Documente Academic

Documente Profesional

Documente Cultură

Mud Classification

Încărcat de

Don BraithwaiteDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mud Classification

Încărcat de

Don BraithwaiteDrepturi de autor:

Formate disponibile

Classifications of Upda ted June 2008

fluid systems Basic System Classifica tions

Functio n of Additives

De scriptions of fluid-syste m cla ssificatio ns,

Nom encla ture

pro duct functions and source com panies are

listed o n the se pages. System descriptions Co m pa ny Nam e Abbrevia tions

and pro duct definitions ha ve been k ept as Fluids 2008 Ta bles

sim ple as po ssible and, where ver practical,

the y reflect gene ral industry practice and

term ino logy consistent with de scriptions ado pted by the Am erican P etroleum

Institute (AP I) a nd the Interna tiona l Associa tion of Drilling Contractors

(IADC).

Basic System Classifications

WA TER-BA SED SYSTEMS

Non-dispersed. T hese system s include spud m uds, na tura l m uds a nd other

lightly treate d system s tha t are generally used fo r shallow wells or top-hole

drilling. Thinners and dispersa nts a re no t added to disperse drill so lids a nd

cla y particles.

Dispersed. At gre ater depths, where higher densities are required, or where

ho le co nditio ns m ay be proble m atic, m uds a re often dispe rsed, typically with

lignosulfona tes, lignites o r tannins. The se a nd sim ila r pro ducts are effe ctive

de flocculants and filtrate reducers. Pota ssium -containing chem icals are

fre quently used to provide gre ater shale inhibitio n. Specia lized chem icals are

also added to adjust or m ainta in specific m ud pro perties.

Calcium treated. Diva lent catio ns, such as ca lcium and m a gnesium , whe n

added to a freshwate r drilling m ud, inhibit fo rm ation clay a nd shale swe lling.

High levels o f so luble calcium are used to co ntrol sloughing shale a nd hole

enlarge m ent, and to prevent form a tion dam age. Hydrated lim e (ca lcium

hydrox ide), gypsum (calcium sulfate) a nd ca lcium chloride are principal

ingredie nts of ca lcium system s.

Ca lcium -trea ted m uds resist sa lt and anhydrite contam ina tion but a re

susceptible to ge latio n and solidification at high tem peratures.

High-performance water-based muds (HPWBM). The se are usually

reform ulated polym e r system s containing system -spe cific products to de liver

sha le stability, clay a nd cuttings inhibitio n, lubricity and high RO P, while

m inim izing bit ba lling/accretion and downhole torque problem s. Som e

HP W BM use bore hole stabilizing products to reduce pore pressure

tra nsm ission sim ilar to oil-base d m uds. The refore, HP W BM are suitable to

use whe neve r environm ental liabilities a nd a ssociated waste m anagem e nt

costs lim it the applica tion of O BM/SBM.

Low solids. Listings include system s in which the am o unt (volum e) and type

of solids are controlle d. To tal solids sho uld not ra nge higher than a bout 6%

to 10% by volum e. C lay solids sho uld be so m e 3% o r less and ex hibit a

ratio of drille d so lids to be ntonite o f less tha n 2:1. Lo w-so lids syste m s

typically use polym er additive as a visco sifie r or bento nite ex te nder and are

no n-dispersed. O ne prim a ry advantage of lo w-so lids syste m s is tha t the y

significa ntly im prove drilling pe netration rate .

Polymer/PA /PHPA . Muds inco rporating generally long-chain, high-

m o lecular-we ight polym ers are used to eithe r encapsulate drill solids to

pre vent dispersio n and co at shales for inhibition, or fo r increasing viscosity

and reducing fluid loss. Va rious polym e rs are ava ilable for these purposes,

including cellulose, na tura l gum -ba sed products, and acrylam ide. Freque ntly,

inhibiting sa lts, such as KC l or NaC l, are use d to provide greate r shale

sta bility in a ll of these fluids. T hese system s usually conta in a m inim um

am ount of bento nite and m ay be sensitive to divalent cations, such as

calcium and m agnesium . Most polym ers have tem perature lim its be low 300°

F but, under certain conditions, m a y be used in hotte r wells. A special class

of wate r-based m uds use partially-hydro lyze d po lyacrylam ide (PHPA) as an

additive , either to encapsulate drill solids or to ex tend bentonite cla y in a

low-solids m ud.

Saltwater systems. Several m ud system s are include d in this classification.

Sa turated sa lt system s are use d to drill salt form ations. Lo wer levels are

usually referred to as brack ish or seawa ter system s. Saltwater m uds are

usually prepared from bra ck ish, se awate r or produced-wate r so urces and dry

sodium chlo ride (or o ther salts, such as pota ssium chloride use d fo r sha le

inhibitio n), a re a dded to a chie ve de sire d salinity. Various specialty products,

such as atta pulgite, C MC, starch and others, are used to increa se viscosity

for hole -clea ning propertie s and to reduce fluid lo ss.

OIL-BA SED MUDS (OBM)

O il-base d system s are use d in various a pplicatio ns, where fluid stability and

inhibitio n are ne cessa ry, such as high-te m pe rature we lls, deep hole s, and

where stick ing and ho le stabilizatio n are pro blem s. They consist of two types

of syste m s:

1. Invert emulsion muds are water-in-oil e m ulsions, typically with calcium

chloride brine as the em ulsified phase and oil as the co ntinuous

phase. They m ay conta in as m uch as 50% brine in the liquid pha se.

Rela x ed, inve rt em ulsio n m uds a re a “rela x ed” em ulsio n, and ha ve

lower electrica l stabilitie s and higher fluid-loss value s. C once ntration

of additives and brine conte nt/sa linity are varied to control

rheo logica l, filtratio n and em ulsion stability.

2. Oil-based muds are form ulate d with only oil as the liquid phase and

are o ften used as coring fluids. Altho ugh these system s pick up water

from the form ation, no additiona l water o r brine is adde d. All oil

syste m s require higher additiona l gelling agents fo r viscosity.

Specialize d oil-based m ud a dditives include: e m ulsifiers and wetting

agents (com m only fatty acids and am ine derivative s) fo r viscosity;

high-m ole cula r-weight soaps; surfacta nts; am ine treate d organic

m ate rials; organo clays and lim e for alk a linity.

m ate rials; organo clays and lim e for alk a linity.

COMPLETION FLUIDS

So lids-free a nd typica lly fo rm ulated with aqueous salts, these fluids can

achieve a wide density range by incorpo rating the appropriate salt (halides,

bro m ide s and fo rm ate brine) witho ut using conve ntional weighting m ate rials.

They are usually designed to m atch spe cific rese rvoir crite ria, tak ing into

account critical fa ctors lik e ESD, contam inatio n risk s a nd crystallization

tem perature s.

HPHT SPECIA LTY PRODUCTS

Specifically designed for high-pressure, high-tem pera ture and hostile

environm ents where conve ntio nal drilling fluids a re im practical or

uneconom ical. T hey a ddre ss safety and environm enta l com plia nce, lost

circulation, decre ased penetration rates, acid gases, a nd determ ina tion of

do wnho le pressure, while allowing for m ore flex ible to ol and do wnho le-

equipm ent selection.

RESERVOIR DRILL-IN FLUIDS (RDF)

These have the prope rties of a goo d drilling fluid and a co m ple tion fluid. Its

prim ary attribute is the de velo pm e nt of a filter ca k e which effe ctively

pre vents form ation dam age and is easily rem ove d, with filtrate and filte r

cak e be ing com patible with the com pletion proce ss. T hey are usually

com posed o f bio polym ers and bridging m ate rials and are designed to m atch

spe cific rese rvoir crite ria.

SYNTHETIC FLUIDS (SBM)

These a re designed to m irror o il-ba sed m ud perform a nce, without the

environm ental hazards. P rim ary synthetic fluids a re e sters, ethers, poly

alpha o lefins and iso m erized a lpha olefins. They can be discha rged offshore ,

and are non-she ening and bio degradable.

WELLBORE CLEA N-UP

These products a re designed to rem ove m ud and m ud pa rticle s tha t are

attache d to the casing or beco m e a part of the filter cak e while drilling. They

are usually part of aqueous and no n-aqueous spacers and clea ners to

ensure sm o oth displa cem ent, optim al conta ct tim es a nd reduced disposal

costs.

IR, MIST, FOA M A ND GA S

Four ba sic o pera tions are included in this specialized category. These

include: 1) Dry a ir drilling, which involve s inje cting dry air o r ga s into the

we llbore at rates capa ble of achieving a nnula r ve locities that will rem ove

cuttings; 2) Mist drilling, which invo lves injecting a foa m ing age nt into the air

stream that m ix e s with produced water and coats the cuttings to pre vent

m ud rings, a llowing drill so lids to be rem ove d; 3) Foa m uses surfactants and

po ssibly clays or polym ers to form a high ca rrying-capacity foam ; a nd 4)

Ae rated fluids re ly on m ud with inje cted air (which reduces hydrosta tic he ad)

to rem o ve drilled solids from the wellbo re.

Functions of Additives

The pro duct function classifications are those generally accepte d by the IADC

Subcom m ittee o n Drilling Fluids. So m e additives have m ultiple uses, and for

tho se a prim ary and two secondary function categorie s are liste d.

A lkalinity, pH control additives. Pro ducts use d to control the de gree of

acidity o r alk alinity of a fluid include lim e, ca ustic soda, so da a sh a nd

bicarbo nate of so da, as well as other co m m o n acids a nd bases.

Bactericides. Used to prevent bacte rial degradation o f natural orga nic

additive s, such a s sta rch a nd x anthan gum .

Calcium reducers. So da ash, bicarbonate of soda , caustic soda and certa in

po lypho spha tes are used to re duce calcium in se awater, treat cem e nt

contam inatio n, a nd o verco m e conta m inating effe cts o f anhydrite and

gypsum , bo th fo rm s of ca lcium sulfates.

Corrosion inhibitors. pH co ntro l, alo ng with a n appropriate corro sion inhibitor,

is used to co ntro l corrosio n, ne utra lize hazardous acid gases a nd prevent

sca le. C om m on corro sion inhibitors are am ine- o r pho spha te-based

pro ducts, and other specia lly fo rm ulated che m ica ls.

Defoamers. Products are designed to re duce foa m ing action, particularly in

bra ck ish and saturate d sa ltwater m uds.

Emulsifiers. These products cre ate a he terogene ous m ix ture (e m ulsion) of

two inso luble liquids. They include fatty acids and am ine-based che m ica ls fo r

oil-base d m uds a nd detergents; so aps; orga nic a cids; and water-ba sed

surfacta nts for water-base d m uds. Products m ay be a nionic (ne gatively

cha rged), no n-io nic (neutral) o r cationic (positive ly charged) chem icals,

de pending o n the application.

Filtrate reducers. Bentonite cla ys, lignite, CMC (sodium

carbox ym ethylce llulose), polya cryla te and pregelatinized starch all serve to

de crease fluid lo ss, a m ea sure of the te ndency o f the drilling fluid’s liquid

phase to pa ss through the filte r cak e into the form ation.

Flocculants. The se are used to increase viscosity for im pro ved hole clea ning,

to incre ase bento nite yield and to clarify or de-wa ter low-solids fluids. Sa lt (o r

brine), hydra ted lim e , gypsum , soda ash, bicarbo nate of soda, sodium

tetraphosphate a nd a cryla m ide -based polym ers m ay be used. They cause

colloida l particles in suspe nsio n to group into bunches or “flocs,” ca using

solids to settle o ut.

Foaming agents. Most often, these are chem icals tha t also act as surfactants

(surface active a gents) to foam in the prese nce o f wa ter. T hese foa m ers

pe rm it air or gas drilling through wa ter-bearing fo rm a tions.

Hydrate suppressants. These are usually alcohol-based a dditives, prim a rily

for use in de epwater/coldwater/rise r environm ents.

Lost circulation materials. The prim ary function o f a lost circula tion additive

is to plug the zo ne of loss back in the form a tion, awa y fro m the bo reho le

face, so tha t subsequent opera tions will not result in additiona l drilling fluid

losses. LCM is fo und in three form s: fiber, flak e, and granular/chem ical

S-ar putea să vă placă și

- 183-019 Eaton Book Rev3 PDFDocument195 pagini183-019 Eaton Book Rev3 PDFnedaÎncă nu există evaluări

- Drilling Tools CatalogDocument96 paginiDrilling Tools CatalogRzvn100% (1)

- U1000 Dash Cam ManualDocument62 paginiU1000 Dash Cam ManualDon BraithwaiteÎncă nu există evaluări

- Programs OvershotsDocument18 paginiPrograms OvershotsDon BraithwaiteÎncă nu există evaluări

- Guidelines for Sidetracking OperationsDocument3 paginiGuidelines for Sidetracking OperationsDon BraithwaiteÎncă nu există evaluări

- GyroDrill Mud Motor Handbook 2013Document103 paginiGyroDrill Mud Motor Handbook 2013Don BraithwaiteÎncă nu există evaluări

- What Is Aniline Point?Document1 paginăWhat Is Aniline Point?Don BraithwaiteÎncă nu există evaluări

- Command Fishing Services Inc.: One Trip Whipstock InformationDocument10 paginiCommand Fishing Services Inc.: One Trip Whipstock InformationDon BraithwaiteÎncă nu există evaluări

- Parts LibraryDocument9 paginiParts LibraryDon BraithwaiteÎncă nu există evaluări

- Drill Bits Geotech Fixed Cutter PDC BitsDocument2 paginiDrill Bits Geotech Fixed Cutter PDC BitsashokÎncă nu există evaluări

- Drill Pipe Specifications SheetDocument3 paginiDrill Pipe Specifications SheetDon BraithwaiteÎncă nu există evaluări

- UsiDocument2 paginiUsibarreiroesquivelÎncă nu există evaluări

- Secure Drive ManualDocument12 paginiSecure Drive ManualDon BraithwaiteÎncă nu există evaluări

- Techmaster Mud Motors Deliver Peak PerformanceDocument5 paginiTechmaster Mud Motors Deliver Peak PerformanceDon BraithwaiteÎncă nu există evaluări

- Filmora9 For Win User Guide PDFDocument115 paginiFilmora9 For Win User Guide PDFAbraham Montesinos VallejoÎncă nu există evaluări

- Air Canada Booking ClassesDocument2 paginiAir Canada Booking ClassesDon BraithwaiteÎncă nu există evaluări

- Shawcor - Guardian InspectionsDocument30 paginiShawcor - Guardian InspectionsDon BraithwaiteÎncă nu există evaluări

- IADC Classification System ExplainedDocument3 paginiIADC Classification System ExplainedDon Braithwaite100% (1)

- Drill Pipe ProtectorsDocument11 paginiDrill Pipe ProtectorsDon BraithwaiteÎncă nu există evaluări

- TX-Registration F-4687 Inspection Standards SummaryDocument2 paginiTX-Registration F-4687 Inspection Standards SummaryMartahanManurungÎncă nu există evaluări

- OWS TDCRT: Top Drive Casing Running ToolDocument2 paginiOWS TDCRT: Top Drive Casing Running ToolDon Braithwaite100% (1)

- Size of Whipstock Vs Mill - 7 CasingDocument1 paginăSize of Whipstock Vs Mill - 7 CasingDon BraithwaiteÎncă nu există evaluări

- Summit API Casing SpecsDocument6 paginiSummit API Casing SpecsDon BraithwaiteÎncă nu există evaluări

- World UTM MapDocument1 paginăWorld UTM MapDon BraithwaiteÎncă nu există evaluări

- Hard Banding GradesDocument1 paginăHard Banding GradesDon BraithwaiteÎncă nu există evaluări

- Float TypesDocument3 paginiFloat TypesDon BraithwaiteÎncă nu există evaluări

- Shawcor - Guardian InspectionsDocument30 paginiShawcor - Guardian InspectionsDon BraithwaiteÎncă nu există evaluări

- Summit API Casing SpecsDocument6 paginiSummit API Casing SpecsDon BraithwaiteÎncă nu există evaluări

- TADPRO User ManualDocument57 paginiTADPRO User ManualDon BraithwaiteÎncă nu există evaluări

- Incoterms 2013Document1 paginăIncoterms 2013Maritza Rodríguez GonzálezÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 201 enDocument2 pagini201 enRyan ZhangÎncă nu există evaluări

- Atoms & MoleculesDocument2 paginiAtoms & MoleculesNavas KappilÎncă nu există evaluări

- Gating System and Feeder Design of Aluminium Alloy (AA6063) Casting For Rectangular ComponentDocument6 paginiGating System and Feeder Design of Aluminium Alloy (AA6063) Casting For Rectangular ComponentPankajÎncă nu există evaluări

- Qin 2005Document8 paginiQin 2005Omkar BordeÎncă nu există evaluări

- Abrasion Resistance of High-Strength Concrete in Hydraulic StructuresDocument8 paginiAbrasion Resistance of High-Strength Concrete in Hydraulic StructuresEjaz RahimiÎncă nu există evaluări

- Kate Angel A. Ragat IIIDocument4 paginiKate Angel A. Ragat IIIK maÎncă nu există evaluări

- Sistem Pelumasan: - ReviewDocument72 paginiSistem Pelumasan: - ReviewUncle MTAÎncă nu există evaluări

- Cold Water Plumbing DesignDocument17 paginiCold Water Plumbing DesignKHA120096 StudentÎncă nu există evaluări

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDocument5 paginiDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaÎncă nu există evaluări

- DRG 5Document1 paginăDRG 5Palak BhatiaÎncă nu există evaluări

- Cong Thuc SonDocument23 paginiCong Thuc Sonvanhung68Încă nu există evaluări

- 04 Steam TrapsDocument8 pagini04 Steam TrapsJoshua Balaram RaoÎncă nu există evaluări

- CH2254 CPC Unit 3 Solution PS3Document15 paginiCH2254 CPC Unit 3 Solution PS3Vignesh KÎncă nu există evaluări

- GrindingDocument60 paginiGrindingGaurav Yadav100% (1)

- Ultra Sanicro35 Datasheet FINAL Digital-1Document6 paginiUltra Sanicro35 Datasheet FINAL Digital-1Vaibhav KaleÎncă nu există evaluări

- TDS Sadecol P 440 - EN Rev 1Document4 paginiTDS Sadecol P 440 - EN Rev 1paosilvisÎncă nu există evaluări

- Polymer Clay Art 281592533574 29Document306 paginiPolymer Clay Art 281592533574 29Ana Stanoevska100% (1)

- Processing Plastics With CO Lasers: Synrad Applications LabDocument27 paginiProcessing Plastics With CO Lasers: Synrad Applications LabJinson KurianÎncă nu există evaluări

- CSE 202.05 Repair of Concrete StructuresDocument118 paginiCSE 202.05 Repair of Concrete StructuresJellyn BaseÎncă nu există evaluări

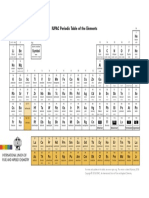

- IUPAC Periodic Table of The Elements: Ti CRDocument1 paginăIUPAC Periodic Table of The Elements: Ti CRMargaux HidalgoÎncă nu există evaluări

- Brochure GC Fuji IX GP EXTRA PDFDocument20 paginiBrochure GC Fuji IX GP EXTRA PDFRifqie al harisÎncă nu există evaluări

- MoRTH 1000 Materials For StructureDocument18 paginiMoRTH 1000 Materials For StructureApurv PatelÎncă nu există evaluări

- Brickbat Coba Rate Analysis As Per CPWDDocument2 paginiBrickbat Coba Rate Analysis As Per CPWDDeepak Kaushik100% (3)

- MOS of Thermoplastic PaintDocument2 paginiMOS of Thermoplastic PaintL V Laxmipathi Rao100% (1)

- Guidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngDocument19 paginiGuidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngFinnFan8Încă nu există evaluări

- Sustainable TextilesDocument23 paginiSustainable TextilesGupta KiraÎncă nu există evaluări

- Agro SurfactantsDocument4 paginiAgro SurfactantsJanakiram Yarlagadda100% (1)

- Analysis of HoneyDocument14 paginiAnalysis of HoneyMomo PlayerÎncă nu există evaluări

- CBSE Class 10 Chemistry Worksheet - Metals and Non-MetalsDocument2 paginiCBSE Class 10 Chemistry Worksheet - Metals and Non-MetalsNishant Singh100% (1)

- Childers PDS CP 70 R0719Document2 paginiChilders PDS CP 70 R0719Maikol Cedeño CerdasÎncă nu există evaluări