BOLT

125

+0.570mm) (THERMAL EXPANSION +6.693mm) (THERMAL EXPANSION +8.3mm)

(THERMAL EXPANSION +3.347mm)

146

(THERMAL EXPANSION +0mm)

22

22 x 18 SLOTS 18 22 x 18 SLOT

- 2 PLACES 681

25

14 No. M20 x 100 HEX BOLTS BZP

GRADE 8.8 SUPPLIED BY SPIROTECH.

NOZZLE 10 NOZZLE 1 N1

NOZZLE 2

INLET DRILLING DETAILS INLET DRILLING DETAILS REMOVEABLE

OUTLET DRILLING DETAILS

15mm THK (AS PER 22" ASME B16.5 150#) LIFTING LUGS (x4)

(TO BE CONFIRMED)

1686 15mm THK

15mm THK

698.5 29.50

1638 CTRS 749.3

500 I/S (7 x 234 PITCH) N10

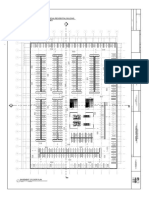

CONVEYOR SPECIFICATION DATA.

18° TYP

5 - DRIVE DETAILS CONTINUED 10 - MATERIAL HANDLED - PURE TEREPHALTIC ACID CAKE.

1 - QUANTITY - 1 No. AS DRAWN. 5.6 - ELECTRICAL SUPPLY - 380v / 3PH / 50Hz, IP55. 11 - BULK DENSITY - 800 Kgs/M³. N5a

3 x 220 PITCH)

50

5.7 - DRIVE COUPLING - BIBBY (90010-0075 JSE1-0300CEA T/L B+K) N3 NAMEPLATE DETAIL

9°

550 I/S

538 I/S

2 - MATERIAL - SS304L 1 No. TO SUIT GEARBOX. 12 - OPERATING & DESIGN CONDITIONS -

748.5

N5c

710

660

INDORAMA

3 - SCREW DETAILS 6 - BEARINGS & SEALS 12.1 - OPERATING TEMP: 100 C. VENDOR NAME : SPIROTECH-SRD GROUP LIMITED

12.2 - OPERATING PRESSURE: ATMOSPHERIC. 27.25 550 I/S VENDOR SERIAL No. : 19460-02 / P1-1422AX

3.1 - 550 x 8mm THICK 304L FINISH FLIGHTS CONTINUOUSLY 6.1 - SHAFT SEAL: STB 160L GLAND PACKING. 12.3 - DESIGN PRESSURE: +/- 0.3 barg. 692.15 P.C.D SIZE : Ø550

TYPE : SCREW CONVEYOR

MODEL : TROUGH

WELDED BOTH SIDES TO A 10" NB SCHD 100 SS304L TUBE. 6.2 - DRIVE END BEARING - SKF SNL3134 - 150mm. 12.4 - TEST PRESSURE: 1.7 barg. PURCHASER'S P/O No. : PTIP/2018/466

3.2 - DRIVE SHAFT - 150 SS304L. 6.3 - NON-DRIVE END BEARING - SKF SNL3134 - 150mm. 12.5 - DESIGN TEMP: 0-125 C. PURCHASER'S ITEM No. : P1-1422AX

R250 1574 I/S

YEAR OF MANUFACTURE : JUNE 2018

3.3 - TAIL SHAFT - 150 SS304L. 14 THRU 35.05 1.38 THRU CONVEYING RATE: DESIGN: FILTER CAKE - 68000 KG/HR

MAX INSTANTANEOUS:- FILTER CAKE - 136.5000 KG/HR

3.4 - FLIGHT CONFIGURATION - SEE DRAWING. HOUSING = SNL 3134. 13 - ROTATION SENSOR - 20 PLACES N2

635 P.C.D - 20 PLACES

BEARING = 23134 CCK/W33. 32 THRU

4 - CASING DETAILS ADAPTOR = H3134. 13.1 - SUPPLIER: P&F (NCB518GM40-N0) - 20 PLACES

LOCATING RING = 2 x FRB 10/280. FITTED TAIL END (Ex 'D' SUITABLE FOR CLASS 1, DIV 2, D, T2).

NOTES:

TAG No. P1-1422AX - CONVEYOR GROSS WEIGHT EMPTY: 4810 KGS.

4.1 - 8mm THICK SS304L TROUGH. AES SEAL = LABTECTA 316L SS PB SNL 3134. 13.2 - SENSOR FLAG BY SPIROTECH-SRD GROUP.

1.) CLADDING PINS FOR INSULATION OF 75mm THK - OPERATING WEIGHT: 5346 KGS.

4.2 - INLET SPIGOTS AS SHOWN. 13.3 - JUNCTION BOX: EXE GRP TERMINAL BOX (120x122x90).

SHALL BE SUPPLIED BY LOOSE & INSTALLED ONSITE AS DESIGN CODE: PD5500 CAT II 2015 *FOR INFORMATION ONLY - THIS IS NOT A FABRICATION DRAWING*

4.3 - OUTLET SPIGOT AS SHOWN. 7 - FINISH THIRD ANGLE PROJECTION

PER SPIROTECHS GUIDELINES. TOLERANCES U.O.S HEAD OFFICE: CLIENT:

4.4 - END PLATES - 25mm SS304L. 14 - OTHER FEATURES CHECKED:

2.) INSULATION SURFACE AREA 24 MTRS APPROX.

4.5 - JOINT FLANGES - 25mm SS304L. 7.1 - INTERNAL - NATURAL, ALL WELDS CONTINUOUS & GROUND SMOOTH 400 GRIT. FABRICATION MACHINING BROOKSIDE IND ESTATE

3.) NON - DESTRUCTIVE TESTING: INDORAMA

7.2 - EXTERNAL - STAINLESS STEEL - ALL WELDS LEFT AS LAID - BEADBLASTED FINISH. 14.1 - DESIGN SAFE NON HAZARDOUS AREA COMPLIANT. 0 TO 250 ±0.75 WHOLE 0 ±0.25 GLATTON ROAD

5 - DRIVE DETAILS

a) MAIN SHELL 10% ULTRASONIC TESTING ON CIRCUMFERENTIAL

SAWTRY SCALE: 1:20

7.3 - INLET & OUTLET TO BE POLISHED TO 400 GRIT. 14.2 - END PLATES TO BE DOWELLED TO JOINT FLANGES.

& LONGITUDINAL WELDS; TO PD5500. 250 TO 1000 ±1.0 DECIMAL 0.0 ±0.25

14.3 - END BEARINGS TO BE DOWELLED TO PLATFORMS. CAMBRIDGESHIRE

5.1 - DIRECT INLINE AT INFEED END.

b) ALL NOZZLE WELDS & ATTACHMENTS 100% DYE PENETRANT TESTED. 1000 & ABOVE ±2.0 DECIMAL 0.00 ±0.10

8 - CONVEYOR SPEED - 49 RPM @ 50Hz. PE28 5SB DRAWN: KLB TITLE: THIS DOCUMENT IS THE PROPERTY

5.2 - GEARBOX SUPPLIER - SIEMENS. 15 - OPERATING/DESIGN CONDITIONS OF STEAM TRACING. Tel: +44(0)1487 832053 550 SCREW CONVEYOR OF SPIROTECH-SRD GROUP LIMITED

AND CONTAINS CONFIDENTIAL

5.3 - GEARBOX UNIT MODEL - Z129-K4-160. 9 - MACHINE DUTY : DESIGN 68 TPH OF CAKE. REV. DESCRIPTION DATE APPROVED REMOVE ALL BURRS AND SHARP EDGES Fax +44(0)1487 832252 GENERAL ARRANGEMENT

5.4 - OUTPUT SPEED - 49 RPM @ 50 Hz. MAX INSTANTANEOUS 136.5 TPH. 15.1 - OPERATING/DESIGN PRESSURE: 5/6.9 & FV bar(g).

A UPDATED TO CLIENT COMMENTS 23/03/2018 MKM TAPPED HOLES TO BE CLEAR

DATE: 05/03/18 INFORMATION WHICH MUST NOT BE

COPIED WHOLLY OR IN PART NOR

5.5 - MOTOR POWER - 15 Kw. 15.2 - OPERATING/DESGN TEMP: 159-185 C.

B UPDATED TO CLIENT COMMENTS 03/04/2018 MKM ALL DIMENSIONS IN MILIMETERS U.O.S sales@spirotechgroup.co.uk DISCLOSED TO ANY 3rd PARTY

All dimensions in mm.

15.3 - TEST PRESSURE: 9.8 barg.

C UPDATED TO CLIENT COMMENTS & SCREW FLIGHTS UPDATES 10/05/2018 MKM SURFACE TEXTURE TO BE 3.2 U.O.S

www.spirotechgroup.co.uk DRWG NO. 19460-02 REV: C WITHOUT WRITTEN CONSENT

© SPIROTECH-SRD GROUP LTD. 2017

S-ar putea să vă placă și

- Nozzle Table: K-K Foundation Detail TypDocument1 paginăNozzle Table: K-K Foundation Detail TypVishal KandÎncă nu există evaluări

- 3147 Hoist r3Document1 pagină3147 Hoist r3Ade Y SaputraÎncă nu există evaluări

- Detail H Scale 1: 3: Section E-E SCALE 1: 10Document2 paginiDetail H Scale 1: 3: Section E-E SCALE 1: 10Brahamadandi Achyuth KumarÎncă nu există evaluări

- Assembly: Section "A"Document2 paginiAssembly: Section "A"mrmp bbiÎncă nu există evaluări

- Kennedy Valve: 3"-12" Oil Cushion Check Valve AssemblyDocument1 paginăKennedy Valve: 3"-12" Oil Cushion Check Valve AssemblySamuel Lopez BenitesÎncă nu există evaluări

- m0043 016 2 PDFDocument1 paginăm0043 016 2 PDFajarekarga ajarekarÎncă nu există evaluări

- S.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen BoltDocument1 paginăS.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen Boltsabir hussainÎncă nu există evaluări

- Sliding Elastomeric Bearing - 301 MTDocument1 paginăSliding Elastomeric Bearing - 301 MTAnusha KishoreÎncă nu există evaluări

- North: East Elevation View SCALE 1/100Document16 paginiNorth: East Elevation View SCALE 1/100Potential SupportÎncă nu există evaluări

- SEMA AH Hook Block Assly. Sheet 2 3Document1 paginăSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraÎncă nu există evaluări

- 11-2756-b Elevator Boot Assy 28SIDocument1 pagină11-2756-b Elevator Boot Assy 28SIBoanerges BritoÎncă nu există evaluări

- Sae Insert S1yt3232 DWG 0Document1 paginăSae Insert S1yt3232 DWG 0kaliya12Încă nu există evaluări

- Weld Map Control RoomDocument12 paginiWeld Map Control RoomAry Cipta KusumaÎncă nu există evaluări

- Machine Afzar Shams: Bearing HousingDocument8 paginiMachine Afzar Shams: Bearing HousingmasoodkamaliÎncă nu există evaluări

- Sheet 1 of 1: All Dimensions Are in MMDocument1 paginăSheet 1 of 1: All Dimensions Are in MMPRASHANTHÎncă nu există evaluări

- Power Powders: The inDocument6 paginiPower Powders: The insalkan_rahmanovic810Încă nu există evaluări

- Be 4800 Spec Sheet 2Document1 paginăBe 4800 Spec Sheet 2Nhero DulatreÎncă nu există evaluări

- 0740 19a PDFDocument1 pagină0740 19a PDFDavid SarccoÎncă nu există evaluări

- Test Fixture Optical MountDocument1 paginăTest Fixture Optical Mounti50229Încă nu există evaluări

- Preliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingDocument1 paginăPreliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingbarrosojmsÎncă nu există evaluări

- Belt Conveyor 600x12000 (k2) - Belt Conveyor TataDocument1 paginăBelt Conveyor 600x12000 (k2) - Belt Conveyor TataAde SÎncă nu există evaluări

- A554 y 730 HV DWG Hva 300Document1 paginăA554 y 730 HV DWG Hva 300josephÎncă nu există evaluări

- GA-150027-1 (003) Ffetbigbore1750 PDFDocument1 paginăGA-150027-1 (003) Ffetbigbore1750 PDFriinÎncă nu există evaluări

- Part 1 - Trolley WheelDocument1 paginăPart 1 - Trolley WheellexatrinÎncă nu există evaluări

- Notes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512Document2 paginiNotes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512antoine131Încă nu există evaluări

- 185-170-5-300-M44-0055 RevBDocument1 pagină185-170-5-300-M44-0055 RevBVashish RamrechaÎncă nu există evaluări

- Manual Da Deslintadeira-200 SerrasDocument56 paginiManual Da Deslintadeira-200 SerrasAilson Silva AlvesÎncă nu există evaluări

- App1002413340030-03 Piping Drawing Miscellaneous Piping Ass Rev.ADocument11 paginiApp1002413340030-03 Piping Drawing Miscellaneous Piping Ass Rev.AAswindana Ibnu SenaÎncă nu există evaluări

- PPD 0600-00 2DRT2 2018-EN 4367.076.00M Rev.1Document1 paginăPPD 0600-00 2DRT2 2018-EN 4367.076.00M Rev.1Mujahidin AhmadÎncă nu există evaluări

- Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMDocument1 paginăDrawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMjonodo89Încă nu există evaluări

- V-8120 DWG CommentsDocument1 paginăV-8120 DWG CommentsSulist N WahyudieÎncă nu există evaluări

- Peract Pi Q23 DW 0004 PDFDocument5 paginiPeract Pi Q23 DW 0004 PDFGÎncă nu există evaluări

- Bill of Material - 3105538: QTY Description Part No. ItemDocument3 paginiBill of Material - 3105538: QTY Description Part No. ItemluisÎncă nu există evaluări

- Sprocket PT Petrodrill Manufacture IndonesiaDocument1 paginăSprocket PT Petrodrill Manufacture Indonesiaer_winwibowoÎncă nu există evaluări

- Confidencial: Klabin S.ADocument5 paginiConfidencial: Klabin S.AIgor FelipeÎncă nu există evaluări

- Co2 Damper6Document4 paginiCo2 Damper6sabir hussainÎncă nu există evaluări

- 50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDocument1 pagină50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDavid SarccoÎncă nu există evaluări

- Plan Elevation: Job No. ClientDocument1 paginăPlan Elevation: Job No. Clientriz2010Încă nu există evaluări

- Rti, Mois, Mec, Ga, GaDocument3 paginiRti, Mois, Mec, Ga, GaLuis PurisÎncă nu există evaluări

- STD Drainage Drawings Page 2 PDFDocument1 paginăSTD Drainage Drawings Page 2 PDFcherielyn.riveraÎncă nu există evaluări

- Ambaji Stone Decor PVT LTD-R1-16-09-20 PDFDocument1 paginăAmbaji Stone Decor PVT LTD-R1-16-09-20 PDFpatelchiragisÎncă nu există evaluări

- Ls Bearing Positioning Ls Bearing Positioning: Section View Reducer Jumborex Jc62Document1 paginăLs Bearing Positioning Ls Bearing Positioning: Section View Reducer Jumborex Jc62Luu Thanh CongÎncă nu există evaluări

- 06) 5333-106-D - General Arrangement Drawing CN7065 Screw ConveyorDocument1 pagină06) 5333-106-D - General Arrangement Drawing CN7065 Screw ConveyorluisleojossewÎncă nu există evaluări

- 1714010223-Vent Ext Fima - RDocument1 pagină1714010223-Vent Ext Fima - RMilton IngaÎncă nu există evaluări

- Ba 204302 001Document1 paginăBa 204302 001Muhammad ArshadÎncă nu există evaluări

- CombineddrawingsDocument20 paginiCombineddrawingsapi-429073519Încă nu există evaluări

- Conveyor Cross Section at Each Typical Segment r0 - c3Document1 paginăConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarÎncă nu există evaluări

- Belt Conveyor Maxwell 500BW X 17.5MTRDocument1 paginăBelt Conveyor Maxwell 500BW X 17.5MTRHritika PatelÎncă nu există evaluări

- Intercambiador de Calor PDFDocument10 paginiIntercambiador de Calor PDFShalber Jhoel Garcia SaraviaÎncă nu există evaluări

- Maxwell Crushtech: Tunnle, Tunnle Structure and ConveyorDocument1 paginăMaxwell Crushtech: Tunnle, Tunnle Structure and ConveyorHritika PatelÎncă nu există evaluări

- Approval Required: Material ListDocument2 paginiApproval Required: Material ListJorge VarelaÎncă nu există evaluări

- Ротациона глава - Обновен каталогDocument3 paginiРотациона глава - Обновен каталогGoran BogdanoskiÎncă nu există evaluări

- Wip Rev-E 25-Jun-19Document2 paginiWip Rev-E 25-Jun-19QuyetÎncă nu există evaluări

- DWG 415-019 REV 0Document7 paginiDWG 415-019 REV 0jonodo89Încă nu există evaluări

- 267497-1-H Ga Drawing Olbc PDFDocument10 pagini267497-1-H Ga Drawing Olbc PDFaansewuÎncă nu există evaluări

- Donaldson UK Manual TDS PDFDocument19 paginiDonaldson UK Manual TDS PDFPatricio TamayoÎncă nu există evaluări

- Belt Drive LH: Projectionsmeth.1 ISO5456-2Document1 paginăBelt Drive LH: Projectionsmeth.1 ISO5456-2Traian SerbanÎncă nu există evaluări

- Fab Shop DrawingsDocument14 paginiFab Shop DrawingszainyousafzaiÎncă nu există evaluări

- Jeblix: A Proposed 50 Storey Commercial/Residential Building Paoay, Ilocos Norte, PhilippinesDocument1 paginăJeblix: A Proposed 50 Storey Commercial/Residential Building Paoay, Ilocos Norte, Philippineshanna gabrielÎncă nu există evaluări

- ST SD Ta 0036 0046 - 00Document11 paginiST SD Ta 0036 0046 - 00Muneeswaran BalaguruÎncă nu există evaluări

- Deliverable List: Alindo Hydrogen Transfer Line Facility ProjectDocument4 paginiDeliverable List: Alindo Hydrogen Transfer Line Facility ProjectEdo FaiZal CandraWinataÎncă nu există evaluări

- RFQ - BQ Hydrant - Project Pertamina RU II - DumaiDocument4 paginiRFQ - BQ Hydrant - Project Pertamina RU II - DumaiEdo FaiZal CandraWinataÎncă nu există evaluări

- Deliverable List: Alindo Hydrogen Transfer Line Facility ProjectDocument4 paginiDeliverable List: Alindo Hydrogen Transfer Line Facility ProjectEdo FaiZal CandraWinataÎncă nu există evaluări

- C200004 - Bridge Rev 1 Bridge V6001-V6003Document1 paginăC200004 - Bridge Rev 1 Bridge V6001-V6003Edo FaiZal CandraWinataÎncă nu există evaluări

- Schedule Direct Hire: Date Rev. No 1 Admin BuildingDocument1 paginăSchedule Direct Hire: Date Rev. No 1 Admin BuildingEdo FaiZal CandraWinataÎncă nu există evaluări

- Adam Naufal IrtizaDocument1 paginăAdam Naufal IrtizaEdo FaiZal CandraWinataÎncă nu există evaluări

- Cas 050624 Qa QC ManualDocument33 paginiCas 050624 Qa QC ManualEdo FaiZal CandraWinataÎncă nu există evaluări

- Layout Evaporator 2400-ModelDocument1 paginăLayout Evaporator 2400-ModelEdo FaiZal CandraWinataÎncă nu există evaluări

- Plug in S User GuideDocument16 paginiPlug in S User GuideSambuca DocÎncă nu există evaluări

- Document TransmittalDocument4 paginiDocument TransmittalEdo FaiZal CandraWinataÎncă nu există evaluări

- Sloping Ceiling GuideDocument18 paginiSloping Ceiling GuideSakthi SundarÎncă nu există evaluări

- Reactive Power Compensation PDFDocument97 paginiReactive Power Compensation PDFGilberto Sanchez100% (1)

- BESI Actuators (Hydraulic)Document2 paginiBESI Actuators (Hydraulic)mister_no34Încă nu există evaluări

- HL Chapter 14 RevisionMSDocument25 paginiHL Chapter 14 RevisionMSanon_709158140Încă nu există evaluări

- PowerformerDocument15 paginiPowerformerAshish BhardwajÎncă nu există evaluări

- Lesson Plan 6.6Document5 paginiLesson Plan 6.6Josh ArgonzaÎncă nu există evaluări

- Design of Air Pre Heater and EconomizerDocument4 paginiDesign of Air Pre Heater and EconomizerRyan PerezÎncă nu există evaluări

- LP2 - Pre CalculusDocument54 paginiLP2 - Pre CalculusZyrelle AgullanaÎncă nu există evaluări

- Automatic Labeling Machine and MethodDocument14 paginiAutomatic Labeling Machine and MethodHùng ThanhÎncă nu există evaluări

- Wa0000.Document52 paginiWa0000.akashrathor19115Încă nu există evaluări

- Chapter 5: Fundamental Principles of Traffic Flow: Without Inducing Undesirable Side Effects To Society at LargeDocument28 paginiChapter 5: Fundamental Principles of Traffic Flow: Without Inducing Undesirable Side Effects To Society at Largeአድሜ ልስልሱÎncă nu există evaluări

- Q of WZPDCL Ae 2014Document1 paginăQ of WZPDCL Ae 2014Rashed IslamÎncă nu există evaluări

- Preliminary: ANSI C136.41-2013 Dimming Light Controller BaseDocument7 paginiPreliminary: ANSI C136.41-2013 Dimming Light Controller BaseShung Tak ChanÎncă nu există evaluări

- Effect of Coarse Aggregate Content On Stone Matrix Asphalt Rutting and Drain DownDocument1 paginăEffect of Coarse Aggregate Content On Stone Matrix Asphalt Rutting and Drain Downvarun persadÎncă nu există evaluări

- Grey Cast Iron CompositionDocument6 paginiGrey Cast Iron CompositionSatendra ThakurÎncă nu există evaluări

- by Nvs Teacher Coordination CompoundsDocument138 paginiby Nvs Teacher Coordination CompoundsDarshan PatilÎncă nu există evaluări

- Gas Turbine PowerplantDocument1 paginăGas Turbine PowerplantVon A. DamirezÎncă nu există evaluări

- Fan Wall Technology Versus Centrifugal FansDocument3 paginiFan Wall Technology Versus Centrifugal FansWilliam Greco100% (1)

- Design, Construction and Testing of A Dry Sand Sieving Machine Oladeji Akanni OgunwoleDocument3 paginiDesign, Construction and Testing of A Dry Sand Sieving Machine Oladeji Akanni OgunwoleRex Sotelo BaltazarÎncă nu există evaluări

- Mid-Semester Examination: Solution: PHY103A: Physics II Semester II, 2017-18 IIT KanpurDocument11 paginiMid-Semester Examination: Solution: PHY103A: Physics II Semester II, 2017-18 IIT KanpurPaola GongoraÎncă nu există evaluări

- VLSI System Design Lab Digital Assignment 1Document11 paginiVLSI System Design Lab Digital Assignment 1SMÎncă nu există evaluări

- Precautions of Experiment of PhysicsDocument1 paginăPrecautions of Experiment of PhysicsA. Suhaimi50% (10)

- Drill Bit NotesDocument54 paginiDrill Bit Notesamin peyvandÎncă nu există evaluări

- f3 Chemistry Simplified Notes SPDocument40 paginif3 Chemistry Simplified Notes SPmicah isabokeÎncă nu există evaluări

- Unit h630 01 Pure Mathematics and Mechanics Sample Assessment MaterialDocument36 paginiUnit h630 01 Pure Mathematics and Mechanics Sample Assessment MaterialanuÎncă nu există evaluări

- Recipiente: Equipment Data SheetDocument1 paginăRecipiente: Equipment Data SheetAlonso DIAZÎncă nu există evaluări

- Hydraulics 3-Hydrostatic Forces, DAms, and BuoyancyDocument91 paginiHydraulics 3-Hydrostatic Forces, DAms, and Buoyancyjmeeramil5Încă nu există evaluări

- Pile Cap For 6 PilesDocument4 paginiPile Cap For 6 PilesHemant Sonawadekar100% (2)

- KF Plasma Times 2018 10Document33 paginiKF Plasma Times 2018 10Claudio MachadoÎncă nu există evaluări

- Plasma: Plasma (from Greek πλάσμα, "anything formed"Document7 paginiPlasma: Plasma (from Greek πλάσμα, "anything formed"Maitri ShahÎncă nu există evaluări

- BITS Pilani AssignmentDocument9 paginiBITS Pilani AssignmentNaresh SehdevÎncă nu există evaluări