Documente Academic

Documente Profesional

Documente Cultură

DPS Chart

Încărcat de

sergioTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DPS Chart

Încărcat de

sergioDrepturi de autor:

Formate disponibile

DUAL LINER WIPER PLUG SYSTEM

Dual Plug System Operational Sequence

Figure 1

The Dual Plug System (DPS) wipes both in front of First pump down plug is released from cementing

and behind the cement, physically isolating the manifold ahead of the cement. The plug is pumped

cement column from contamination. The system has down the drill string wiping the inner bore and isolating

the same advantages as the traditional lead and the cement from the drilling fluid. When the plug

following plugs in conventional full string cementing. reaches the setting equipment, it latches into the lower

liner wiper plug.

The DPS system uses two pump down plugs in a

special cementing manifold. The plugs are dropped Figure 2

one at a time; one in front of the cement and one With first pump down plug latched, pressure up and

behind the cement. Two liner wiper plugs are used on shear lower liner wiper plug from setting tool. Continue

the end of the setting tool, each accepting a different pumping cement . During pumping, the liner wiper plug

pump down plug. isolates the cement from the drilling fluid down the liner

string. Continue pumping until lower liner wiper plug

latches into the landing collar.

Figure 3

When the liner wiper plug is latched, increase pressure

to shear the inner sleeve from the wiper plug

re-establishing fluid circulation. The sleeve containing

the pump down plug falls to the bottom of the well.

Figure 4

Release the upper pump down plug from the

cementing manifold. Pump displacing fluid behind the

plug. As the plug is pumped down the drill string, it

wipes the cement. Like the first plug, it isolates the

cement from the displacing fluid. Continue pumping

fluid until the second pump down plug latches into the

upper liner wiper plug.

Figure 5

With the second pump down plug latched into place,

increase pressure and shear upper liner wiper plug

from the setting tool. Continue with displacement. The

pressure from the drilling fluid on the back side of the

liner wiper plug causes the plug to wipe the cement

from the annulus of the liner and displacing it out

through the float shoe and up the annulus between the

liner and casing. Continue pumping until the upper

liner wiper plug latches into the top of the lower liner

wiper plug.

Advantages:

The plug system cleans residual mud from the

setting string and the liner while separating the

cement slurry from the drilling and displacement

fluids.

Plugs shear independently from running tool

The plug system is vented which virtually

eliminates the risk of premature release.

All components are PDC drillable.

DUAL LINER WIPER PLUG SYSTEM

Figure 1 Figure 2 Figure 3 Figure 4 Figure 5

S-ar putea să vă placă și

- WiperDocument2 paginiWiperRonald MedranoÎncă nu există evaluări

- Knapsack Sprayer: 16 LitresDocument2 paginiKnapsack Sprayer: 16 LitressubyÎncă nu există evaluări

- BHKA - HalliburtonDocument8 paginiBHKA - HalliburtonAmbroise RichardÎncă nu există evaluări

- Hankison Tripltrap 505Document12 paginiHankison Tripltrap 505syahril boonieÎncă nu există evaluări

- Single Stage CementingDocument3 paginiSingle Stage CementingJoshua ZanyohÎncă nu există evaluări

- Pump Maintenance ManualDocument31 paginiPump Maintenance ManualSly Mubaiwa NzenzaÎncă nu există evaluări

- Liquid End Liquid End Liquid End Liquid End Liquid End: Sheet Sheet Sheet Sheet SheetDocument2 paginiLiquid End Liquid End Liquid End Liquid End Liquid End: Sheet Sheet Sheet Sheet SheetBreynner Nieto-LinaresÎncă nu există evaluări

- Liner CementingDocument5 paginiLiner Cementingbhavik PanchalÎncă nu există evaluări

- GF 11435Document16 paginiGF 11435Anthony NavarroÎncă nu există evaluări

- AxSym Instrument Buffer Pump Drip TrayDocument2 paginiAxSym Instrument Buffer Pump Drip TrayPhong DoÎncă nu există evaluări

- TI009 PrimingPot Rev02Document2 paginiTI009 PrimingPot Rev02Sanket SonaraÎncă nu există evaluări

- Maintenance Advice RPS SystemDocument9 paginiMaintenance Advice RPS SystemKhoerul Anwar RizkiÎncă nu există evaluări

- Flush ValveDocument4 paginiFlush Valveelvacas100% (1)

- Maintenance and Repair ManualDocument15 paginiMaintenance and Repair ManualfabricioillescasjÎncă nu există evaluări

- s450 700 Filter ManualDocument2 paginis450 700 Filter ManualBishri LatiffÎncă nu există evaluări

- Antlia Engineering Works - Diaphragm Pump Manufacturer and SupplierDocument5 paginiAntlia Engineering Works - Diaphragm Pump Manufacturer and SupplierAjay YadavÎncă nu există evaluări

- Owner'S Manual: V-KC681HDocument14 paginiOwner'S Manual: V-KC681HMohamed HassanÎncă nu există evaluări

- ATOM V-808: Cleaning InstructionsDocument10 paginiATOM V-808: Cleaning Instructionsjerson_rojas19899571Încă nu există evaluări

- Drilling Operation OverviewDocument21 paginiDrilling Operation OverviewWai HtutÎncă nu există evaluări

- LT36720 Drain Valve Service InstructionsDocument3 paginiLT36720 Drain Valve Service InstructionsKe HalimunÎncă nu există evaluări

- Surface Cementing EquipmentDocument14 paginiSurface Cementing EquipmentDjohan Pranata KabanÎncă nu există evaluări

- How To UnClog Your SoftTop DrainsDocument5 paginiHow To UnClog Your SoftTop DrainsPaul JohÎncă nu există evaluări

- 2006+ Z4 Clean Droptop Drains PDFDocument5 pagini2006+ Z4 Clean Droptop Drains PDFOscar SanchezÎncă nu există evaluări

- CM M 11 Reciprocating PumpDocument60 paginiCM M 11 Reciprocating PumpAuthers Raj SÎncă nu există evaluări

- MMC 16101 - Positive Displacement Pump - 01Document19 paginiMMC 16101 - Positive Displacement Pump - 01HET DEDHIAÎncă nu există evaluări

- UM-F003G - EMFI12072722 EMAUX S1000-1200 FilterDocument2 paginiUM-F003G - EMFI12072722 EMAUX S1000-1200 FilterMarian LazarÎncă nu există evaluări

- Baker Pressure Relief Sub For Pumping Wells: Remedial Systems Technical UnitDocument2 paginiBaker Pressure Relief Sub For Pumping Wells: Remedial Systems Technical Uniteberthson hernandezÎncă nu există evaluări

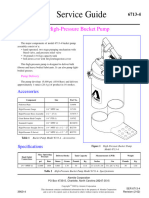

- Service Guide: High-Pressure Bucket PumpDocument10 paginiService Guide: High-Pressure Bucket PumpRodrigoÎncă nu există evaluări

- UM-F002B - EMFI12072705 EMAUX SP Series FilterDocument2 paginiUM-F002B - EMFI12072705 EMAUX SP Series FilterMarian LazarÎncă nu există evaluări

- The Rotary Drum Filter: DescriptionDocument5 paginiThe Rotary Drum Filter: DescriptionPradeep KatariaÎncă nu există evaluări

- (Link by Clamp Type Valves) Models: V400 V450 V500 V650 V700 V350Document2 pagini(Link by Clamp Type Valves) Models: V400 V450 V500 V650 V700 V350mbgprsmsÎncă nu există evaluări

- VSystem-Honda Africa Twin 2016-EnDocument2 paginiVSystem-Honda Africa Twin 2016-EnRicardo LopesÎncă nu există evaluări

- 2700 - 2 of 4 - 10 07Document57 pagini2700 - 2 of 4 - 10 07Erick Budde HernandezÎncă nu există evaluări

- BJ Plug Catcher - Cement Displacement ToolDocument2 paginiBJ Plug Catcher - Cement Displacement Toolilkerkozturk100% (1)

- LinerDocument2 paginiLinerjoo123456789Încă nu există evaluări

- WheelHorse Hydraulic Lift Accessory 8-4113Document4 paginiWheelHorse Hydraulic Lift Accessory 8-4113Kevins Small Engine and Tractor ServiceÎncă nu există evaluări

- Cimv Design GuideDocument10 paginiCimv Design GuideleejaemunÎncă nu există evaluări

- M "EA" R C P P N - 25.214: Odel Etrievamatic Ementer Acker Roduct ODocument2 paginiM "EA" R C P P N - 25.214: Odel Etrievamatic Ementer Acker Roduct ORodolfo Rider100% (1)

- v900 C v1400 Filter User Manual EnglishDocument2 paginiv900 C v1400 Filter User Manual EnglishvominhbinhÎncă nu există evaluări

- Common Pumping Principles: Flexible Impeller Progressing Cavity RotaryDocument12 paginiCommon Pumping Principles: Flexible Impeller Progressing Cavity RotaryPuneet KankariaÎncă nu există evaluări

- Experiment 4Document6 paginiExperiment 4Nod salÎncă nu există evaluări

- KIKAWA Manual kp8 enDocument4 paginiKIKAWA Manual kp8 enRamesh KrishmedaÎncă nu există evaluări

- RLGF Self Priming Centrifugal Pumps: Owner's ManualDocument12 paginiRLGF Self Priming Centrifugal Pumps: Owner's ManualBuentello B GonzalezÎncă nu există evaluări

- SFC Belt Filter Press IntroductionDocument38 paginiSFC Belt Filter Press Introductionthinh phanÎncă nu există evaluări

- L51050en CDocument4 paginiL51050en CSebei ChakibÎncă nu există evaluări

- Positive Air Displacement TheoryDocument4 paginiPositive Air Displacement TheoryAniket TeredesaiÎncă nu există evaluări

- LifeStraw Community User ManualDocument17 paginiLifeStraw Community User ManualfightnetÎncă nu există evaluări

- System Cuts P&A Cost by Creating Rock-to-Rock Barrier in One TripDocument4 paginiSystem Cuts P&A Cost by Creating Rock-to-Rock Barrier in One TripАлександр ГераськинÎncă nu există evaluări

- Bucyrus: Technical ManualDocument7 paginiBucyrus: Technical ManualJohn GrayÎncă nu există evaluări

- Frontier Pro insert фильтрDocument1 paginăFrontier Pro insert фильтрGoBliNukeÎncă nu există evaluări

- BHKA DisconnectDocument10 paginiBHKA Disconnectbagus918100% (1)

- Camshaft InstallDocument4 paginiCamshaft Installatorres611Încă nu există evaluări

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 paginiRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoÎncă nu există evaluări

- kx80 Página 153Document1 paginăkx80 Página 153PabloÎncă nu există evaluări

- Operation Instructions Seal Replacement: Vil 4300 - 20×20×19 Installation and Operating InstructionsDocument4 paginiOperation Instructions Seal Replacement: Vil 4300 - 20×20×19 Installation and Operating InstructionsDiego ArmandoÎncă nu există evaluări

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 paginiRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoÎncă nu există evaluări

- C2020 Standard: Assembly & Installation InstructionsDocument5 paginiC2020 Standard: Assembly & Installation InstructionsHidetoshi NakataÎncă nu există evaluări

- Reverse Modulated Wet Disc Brake System: SectionDocument7 paginiReverse Modulated Wet Disc Brake System: SectionAlexander MugabeÎncă nu există evaluări

- Manual Servicio Cámaras de FrenoDocument2 paginiManual Servicio Cámaras de FrenoJuan Jose PerdomoÎncă nu există evaluări

- Installation and Maintenance: Sto Beg Iven To Use RDocument16 paginiInstallation and Maintenance: Sto Beg Iven To Use RMuhammad Rizwan SiddiquiÎncă nu există evaluări

- Symbols PDFDocument2 paginiSymbols PDFKuttappa I GÎncă nu există evaluări

- ABB 64605666 SheetDocument13 paginiABB 64605666 SheetsergioÎncă nu există evaluări

- Datasheet 5 PDFDocument1 paginăDatasheet 5 PDFsergioÎncă nu există evaluări

- RL57Document1 paginăRL57sergioÎncă nu există evaluări

- DHEDHERDocument4 paginiDHEDHERsergioÎncă nu există evaluări

- NuevoDocumento 2017-11-27 - 1 PDFDocument1 paginăNuevoDocumento 2017-11-27 - 1 PDFsergioÎncă nu există evaluări

- Guaranteed Cost Output Feedback Control of Uncertain Discrete Linear SystemsDocument8 paginiGuaranteed Cost Output Feedback Control of Uncertain Discrete Linear SystemssergioÎncă nu există evaluări

- Curso PID MateriasDocument5 paginiCurso PID MateriassergioÎncă nu există evaluări

- Guaranteed Cost Output Feedback Control of Uncertain Discrete Linear SystemsDocument8 paginiGuaranteed Cost Output Feedback Control of Uncertain Discrete Linear SystemssergioÎncă nu există evaluări

- MixtosDocument7 paginiMixtossergioÎncă nu există evaluări

- NuevoDocumento 2017-11-27 1Document1 paginăNuevoDocumento 2017-11-27 1sergioÎncă nu există evaluări

- Co Co: Bbyy. BbyyDocument1 paginăCo Co: Bbyy. BbyysergioÎncă nu există evaluări

- Letras de Canciones en InglesDocument25 paginiLetras de Canciones en InglessergioÎncă nu există evaluări

- Ed13 NDocument16 paginiEd13 NsergioÎncă nu există evaluări

- Powertek SeriesiDocument2 paginiPowertek SeriesisergioÎncă nu există evaluări

- Co Co: Bbyy. BbyyDocument1 paginăCo Co: Bbyy. BbyysergioÎncă nu există evaluări

- DocDocument1 paginăDocsergioÎncă nu există evaluări

- Unit 3 - Water Resources Engineering - WWW - Rgpvnotes.inDocument28 paginiUnit 3 - Water Resources Engineering - WWW - Rgpvnotes.inKishore Naik MalothÎncă nu există evaluări

- Problems in Fluid Mechanics - Baranyi PDFDocument130 paginiProblems in Fluid Mechanics - Baranyi PDFNasser ShelilÎncă nu există evaluări

- Din-Dvgwtype Examination Certificate: Din-Dvgw-BaumusterprüfzertifikatDocument2 paginiDin-Dvgwtype Examination Certificate: Din-Dvgw-BaumusterprüfzertifikatRicardo BarrosÎncă nu există evaluări

- Hydraulics in Civil and Environmental EngineeringDocument639 paginiHydraulics in Civil and Environmental EngineeringSantiago Piedra89% (19)

- Phase DiagramDocument49 paginiPhase DiagramJaber HasanÎncă nu există evaluări

- Sample WW QuestionsDocument10 paginiSample WW QuestionsKrishna Kumar MeenaÎncă nu există evaluări

- Tech Diary of Turbine & AuxiliaryDocument70 paginiTech Diary of Turbine & AuxiliarysambhuÎncă nu există evaluări

- Objectives: CCFD5110 Incompressible FlowDocument13 paginiObjectives: CCFD5110 Incompressible Flowalagarg137691Încă nu există evaluări

- Flow Measurement and Fluid Machinery Lab - 18MEL67Document63 paginiFlow Measurement and Fluid Machinery Lab - 18MEL67Madhu KNÎncă nu există evaluări

- Polyflow Dec 2020Document16 paginiPolyflow Dec 2020Abdul Rahman HilmiÎncă nu există evaluări

- CFD Simulation For Fire Emergency-Howrah Station: Reference Number UG1-SYST-310-NME-REP-808 - BDocument56 paginiCFD Simulation For Fire Emergency-Howrah Station: Reference Number UG1-SYST-310-NME-REP-808 - BDebasish DeyÎncă nu există evaluări

- Differences Between IRIS, ECT, RFETDocument1 paginăDifferences Between IRIS, ECT, RFETbenergy84100% (9)

- Marine Pumps: Click To Edit Master Title StyleDocument13 paginiMarine Pumps: Click To Edit Master Title StylePaul OlimposÎncă nu există evaluări

- Fundamentals of Material Science and Engineering ExamDocument23 paginiFundamentals of Material Science and Engineering ExamJesimie OriasÎncă nu există evaluări

- Nitrogen Pilot Cylinder 40L, 95 Bar: SNS IG-100 Fire Suppression SystemDocument2 paginiNitrogen Pilot Cylinder 40L, 95 Bar: SNS IG-100 Fire Suppression SystemNguyễn Minh ThiệuÎncă nu există evaluări

- ASTM D3195. Rotameter Calibration Std.Document4 paginiASTM D3195. Rotameter Calibration Std.Princess NobleÎncă nu există evaluări

- CHE 482 Reaction Engineering & Separations Including Properties Abdulaziz Oqlah Abdullah AbdulraheemHamad Alhajri Ali AlsubaieDocument11 paginiCHE 482 Reaction Engineering & Separations Including Properties Abdulaziz Oqlah Abdullah AbdulraheemHamad Alhajri Ali AlsubaieTimelessÎncă nu există evaluări

- Permeability of ConcreteDocument36 paginiPermeability of ConcretealungsuharÎncă nu există evaluări

- Drilling Note BookDocument100 paginiDrilling Note Booksalcedopozas100% (2)

- Waste Water Technologies Leaflet (US)Document6 paginiWaste Water Technologies Leaflet (US)gjpareÎncă nu există evaluări

- Performance CurvesDocument1 paginăPerformance CurveskapsarcÎncă nu există evaluări

- Pengadaaan PANEL Ruang Pompa: Satuan Harga Upah Kerja ItemDocument6 paginiPengadaaan PANEL Ruang Pompa: Satuan Harga Upah Kerja ItemALIF NAUFALÎncă nu există evaluări

- Lab Manual (Cre)Document41 paginiLab Manual (Cre)akash100% (1)

- Vacuum PumpsDocument2 paginiVacuum PumpsStefanVisÎncă nu există evaluări

- MorleyPresentation (MHD) PDFDocument56 paginiMorleyPresentation (MHD) PDFRehman Ullah0% (1)

- Simultaneous Heat & Mass Transfer Lab: Submitted ToDocument12 paginiSimultaneous Heat & Mass Transfer Lab: Submitted ToSumair Imtiaz SheikhÎncă nu există evaluări

- Acs Energyfuels 2c03625Document30 paginiAcs Energyfuels 2c03625Israel Arias GonzálezÎncă nu există evaluări

- Optimization andCFD Analysis of A ShellDocument16 paginiOptimization andCFD Analysis of A ShellErmias AbelnehÎncă nu există evaluări

- Pompa CT Clu 3 Tip S1 L15 N2, 12-30 Bar, 80-95 LH, Sens de Rotatie OrarDocument7 paginiPompa CT Clu 3 Tip S1 L15 N2, 12-30 Bar, 80-95 LH, Sens de Rotatie OrarVictor HutanuÎncă nu există evaluări

- Fire Fighting & Fire PreventionDocument4 paginiFire Fighting & Fire Preventionjokish0% (1)