Documente Academic

Documente Profesional

Documente Cultură

ATV312 Quick Start en S1A10942 03

Încărcat de

w.priatmadiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ATV312 Quick Start en S1A10942 03

Încărcat de

w.priatmadiDrepturi de autor:

Formate disponibile

ENGLISH Quick Start Guide - ATV312

S1A1094203

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product

documentation and who have received safety training to recognize and avoid hazards involved are authorized to work on and with this drive

system. Installation, adjustment, repair and maintenance must be performed by qualified personnel.

• The system integrator is responsible for compliance with all local and national electrical code requirements as well as all other applicable

regulations with respect to grounding of all equipment.

• Many components of the product, including the printed circuit boards, operate with mains voltage. Do not touch. Use only electrically

insulated tools.

• Do not touch unshielded components or terminals with voltage present.

• Motors can generate voltage when the shaft is rotated. Prior to performing any type of work on the drive system, block the motor shaft to

prevent rotation.

• AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused conductors of the motor cable.

• Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

• Before performing work on the drive system:

- Disconnect all power, including external control power that may be present.

- Place a "Do Not Turn On" label on all power switches.

- Lock all power switches in the open position.

- Wait 15 minutes to allow the DC bus capacitors to discharge. The DC bus LED is not an indicator of the absence of DC bus voltage that

can exceed 800 Vdc.

- Measure the voltage on the DC bus between the DC bus terminals using a properly rated voltmeter to verify that the voltage is < 42 Vdc.

- If the DC bus capacitors do not discharge properly, contact your local Schneider Electric representative.

• Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by Schneider

Electric for any consequences arising out of the use of this product.

Information below is designed to use single drive connected to single motor with a motor cable length less than 50 meters (164 ft).

In any other case, consult the ATV312 installation manual (BBV46391) and programming manual (BBV46385) on www.schneider-electric.com.

1 Check the delivery of the drive

• Remove ATV312 from the packaging and check that it has not been damaged.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

• Check that the drive reference printed on the label matches the delivery note and corresponding purchase order.

Write the drive Model Reference: _____________ ___________and Serial Number: ____________________________

2 Check the line voltage compatibility

• Check that the line voltage is compatible with the supply range of the drive.

Line voltage _______ Volts / Drive voltage range _______ Volts

8B0917121134

Drive range: ATV312ppppM2 = 200/240 V single phase / ATV312ppppM3=200/240 V three-phase

ATV312ppppN4 = 380/500 V three-phase / ATV312ppppS6 = 525/600 V three-phase

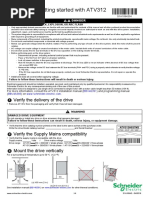

3 Mount the drive vertically

For a surrounding air temperature up to 50 °C (122 °F)

(a)

(a) (a)

(b)

(a)

(a) 50 mm (2 in.)

(b) 10 mm (0.4 in.)

See installation manual (BBV46391) on www.schneider-electric.com for other thermal conditions.

www.schneider-electric.com 1/4 S1A10942 - 04/2014

4 Connect power wiring 5 Connect control wiring and

• Wire the drive to the ground.

• Check circuit breaker rating or fuse rating (see SCCR annex) select control configuration:

• Check that the motor voltage is compatible with the drive voltage.

Motor voltage ______Volts. 5.1 or 5.2

• Wire the drive to the motor.

• Wire the drive to the line supply. [REMOTE configuration]

5.1 (Control by external reference)

Source

• Ensure SW1 = ‘’SOURCE’’ CLI

SINK

• Wire the speed reference:

RUN

REF

200/240 V MON

CONF

CAN

ERR

+10 v

ATV312 M2

AI 1

COM

or

2.2 KΩ

See

SCCR annex

200/240 V • Wire the command:

ATV312 M3 Control command 2-wire: Control command 3-wire:

ATV 312 ATV 312

OR

24 V LI1 LI2 24 V LI1 LI2 LIx

380/500 V

ATV312 N4

LI1: forward LI1: stop

LI2: reverse LI2: forward

LIx: reverse

525/600 V • Next steps, do: 6 + 7 + 8 + 9.1

ATV312 S6

[LOCAL configuration]

5.2 (control by internal reference).

RUN

REF

MON CAN

6 + 7 + 8 + 9.2

CONF ERR

Do:

6 Apply power to the drive

• Ensure that Logic Inputs are not active (see Li1, Li2, Lix ).

• Apply power to the drive. ENT

• At first power up, the drive displays nSt (3-wire control) or rdY (2 -wire control), after pushed drive displays bFr.

• On next start-ups, the drive displays nSt or rdY .

7 Set motor parameters

• Refer to the motor nameplate for the following parameter settings.

Customer

Menu Code Description Factory setting

setting

[Standard mot. freq]:

bFr 50.0

Standard motor frequency (Hz)

[Rated motor volt.]:

UnS drive rating

Nominal motor voltage on motor nameplate (V)

[Rated motor freq.]:

drC- FrS 50.0

Nominal motor frequency on motor nameplate (Hz)

[MOTOR CONTROL]

[Rated mot. current.]:

nCr drive rating

Nominal motor current on motor nameplate (A)

[Rated motor speed]:

nSP drive rating

Nominal motor speed on motor nameplate (rpm)

[Motor 1 Cosinus Phi.]:

COS drive rating

Nominal motor cos ϕ on motor nameplate

www.schneider-electric.com 2/4 S1A10942 - 04/2014

7 Set motor parameters (continued)

• Set tUn parameter to YES.

Customer

Menu Code Description Factory setting

setting

drC- [Auto Tunning]:

tUn nO

[MOTOR CONTROL] Auto-Tunning for UnS, FrS, nCr, nSP and COS

DANGER DANGER

HAZARD OF ELECTRIC SHOCK OR ARC FLASH UNINTENDED EQUIPMENT OPERATION

• The Nominal Motor Parameters UnS, FrS, nCr, nSP and COS

• During auto-tuning, the motor operates at rated must be correctly configured before starting auto-tuning.

current. • If one or more of these parameters is modified after auto-tuning has

• Do not service the motor during auto-tuning. been performed, tUn will return to nO and the procedure must be

repeated.

Failure to follow these instructions will result in death

or serious injury. Failure to follow these instructions will result in death or serious injury.

8 Set basic parameters

Customer

Menu Code Description Factory setting

setting

[Acceleration]:

ACC 3.0

Acceleration time (s)

[Deceleration]:

dEC 3.0

Deceleration time (s)

SEt- [Low speed]:

LSP 0.0

[SETTINGS] Motor frequency at minimum reference (Hz)

[High speed]:

HSP 50.0

Motor frequency at maximum reference (Hz)

[Mot. therm. current]:

ItH drive rating

Nominal current on motor nameplate (A)

I-O- [Reverse assign.]:

rrS LI2

[INPUTS / OUTPUTS CFG] Reverse assignment

[2 preset speeds]:

PS2 LI3

Fun-> PSS- Preset speeds

[PRESET SPEEDS] [4 preset speeds]:

PS4 LI4

Preset speeds

Fun-> SAI- [Summing ref. 2]

SA2 AI2

[SUMMING INPUTS] Analog input

9 Set control choice

Menu Code Description 5.1 [REMOTE configuration] 5.2 [LOCAL configuration] Customer Setting

CtL- [Ref.1 channel]: Al1 (factory setting),

Fr1 AlU1

[COMMAND] Reference control Al2, Al3

I-O- [2/3 wire control]: 2C: 2-wire (factory setting)

tCC LOC

[INPUTS / OUTPUTS CFG] Command control 3C: 3-wire

9.1 [REMOTE configuration] 9.2 [LOCAL configuration]

(Factory setting)

MODE

Factory settings of parameters: 3s

LOC rdY

Fr1 = AI1

tCC = 2C

Factory settings of parameters:

Fr1 = AIU1

tCC = LOC

rrS = LI2

PS2 = LI3 35.

1

PS4 = LI4

[Output frequency] (Hz)

10 Start the motor

www.schneider-electric.com 3/4 S1A10942 - 04/2014

Menus structure

= ENT MODE

ESC

3s LOC 2s

rdY rdY

These 3 parameters are rEN

MODE

only visible at first power up ESC ENT

of the drive.

bFr 3s

Settings can be changed

subsequently in menu:

drC- for bFr Fr1 35. [Output frequency] (Hz)

CtL- for Fr1

I-O- for tCC.

tCC

MODE

[SPEED REFERENCE] rEF-

[SETTINGS] SEt-

[MOTOR CONTROL] drC-

[INPUTS / OUTPUTS CFG] I-O-

[COMMAND] CtL-

[APPLICATION FUNCT.] FUn-

[FAULT MANAGEMENT] FLt-

[COMMUNICATION] COM-

[MONITORING] SUP-

Parameter selection

= ENT

ESC ESC

SEt- ACC 15. Refer to the programming manual (BBV46385) for comprehensive menu descriptions.

ENT ENT

ESC A dash appears after menu codes to differentiate them from parameter codes.

dEC 26.

Example:

ENT

[SETTINGS] (SEt-), ACC parameter.

26.

SFr 1 flash

(save)

www.schneider-electric.com 4/4 S1A10942 - 04/2014

S-ar putea să vă placă și

- IP5A (5.5-450kW) Service Manual - 100827Document198 paginiIP5A (5.5-450kW) Service Manual - 100827cocodrilo36067% (3)

- Pioneer VF5000Document97 paginiPioneer VF5000Fida HussainÎncă nu există evaluări

- 01 Technical Specification For 160MVA 220 132 33KV Power TransformerDocument88 pagini01 Technical Specification For 160MVA 220 132 33KV Power Transformerk. harikarasudhan33% (3)

- Deep Sea 4120 ManualDocument30 paginiDeep Sea 4120 Manualw.priatmadi100% (1)

- Deep Sea 4120 ManualDocument30 paginiDeep Sea 4120 Manualw.priatmadi100% (1)

- LV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring InstructionsDocument113 paginiLV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring Instructionsedvaldo alves pintoÎncă nu există evaluări

- Electric Wiring and Basic Electricity 2003Document163 paginiElectric Wiring and Basic Electricity 2003walkerproductions20009116Încă nu există evaluări

- Getting Started With ATV312: Verify The Delivery of The DriveDocument4 paginiGetting Started With ATV312: Verify The Delivery of The Driveteguh perkasaÎncă nu există evaluări

- Altivar 312 Quick Reference GuideDocument4 paginiAltivar 312 Quick Reference GuideMaky Hermosa ReinaÎncă nu există evaluări

- DSARS0044817Document4 paginiDSARS0044817Andresilitonga silitongaÎncă nu există evaluări

- Quick Start Guide - ATV212: Check The Delivery of The DriveDocument4 paginiQuick Start Guide - ATV212: Check The Delivery of The DriveDella Ayu OktaÎncă nu există evaluări

- Quick Start Guide - ATV212: Check The Delivery of The DriveDocument4 paginiQuick Start Guide - ATV212: Check The Delivery of The DriveEmir HarismiÎncă nu există evaluări

- Schneider Electric Altivar 21 Quick StartDocument4 paginiSchneider Electric Altivar 21 Quick StartMahdi HadadzadehÎncă nu există evaluări

- Atv312 Quick Start en S1a10942 01Document4 paginiAtv312 Quick Start en S1a10942 01Auliya UrrochmanÎncă nu există evaluări

- Getting Started With ATV12: Verify The Delivery of The DriveDocument4 paginiGetting Started With ATV12: Verify The Delivery of The DriveCode JonÎncă nu există evaluări

- ATV 312 Quick StartDocument4 paginiATV 312 Quick StartFcml Master Lefty RapÎncă nu există evaluări

- ATV32 Quick Start GuideDocument4 paginiATV32 Quick Start GuideFilipe BarateiroÎncă nu există evaluări

- Storage: Supplemental Installation InstructionsDocument2 paginiStorage: Supplemental Installation InstructionsJonalou ArominÎncă nu există evaluări

- ATV320 Getting Started EN NVE21763 01 PDFDocument4 paginiATV320 Getting Started EN NVE21763 01 PDFmaristele rimolo JuniorÎncă nu există evaluări

- Operating Instructions: VLT HVAC Drive FC 102, 1.1-90 KWDocument94 paginiOperating Instructions: VLT HVAC Drive FC 102, 1.1-90 KWHoàng Xuân DiệmÎncă nu există evaluări

- LC-22AD1E: Service ManualDocument111 paginiLC-22AD1E: Service ManualMatt SephtonÎncă nu există evaluări

- 02 40058 02 enDocument4 pagini02 40058 02 enShirin AzadiÎncă nu există evaluări

- VLT HVAC Drive FC 102 Operating InstructionsDocument94 paginiVLT HVAC Drive FC 102 Operating Instructionsduycang NguyentanleÎncă nu există evaluări

- FC 300 DanfossDocument100 paginiFC 300 Danfossiman sulaemanÎncă nu există evaluări

- Sharp 2T-C32BG1X Service ManualDocument74 paginiSharp 2T-C32BG1X Service ManualA NguyenÎncă nu există evaluări

- 1-Spec 500 KV TransformerDocument72 pagini1-Spec 500 KV TransformerAhsan SNÎncă nu există evaluări

- LC-20B2U: Service ManualDocument51 paginiLC-20B2U: Service ManualJohn SmithÎncă nu există evaluări

- GK3000 User ManualDocument137 paginiGK3000 User ManualjohnndoeeÎncă nu există evaluări

- PDFDocument167 paginiPDFAbel GaunaÎncă nu există evaluări

- ATV600 Getting Started en EAV63253 03Document4 paginiATV600 Getting Started en EAV63253 03Pustinjak SaharicÎncă nu există evaluări

- Getting Started With Altivar Process ATV600: Download The ManualsDocument4 paginiGetting Started With Altivar Process ATV600: Download The ManualsTnT ElektricÎncă nu există evaluări

- Dual Avr Unit Installation and AdjustmentsDocument4 paginiDual Avr Unit Installation and AdjustmentsKenNaÎncă nu există evaluări

- 02.power Transformer-160 &63mvaDocument138 pagini02.power Transformer-160 &63mvaraj_stuff006100% (1)

- VFDVJ SeriesDocument149 paginiVFDVJ SeriesLeonilson AraujoÎncă nu există evaluări

- Service Manual TV Sharp Led Aquos 50 Inch PDFDocument53 paginiService Manual TV Sharp Led Aquos 50 Inch PDFSatria Baharu100% (1)

- Delta VFD B Complete User Manual 5011025710 PDFDocument179 paginiDelta VFD B Complete User Manual 5011025710 PDFHelder Dos SantosÎncă nu există evaluări

- PLC Traction Temporary Run Manual PDFDocument13 paginiPLC Traction Temporary Run Manual PDFfreddyjoertyÎncă nu există evaluări

- MG11AH22Document93 paginiMG11AH22Dirga Setiawan AsharÎncă nu există evaluări

- Manualde Instrucción Danfoss HVACDocument102 paginiManualde Instrucción Danfoss HVACmantenimiento via elevadoresÎncă nu există evaluări

- RVS-DN: Digital Soft Starter 8-3500A, 220-1000VDocument54 paginiRVS-DN: Digital Soft Starter 8-3500A, 220-1000VFiras Nabiel Abu NqeirahÎncă nu există evaluări

- Service Manual: LCD Color TelevisionDocument10 paginiService Manual: LCD Color TelevisionantonlastnamÎncă nu există evaluări

- Quick Start PF70Document18 paginiQuick Start PF70selvan_rsk761Încă nu există evaluări

- MANUAL For Inverter 3.5 KW LNCDocument78 paginiMANUAL For Inverter 3.5 KW LNCEduardo Gonzalez OleaÎncă nu există evaluări

- Sharp Lc-32le244e SMDocument38 paginiSharp Lc-32le244e SMIonel SimaÎncă nu există evaluări

- An 4103Document16 paginiAn 4103taninavcoÎncă nu există evaluări

- Warner Bernstein 801 1Document4 paginiWarner Bernstein 801 1Juan Carlos EchevesteÎncă nu există evaluări

- Specification For Single Phase Padmount Distribution TransformersDocument6 paginiSpecification For Single Phase Padmount Distribution TransformersAlexis AguillonÎncă nu există evaluări

- POWER TRANSFORMER - Rev 6Document44 paginiPOWER TRANSFORMER - Rev 6Samuel DelgadoÎncă nu există evaluări

- Sharp LC20SH1E LCD TV Service ManualDocument74 paginiSharp LC20SH1E LCD TV Service Manualrogermb100% (1)

- Delta Ia-Mds VFD-VJ Um en 20141015Document144 paginiDelta Ia-Mds VFD-VJ Um en 20141015rahmatmemetÎncă nu există evaluări

- 520-qs001 - En-E Configuracion Basica PDFDocument38 pagini520-qs001 - En-E Configuracion Basica PDFluis.chuquimiaÎncă nu există evaluări

- Idcgroupsliteraturedocumentsqs520 Qs001 en e PDFDocument38 paginiIdcgroupsliteraturedocumentsqs520 Qs001 en e PDFCody KeiferÎncă nu există evaluări

- Manual - Conversor CACC - WNTCDocument148 paginiManual - Conversor CACC - WNTCRafael GarciaÎncă nu există evaluări

- Circuit Breaker - Rev 2Document22 paginiCircuit Breaker - Rev 2Pedro OcantoÎncă nu există evaluări

- ABB ZS2 Switch GearDocument94 paginiABB ZS2 Switch GearAneesh PrabhakaranÎncă nu există evaluări

- Manual InversorDocument44 paginiManual InversorAna BeatrizÎncă nu există evaluări

- Service Manual: LC-32SV1EA/RUA LC-32SA1EA/RUADocument48 paginiService Manual: LC-32SV1EA/RUA LC-32SA1EA/RUATri YuliantoÎncă nu există evaluări

- TV LCD Sharp Lc20A2MDocument34 paginiTV LCD Sharp Lc20A2MvideosonÎncă nu există evaluări

- ATV900 Getting Started en NHA61578 01Document4 paginiATV900 Getting Started en NHA61578 012015 hasÎncă nu există evaluări

- Rad-Hard 160 V, 0.5 A NPN Bipolar Transistor: FeaturesDocument15 paginiRad-Hard 160 V, 0.5 A NPN Bipolar Transistor: FeaturesNerza ElectronicsÎncă nu există evaluări

- Operating Instructions: VLT Refrigeration Drive FC 103, 75-400 KWDocument84 paginiOperating Instructions: VLT Refrigeration Drive FC 103, 75-400 KWleung ka kitÎncă nu există evaluări

- 12V Battery Tester Color Display With PrinterDocument6 pagini12V Battery Tester Color Display With Printerw.priatmadiÎncă nu există evaluări

- Candlesticks Made Simple A Free Introduction To CandlestickDocument17 paginiCandlesticks Made Simple A Free Introduction To Candlestickw.priatmadiÎncă nu există evaluări

- iSTS Model H User Manual v5 1Document45 paginiiSTS Model H User Manual v5 1w.priatmadiÎncă nu există evaluări

- Midtronics MDX-650P SOH BrochureDocument2 paginiMidtronics MDX-650P SOH Brochurew.priatmadiÎncă nu există evaluări

- 31-Gambaran Faktor Risiko Kejadian Hiperglikemia Pada Pralansia Di Dusun Rejosari, Kemadang, Gunung Kidul, YogyakartaDocument7 pagini31-Gambaran Faktor Risiko Kejadian Hiperglikemia Pada Pralansia Di Dusun Rejosari, Kemadang, Gunung Kidul, Yogyakartaw.priatmadiÎncă nu există evaluări

- 990 2483 EnglishDocument34 pagini990 2483 EnglishMihai MoldoveanuÎncă nu există evaluări

- Tesys D Lc1d25bdDocument7 paginiTesys D Lc1d25bdw.priatmadiÎncă nu există evaluări

- RPS (Keperawatan)Document3 paginiRPS (Keperawatan)w.priatmadiÎncă nu există evaluări

- New Doc 2018-04-18 PDFDocument1 paginăNew Doc 2018-04-18 PDFw.priatmadiÎncă nu există evaluări

- PDFDocument48 paginiPDFJose FigueroaÎncă nu există evaluări

- Lift FixDocument52 paginiLift Fixw.priatmadiÎncă nu există evaluări

- Pathway Reaksi Obat DN AlergiDocument1 paginăPathway Reaksi Obat DN Alergiw.priatmadiÎncă nu există evaluări

- S32k144evb SCH 29248 RBDocument6 paginiS32k144evb SCH 29248 RB정현우Încă nu există evaluări

- Rural Electrification in RwandaDocument4 paginiRural Electrification in RwandaJean-Louis KayitenkoreÎncă nu există evaluări

- Amarraj 2020Document6 paginiAmarraj 2020rock starÎncă nu există evaluări

- System Wiring DiagramsssDocument175 paginiSystem Wiring DiagramsssFahru ZainiÎncă nu există evaluări

- 223 Units Rs. 2,748.58: M/S Al Noor Cop H Society Plot FL 7Document2 pagini223 Units Rs. 2,748.58: M/S Al Noor Cop H Society Plot FL 7ZeeshanÎncă nu există evaluări

- IndexDocument8 paginiIndexdwdawadÎncă nu există evaluări

- Presentation On All Products With Detailed CCV and CTDocument121 paginiPresentation On All Products With Detailed CCV and CTS ManoharÎncă nu există evaluări

- FFPF20UP20DNDocument6 paginiFFPF20UP20DNJesus Maria LizarzabalÎncă nu există evaluări

- VarPlus Logic - 52449 PDFDocument2 paginiVarPlus Logic - 52449 PDFJosé Alejandro RangelÎncă nu există evaluări

- IDU Online Kit ManualDocument21 paginiIDU Online Kit ManualAhmed SeragÎncă nu există evaluări

- ABB Uniswitch 36kV LE ENDocument2 paginiABB Uniswitch 36kV LE ENVictor GuzmanÎncă nu există evaluări

- Fq1pwm Rf4pwm EngDocument2 paginiFq1pwm Rf4pwm Engayman qunaibiÎncă nu există evaluări

- Course Code EEE2310 EX-04Document4 paginiCourse Code EEE2310 EX-04Fardin ChowdhuryÎncă nu există evaluări

- Surge Arrester Buyers Guide Edition 6 - Section PEXLIM PDocument7 paginiSurge Arrester Buyers Guide Edition 6 - Section PEXLIM PLuis Gerardo Noy DomínguezÎncă nu există evaluări

- User Manual: HGM170/170HCDocument11 paginiUser Manual: HGM170/170HCazocarÎncă nu există evaluări

- 475-20 DC Dielectric Test Set - Version 5.0Document31 pagini475-20 DC Dielectric Test Set - Version 5.0davidramirezmÎncă nu există evaluări

- Enlzt145258ra Inv 4kvaDocument2 paginiEnlzt145258ra Inv 4kvaumair_aeÎncă nu există evaluări

- Plurijet 60 80 100 PDFDocument4 paginiPlurijet 60 80 100 PDFSartika Nur AisyahÎncă nu există evaluări

- Aluminium Conductors Steel Reinforced ACSRDocument1 paginăAluminium Conductors Steel Reinforced ACSRBaskar ElÎncă nu există evaluări

- User Manual: HGM9520 Genset Parallel (With Mains) UnitDocument70 paginiUser Manual: HGM9520 Genset Parallel (With Mains) UnitArc HieÎncă nu există evaluări

- Disconnection NoticeDocument2 paginiDisconnection NoticeAli ParkÎncă nu există evaluări

- Assignment On Renewable EnergyDocument3 paginiAssignment On Renewable Energyeglits4170Încă nu există evaluări

- 04 TransformerDocument28 pagini04 TransformerTheysingh RajaÎncă nu există evaluări

- Philips Miniwatt Battery Receiving TubesDocument75 paginiPhilips Miniwatt Battery Receiving TubesFlyForFunÎncă nu există evaluări

- Conversol Off Grid EV 1-5KVA Manual 20140327Document35 paginiConversol Off Grid EV 1-5KVA Manual 20140327Caraiane Catalin100% (1)

- Article 240 - Overcurrent Protection: National Electrical CodeDocument1 paginăArticle 240 - Overcurrent Protection: National Electrical CodeAhmed GhaniÎncă nu există evaluări

- ATS2018 Installation ManualDocument28 paginiATS2018 Installation ManualJohnny BravooÎncă nu există evaluări