Documente Academic

Documente Profesional

Documente Cultură

Manual IRD 256

Încărcat de

Briseidaa MartinezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manual IRD 256

Încărcat de

Briseidaa MartinezDrepturi de autor:

Formate disponibile

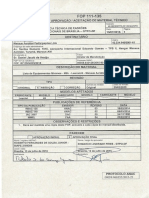

Model 256 Balancer / Analyzer Operator Manual

Model 256

Balancer / Analyzer

Operator Manual

P/N 46966 Page 1 of 92

Model 256 Balancer / Analyzer Operator Manual

1 The Manual ____________________________________ 7

2 Important User Information ______________________ 7

3 Instrument Layout _____________________________ 15

3.1 Interface Panel _____________________________ 15

3.2 Enter Keys ________________________________ 16

3.3 Arrow keys ________________________________ 16

3.4 Alpha-Numeric Keypad ______________________ 16

3.5 PCMCIA Card Port _________________________ 17

3.6 On / Off___________________________________ 17

3.7 Touch Screen ______________________________ 17

3.8 Softkeys __________________________________ 17

3.9 Indicator Lights_____________________________ 18

3.10 Navigating The Screen _______________________ 18

4 Main Menu Screen _____________________________ 22

4.1 Balancing _________________________________ 23

4.2 Analysis __________________________________ 28

5 Balancing _____________________________________ 35

5.1 Balance Setup Screen ________________________ 35

5.2 Advanced Setup Screen ______________________ 38

5.3 “Run” Screens______________________________ 39

5.4 Add Trial Weight Screen _____________________ 41

5.5 Solution Screen_____________________________ 41

5.6 Memory Screen_____________________________ 43

5.7 Go To Screen ______________________________ 47

5.8 Weight / Vibration Summary Screen ____________ 48

5.9 Combine Weights Screen _____________________ 50

5.10 The Trial Weight Estimator ___________________ 53

P/N 46966 Page 2 of 92

Model 256 Balancer / Analyzer Operator Manual

6 Analysis ______________________________________ 54

6.1 Standard w/accl _____________________________ 54

6.2 User – Defined _____________________________ 55

6.3 Measure Speed _____________________________ 66

6.4 Review Data _______________________________ 66

7 Instrument Setup ______________________________ 67

7.1 Analysis Memory ___________________________ 67

7.2 Timeout ___________________________________ 67

7.3 IrDA _____________________________________ 67

7.4 Baud Rate _________________________________ 67

7.5 Data Format _______________________________ 68

7.6 Data / Time ________________________________ 68

7.7 Memory___________________________________ 68

8 General Information ____________________________ 68

8.1 Print Setup screen ___________________________ 68

8.2 Configuration Screen ________________________ 70

8.3 Battery Level Information_____________________ 71

8.4 Display Features ____________________________ 72

8.5 Help Screens _______________________________ 73

8.6 Display Contrast ____________________________ 73

8.7 Resume Operation___________________________ 74

8.8 ICP Fail Warning ___________________________ 74

8.9 Key Codes _________________________________ 74

8.10 Hardware Reset _____________________________ 75

9 An Instrument “Walk Through”__________________ 76

10 Model 256 Summary Specifications _______________ 89

P/N 46966 Page 3 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 3-1 Instrument Layout..................................................... 15

Figure 3-2 Analysis User Setup screen....................................... 19

Figure 4-1 Main Menu showing BALANCING selected........... 22

Figure 4-2 Balance Run Flow Chart.......................................... 26

Figure 4-3 Change name box...................................................... 31

Figure 4-4 The Review Analysis Data screen ............................ 34

Figure 5-1 The Balance Setup screen ......................................... 36

Figure 5-2 Advanced Setup screen ............................................. 38

Figure 5-3 Run Screen, this example shows an initial run for a

simultaneous 2-plane balance job............................................... 40

Figure 5-4 Add Trial Weight screen, note how the Trial Weight

estimator has been used to calculate a suitable trail weight mass

.................................................................................................... 41

Figure 5-5 Solution Screen example – Correction weight in this

case ............................................................................................. 42

Figure 5-6 The Memory screen – shows Internal memory selected

.................................................................................................... 43

Figure 5-7 Alternative Memory screen softkeys ........................ 44

Figure 5-8 The Save As… screen............................................... 45

Figure 5-9 Save As type-in box .................................................. 45

Figure 5-10 Go to… screen ........................................................ 47

Figure 5-11 Vibration Summary Table screen ........................... 49

Figure 5-12 Weights Summary Table screen ............................. 50

Figure 5-13 Combine Weights screen – before combining ........ 51

Figure 5-14 Combine Weight screen – after combining all ....... 52

Figure 5-15 Trial Weight Estimator screen ................................ 53

Figure 6-1 Analysis menu showing STANDARD selected ....... 54

P/N 46966 Page 4 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 6-2 Analysis User Setup, Change Name option

highlighted. ................................................................................. 55

Figure 6-3 Change Name type-in box......................................... 56

Figure 6-4 A spectrum showing an RSS overall (value on LHS at

top – 0.585G) .............................................................................. 57

Figure 6-5 An example of a spectrum signature ......................... 58

Figure 6-6 An example of a time signature................................. 59

Figure 6-7 An example of a phase signature............................... 60

Figure 6-8 An example of an orders signature............................ 61

Figure 6-9 Review Analysis Data screen – second point has been

re-named using Analysis User Setup Change Name option ....... 66

Figure 8-1 The Print Setup screen............................................... 69

Figure 8-2 Battery level popup box ............................................ 71

Figure 8-3 Help screen................................................................ 73

Figure 8-4 Resume Operation popup screen............................... 74

Figure 8-5 Rear face of instrument with hard reset aperture

indicated ...................................................................................... 75

Figure 9-1 Instrument layout ...................................................... 76

Figure 9-2 Main Menu screen..................................................... 77

Figure 9-3 Setup screen .............................................................. 77

Figure 9-4 Analysis Menu .......................................................... 78

Figure 9-5 Help Contents Menu.................................................. 78

Figure 9-6 Current Point Info screen .......................................... 78

Figure 9-7 Analysis Menu .......................................................... 79

Figure 9-8 Speed Readout screen................................................ 79

Figure 9-9 Analysis Menu .......................................................... 80

Figure 9-10 Instrument Configuration Menu.............................. 80

Figure 9-11 Analysis User Setup ................................................ 80

Figure 9-12 Signature measurement display............................... 81

P/N 46966 Page 5 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 9-13 Review Analysis Data screen.................................. 81

Figure 9-14 Review Signature screen......................................... 82

Figure 9-15 Example of cursor positioning ................................ 82

Figure 9-16 Example of peak search .......................................... 82

Figure 9-17 Harmonic cursor function ....................................... 83

Figure 9-18 Example of zoom function...................................... 83

Figure 9-19 Example of boost function ...................................... 83

Figure 9-20 Balance Setup Menu ............................................... 84

Figure 9-21 Advanced Balance Setup Menu .............................. 84

Figure 9-22 Initial Run screen .................................................... 84

Figure 9-23 Add Trial Weight screen......................................... 85

Figure 9-24 Trial Run screen...................................................... 85

Figure 9-25 Correction Weight screen ....................................... 85

Figure 9-26 Correction Run screen............................................. 86

Figure 9-27 Balance Trim........................................................... 86

Figure 9-28 Trim Weight Solution ............................................. 86

Figure 9-29 Trim Run screen...................................................... 87

Figure 9-30 Vibration Summary Table....................................... 87

Figure 9-31 Weights Summary Table......................................... 87

P/N 46966 Page 6 of 92

Model 256 Balancer / Analyzer Operator Manual

1 The Manual

This manual has 10 sections including this one. Sections 3

Instrument Layout & 4 Main Menu Screen are tutorial in style.

The exercises set out in these sections are very simple and the

intent is to get you up and running with the instrument as quickly

as possible. They touch on the main features of the instrument

and hopefully after working through them with the instrument at

hand, you’ll have a good mental picture of the unit’s basic

architecture and layout, and a little experience of how to navigate

a touch-screen instrument.

Sections 5 Balancing, 6 Analysis, 7 Instrument Setup, and 8

General Information are more reference – like in style and you

may have to dip into these for a fuller explanation of some of the

options and features available with your IRD Model 256 Balancer

/ Analyzer.

2 Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable

laws, regulations, codes and standards.

The illustrations, charts, and examples shown in this guide are

intended solely for purposes of example. Since there are many

variables and requirements associated with any particular

installation, Entek IRD International Corporation does not

assume responsibility or liability (to include intellectual property

P/N 46966 Page 7 of 92

Model 256 Balancer / Analyzer Operator Manual

liability) for actual use based upon the examples shown in this

publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Entek IRD

International Corporation, is prohibited.

IRD Balancing is a business unit of Entek IRD International

Corporation, a Rockwell Automation company.

Microsoft and Windows are registered trademarks of the

Microsoft Corporation.

All other trademarks are the property of their respective holders

and are hereby acknowledged.

P/N 46966 Page 8 of 92

Model 256 Balancer / Analyzer Operator Manual

ENTEK IRD INTERNATIONAL CORPORATION

General Terms and Conditions

1. CONTRACT. When Customer accepts a Quotation from Entek IRD International

Corporation or an affiliate (the entity issuing the quotation being "Entek IRD") by

issuance of a purchase order or otherwise and Entek IRD accepts the order,

Customer is deemed to have agreed to all the Terms and Conditions contained

herein. Unless otherwise approved in writing, the acceptance of Entek IRD is

expressly conditioned upon Customer accepting these Terms and Conditions, and

any different or additional terms and conditions contained in Customer's order or

related documents are expressly objected to by Entek IRD and not binding upon it.

Entek IRD reserves the right to accept or reject all orders received by it and all

orders may only be accepted at the contracting office of Entek IRD located in

Ohio. Entek IRD may accept in writing, by commencement of performance or

otherwise.

2. QUOTATIONS. All quotations expire automatically thirty days from date of

quotation or earlier by notice from Entek IRD. Unless otherwise noted in writing

by Entek IRD, all prices are F.O.B. the place of origin for domestic shipments and

Ex Works (as defined in INCOTERMS 1990) for international shipments; and risk

of loss in transit is on Customer. Prices do not include any applicable taxes,

however designated, levied or based upon the goods or services being quoted.

Customer agrees to pay all such taxes or provide acceptable evidence of exemption

therefrom.

3. TIMING. All delivery/shipping and service dates stated by Entek IRD are

approximate dates only and estimated in good faith to the best of Entek IRD's

ability and are dependent upon Entek IRD's prompt receipt of all necessary

information from Customer. Time shall not be deemed to be of the essence in

Entek IRD's performance of this agreement, and no penalty clause of any

description in any specification or order will be effective unless specifically

approved in writing by an authorized officer of Entek IRD. In any event

delivery/shipping and service dates are always quoted subject to unavoidable

delays due to causes beyond Entek IRD's control including but not limited to

strikes, casualty, war, acts of God, systems failure or government action.

4. TERMS. Payment terms for domestic orders are net 10 days from date of invoice,

unless otherwise provided in the quotation. For international orders, Entek IRD

reserves the right to specify prepayment, letter of credit, or payment net 10 days

from the date of invoice. Each shipment shall be considered a separate and

independent transaction and payment must be made accordingly. If the financial

P/N 46966 Page 9 of 92

Model 256 Balancer / Analyzer Operator Manual

condition or credit of Customer at any time in the judgment of Entek IRD, does

not warrant shipment of goods ordered, Entek IRD may at its option require full

payment prior to shipment or refuse to ship and terminate any order outstanding

without liability to Entek IRD. If any sum is not paid by Customer when due,

Entek IRD shall not be obligated to continue performance. If any amount is not

paid when due, to the extent permitted by law a late fee of 1% per month (or any

part thereof) shall be charged on past due amounts until paid.

5. CONFIDENTIALITY. If Customer data comes into Entek IRD's possession, Entek

IRD shall use the same level of care to maintain the confidentiality of that data

which Entek IRD uses for its own confidential information. Subject thereto, Entek

IRD may use data in its possession to compile and maintain commercial

machinery information databases in which the origin of specific data is not

identifiable by users. Such databases shall be the sole property of Entek IRD.

6. CANCELLATION. Once accepted by Entek IRD, an order is not subject to

cancellation in whole or in part by Customer without Entek IRD's prior written

consent. Any such cancellation shall be subject to a cancellation charge as

determined by Entek IRD to cover any loss that may be incurred by Entek IRD as

a result of such cancellation, including without limitation a 25% restocking charge

for standard products.

7. CUSTOMER RESPONSIBILITIES. Customer shall be solely responsible for the

accuracy and adequacy of the information provided to Entek IRD, and Entek IRD

shall not be liable for any damages resulting from the loss, disclosure or

inaccuracy of such information. Customer shall, for those contracts which include

on-site installation, have the installation site prepared at its expense prior to the

scheduled installation date to enable Entek IRD to promptly deliver and

commence installation. The products are not for use in or with any nuclear

facility, unless the Quotation expressly permits such use; and Customer shall

indemnify and hold Entek IRD harmless from all liability (including such liability

resulting from Entek IRD's negligence) arising out of such improper use.

Customer shall not send or use the products outside the United States except in

compliance with all applicable law, including U.S. export regulations and

restrictions.

8. SOFTWARE AND SERVICES DOCUMENTS. If any computer software, whether

incorporated into a piece of equipment ("firmware"),or provided separately, and

related user documentation in any medium (collectively referred to as "Software")

are included in the contract, the terms of the Entek IRD Standard Software License

Agreement shall govern the contract with respect to Software. If any services other

than oil analysis services are included in the contract, the Entek IRD Standard

Field Engineering Services Terms and Conditions shall govern such services.

P/N 46966 Page 10 of 92

Model 256 Balancer / Analyzer Operator Manual

Those documents are available to Customer upon request, and Customer is

responsible to obtain and read the Standard Software License Agreement and the

Standard Field Engineering Services Terms and Conditions.

9. LIMITED WARRANTIES AND REMEDIES. A. Entek IRD warrants to Customer

(and not anyone else) that (i) all products manufactured by Entek IRD shall be free

of defects in materials and workmanship under normal conditions for a period of

one (1) year from the date of shipment (except that items with limited life such as

batteries and lamps are warranted for 90 days from date of shipment) and that (ii)

services will be free from defects in workmanship under normal conditions, for 90

days from performance. With respect to performance related in any way to the

passage of time to the year 2000 and beyond, or the occurrence of a leap year,

Entek IRD does not make any representation or warranty; Entek IRD has issued a

Year 2000 readiness disclosure statement, which is available to Customer upon

request.

B. With respect to any Entek IRD product or service that fails to satisfy the

limited warranty provisions in this Section, as Customer's exclusive remedy, and at

Entek IRD's option, Entek IRD will repair or replace the product or refund its

purchase price or refund the purchase price of the service, provided that any defect

is brought to the attention of Entek IRD within the warranty period. To qualify for

this warranty concerning a product Customer must return the defective product to

Entek IRD's designated facility freight prepaid, and after repair or replacement

Entek IRD will return the product freight prepaid; or, if in Entek IRD's opinion

the product is impractical to ship, Customer shall be charged for labor,

transportation and subsistence expenses for the service representative(s) providing

the warranty work at Customer's site. Entek IRD alone will be authorized to

furnish or arrange for repairs or replacements.

C. The above limited warranties do not apply, and no warranty, either express or

implied, shall be applicable, (a) to damage resulting from accident, alteration,

misuse or abuse, harmful conditions, systems failure or Act of God; (b) if the

product is not installed, operated and maintained according to procedures

recommended by Entek IRD; or (c) if the Entek IRD serial number is obliterated.

In no case shall the limited warranty extend to defects in materials, components, or

services furnished by third parties or to the repair or installation of the product

performed by third parties. The above warranties do not extend to any products

sold "as-is" or "as-inspected;" no warranties, either express or implied, are made

with respect to such products.

D. Entek IRD makes no representations or warranties to Customer, or anyone else,

with respect to products manufactured by a third party. Any warranties of the

P/N 46966 Page 11 of 92

Model 256 Balancer / Analyzer Operator Manual

third party manufacturers shall run directly to Customer to the extent permitted by

law and Entek IRD shall have no liability therefor.

E. The limited warranties in this Section constitute Entek IRD's entire warranty as

to the products and services provided hereunder. ENTEK IRD HEREBY

DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING CONFORMITY TO ANY REPRESENTATION OR

DESCRIPTION AND INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSES

WHATSOEVER.

10. EXCLUSIVE REMEDIES AND LIABILITY LIMITATION. THE REMEDIES

PROVIDED HEREIN ARE CUSTOMER'S SOLE AND EXCLUSIVE

REMEDIES, AND ENTEK IRD'S EXCLUSIVE LIABILITY WHETHER

ARISING IN CONTRACT, TORT (INCLUDING NEGLIGENCE), STRICT

LIABILITY OR ANY OTHER LEGAL THEORY. CUSTOMER AGREES

THAT NO OTHER REMEDY (INCLUDING, BUT NOT LIMITED TO,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOST PROFITS, LOST

SALES, LOST PRODUCTION, OVERHEAD, LABOR, INJURY TO PERSON

OR PROPERTY, OR ANY OTHER INCIDENTAL LOSS) SHALL BE

AVAILABLE TO CUSTOMER. THIS ALLOCATION OF RISK IS

REFLECTED IN THE PRICES OF THE PRODUCTS AND SERVICES. ENTEK

IRD'S MAXIMUM LIABILITY HEREUNDER ARISING FROM ANY CAUSE

WHATSOEVER SHALL BE LIMITED TO THE PURCHASE PRICE OF THE

PRODUCTS AND SERVICES IN QUESTION. Any suit related to this

Agreement, on any legal theory, must be commenced within one year after the

cause of action accrues.

11. TITLE AND LIEN RIGHTS. Each product shall remain personal property

regardless of how it is affixed to Customer's real property and Entek IRD reserves

a purchase money security interest in the product until the purchase price has been

fully paid. Customer agrees to execute, and hereby appoints Entek IRD as its

attorney-in-fact to execute on Customer's behalf, any documents requested by

Entek IRD which are necessary for attachment and perfection of its security

interest. If Customer defaults, Entek IRD shall have all the rights of a secured

creditor under the Uniform Commercial Code as enacted in Ohio.

12. OTHER TERMS. These terms and conditions and any issue, claim or dispute

arising hereunder shall be interpreted under and governed in all respects by the

internal laws of the State of Ohio, and not by the 1980 U.N. Convention on the

International Sale of Goods. These terms and conditions and the written quotation

to which they relate constitute the entire contract between the parties, and

supersede all other oral or written statements of any kind whatsoever made by the

P/N 46966 Page 12 of 92

Model 256 Balancer / Analyzer Operator Manual

parties or their representatives. Waiver by Entek IRD of strict compliance with any

one or more of these Terms and Conditions is not to be considered a continuing

waiver or a waiver of any other term or condition. No statement purporting to

modify any of these terms or conditions shall be binding unless expressly agreed

to in writing signed by an officer of Entek IRD and by Customer.

P/N 46966 Page 13 of 92

Model 256 Balancer / Analyzer Operator Manual

Contacting Customer Support

If you are under warranty or have an active ESAFE Agreement,

Rockwell Automation Integrated Condition Monitoring Technical

Support provides a variety of customer support services for Entek

products. In the United States you can reach the Technical

Support Hotline by dialing 1-800-368-3547 Monday through

Friday 8:00 a.m.–7:00 p.m. eastern time. You can send a fax

detailing your questions or comments 24 hours a day by dialing

(513) 576-4213. Please address the fax to the Technical Support

department. You can also reach Technical Support from your

computer.

§ Send questions to support@entek.com

§ Send suggestions and comments to suggestions@entek.com

§ Visit our IRD Balancing web site at

http://www.irdbalancing.com

For support outside of the United States, please contact your local

Rockwell Automation Asset Management representative or the

nearest Rockwell Automation office. You can find a list of

Rockwell Automation Asset Management offices on our web site.

If your local support representative is not available, please

contact the U.S. Technical Support department.

P/N 46966 Page 14 of 92

Model 256 Balancer / Analyzer Operator Manual

3 Instrument Layout

As a first step, it will be necessary for you to familiarize yourself

with the Model 256 Balancer / Analyzer instrument layout in

terms of operator interface.

Figure 3-1 Instrument Layout

Shown in Figure 3-1 is an instrument drawing, with key areas

indicated.

3.1 INTERFACE PANEL

The interface panel is on the top face of the instrument. The panel

includes two signal input channels, a built-in laser tachometer, a

connection for the external charger (which also allows for an

P/N 46966 Page 15 of 92

Model 256 Balancer / Analyzer Operator Manual

external trigger), and a computer port for loading the operating

system and interfacing to the printer.

3.2 ENTER KEYS

The Enter keys (in Figure 3-1 the right-hand key is obscured by

the operator’s thumb) are placed prominently on in the “ears” of

the instruments. These are typically used for confirming status,

entering a data field, or storing data. These keys are also

sometimes called the “fire” keys.

3.3 ARROW KEYS

An array of four keys laid out in an ellipse pattern. These keys are

a primary method of navigating the instrument.

3.4 ALPHA-NUMERIC KEYPAD

The instrument keypad is a 4 by 3 array of keys containing the

numerals [0 – 9] plus the “.” and the “+ –” keys. The keys [2 – 9]

have associated with the groups of letters.

These keys are used for character entry in certain text entry

screens. The method is to cycle through the character sequence by

repeated presses of the key until the correct character is reached.

Note the sequence begins with the numeric value. Therefore to

type, for example, the character “Z” the “9” key would be pressed

5 times in succession. The resulting sequence would be

“9WXYZ”. To proceed to the next character either hit the right

arrow key, or pause momentarily and the instrument will

automatically move on. A backspace softkey is available to

correct mistakes.

P/N 46966 Page 16 of 92

Model 256 Balancer / Analyzer Operator Manual

3.5 PCMCIA CARD PORT

The PCMCIA card port is accessible via a hatch on the bottom

face of the instrument. The recommended type of card for data

storage is the ATA linear flash card.

3.6 ON / OFF

The on / off button is slightly recessed to prevent accidental shut

down, and is further protected by a hold down feature. That is,

you need to hold the button down for a few seconds for the unit to

turn off. Switching on is immediate.

3.7 TOUCH SCREEN

The LCD screen is a Quarter VGA resolution display, complete

with touch screen. Along the bottom of the screen is an area

reserved for 4 softkeys, sometimes referred to as F1, F2, F3, and

F4.

3.8 SOFTKEYS

As mentioned above, the bottom part of the screen is reserved for

4 softkeys, which are activated by touching the screen with your

stylus directly over the key. Not all screens have all 4 keys, and

the function of each key can vary depending on the screen.

For consistency, the left-hand key is normally the Help button,

and the right-hand key is normally the Esc (escape) button.

P/N 46966 Page 17 of 92

Model 256 Balancer / Analyzer Operator Manual

3.9 INDICATOR LIGHTS

Directly above the display is a panel for indicator lights to show

measurement status (red is displayed when the data has not

settled and the instrument is ranging, amber indicates that settling

is in progress, and green indicates good, stable, data.)

3.10 NAVIGATING THE SCREEN

This section is intended as a quick tutorial on the do’s and don’ts

of touch screen navigation for the novice. It also outlines some

naming conventions used throughout the manual so please spend

a few moments reading over it. It also contains a few tips and

tricks you may not be aware of and that you hopefully will find

useful.

A dialog screen is a screen where you interact, or have a dialog,

with the unit. A typical dialog, in this case the Analysis User

Setup screen, is shown in Figure 3-2.

P/N 46966 Page 18 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 3-2 Analysis User Setup screen

3.10.1 General Layout

The top part of the screen is called the caption bar. This contains

the title of the screen and in this manual, to avoid confusion;

we’ll always call a screen by the name shown in the caption bar.

At the bottom of the screen are the softkeys; in this example there

are only two, the Help and Esc. We often call the softkeys the “F”

keys, for example the Help is F1 and Esc is F4.

On the right of this particular screen is a scroll bar. These only

appear when the screen is not large enough to display all the

necessary text, so some screens will not have them.

P/N 46966 Page 19 of 92

Model 256 Balancer / Analyzer Operator Manual

The highlight feature indicates the item that is active or selected.

On the left of the screen is a column of variables. These are

generally measurement parameter and such like.

On the right of the screen is the currently selected option, or

value, for each variable. There are two main mechanisms for

changing a variable value. These are:

The drop down list presents a list of all the possible values from

which you can select.

A type in box allows you to enter a numeric value using the

keypad.

3.10.2 Touch Screen Navigation

The unit has a touch screen; this means you can select an item by

touching the screen with a stylus directly over the item you want.

When you touch an item in the left – hand column, that is, a

variable you highlight it. This is now the active item.

When you touch one of the items in the right – hand column you

activate its change mechanism. For example, if you touch the

screen directly over the item “RMS”, a drop down list appears

containing the all the possible options for “Detection”. You can

select another detection method, say, “True Peak”, by touching

directly over the “True Peak” item. This should highlight True

Peak, now touching elsewhere on the screen will close the drop

down list, and the item will be selected. Be careful at this point

because you may accidentally open another drop down list or

type in box. This can be irritating so it’s best to always close a

P/N 46966 Page 20 of 92

Model 256 Balancer / Analyzer Operator Manual

drop down list or type in box by touching on the left – hand

column.

Changing a variable value using a type in box is similar except

you must use the keypad to type in the value you want.

3.10.3 Numeric Keypad and Arrow Keys Navigation

The same navigation can be accomplished using the numeric

keypad and the arrow keys.

For example, assuming you start with the screen as displayed in

Figure 3-2, that is with the “Change Name” item highlighted,

pressing the down arrow key 6 times will bring you to the

“Detection” item. Now press the right arrow key and a drop down

list containing all possible detection type opens. Use the up and

down arrow keys to highlight your choice, and finally, press the

left arrow key to make your selection.

You can also select an item in a drop down list by using the

numeric keypad. For example, open up the “Detection” drop

down list and press 4. The “True Pk-Pk” item should now be

highlighted. Note that the indexing is 0 based, that is, the first

item on the list is numbered zero!

3.10.4 Final Thoughts

Everyone develops his or her own preferred style of working with

a touch screen unit. Some prefer to use the keypad and arrow

keys as much as possible; others tend towards exclusive use of

the touch screen and only use the keypad when absolutely

necessary. A couple of tips are offered up for you to experiment

with.

P/N 46966 Page 21 of 92

Model 256 Balancer / Analyzer Operator Manual

If a screen has a vertical scroll bar and you want to get to an item

at the bottom of the screen, rather than use the arrow keys to

scroll down, touch on the screen just above the bottom arrow on

the scroll bar.

The signature screens are touch sensitive, so you can move the

cursor by touching at the point you want the cursor at. Depending

on your accuracy you may not get it exact, but a few left / right

arrow key presses can be used to trim the cursor position exactly.

4 Main Menu Screen

The Main Menu screen appears as shown in Figure 4-1. It

contains three options, which you can highlight by using either

the touch screen or arrow keys. Hit an Enter key to select an

option.

Figure 4-1 Main Menu

showing BALANCING

selected

The remainder of this

section will examine the

balancing and analysis

options.

The style is a simple

tutorial exercise, which is

intended to familiarize

you with the operation of

the unit and to build your

confidence in the

instrument.

P/N 46966 Page 22 of 92

Model 256 Balancer / Analyzer Operator Manual

These simple exercises are NOT intended to teach the principles

of balancing, or analysis.

4.1 BALANCING

4.1.1 A Simple Balancing Run

This section will give a quick run through on a balancing job. It is

not intended as an in depth tutorial, but, rather, to give a feel for

the instrument and the balancing application. The circled

numbers, for example À, refer to the Balancing Run Flow Chart

shown in Figure 4-2.

A trigger source is required to run through this example.

Start up the balancing application by highlighting BALANCING

in the Main Menu and hitting an Enter key. If this is the first time

in balancing and no previous jobs have been stored, the

instrument should go to the Balance Setup screen, À.

Use this screen and the Advanced Setup screen (hit the Options

softkey to enter) to set up the various parameters for the job. As

this is a simple exercise, we will only adjust a couple of them.

In the Balance Setup screen set the number of planes to 2, the

Trigger Type to ext Analog, Ext Trig slope to +ve and Trigger

Level to 2V. Now go to the Advanced Setup screen and set the

Solution to Dynamic and for ←Plane→ 1 set the Input Chan. to X

and Coupling to AC, then for ←Plane→ 2 set the Input Chan. to

Y, and the Coupling to AC. Hit the Apply softkey and return to

the Balance Setup screen.

P/N 46966 Page 23 of 92

Model 256 Balancer / Analyzer Operator Manual

Hit an Enter key and a popup dialog appears with the query

“Transducers Attached in Planes 1 and 2?” Hit the OK softkey or

just hit an Enter key again. The measurement will start, Á.

When you’re happy with the quality of the measurements, hit an

Enter key and the Add Trial Weight screen, Â, will appear. A

trial weight estimator is available by pressing the Estimate

softkey, and this allows you to enter the mass supported in this

plane and provides an estimate for the trial weight.

Having added the trial weight, hit the enter key and the

instrument takes a trial run measurement, Ã. When your happy

with the quality of the measurement, hit the Enter key again, the

result is stored, and a popup dialog appears asking, “Is the trial

weight in plane X left attached?” ( X is either 1 or 2), Ä. Hit

whichever softkey is relevant.

Steps Â, Ã, and Ä are repeated for the second plane if the job is 2

plane.

The Correction Weight Solution screen, Å, appears after all trial

runs have been completed. This screen allows you to modify

various settings such as splitting the weight and changing the

radius, as well as displaying the results for each plane. You vary

these settings to suit your particular balancing job, and the

instrument’s computation engine generates the correct mass and

angle results. When your happy with the result and the correction

weight has been applied, hit the Enter key and the unit takes a

Correction run measurement, Æ, to verify success of the balance.

Hit an Enter key when you’re satisfied with the quality of the

measurement and a pop dialog appears with the query, “Do you

wish to trim the residual?”, Ç.

P/N 46966 Page 24 of 92

Model 256 Balancer / Analyzer Operator Manual

Hit the Yes softkey and a Trim #n weight solution screen, È

similar to the Correction Weight Solution screen appears. Again

you can modify various parameters to suit your particular

balancing job, and then proceed to a Trim #n run, É, to measure

the success of the trim.

P/N 46966 Page 25 of 92

Model 256 Balancer / Analyzer Operator Manual

À Balance &

Advanced Setup

Á Initial Run

Add trial weights

Do for all à Trial Run

planes

Ä Trial weights

left in place?

Å Correction Weight

Solution

Æ Correction

Run

NO

Ç Trim #n Residuals? Quit

YES

È Trim #n Weight

Solution

É Trim #n Run

Figure 4-2 Balance Run Flow Chart

P/N 46966 Page 26 of 92

Model 256 Balancer / Analyzer Operator Manual

Hit the No softkey and you Quit this particular balance job for

now. Save the job and you can come back to it later. The next

section will show you how to save the job.

4.1.2 Saving the Balancing Run

It is possible to save a balance run from the either of the Solution

screens. Hit the Memory softkey and the instrument goes to the

Memory screen. This screen lists all the saved balance jobs on the

instrument, and the date they were last saved. Hit the Save

softkey and the popup dialog presents you with the opportunity to

save the present balance job as –new– or as one of the currently

saved jobs (if any exist).

If you select a currently save balance job and hit OK, this job will

be overwritten.

Selecting –new– and hitting the OK softkey causes a popup

dialog to appear with a default name in the format BALXXX,

where XXX is a number in the range 001 – 999.

This dialog also allows you to type in the name of the new

balance job using the keypad. As an example, to call the new

balance job NEWJOB, enter the following key press sequence.

Hit Clear to erase ALL the current characters in the dialog. Hit

the 6 key three time in succession, hit the 3 key three times in

succession, hit the 9 key twice in succession, hit the 5 key twice

in succession, hit the 6 key four times in succession, and finally

hit the 2 key 3 times in succession.

If you make a mistake use the Bksp (Backspace) softkey to erase

the error and re-enter the letter.

P/N 46966 Page 27 of 92

Model 256 Balancer / Analyzer Operator Manual

4.2 ANALYSIS

The analyzer is designed to allow you to determine the root cause

of a vibration fault before committing yourself to a balancing job.

For example you can use the analyzer to help determine if

vibration is due to misalignment rather than unbalance.

This section presents some simple exercises that will familiarize

you with the look and feel of the analyzer. It is not intended as an

in-depth tutorial on the analysis of mechanical vibration, but,

rather, as an introduction to the Model 256 analyzer.

4.2.1 Configuring The Analysis Measurement

From the Main Menu, see Figure 4-1, highlight the ANALYSIS

option and hit an Enter key. Now hit the Config softkey (F3) and

the Instrument Configuration screen is displayed. The

configuration screen is used to setup your preferences, and for his

example we’ll set the Freq. Units, Acquisition and Autoranging

preferences.

Select the Freq. Units item in configuration list by either scrolling

using the arrow keys or touch on the screen using your stylus. Hit

the right arrow key a drop down list containing the option will

appear. Again, use the arrow keys or the touch screen to select the

CPM option and confirm your selection by hitting the left arrow

key. The instrument will now display all frequency information

annotated as CPM. This includes spectrum signatures and filter

ranges.

P/N 46966 Page 28 of 92

Model 256 Balancer / Analyzer Operator Manual

The instrument can be configured to acquire data in either single

shot or continuous mode. When configured to acquire data

continuously the instrument will repeatedly take the measurement

you setup. This feature is useful if you want to track a slowly

varying signal for instance. To set the instrument to continuous,

highlight the acquisition item in the configuration list and hit the

right arrow key. This will open the drop down list containing the

two options. Select the continuous option and hit the left arrow

key. The instrument is now configured to acquire data

continuously.

Your Model 256 is equipped with a 20 bit analog – to – digital

converter. This converter has such a large dynamic range that it is

possible to trade-off some of this dynamic range in exchange for

speed of autoranging. The autoranging option allows you choose

which of these options you want. Selecting the aggressive option

trades dynamic range for speed, which may be important if you

need to take many measurements. This allows the instrument to

spend more time autoranging, and hence it is more likely to select

the ideal range to match the signal. To set the autoranging,

highlight the Autoranging item in the configuration list and hit

the right arrow key. Select the option from the drop down list by

scrolling with the up down arrow keys until the item you want is

highlighted, and hit the left arrow key to confirm your selection.

To return to the Analysis menu hit the Apply softkey (F4).

4.2.2 A Simple Analysis Job

From the Analysis menu there are three ways you can take a

measurement. This section will examine how to setup and take a

measurement using the User-defined option, as this is the most

P/N 46966 Page 29 of 92

Model 256 Balancer / Analyzer Operator Manual

involved. The Standard W/ACCL, (section 6.1) and Measure

Speed, (section 6.3) options are not examined here.

In this simple example, the requirement is to take three spectral

measurements, one in each plane: that is horizontal, vertical, and

axial. The operating condition is known to be approximately 3600

RPM. Therefore, we decide to use an Fmax of 38400 CPM (640

Hz). Since our sensor is an accelerometer, we need to select an

integrated measurement in order to obtain velocity. We also need

to use a high pass filter because all integrated measurements

require the use of a high pass filter, and use ICP for the

accelerometer.

To setup the measurement begin by opening the Analysis User

Setup screen. Select the User – defined option on the Analysis

screen and press an Enter key. Assume the measurements are to

be made in the sequence, horizontal, vertical, and finally axial. It

is good practice to name important data, so highlight the Change

Name item and press the right arrow key. Only a single level is

available so select Point and hit an Enter key.

The change name box shown in Figure 4-3 will appear.

P/N 46966 Page 30 of 92

Model 256 Balancer / Analyzer Operator Manual

This screen allows you to

re-name a measurement to

a more meaningful name.

Figure 4-3 Change name box

Hit the Clear softkey and then enter the abbreviated name HOR1

by hitting the key press sequence:

hit the “4” key three times in succession then the right arrow key,

hit the “6” key four times in succession then the right arrow key,

hit the “7” key four times in succession then the right arrow key,

hit the “1” key once.

Press the OK softkey to accept the name, or if you make a

mistake hit the Bksp (backspace key), and reenter the correct

letter. This method of re – naming may seem cumbersome at first

but you soon acquire a surprising degree of dexterity and it

becomes second nature.

To set up the measurement proper begin with setting the

Coupling to ICP. Highlight the Coupling item and open the drop

down list of option by hitting the right arrow key. Scroll down the

list of option until the ICP option is highlighted and then confirm

your selection by hitting the left arrow key.

As we require a spectrum, set the Collection option to Sig. only.

Do this by highlighting the Collection item and hitting the right

arrow key. Select the Sig. only option and hit the left arrow key

to confirm.

P/N 46966 Page 31 of 92

Model 256 Balancer / Analyzer Operator Manual

Set the Display Format item and hit the right arrow key, now

select the Spectrum option from the drop down list and hit the left

arrow key to confirm you selection. Incidentally, if the correct

option is displayed along side the item, then it is already setup

and you don’t have to do anything.

Setup an integrated measurement; we’ll use IPS, by highlighting

the Units item and hitting the right arrow key. From the drop

down list that appears select the A→V (IPS) option and hit the

left arrow key to confirm your selection.

Next, set the high pass filter by highlighting the High-pass filter

item and hitting the right arrow key. Select the 318CPM option

and hit the left arrow key to confirm.

Finally, set the Fmax by highlighting the Fmax item and hitting

the right arrow key. This item does not have a drop down list of

options, but a numeric type in box. Type in the value 38400 then

hit the left arrow key to confirm.

The measurement is now setup. You can explore the other

options available by referring to appropriate section in the

Analysis reference section of this document.

To begin the measurement hit an Enter key. The instrument will

first enter autoranging mode, this is indicated on the display, and

by the amber indicator light. Depending on the signal the

instrument may take a few seconds to determine the optimal input

range. Following autoranging the instrument goes into collection

mode. This again is indicated on the display. Collection in this

case requires a few hundreds of milli seconds. Finally the data is

displayed and the green indicator should light. If the spectrum has

P/N 46966 Page 32 of 92

Model 256 Balancer / Analyzer Operator Manual

large peaks you can pick them out automatically using the peak

picker. Do this by hitting the “7” key. Note that a useful

mnemonic is used here as the “7” key also has the group of letters

“PQRS” associated with it. The letter “P” is a reminder that the

“7” key is for the peak – picker.

Having examined the spectrum you now want to store the data.

As the instrument was configured to acquire data continually,

hitting the Enter key once will pause the data acquisition. Note

that the Esc softkey (F4) changes to Continue. You don’t want to

continue so hit an Enter key again and the data is stored and the

instrument returns to the Analysis screen – not the User setup

screen.

To take the remaining measurements for the vertical and the axial

planes re-enter the User set up screen. Notice how the previous

settings have been retained. All you have to do is correctly name

the next point, say VER1, and hit an Enter key. If you don’t name

the point it will be given a default name in the form “Analysis

XXX” where XXX is a number in the range 001 – 999.

Now you have taken and stored data, the next section will quickly

guide you through the Review facility.

4.2.3 Reviewing Your Data

The Review feature allows you to examine the data you have

collected and stored when convenient.

P/N 46966 Page 33 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 4-4 The Review Analysis Data screen

The Analysis Review Data screen is shown in Figure 4-4. The

screen consists of a list of stored measurements numbered in the

format X/Y, where Y is the total number of stored measurements

and X is the number corresponding to that particular

measurement. If you take data using the Overall/Sig collection

option then the overall and signature are counted as a single

measurement with an overall and signature part. The softkeys F2

and F3 will indicate if a measurement has an overall and

signature component, as only the appropriate keys will appear

depending on the measurement. For example if a measurement

only has a signature component then only the Sig. (F3) softkey

will appear and the Overall (F2) softkey will be hidden. To

review a particular measurement scroll down the list of available

P/N 46966 Page 34 of 92

Model 256 Balancer / Analyzer Operator Manual

measurements until the correct one is highlighted then select

which component to view if this is applicable. Alternatively,

assuming a particular measurement has an overall and a

signature, hit an Enter key and the overall will be displayed. Hit

an Enter key again and the signature is displayed.

All display features such as peak – picking are available in

Review.

5 Balancing

5.1 BALANCE SETUP SCREEN

The Balance Setup (shown in Figure 5-1) and Advanced Setup

(shown in Figure 5-2) screens allow you to modify the various

parameters that affect a balance job.

P/N 46966 Page 35 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-1 The Balance Setup screen

5.1.1 Menu Options1

No. of Planes [1, 2]

Vib Measm’t Type [Accel (G), A→V (IPS), A→V (mm/s), Vel

(IPS) Vel (mm/s), A→ →D (mil), A→D (µm), V→D (mil), V→D

(µm), Dips (mil), Disp (µm), Volts, Keypress]

Weight Units [g, kg, oz, lb, EU]

Length Units [mm, cm, m, inch, feet, EU]

Movement [With Rotn, Against Rotn]

Trigger Type [ext Analog, ext TTL, Laser Tach]

Ext trig slop [-ve, +ve]

1

Defaults in Bold type.

P/N 46966 Page 36 of 92

Model 256 Balancer / Analyzer Operator Manual

Trigger Level [#Volts]

5.1.2 Proceed Keys

Key Press To Where?

Enter Launches a new balancing run using the setting in

the Balancing Setup and Advanced Setup screens –

will popup a “Transducer Attached” query box.

F1 Help

F2 Advanced Setup

F3 Memory – Internal / Card

F4 Quit? Message Box.

Table 5-1 Balance Setup proceed key presses

P/N 46966 Page 37 of 92

Model 256 Balancer / Analyzer Operator Manual

5.2 ADVANCED SETUP SCREEN

Figure 5-2 Advanced Setup screen

5.2.1 Menu Option

Filter [Off, 2Hz, 10Hz, 70Hz, User Defn]

Detection [Peak, Pk – Pk, RMS]

No. Averages [1 – 255] (default is 4)

Solution [Dynamic, Static – Couple]

←Plane→ [All, 1, 2]

Input Chan [X, Y, Z]2

Coupling [ICP, AC]

2

Plane 1 defaults to Y and Plane 2 defaults to X

P/N 46966 Page 38 of 92

Model 256 Balancer / Analyzer Operator Manual

Sensitivity [0.010 – 1000 mV/ EU] (default is 100)

Type [Continuous, Fixed]

No. of posns [3 - 360]

Posn 1 offset [0 - 360]

5.2.2 Proceed Keys

Key Press To Where?

Enter Save setting and return to Balancing Setup screen

F1 Help

F2 n/a

F3 Save setting and return to Balancing Setup screen

F4 Return to Balancing Setup screen without saving

settings

Table 5-2 Advanced Setup Proceed Keys

5.3 “RUN” SCREENS

The “Run” screens are the actual measurement screens displayed

when the instrument is collecting data. There are four flavours of

run screen: Initial, Trial, Correction, and Trim. The caption bar

title and layout of the screen can vary slightly depending on

various factors, but generally, they are similar to the screen shot

shown in Figure 5-3.

Factors that can affect the appearance of the screen include:

Number of planes

Simultaneous or sequential 2 plane job

Trial, initial, correction or trim run

P/N 46966 Page 39 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-3 Run Screen, this example shows an initial run for a

simultaneous 2-plane balance job.

5.3.1 Proceed Keys

Key Press To Where?

Enter

F1 Help

F2 Summary

F3 n/a

F4 Quit? Message Box.

Table 5-3

P/N 46966 Page 40 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-4 Add Trial Weight screen, note how the Trial Weight

estimator has been used to calculate a suitable trail weight mass

5.4 ADD TRIAL WEIGHT SCREEN

Add trial Weight screen allows you to enter details of the trial

weight added prior to a trial run.

5.5 SOLUTION SCREEN

Solution screen (shown in Figure 5-5) comes in two flavors:

Correction solutions and Trim solutions. These screens allow you

P/N 46966 Page 41 of 92

Model 256 Balancer / Analyzer Operator Manual

to manipulate the particulars of an individual balance job, and use

the computational engine in the instrument to re-evaluate the

mass and angle values of the result. With reference to Figure 5-5,

the Plane option is selected using the touch screen or the arrow

keys and/or numerical keypad. Each plane in turn can have the

weight split. This option allows you to manipulate the placement

of the weight(s). The Weight option allows you to select between

adding and removing weight to achieve the desired solution. The

Radius option allows vary the radial placement of the correction /

trim weight.

Figure 5-5 Solution Screen example – Correction weight in this case

These screens also have access to the Memory Screen where you

can save the current balance job, and delete and or load previous

balance jobs.

P/N 46966 Page 42 of 92

Model 256 Balancer / Analyzer Operator Manual

5.6 MEMORY SCREEN

The safe storage of your data is of vital importance, and the

Model 256 has been designed with this in mind. This section will

show you how to manage your data and work with confidence

that you data is safe.

The Model 256’s Memory screen is shown inFigure 5-6.

Figure 5-6 The Memory screen – shows Internal memory selected

Alternative softkeys are shown in Figure 5-7. These are the

softkeys displayed when you press and hold the “0” key, which

acts like the Alt key on your computer keyboard.

P/N 46966 Page 43 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-7 Alternative Memory screen softkeys

The function of these eight keys will now be explained in more

detail. The Help (F1) and Esc (F4) are found on many of the

screens and they function here in the standard sense. Help

invokes the on-line help and Esc returns you to the previous

screen. The Alt+F2 and Alt+F3 are the contrast keys and again

these are standard alternative keys. They are used to adjust the

contrast of the screen.

The four remaining keys are Save (F2) Load (F3), Memory

(Alt+F1) and Delete (Alt+F4). These four keys perform the

majority of memory management functions and their actions will

now be examined.

The Memory softkey (Alt+F1) is used to switch between Internal

memory and Card memory. To switch between memory spaces,

that is Internal and Card hold down the Alt key (the “0” key) and

then hit the Memory softkey. The current memory space is

indicated in the caption bar. If you select the card option please

ensure a card is actually inserted into the PCMCIA card port.

At any point during a balance job you can choose to save your

work. To do this hit the Memory softkey and the Memory screen

(Figure 5-6) will be displayed. To save your work hit the Save

(F2) softkey and this will invoke the Save As… screen. This

screen is shown in Figure 5-8. This screen consists of a list of

currently saved balance jobs and the –new– option. If you want to

update a previously saved job then select the correct job from the

list and hit the OK softkey. You will be prompted to overwrite

the currently saved version, hit the Yes softkey, or if you have

made an error hit the No softkey.

P/N 46966 Page 44 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-8 The Save As… screen

If this is the first time you have saved the job then select the –

new– option from the list and hit the OK softkey. The Save As…

type-in box will be displayed. This is shown inFigure 5-9.

Figure 5-9 Save As type-in box

P/N 46966 Page 45 of 92

Model 256 Balancer / Analyzer Operator Manual

The Save As… type in box will contain a default name in the

format BALXXX where XXX is a numeric value in the range

001-999. You can accept this name or clear it and enter your own

name. To save the job hit the OK softkey. The instrument will

return to the Memory screen and the new balance job will be

appended to the end of the list of saved balance jobs.

To load a previously saved balance job enter the Memory screen

and select the job you wish to load from the list of jobs displayed.

If the job was save on a card, insert the card and switch to Card

memory. Hit the Load softkey (F3) on the Memory screen and

one of two things will happen depending on the file you have

selected to load. If the file contains only setup information but no

actual data then the instrument will automatically switch to the

Balance Setup screen. The second case involves loading a

completed or partially completed balancing run that is a file and

contains data. Loading a file with data cause the instrument to

switch to the Go To screen. The operation of the Go To screen is

examined in the next section.

A “special” balance job, called “-default-“, is included in the list

of stored balance jobs. If you select “-default-“ and hit Load (F3)

then the balancing settings are restored to their factory default

settings. The “-default-“ balance job cannot be overwritten.

P/N 46966 Page 46 of 92

Model 256 Balancer / Analyzer Operator Manual

5.7 GO TO SCREEN

Figure 5-10 Go to… screen

To access the Go To screen press and hold the “0” key and then

press F1, that is effectively SHIFT F1, from any screen within the

Balancing application.

The Go To screen, shown in Figure 5-10, presents a

chronological list detailing the history of a particular balance job.

This list should be review with reference to Figure 4-2 Balance

Run Flow Chart. This will allow you to easily identify each

stage in the job.

The job may be completed or only partially completed. The tick

marks on the left hand side of the screen indicate those parts that

are completed.

P/N 46966 Page 47 of 92

Model 256 Balancer / Analyzer Operator Manual

Select where you want to re-start the balance job by scrolling the

Go To list to highlight the correct item, then hit the Go to pt

softkey (F2). This action will return the instrument the selected

step in the balance job. At this point, you merely continue with

the balance job as normal.

Be aware that you will not over write any data that has been

previously stored by re-starting the balance job and continuing.

Data can only be overwritten when you save actual save the

balance job.

5.8 WEIGHT / VIBRATION SUMMARY SCREEN

The summary screens are useful features that allow you to pause

and scrutinize an overview of the balance job. There are separate

summary screens for both vibration, see Figure 5-11, and

weights, see Figure 5-12.

P/N 46966 Page 48 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-11 Vibration Summary Table screen

When the summary screens are available to view, the F2 softkey

will display the Summary caption. Otherwise, no summary

screens are available. On invoking the summary screens, you are

always presented with the vibration screen first. Switch to the

weights screen by pressing the Wts (F2) softkey, hitting the F2

softkey again switches back to the vibration screen.

P/N 46966 Page 49 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-12 Weights Summary Table screen

For two plane balance jobs, you can switch between planes by

highlighting the Plane item and using the right arrow key to open

the drop down list. Select the plane you require and confirm your

selection by hitting the left arrow key.

Note that if a Trial weight has a ‘*’ character as the beginning,

this means that you have previously removed the trial weight.

5.9 COMBINE WEIGHTS SCREEN

This feature is essentially a vector addition calculator. It allows

you to select all or some of the trial / correction / trim weights

and combine them to give a single weight.

P/N 46966 Page 50 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-13 Combine Weights screen – before combining

To use the combine weights calculator, invoke the Combine

Weights screen, by pressing the Combine softkey. Note that this

key is only visible when weight combination is possible. In the

Combine Weights screen, shown in Figure 5-13, scroll the list of

candidate weights and select those you wish to combine by

highlighting the item and hitting select. This action will cause a

tick mark to appear in the small box on the left hand side of the

item.

P/N 46966 Page 51 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 5-14 Combine Weight screen – after combining all

When you have selected all the weights you wish to combine,

press the Accept softkey (F2) and you will be queried to combine

the selected weights, reply Yes and you will be asked to enter a

radius. This is the radius where the combined weight is to be

placed. Enter a value and the instrument will calculate a

replacement weight.

The display after combining will show a single weight equivalent

to all those that have been combined called CombX where X is an

appropriate numeric identifier to ensure uniqueness, and those

weight that were not included in the combination. The screen

shown in Figure 5-14 shows the effect after combining ALL the

weights shown in the previous screen into a single combined

weight.

P/N 46966 Page 52 of 92

Model 256 Balancer / Analyzer Operator Manual

Note that as long as there are two or more weights available then

it is possible to continue combining them.

5.10 THE TRIAL WEIGHT ESTIMATOR

The trial weight estimator is a useful feature which estimates a

trail mass based on the RPM, mass supported in the plane and

radius of the plane. The approach is based on producing an

unbalance force of approximately 10% of the rotor weight

supported in the plane.

Figure 5-15 Trial Weight Estimator screen

Hitting the Estimate sofkey in an Add Trial Weight screen

activates the estimator, and the popup dialog shown in Figure

5-15 appears. Enter the supported mass and hit the OK softkey

and the instrument automatically fills the Mass and Estimated

Mass fields in the Add Trial Weight screen with the value

calculated. Note that you must use the units of mass specified in

the Balance Setup screen for the supported mass.

P/N 46966 Page 53 of 92

Model 256 Balancer / Analyzer Operator Manual

6 Analysis

The analyzer functions allow you to examine machine vibration

and determine if the cause is indeed unbalance.

Figure 6-1 Analysis menu showing STANDARD selected

6.1 STANDARD W/ACCL

A Standard point consists of an overall and spectrum, taken using

an accelerometer. Standard point settings are:

- IPS (A->V)

- 12000 CPM

- 400 lines

- 4 averages

- Peak Detection

P/N 46966 Page 54 of 92

Model 256 Balancer / Analyzer Operator Manual

- 120 CPM filter

6.2 USER – DEFINED

The Analysis User Setup screen shot is shown in Navigating The

Screen, but is reproduced here, (Figure 6-2).

This is an extremely useful feature that allows you to setup and

measure a wide selection of measurements such as time traces or

spectrum. You can also vary the Fmax frequency and the number

of lines. All possible options are outlined in the following

sections.

Figure 6-2 Analysis User Setup, Change Name option highlighted.

P/N 46966 Page 55 of 92

Model 256 Balancer / Analyzer Operator Manual

6.2.1 Change Name

The Change Name option displays the window shown in Figure

6-3. This type-in box allows you to re – name a point using the

keypad.

Figure 6-3 Change Name type-in box

6.2.2 Collection

Options are [Overall / Sig, Overall only, Sig only, RSS Overall]

An overall is a single value measurement representing the total

vibration being measured.

Overall / Sig takes an overall measurement first, you then have to

hit an Enter key to take the Sig. Sig is an abbreviation for

Signature which is how we describe BOTH a time trace and a

spectrum. You select the type of signature in the Display Format

option. Overall only and Sig only measurements are as you would

expect, an overall only and a signature only. An RSS Overall is

an overall value that is extracted from the signature trace, so an

RSS Overall is really a signature with an associated overall value

obtained from the signature data, as shown in Figure 6-4.

P/N 46966 Page 56 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 6-4 A spectrum showing an RSS overall (value on LHS at top –

0.585G)

6.2.3 Display Format

Options are [Spectrum, Time, Phase, Orders]

A spectrum display format is illustrated in Figure 6-5. The x-axis

is annotated in either Hz or CPM. The y-axis is annotated in the

selected units. The numbers at the top right-hand side of the

display are the current cursor values.

P/N 46966 Page 57 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 6-5 An example of a spectrum signature

A time display format is illustrated in Figure 6-6. The x-axis is

annotated in second of time. The y-axis is annotated in the

selected units.

P/N 46966 Page 58 of 92

Model 256 Balancer / Analyzer Operator Manual

Figure 6-6 An example of a time signature

A phase measurement requires a trigger input.

A phase display format is illustrated in Figure 6-7. This screen is

annotated in a manner similar to the spectrum, but obviously has

the important addition of a phase table. The phase table can be

toggled on and off by pressing the “8” button on the numeric

keypad.

The RPM is also displayed at the top of the screen.

Note that the Fmax used for phase measurement is NOT selected

by you. The instrument automatically selects an Fmax based on

the measured RPM.

P/N 46966 Page 59 of 92

Model 256 Balancer / Analyzer Operator Manual

The phase table displays the magnitude and phase of the

measurement at the first 8 orders. Note that the magnitude value

displayed in the phase table may not exactly match the spectrum

peak shown in the plot. This is because the values displayed in

the table have been adjusted to account for losses due to the

window used.

Figure 6-7 An example of a phase signature

P/N 46966 Page 60 of 92

Model 256 Balancer / Analyzer Operator Manual

`

Figure 6-8 An example of an orders signature

An orders measurement requires a trigger input.

An orders display format is illustrated in Figure 6-8. An orders

screen is similar to the phase screen. The main differences are

that the first 50 orders are displayed, rather than 8 for phase and

only the magnitude is displayed.

6.2.4 Units

Options are [Accel (G), gSE, RPM, A→V (IPS), A→V (mm/s),

Vel (IPS) Vel (mm/s), A→D (mil), A→D (µm), V→D (mil),

V→D (µm), Dips (mil), Disp (µm), Volts, Eus [S], Temperature

[S], Current (A)[S], Pressure (PSI)[S], Flow (m3/s)[S], Rot.

Speed [S], Linear displ. (mm) [S], Count [S], Count Rate [S],

P/N 46966 Page 61 of 92

Model 256 Balancer / Analyzer Operator Manual

Volts [S], Accel (G) [S], Vel. (IPS)[S], Vel. (mm/s)[S], Disp

(mil)[S], Disp(µm)[S]]

Note that all Units denoted [S] are static, that is a numeric value

is entered manually at the keypad.

The NON-STATIC options signify:

Accel (G) – acceleration in g’s

gSE – g spike energy in g’s

RPM – RPM

A→V (IPS) – velocity obtained via single integration in inches

per second

A→V (mm/s) – velocity obtained via single integration in

millimetres per second

Vel (IPS) – velocity in inches per second

Vel (mm/s) – velocity in millimetres per second

A→D (mil) – displacement obtained via double integration in

mils or thousandths of an inch

A→D (µm) – displacement obtained via double integration in

micrometres

V→D (mil) – displacement obtained via single integration in mils

or thousandths of an inch

V→D (µm) – displacement obtained via single integration in

micrometres

Dips (mil) – displacement in mils or thousandths of an inch

Disp (µm) – displacement in micrometers

Volts – Volts

6.2.5 Coupling

Options are [AC, DC, ICP]

The AC option allows only the alternating component of a signal

to enter the instrument by inserting a high pass filter with a very

P/N 46966 Page 62 of 92

Model 256 Balancer / Analyzer Operator Manual

low cut off frequency at the input. The DC option allows both the

direct and alternating components of the signal to enter. The ICP

option is designed to power special accelerometers, which have a

built amplifier. This type of sensor requires that the instrument

supplies power to the amplifier, and this is what the ICP option

does.

6.2.6 Input channel

Options are [X, Y, Z]

These options are used with triaxial transducers to select which of

the 3 directions are being measured.

6.2.7 Detection

Options are [RMS, Peak, Pk-Pk, True Peak, True Pk-Pk]

True Peak and True Pk-Pk are only used for overall

measurement. RMS, Peak and Pk-Pk are used for both spectrum

and overall measurement.

6.2.8 Sensitivity

Options is numeric keypad entry [0.010 – 1000 mV/ EU]

Be sure to enter the exact sensitivity of your sensor to ensure

accurate measurement values.

6.2.9 High-pass filter

Options are [Off, 0.18Hz (100hz), 0.36Hz (200Hz), 2Hz(500Hz),

2.67Hz (1kHz), 5.3Hz (2kHz), 10Hz (5kHz), 23.8Hz, 70Hz] –

options shown in parenthesis are for gSE.

This option inserts a high pass filter with the given –3dB, or cut

off, frequency into the signal chain. Note that the Off option is

NOT allowed with integrated measurement unit types. Note that

P/N 46966 Page 63 of 92

Model 256 Balancer / Analyzer Operator Manual

gSE is a method of extracting information on high frequency

bearing faults.

6.2.10 Fmax

Option is numeric keypad entry [25Hz – 40kHz]

Note that only a discrete set of Fmax frequencies is available on

the instrument (approximately 40). Therefore you may find the

Fmax value you type in being automatically changed to the

nearest available Fmax.

6.2.11 Lines/Samples

Options are [ 100/256, 200/512, 400/1024, 800/2048, 1600/4096,

3200/8192, 6400/16384, 12800/32768]

The number of lines is applicable to spectral data, and the number

of samples is applicable to time data.

6.2.12 Windows

Options are [Hanning, FlatTop, Rectangular, Hamming]

The normal recommendation is to use the Hanning window for all

(spectral) measurements, as the properties of the other three

window types are known to be non-ideal for most measurements.

The one exception to this is the use of the Flattop window when

absolute amplitude accuracy of spectral peaks is all that is

required, for example during a calibration measurement.

6.2.13 Averages

Option is numeric keypad entry [1-255 for time averages, 1-4095

for spectral averages]

Selects the number of averages performed when taking the

measurement.

P/N 46966 Page 64 of 92

Model 256 Balancer / Analyzer Operator Manual

6.2.14 Overlap

Option is numeric keypad entry [0% - 99%]

The recommendation is to select an overlap % in the range 25% -

75%.

6.2.15 Type

Options are [Spectral, Time Synch.]

Time synchronous averaging requires a trigger.

6.2.16 Ext trig slope

Options are [+ve, -ve]

Determines which edge of the trigger signal to trigger on.

6.2.17 Level

Option is numeric keypad entry [#Volts]

Determines the voltage level to trigger on for the external trigger.

6.2.18 Type

Options are [Laser Tach, External]

Laser tach option selects the unit's built in laser tachometer.

External requires an external trigger source connected to the unit

using a suitable cable.

6.2.19 Bin Zeroing

Options are [Off, On]

Selecting this option on enables a feature that causes the spectrum

lines (or bins) up to the high pass filter cut off frequency to be

zeroed regardless of their actual value. The assumption is that

their actual values are spurious and can therefore be discarded.

P/N 46966 Page 65 of 92

Model 256 Balancer / Analyzer Operator Manual

6.3 MEASURE SPEED

This feature is useful if you need a quick measurement of RPM.

It uses the built in laser tachometer, but the measurement cannot

be save. If you need to save an RPM measurement, it

recommended you use the User – Defined measurement facility

and select RPM Units.

6.4 REVIEW DATA

This feature allows you to review all the data you have collected

in Analyzer mode. The data points are listed chronologically, that

is, in the order they were taken.

Figure 6-9 Review Analysis Data screen – second point has been re-

named using Analysis User Setup Change Name option

P/N 46966 Page 66 of 92

Model 256 Balancer / Analyzer Operator Manual

7 Instrument Setup