Documente Academic

Documente Profesional

Documente Cultură

Engineering Impact Assessment of Asphalt Plant

Încărcat de

Saxum AquaSamuelDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Engineering Impact Assessment of Asphalt Plant

Încărcat de

Saxum AquaSamuelDrepturi de autor:

Formate disponibile

ENVIRONMENTAL ENGINEERING IMPACT ASSESSMENT OF

ASPHALT PLANT

(CAS E S TUDY: S ETRACO NIGERIA LIMITED AS PHALT PLANT, AGBARHA - OTOR)

BACKGROUND: “although there are obligatory environmental standards and regulations as

regards asphalt plant pollution, the operation of asphalt plants as well as the manufacture of

asphaltic concrete over time despite routine measures, get to pose risks considerable to the

surroundings. Thus, whether unnoticed, ignored, managed or neglected becomes an

occupational and environmental hazard to health and safety. Therefore, thus, is the aim of

investigating the analysis as carried out on the HMA facility”

ENVIRONMENTAL ENGINEERING

ABSTRACT

IMPACT ASSESSMENT OF ASPHALT

This study assessed the

impact of asphalt

PLANT production on

environment in Nigeria,

the

(CASE STUDY: SETRACO NIGERIA LIMITED ASPHALT PLANT, AGBARHA - using the HMA facility of

OTOR) Serco Nigeria Limited

located at Agbarha-Otor in

Moses .O. Utoyo Ughelli North Local

Government Area, Delta

Department of Civil/Environmental Engineering, State as a case study. Soil,

air, water and vegetation

Faculty of Engineering, samples were obtained in a

field survey, while

Delta State University, Abraka, Oleh Campus interviews and focus group

discussions were also held

utoyo.moses@gmail.com with the stakeholders.

Analysis of the laboratory

results of field samples

taken reveal that the HMA

facility has some limited

impact on the soil,

vegetation and water

KEYWORDS: HMA facility, Asphalt plant, Asphalt, Pollution around it. In particular, the

statistical analysis shows

that the Cadmium and

Benzene contents impact in

the soil is significant, while

the impact on the other

pollutant elements

considered are not

significant. For vegetation

and water, the impact on

the elements considered is

not significant. Analysis of

ACKNOWLEDGEMENT the interviews and

discussions held with the

Sincere gratitude to God and our Lord Jesus Christ, who has stakeholders’ reveal that

been my benefactor all my life. To the Spirit Divine, I implore attend the HMA facility has

my prayer. My parents for all their love, provision and care. Also I impacted both positively

wish to thank my Daddy, Engr. Agori J. for all your impact. As well and negatively on the socio-

economic activities and

not leaving out my spiritual guardians for all of their efforts in build ing health of the host

me to what I am today. I am also thankful to the management and staff community.

of the study area for their cooperation and support. As well, the

measure extended me by my siblings, extended relations, friends and

well-meaning people, God bless you all.

1

Research Engineering Article

Premium, May 2018

1. INTRODUCTION

Road construction emerged as a result of modern development. And this development came as a

result of the Industrial revolution which aimed at sustainable utilization of resources. In Nigeria, the

expansion in road network and vehicular fleets make the road transport mode the dominant mode in terms

of passenger and goods traffic (Arosanyin 2000). More than 90 percent of all the roads constructed in

Nigeria are of the flexible pavement type; Momoh and Fred, 2010. There are two major types of road

pavement in Nigeria. Those finished with asphalt wearing course, are referred to as flexib le pavement

roads, while those finished with a reinforced concrete, are referred to as rigid pavement roads. Both asphalt

concrete wearing course and asphalt surface dressing are as a result of production of hot asphalt concrete

carried out at an asphalt plant also known as Hot Mix Asphalt (HMA) facility. Unfortunately, as all other

industrial endeavors, road building has its own side effects. In the course of road construction, asphalt

plants produce asphaltic concrete that is used to construct the road surface. During the production state,

gases and particulates are discharged from the plant stakes which are emitted directly into the atmosphere

with little or no treatment. These emissions cause pollution both at the site and at distances away from

the site as a consequence of the effect of wind.

A general notion of environmental pollution could mean: “the act of making the surroundings

unsuitable for use by substances known as pollutants”. These pollutants may be any gas, liquid or solid

that interfere with the normal composition of the atmosphere having harmful and unwanted effects. Forms

of pollution includes; noise, heat, water, air, soil, etc. While the society attempts daily to create wealth by

manufacturing and producing in order to sustain a high standard of living, there will always be pollutio n.

Its impacts however, and as stressed by Anyata, 2013, depends on the amount of pollutants released into

the environment. Identified sources include; industries, automobiles, production emissions, agricultura l

wastes and so on. Notwithstanding, the government and well – meaning individuals have led in the tackle

of air pollution with the aid of policy reformation and advancing technology (IJEI, 2011). According to

the Environmental Protection Agency (EPA), the global problem of pollution is known to have negative

influence on worker and public health. The most polluted places in the world are the developing countries,

which are characterized with faulty standards of government, economics, science and technology, in her

quest to put up physical infrastructures and advance as well. In the fields of public health engineering as

well as in civil and environmental engineering technology, there is much scientific evidence of a distinct

relationship between generally dirty environment, its quality control and health effects.

Even now, environmental quality is daily plagued by harmful materials whose limits are injurious to the

environment. These are known to cause all kinds of; illness, poisoning, brain damage, disease,

suffocation, cancer, organ dysfunction, respiratory /cardiovascular disorders and sometimes death.

It is also known to have impact on vegetation, climate, property and greenhouse effects. This follows that

the sources of pollution from an asphalt plant according to Momoh and Fred 2010, are thus; dryer, burne r

– blower, dust collection system, exhaust fan, asphalt cement heating, asphaltic concrete storage and

reclaimed asphalt paving components. In the production of asphalt, most of the pollutants injected into

the atmosphere include; sulphur dioxide, particulates, carbon monoxide, nitrogen oxides, volatile

2

Research Engineering Article

Premium, May 2018

organic compounds (VOCs) and fugitive emissions. These emissions could have been effective ly

controlled but most asphalt plants don’t have adequate provision for pollution control devices. Well said,

they have the pollution control device, but due to lack of routine maintenance, poor housekeeping, neglect

or improper management, the control level of these devices drop with time and their operators being little

aware of such occurrence. Following therefore, a reduction in the standard of the plant and functiona lity

of the device posing on the overall unnoticed potential risk.

Environmental Impact Assessment of Asphalt Plants features the various positive impacts and hazards

associated with this class of projects. The procedure adopted in this enquiry at Serco Nigeria Limited,

Agbarha – Otor aid in the presentation of this research work. This involves understanding the technique

used in the processing of bitumen and aggregates in the asphalt industry to include heating and blending

of these material constituents to a temperature of 1500 C at which asphaltic concrete can be laid in road

pavement works. This study aims at evaluating the impact of pollutants from an asphalt plant on the

environment and its objectives comprise of;

To identify the production process and the pollutants emitted into the environment.

To identify the appropriate measures for mitigating the potential consequences of asphalt plant

pollution.

To facilitate stringent standards in construction companies having asphalt plant by investiga ting

the level of implementation of the terms and conditions of their operation permit as subject to

environmental policies.

To deduce from test, calculation and design the environmental consequences of polluta nt

emissions as a means of promoting sound and sustainable development of asphalt plant operation

to meet environmental protection agency requirements.

This study is useful to provide information on the function of the plants’ integrated air pollutio n

control device to develop support for the challenges of technological innovation in air pollutio n

control practices.

Owing to the above, this research work focuses on the assessment of the impact of asphalt concrete

production on the environment of asphalt plants in the area of operation of Serco Nigeria Limited, Emevor

road, Agbarha – Otor, in Ughelli – North of Delta State, Nigeria, where such Hot Mix Asphalt Facility

(HMA) is located.

3

Research Engineering Article

Premium, May 2018

2. PROJECT AREA

Asphalt occasionally known as bitumen, is a sticky, black and highly gelatinous liquid of petroleum.

It is a semi – solid residue found in natural deposits and is often classed as pitch. Until the 20th century,

the term “asphaltum” was also associated with this substance. Up to 70% of asphalt/bitumen is primarily

used as a binder mixed with aggregate particles to create asphalt concrete applied in road construction. Its

other foremost uses are for sealing flat roofs, production of roofing belt and water proofing products.

Figure 2.1: Serco Asphalt Plant showing visible emissions

Thus, this is the practice of environment impact assessment (EIA) used in determining the

environmental impact associated with production of asphaltic concrete in Serco Nigeria Limited, Agbarha

– Otor, Delta State with evaluation of the necessary measures to be taken to reduce these impacts. Serco

Nigeria Limited operates a fully automatic Batching Plant (Phoenix Paker with a stack height of up to 30

metres) near Ughelli town in Agbarha – Otor located in delta state region approximately at 5º32′4′′ north

of the equator and 6º4′29′′ east of the Prime meridian. It is about 6 kilometers from Ughelli, the

headquarters of Ughelli North local government area. The figure below (Figure 2.2) is a map of delta state

showing the case study area. The study area is on the outskirts of the town and consists of stock piles of

paving materials, heavy duty trucks, large structural machinery, personal offices, necessary equipment

and associated infrastructure.

Figure 2.2: Ughelli Area of Delta State showing the Agbarha – Otor town

4

Research Engineering Article

Premium, May 2018

An HMA plant which can hardly be an easily relocated (skid - mounted) plant may possess reclaimed

asphalt paving (RAP) capabilities of the varied asphalt plants in Nigeria; the fully automatic batch plant

type is the more common. Hot Mix Asphalt (HMA) paving materials are a mixture of size – graded, high

quality aggregate and liquid asphalt cement which is heated and mixed in measured quantities. Whenever

applicable, over 92% by weight of the total mixture is composed of recycled asphalt paving. A certain

percentage of fine aggregate (fine dust of < 74µmdia) is required for the production of good quality HMA

[BS 4987 – 1: 2005; Coated macadam (asphalt concrete) for roads and other paved areas; Specificatio n

for constituent materials and for mixtures]. The influence of air pollution and other forms of it has no

boundaries. Hence, the various ways of mitigating its effects to the surroundings.

The asphalt plant in Serco Nigeria Limited was constructed and is under operation of continuo us

asphalt production at about 1.3km away from the nearest residential area. No fewer than 36 employees

work in the environ adhering to strict management practices. Since 1977, the Asphalt Plant Department

of Serco International Group of Companies employed experts to assess the merits of the project in

accordance with relevant requirements. The impact of the project was then mitigated/controlled to ensure

an acceptable level of environmental performance in Emevor road, Agbarha – Otor. This was certified by

the general public and the Federal Ministry of Environment, Abuja; but then again, thus, has been their

presence in up to 20 states in Nigeria. The asphalt industry therefore of Serco Group, Agbarha – Otor

remains functional to this day with a continual supply of materials from Ifom at Auchi, in their Edo state

office.

Figure 2.3: The Hot Mix Asphalt Facility during production

5

Research Engineering Article

Premium, May 2018

3. ASPHALTIC CONCRETE AND THE ASPHALT PLANT

The production of asphalt is associated with the emission of some gases and particulates as earlier

stated. Asphalt plants, according to Barnard et. al. 2003, consists of some basic environment pollutio n

sources as it deals with many things that can affect the environment. Annually, its emission rates have

been known to exceed emission standards set by controlling bodies. However, the established precept of

source controlling rather than outright condition prevention has made it operate and it has thus far,

continued in operation. As an occupational carcinogen, it should be more feasible to mainta in

concentration levels of such discharges. Thus, the pollutants are so managed and the safety of the facility

to an extent is guaranteed (U.S. EPA, 2000). These compounds and their typical concentration levels are

shown below:

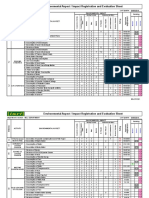

Table 3.1: Compounds and their typical concentration levels

Compound Concentration in stack gas

Nitrogen 67.7%

Water vapour 20.0%

Oxygen 9.5%

Carbon(ii)oxide 2.8%

Carbon monoxide 0.02%

Sulphur(ii)oxide 0.004%

Nitrogen oxides 0.005%

Volatile Organic Compounds (VOCS) 0.004%

e. g Cadmium, formaldehyde, benzene, etc.

Total 100%

In countries like the U.S.A., asphalt pavement mixing facilities are well – regulated by federal and

state environmental agencies, and they employ multiple emissions released from their control systems,

which are thus closely monitored to ensure that they stay well below any permitted level set by the

Environmental Protection Agency (EPA) and other regulators to ensure that they pose no health or

environmental risk to nearby communities. Laura 2008, also states that asphalt plants are known toxins

that represent concentration level of emissions of particles, dust and gases as contained in the atmosphere

(i.e. controlled acceptable levels) which should not be exceeded. This presumption has been demonstrated

accordingly in the table above.

6

Research Engineering Article

Premium, May 2018

In fact, over a decade ago, the EPA reviewed emissions from asphalt plants and determined that

such facilities are not a major source of air pollution by ensuring that they have adequate emission control

devices. The majority of emissions at asphalt mixing facilities come from the combustion of fuel, such as

natural gas, that are used to dry and heat the rock or aggregate and to keep the temperature of the asphalt

hot. Most of the other potential emissions, such as the dust generated during the drying of aggregate, are

captured by bag house filters or similar controls and never released to the environment. It follows that, at

times, there may be noticeable emissions coming from an asphalt plants stack, but in almost all

circumstances this is just steam – the loss of water vapour from the drying of aggregate at high

temperatures. Sometimes, odours from the heated materials may also emanate from an asphalt plant.

Although they may be noticeable, these odours do not indicate a health hazard; there are many instances

of natural and man – made odours that are noticeable but not harmful – dairy farms, garlic, skunks and

marshlands to name a few. Asphalt plant odours are not harmful (NAPA, 2014).

A 2001 study compared emissions from an asphalt plant to emissions from other common

community and industrial sources. The study found that the low annual emissions from an asphalt plant

are equivalent or well below many other common sources:

(1) Similar volatile organic compounds (VOCs) emissions from one bakery operating for about two

weeks or from 13 residential fire places over the course of a year

(2) Less than six months’ worth of toluene emissions from an automobile gasoline filling station

Since 1970, the asphalt pavement industry has documented a decrease in total stack emissions of 97%,

while increasing pavement production by 25%. This is what should be in Nigeria, but the story is differe nt.

Some other times, owing to flawed tests risks could be undervalued. Research studies tells that these plants

can be designed, maintained and operated in manners consistent with preserving environmental quality.

Research Engineering Article

Premium, May 2018

4. METHODOLOGY

The procedure of this project work involved the followings:

SAMPLE COLLECTION

(1) Collection of Soil Samples

(2) Collection of Vegetation Samples

(3) Collection of Particulate Samples

(4) Collection of Gaseous Pollutant Samples

(5) Collection of Water Samples

(6) Temperature Measurement

(7) Noise level measurement

LABORATORY EXPERIMENTS

Collection of Samples:

SOIL AND VEGETATION: The soil sampling points chosen were based on a 300m × 300m grid

system from the exact location of the Asphalt Plant Stack. A total of 14 sampling points were established.

From each sampling points samples were collected using a hand auger to a depth of about 0.15m. Data

extracted were from Cassava plants (a well- known food crop in the area).

AIR: Particulate samples collected were basically stone dust and condensed bitumen particles for

an averaging time of 24 hours daily for 1 month during asphalt production. After appropriate spot

checking, I chose the sampling location to be about 1.5m above ground level using a dust fall bucket to

reflect the human breathing zone (the gravimetric technique).

The method of gas sample collection involved the absorption of the volume of polluted air bubbled

through a selected solvent in which a selected gaseous pollutant component air of interest is made to react

with the solvent while the other components continue through in – line to be absorbed at another stage

(absorption method).

WATER: Proper grab sampling (quick scoop) techniques were adopted as part of the survey to

assess water quality and to check compliance with water quality standards. Water samples were collected

from; rainwater, plant borehole and Okpare creek (a nearby stream).

TEMPERATURE AND NOISE: Temperature readings were collected at established locations

from the plant using a thermometer, while Noise levels were measured using a sound level meter.

Laboratory Tests:

8

Research Engineering Article

Premium, May 2018

The procedure for the air analysis is described below;

I placed a 300mm diameter dust fall bucket at the sampling location around the asphalt site. To

this bucket container, I add some quantity of water to enhance the trapping of particulate matter. The

weight of the empty bucket and the dust particles after the water has been evaporated was taken to deduce

the weight of particulate matter in grammes (g). The dust fall concentration was determined over a period

of 30days.

The following formula was used to compute for the dust fall;

4w

Df = 𝜋𝑑2 ……………………………..(4.1)

where;

W = mass of particulate

d = diameter of bucket

The total weight of particulate collected was 276g and the dust fall was calculated in g/m2 /month.

The Air Quality Impact Assessment (AQIA) was possible owing to this mathematical model in the systems

analysis of air quality modelling;

Figure 4.1: Gaussian Dispersion Model

So that, the concentration of a pollutant, at a distance, from the source is given by:

𝑄 𝑦2 𝑧2

𝐶 𝑖𝑛 𝑡ℎ𝑒 𝑥 𝑑𝑖𝑟𝑒𝑐𝑡𝑖𝑜𝑛, = 𝜋𝜐𝑦 𝜎 𝑒𝑥𝑝 (− 2𝜎 2 − 2𝜎 2 ) ……………………………..(4.2)

𝑧 𝑦 𝑧

Where; Q = Source strength

σ = Standard deviations in x, y and z direction

9

Research Engineering Article

Premium, May 2018

υ = Average wind speed

For a stable atmosphere, the above formula is more often than not affected by temperature

inversion layers and other environmental factors affecting air pollution levels.

Also, the technique employed in analyzing sulphate in the cassava plant sample is given as follows;

Having earlier prepared the plant sample, I weighed about 0.15g of it and put it into a ceramic

boat. This I covered with ComCat Accelerator (tungsten oxide compound). I then placed the boat in a

furnace at a temperature of 13500 C with an oxygen rich atmosphere. The concentration of sulphur was

then determined by infrared absorption of evolved sulphur dioxide upon its combustion on a LECO

sulphur determinator, Model No. S144 – DR.

There were also other standard techniques employed in extraction of the concentration level of

parameters determined based on data collected as required by this study.

10

Research Engineering Article

Premium, May 2018

5. RESULT AND DISCUSSION

The results of the Soil test carried out are stated accordingly:

TABLE OF VALUES

The results for Vegetation Elements Tests are given as follows;

Sample No NO SO2 CO VOC Cadmium Benzene Toluene Formaldehyde

(g/kg) (g/kg) (g/kg) (g/kg) (g/kg) (g/kg) (g/kg) (g/kg)

1 0.110 0.133 1.731 29.10 0.013 0.001 16.401 0.005

2 0.061 0.536 1.121 22.10 0.025 0.001 5.201 0.005

3 0.981 0.402 3.731 46.10 0.031 0.001 6.401 0.005

4 0.581 0.402 2.991 35.10 0.007 0.001 2.401 0.009

5 0.138 0.133 2.851 48.10 0.013 0.401 5.601 0.005

6 0.044 0.267 0.751 29.00 0.019 0.001 5.601 0.050

7 0.175 1.741 2.681 62.10 0.013 0.001 7.601 0.017

8 0.128 2.144 2.241 44.10 0.007 0.001 11.201 0.005

9 0.153 4.280 2.991 43.10 0.013 0.401 11.601 0.050

10 0.118 8.850 2.011 41.10 0.024 0.401 5.601 0.009

11 0.104 0.133 1.631 49.10 0.013 4.001 6.801 0.013

12 0.093 0.402 1.561 35.10 0.013 3.201 10.401 0.004

13 0.160 0.267 2.751 44.10 0.007 3.601 6.001 0.017

14 0.080 12.100 1.351 32.10 0.019 4.001 15.601 0.013

Mean 0.209 2.271 2.171 40.02 0.016 1.144 8.315 0.015

Value

11

Research Engineering Article

Premium, May 2018

Correlation - 0.47 - 0.79 - - 0.144 - 0.031 0.293 - 0.50

Coefficient 0.386 0.342

(T - test)

Analysis of 0.402 0.172 0.744 0.057 0.011 0.377 0.158 0.025

Variance

(F - test)

Table 1.782 1.782 1.782 1.782 1.782 1.782 1.782 1.782

Value @

5%

Confidence

level

Distance Nitrogen Phosphorus Calcium Magnesium Sodium Potassium Sulphate Nitrogen

from

HMA (g/kg) (g/kg) (g/kg) (g/kg) (g/kg) (g/kg) (g/kg) (g/kg)

facility

0.00km 0.97 0.106 0.49 0.20 0.37 0.19 1.05 0.97

0.09km 0.83 0.200 0.46 0.07 0.11 0.16 1.22 0.83

1.50km 0.92 0.107 0.47 0.07 0.18 0.16 1.43 0.92

The results for Air Elements Tests are given as follows;

12

Research Engineering Article

Premium, May 2018

S/No Averaging NO2 SO2 CO H2 S NH3

Period

(µg/m3 ) (µg/m3 ) (µg/m3 ) (µg/m3 ) (µg/m3 )

1 24 hours 0.384 0.312 0.432 0.288 0.408

2 30days (mean 0.017 0.016 0.017 0.011 0.016

concentration)

3 Average Dust fall = 1171.23g/m2 /month

The results for Water Elements Test is given as follows;

Sample pH Chlorine Sulphate Calcium Magnesium Sodium Potassium Nitrogen

Description

(mg/l) (mg/l) (mg/l) (mg/l) (mg/l) (mg/l) (mg/l) (mg/l)

Borehole 6.6 0.37 0.33 5.62 0.98 0.56 1.67 0.20

Okpare 6.2 0.72 0.66 8.03 1.95 1.02 2.57 0.37

creek

Rainwater 5.4 0.36 1.04 2.21 1.46 0.36 0.46 0.52

The results for Temperature measurements and noise level observations are given as follows;

Approximate 5m 10m 15m 20m 25m

Distance

from Plant

Temperature 400 C 38.50 C 36.70 C 31.50 C 270 C

13

Research Engineering Article

Premium, May 2018

Approximate 10m 20m 30m 40m 50m

distance

from Plant

Noise level 110dB 100dB 90dB 70Db 50dB

ANALYSIS OF RESULTS

(1) Soil analysis:

For a 5% confidence level the table value for 14 nos of test result after the correlation and

difference between values was 1.782 for all tested parameters. This tells of an absence of linear correlation

in the positive and negative directions. (i.e. not valid)

It was observed that the average concentration of sulphur which was 2.271g/kg was higher than

the average normal concentration of sulphur in Delta soils which is about 2.06g/kg. This tells of a

possibility of acid deposition in the case study area.

(2) Vegetation Analysis

Comparison of Cassava plant vegetation data in the plant location as against the distance from the

plant as tested accordingly showed an average difference level of -0.03g/kg to 0.28g/kg with the samples

taken at the 0.00km distance used as reference. This and visual observance tell of noticeable impacts but

the results show that the cassava plant is of the same consistency in general, i.e. in terms of distance from

the plant.

(3) Air Analysis

From the air elements test, the concentration of gases obtained is way below USEPA air quality

standards for 24hours average permissible limit (as adopted by Nigeria and South Africa). This is depicted

as follows;

(i) SO 2 concentration of 0.312µg/m3 being way below 6.25µg/m3

(ii) NO 2 concentration of 0.384µg/m3 being way below 2.37µg/m3

(iii) CO concentration of 0.432µg/m3 being way below 1607.14µg/m3 .

But, in contrast, the background impact level of dust fall is very high according to the U.S. Air Quality

Standards for Particulates; Subpart 257 – 3 of 40g/m2 /month as against the Average Dust fall =

1171.23g/m2 /month, indicative of the likelihood of impact.

Smoke observations using the Ringlemann scale gave a smoke density of 2 which was equivalent to a

Percent opacity of 40%.

14

Research Engineering Article

Premium, May 2018

This averaged result indicated a moderate amount of air pollution.

(4) Water Analysis

Results were compared with international reference standards (WHO standards for drinking

water). For instance, the bore hole sample recorded a Chlorine content of 0.37mg/l, the rainwater samp le

0.36mg/l and the sample from Okpare creek 0.72mg/l; as compared to a standard of 1.5mg/l. i.e. still

within acceptable limits as there seem to be no effect on its quality.

(5) Temperature Measurement

It was observed that there was an average temperature difference every 5m distance towards the

asphalt plant of 3.25 0 C rise.

(6) Noise Measurement

The noise level readings show that there was an average increase in noise level of 15dB every 10m

distance one takes approaching the asphalt plant.

GRAPH AND EXPLANATION

During the course of this research work, the relationship between these chemicals concentratio ns

in the soil and the distance from the plant were plotted and shown on a graph (scatter plot). Some of these

graphs are given below:

Graph of Carbon monoxide in relation to the distance from the plant

CO (g/kg) CO (g/kg)

4

Concentration (g/kg)

3.5

3

2.5

2

1.5

1

200 400 600 800

Distance (m)

Graph of NO in relation to distance from the plant

15

Research Engineering Article

Premium, May 2018

NO (g/kg)

NO (g/kg)

3.18

3.16

3.14

Concentration (g/kg) 3.12

3.1

3.08

3.06

3.04

0 200 400 600 800

Distance (m)

Graph of VOC in relation to distance from the plant

VOC (g/kg) VOC (g/kg)

14

Concentration (g/kg)

12

10

8

6

4

2

0

0 200 400 600 800

Distance (m)

Graph of Benzene in relation to distance from the plant

12

Benzene (g/kg) C6H6 (g/kg)

Concentration (g/kg)

10

8

6

4

2

0

0 200 400 600 800

Distance (m)

16

Research Engineering Article

Premium, May 2018

Graph of Sulphur dioxide in relation to distance from the plant

SO (g/kg)

SO (g/kg)

6

Concentration (g/kg)

5

4

3

2

1

0

0 200 400 600 800

Distance (m)

Graph of Formaldehyde in relation to distance from the plant

formaldehyde (g/kg) CH2O (g/kg)

0.035

Concentration (g/kg)

0.03

0.025

0.02

0.015

0.01

0.005

0

0 200 400 600 800

Distance (m)

Graph of Toluene in relation to distance from the plant

toluene(g/kg) C7H8 (g/kg)

12

Concentration (g/kg)

10

8

6

4

2

0

0 200 400 600 800

Distance (m)

17

Research Engineering Article

Premium, May 2018

Graph of Cadmium content in the soil in relation to distance from the asphalt plant

cadmium (g/kg) CdS (g/kg)

0.045

Concentration (g/kg) 0.04

0.035

0.03

0.025

0.02

0.015

0.01

0.005

0

0 200 400 600 800

Distance (m)

DISCUSSION

From the graphs, it could be asserted that apart from Benzene, no correlation exists between these

chemical values in soil and the distance from the Hot Mix Asphalt plant. i.e. the concentration of these

parameters is of no significance to its distance from the plant.

This in general, tells of the impact of the Serco Asphalt Plant around a 1km radius of the

community to be felt around the South – West and North – East directions in both the dry and rainy seasons

of weather. This is so because from the sampling locations established in relation to the analysis carried

out it can be deduced that such evidence from the study depends on the predicted fate of atmospheric

pollutants and stack gases dispersed and diluted under conditions in the area of study. Hence, the

arguments that asphalt plant presents overall risks.

18

Research Engineering Article

Premium, May 2018

6. CONCLUSIONS AND RECOMMENDATIONS

Deductions from this study experience suggest that:

(1) laboratories with accreditation should be used for environmental monitoring

(2) standardization of reporting format to foster availability

(3) review of existing EIA guidelines to incorporate regular supervisory roles

(4) the EIA process should be reviewed at the institutional level

(5) evaluation of the competency and capacity of consulting organizations

(6) recognition of standardized potential impact prediction and evaluation methods

(7) proponent awareness of the EIA process should be increased

LIMITATIONS OF THIS STUDY

(1) Availability of published sources of Environmental Impact Reports (EIR)

(2) Availability of necessary technology

(3) Undue with – holding of information by construction companies

(4) Available literature in the field of air pollution

(5) Financial projections and additional costs

CONCLUDING REMARKS

The total annual emissions estimate from an asphalt plant is at alarming levels even though within

standard limits. Evidence of this is feasible as there is stress on frequent assessment on workplace

pollution, 56% loss in property value and 45% deterioration in human health due to a close proximity with

the industry. This is possible because only 40% of the toxins from asphalt plant smoke stacks meet air

quality standards as the state lack sufficient data to determine safe and over time safe levels. The reason

for this is that asphalt plant operators are assumed to operate perfectly on an “honour system”.

A good EIA practice is more often than not characterized by efficient integration of professiona l

skills in geology, laboratory management, computer science, etc. This study demonstrated that asphalt

plant emissions can be eliminated completely more than its assessed level (during building, as obtainable

in advanced environments) to avoid its multiplier effects due to unforeseen emission increase or untold

migration of people into its buffer zone. Introducing appropriate units of the dust control system integrated

in the plant operation process of utmost design without hampering the process mixture of asphaltic

concrete should be modeled to establish heightened standards of pollution control, especially for future

concerns. This is in line with the World Health Organization (WHO) guidelines for environmental quality

regulations in protecting against pollution.

19

Research Engineering Article

Premium, May 2018

REFERENCES

Ahmad V. J. and Sammy G. K. (1987); Waste Generation and Management Techniques. In; H. T. Jimoh,

I. P. Ifabiyi (eds.): Contemporary Issues in Environmental Studies; Haytec Press and Pub. Co. Ltd, Ilorin.

Aigediou I. N. (2005); Environmental Pollution in the Niger - Delta Nigeria. Inter - Disciplinary J. Enugu

- Nigeria 3(4): 200 - 215.

Ajakaiye D. E. (1985); Environmental Problems Associated with Mineral Exploitation in Nigeria. A

paper presented at the 21st Annual Conference of the Nigeria Mining and Geosciences Society, Jos. pp.

140 - 148.

Akinbamijo O. B. (2002); Dynamics of Environmental Relationships: The Gender Route to Sustainable

Living. The Journal of Urban and Environmental Research, 2(1): 29 - 42.

Andersen Z. J., Hvidberg M., Jensen S. S., Ketzel M., Loft S., Sorensen M. and Raaschou - Nielsen

O. (2011); Chronic Obstructive Pulmonary disease and Long - Term exposure to Traffic-Related

Pollution: a Cohort study. (Research Support, Non - U. S. Govt.). American Journal of respiratory and

critical care medicine, 183(4), 455 - 461.

APHA (1989); Standard Methods for the Examination of Water and Waste Water. 17th Edition. American

Public Health Association, DC.

Areola S. and Olokesusi F. (1993); “An Ex - post Evaluation of land ownership pattern and Tenure

problems in Large-Scale Irrigation Project. A Nigerian Case Study”, Social Development Issues, 5(3),

pp. 56 - 70.

Braden I. B. and Kolstad C. D. (1991); “Measuring the Demand for Environmental Quality”;

Constructions to Economic Analysis No 198, Amsterdam, North Holland.

Brook P. D., Rajagopalan S., Pope C. A., Brook J. R. and Bhatnagar A. (2010); “Particulate Matter

Air Pollution and Cardiovascular disease; An update to the Scientific Statement from the American Heart

Association”. Circulation 121: 2331 - 2378.

Brookshire I. S. and Nell H. R. (1992); “Benefit Transfers Conceptual and Empirical Issues” Water

Resources Research, Vol. 28, No. 3, March, pp. 651 - 655.

Burdge R. J. and Frank V. (1995); “Social Impact Assessment” In: Environmental and Social Impact

Assessment (eds), Frank Vanclay and Daniel Bronstein, John Wiley and Sons. Sussex, pp. 31 - 65.

Byun D. W. (1998a); Dynamically Consistent Formulations in Meteorological and Air Quality Model for

Multi-Scale Atmospheric Studies: I. Governing Equations in a Generalized Coordinate System. Journal

of Atmospheric Science.

Byun D. W. (1998b); Dynamically Consistent Formulations in Meteorological and Air Quality Model

for Multi-Scale Atmospheric Studies: I. Mass Conservation Issues. Journal of Atmospheric Science.

Cannel A. L. and Meadows M. L. (1985); Effects of Recent Operating Experience on the Design of

Spray Dryer FGD Systems, “Journal of the Air Pollution Control Association”, 35(7): 782 - 89.

Canter L. (1995); Environmental Impact Assessment, 2nd Edition; McGraw Hill, New York City.

20

Research Engineering Article

Premium, May 2018

Chatterjee A. K. (2010); Water Supply, Waste Disposal and Environmental Engineering, Eight Edition,

Khanna Publishers; 4575/15, Onkar House, Opp. Happy School, Darya Ganj, New Delhi - 110002.

Chen H., Goldberg M. S. and Villeneure P. J. (2008); “A systematic review of the relation between

long-term exposure to ambient air pollution and chronic diseases”. Reviews on environmental health

23(4); 243 - 97.

Zabbey N. (2007): Climate Change and Flooding; fate of Riverine Communities in the Niger Delta. Paper

Delivered at an interactive roundtable organized by stakeholder Democracy Network (SDN) in

Commemoration of World Environmental Day, SDN Conference Room, Port Harcourt, Nigeria.

21

Research Engineering Article

Premium, May 2018

FURTHER READING

Janyer J. (2001): “Urban Air Pollution and Chronic Obstructive Pulmonary disease: A Review”, European

Respiratory Journal 17(5): 1024 – 1033.

James R. F. and Bethany R. K. of Colby College. “History of the Clean Air Act”. American Meteorological Society;

Retrieved August 2014 from www.ametsoc.org/sloan/cleanair/

John H. (2009); Air Pollution Encyclopedia Article; Microsoft Encarta Online Encyclopedia.

John T.: “Environmental Issues”, The Environmental Blog; Retrieved August 2014 from;

www.theenvironmentalblog.org

Kao A. S. (1994); “Formation and Removal Reactions of Hazardous Air Pollutants” Journal of the Air Pollution

Control Association, 44: p. 683 – 96.

Kent M. and Coker P. (1992): Vegetation Description and Analysis: A Practical Approach, Belhaven Press, London.

Kpopkar S. M. (2004): Environmental Pollution – Monitoring and Control, 1st Edition; New Age International(D)

Limited, Publishers, New Delhi – 110002.

Laboratory Manual for Air Quality Sampling and Analysis, Department of Civil Engineering, Indian Institute of

Technology Delhi, New Delhi – 110016.

Lagos State Environmental Protection Agency (1997): State of Environment Report Lagos.

Lanting R. W., Lee S. D., Schneider T. and Gmat M. D. (1986): Black Smoke and Soiling Aerosols; Lewis

Publishers, USA. pp. 923 – 932.

Laura C. G. (2008): Questions and Answers regarding Hot Mix Asphalt Plants and Environmental and Public

Health Considerations; Cambridge Environmental Inc., 58 Charles Street Cambridge,

Massachusetts 02141.

Leopold L. B. et. al. (1971): A Procedure for Evaluating Environmental Impact; U. S. Geological Survey, Circular

No. 645 U. S. Geological Survey, Washington, D. C.

Letcher T. M. (2007): Developments and Applications in Solubility, 1st Edition; Royal Society of Chemistry. (ed).

ISBN 978 - 0854043729 P. 71.

Lucking A. et. al. (2008): “Diesel Exhaust Inhalation Increases Thrombus Formation in Man”. European Heart

Journal 29(24): 3043 – 3051.

Lutgens F. K. and Edward J. T. (1995): The Atmosphere, 6th Edition; Prentice Hall. ISBN 0 – 13 – 3560612 – 6.

Lutz E. (1995): “Towards Improved Accounting for the Environment: An Overview”, in Lutz E. (Eds). Towards

Improved Accounting for the Environment, An UNSTAT – World Bank Symposium, the World

Bank, Washington, D. C.

Laws E. A. (2000); Aquatic Pollution: An Introductory Test; John Wiley and Sons, New York.

Mackernie L. D. and Susan J. M. (2009): Principles of Environmental Engineering and Science, 2nd Edition; Mc –

Graw Hill Companies, Inc. 1221 Avenue of the Americas, New York. NY 10020.

Menell P. S. (2002): Environmental Law, 1st Edition; Aldershot, England, Burlington, Vt: Ashgate/Dartmouth.

Michelozzi P. Forastiere F., Fusco D., Ostro C. A., Ancona C. and Palloti G. (1998): “Air Pollution and Daily

Mortality in Rome, Italy” – Occupational and Environmental Medicine 55(9): 605 – 610.

22

Research Engineering Article

Premium, May 2018

Momoh L. R. and Fred E. A. (2010): An Assessment of the Environmental Impact of Asphalt Production in Nigeria;

Department of Geography and Regional Planning, Ambrose Alli University, Ekpoma, Edo State.

Morris P. and Therivel R. (1965): Methods of Environmental Impact Assessment; Brookes University, Oxford.

MTN NIGERIA COMMUNICATIONS LIMITED (2013); Environmental Impact Assessment for the Construction

of New Base Stations in Delta State (Vol. 2); Environmental Management Plan Draft Report

Submitted to Federal Ministry of Environment, Abuja.

Munasinghe I. (1997): Environmental Economics and Sustainable Development. World Bank Environmental Paper

No. 3, The World Bank, Washington, D. C.

“NATA; National – Scale Air Toxics Assessments – Technology Transfer Network Air Technical Web site; US

EPA; 2006” Retrieved August 2014 from; http://www.epa-gov. pp. 06 – 28.

Narayanan P. (2007): Environmental Pollution – Principles, Analysis and Control; First Edition, CBS Publishers

and Distributors, New Delhi, Bangalore (India), pp. 145 – 199.

Nathanson J. A. (1997): Basic Environmental Technology – Water Supply, Waste Management and Pollution

Control; Prentice Hall, Inc. Simon and Schuster/A Viacom Company Upper Saddle River, New

Jersey 07458. pp. 341 – 386.

National Environment Protection Management of Solid and Hazardous Wastes Regulations, 1991.

National Guidelines on Environmental Management System in Nigeria, 1991.

National Policy on Environment, Federal Environmental Protection Agency; Revised Edition, 1998.

National Resources Defense Council (NRDC): Reducing Diesel Sulphur Levels to reduce Urban Pollution.

Available online at: http://www.nrdc.org/air/transport/psulphur

NCAPC (1967): Tracing Course Manual in Air Pollution, Control of Particulate Emissions, National Centre for Air

Pollution Control, Department of Health, Education and Welfare, Cincinnati, OH.

Odman M. T. and Russel A. G. (1991): Multiscale Modeling of Pollutant Transport and Chemistry; J. Geophys.

Res., 96, 7362 – 7370.

Ofume G. C. (2001): The Roles and Responsibilities of Professionals in Implementation of the Environmental

Impact Assessment Act No. 86; A Paper presented at the Workshop on “Environmental Impact

Assessment and Construction Projects – Issues and Perspectives. Prodec – Fugro Limited; 11B

Geodetic Road, Rumuobiakani, Portharcourt, Nigeria. 084 - 238964, 084 - 571014.

Olokesusi F. (1984): “Environmental Impact Assessment: Initiating it and Making it work for Nigeria, In: The

Petroleum Industry and the Nigerian Environment, NNPC, Lagos, Nigeria.

Olokesusi F. (1993): “Ex – Post Evaluation of Resettlement and Rehabilitation Issues in Large scale Irrigation

Projects in Nigeria”. Research for Development, Vol. 10 (1 and 2), p. 87 – 102.

Olugbenga O.: Emission Control in Nigeria and South Africa Essential Readings in Environmental Law; IUCN

Academy of Environmental Law, University of Zululand, South Africa.

Omuta G. E. D. (1984):” Urbanization and Industrialization, The Case of Benin”. In: Sada P. O. and Osirike A. B.

(eds.) Case Studies in Urbanization in Nigeria. Perspective in Policy Issues, Benin, pp. 85 – 97.

Onasanya S. O. (1992): “The Relationship Between Topographic Location, Soil Properties and Cultural

Management and the Productivity of Maize – Soybean Intercrop”. An Unpublished Ph.D. Thesis

Submitted to the Department of Agronomy, University of Ibadan, Ibadan.

23

Research Engineering Article

Premium, May 2018

Risse – Kappen T. (1995); Bringing Translational Relations back in: Non - State actors, Domestic Structures and

International Institutions. Cambridge: Cambridge University. pp. 3 – 34.

Robert N. (1993): Pollution Prevention Technology Handbook, 1st Edition, A. K. Jain; For Standard Publishers

Distributors, 1705 – B, Nai Sarak, Delhi – 110006.

Rodgers W. H. Jnr. (1986); Environmental Law: Air and Water, Vol. 2., St. Paul, Minn: West.

Seinfield J. H. (1954): Air Pollution, Physical and Chemical Fundamentals, McGraw – Hill, New York, p. 71.

Short K. C. and Stauble A. J. (1969): “Outline of Geology of the Niger Delta”. Bull Am. Association Petrol Geology.

Vol. 54. pp. 761 – 779.

Source Sampling for Particulate Emission (1984); Paving Materials: Supply; Baltimore County, Maryland –

Ramcon Environmental Corporation, Memphis, TN.

Spengler J. D. and Sexton K. A. (1983): “Indoor Air Pollution: A Public Health Perspective”. Science 221 (4605):

9 – 17 (p. 9).

Stagg M. K. (2001): “The EPA’s New Source Review Enforcement Actions: Will they Proceed?” Trends

33(November - December).

Seinfield J. H. (1954): Air Pollution, Physical and Chemical Fundamentals, McGraw – Hill, New York, p. 71.

Short K. C. and Stauble A. J. (1969): “Outline of Geology of the Niger Delta”. Bull Am. Association Petrol Geology.

Vol. 54. pp. 761 – 779.

Source Sampling for Particulate Emission (1984); Paving Materials: Supply; Baltimore County, Maryland –

Ramcon Environmental Corporation, Memphis, TN.

Stagg M. K. (2001): “The EPA’s New Source Review Enforcement Actions: Will they Proceed?” Trends

33(November - December).

Sys C. (1985): “Land Evaluation”. International Training Centre for Post – Graduate Soil Scientist, Vol. 1, II, III.

State Univ. Ghent.

Technical Ltd (1988): “Techniques for Assessing Industrial Hazards - A Manual”; World Bank Technical Paper

No. 55. The World Bank, Washington, D. C.

Tornqvist H. K. et. al. (2007): “Persistent Endothelial Dysfunction in Humans after Diesel Exhaust Inhalation.”

American Journal of Respiratory and Critical Care Medicine 176(4): 395 – 400.

Turner D. B. (1994); Workbook of Atmospheric Dispersion Estimates; An Introduction to Dispersion Modeling,

Second Edition; CRC Press. ISBN 1 – 56670 – 023 – X.

Tussie D. (2000): The Environment and International Trade Negotiations; Developing Country Stakes (ed.) IDRC,

Ottawa, Canada.

United Nations Environment Programme (1996): Environment Impact Assessment – Issues, Trends and Practice;

UNEP, Nairobi.

United Nations Environment Programme (UNEP), 2014; Our Planet: Climate for Life. Retrieved August 2014

from: www.unep.org/publications/

24

Research Engineering Article

Premium, May 2018

S S

APPENDIX

300m 300m 300m 300m

3 4 5

1 2

300m 300m 300m 300m 300m

300m 300m 300m 300m

E 6 7 8 9 W

Plant

300m 300m 300m 300m 300m

SCALE:

1:500

300m 300m 300m 300m

10 11 12 13 14

m10 05 0 10

20 30m

Emevor

Road

Sampling points from the asphalt plant

Agbarha - Otor

Road

25

Research Engineering Article

Premium, May 2018

S-ar putea să vă placă și

- Isuzu Trooper Workshop ManualDocument3.573 paginiIsuzu Trooper Workshop Manualvit otio89% (19)

- Merlo DBM 2000 2500 3500 en PDFDocument8 paginiMerlo DBM 2000 2500 3500 en PDFJozef50% (4)

- Al Majal QMS - 2018Document19 paginiAl Majal QMS - 2018Adam DeviatteyÎncă nu există evaluări

- 18A - FO - Permit To Work LogDocument2 pagini18A - FO - Permit To Work Lograjesh_rathÎncă nu există evaluări

- EOHS Management System Procedure Procedure For Context of The OrganizationDocument4 paginiEOHS Management System Procedure Procedure For Context of The OrganizationSuresh MuruganÎncă nu există evaluări

- Top Management Audit Questions - ISO 9001Document1 paginăTop Management Audit Questions - ISO 9001dnmuleÎncă nu există evaluări

- Uscg Oupv Guidebook 2013Document54 paginiUscg Oupv Guidebook 2013Ed PifanoÎncă nu există evaluări

- HSE Procedure For Environmental Aspects, Hazards, Evaluation of Impacts, Risks & Determination of Control MeasuresDocument19 paginiHSE Procedure For Environmental Aspects, Hazards, Evaluation of Impacts, Risks & Determination of Control MeasuresSafety IezzproÎncă nu există evaluări

- New ExccavationDocument1 paginăNew ExccavationsunilÎncă nu există evaluări

- Identification of Aspects & ImpactsDocument15 paginiIdentification of Aspects & Impactsvindice flameÎncă nu există evaluări

- Environmental Management SystemDocument145 paginiEnvironmental Management Systemmohamed ibrahimÎncă nu există evaluări

- Environmental Aspects & Impacts For PlantDocument5 paginiEnvironmental Aspects & Impacts For PlantDarren TanÎncă nu există evaluări

- FM ENV 003 EMS ManualDocument33 paginiFM ENV 003 EMS ManualAnggoro Antono100% (1)

- Flow ChartDocument1 paginăFlow ChartJorge Cronwell Montaño VásquezÎncă nu există evaluări

- Contractors Induction ToolboxDocument2 paginiContractors Induction ToolboxGeorge VasileÎncă nu există evaluări

- ASPECT-IMPACT ANALYSIS Reference No. VE-EMS-01/VA/02: ISO 14001:2004 Done by - V.B.TodkarDocument4 paginiASPECT-IMPACT ANALYSIS Reference No. VE-EMS-01/VA/02: ISO 14001:2004 Done by - V.B.TodkarBalachandar SathananthanÎncă nu există evaluări

- ATS Machinery, Plants & Equipment RegisterDocument2 paginiATS Machinery, Plants & Equipment Registershuhada ghazaliÎncă nu există evaluări

- 1929065493Document360 pagini1929065493alecandro_900% (1)

- List of Legal Register and Other RequirementsDocument103 paginiList of Legal Register and Other RequirementsZubaidi OthmanÎncă nu există evaluări

- S. I. 268 of 2018 Environmental Management Hazardous SubDocument78 paginiS. I. 268 of 2018 Environmental Management Hazardous SubMoleki NgendaÎncă nu există evaluări

- Energy Management System Certificate ISO 50001 188409 2015 AE GER DAkkS EnglishDocument2 paginiEnergy Management System Certificate ISO 50001 188409 2015 AE GER DAkkS Englishjamppajoo2100% (1)

- EP06Document5 paginiEP06Chrome PicassoÎncă nu există evaluări

- STP Comparision of ProcessDocument11 paginiSTP Comparision of Processwd100% (1)

- Pest Monitoring May 2023Document9 paginiPest Monitoring May 2023Aisyah Ja'farÎncă nu există evaluări

- Normal Checklist: Preliminary Cockpit Preparation (Silent)Document2 paginiNormal Checklist: Preliminary Cockpit Preparation (Silent)Rob Gronkowsky100% (2)

- Minimize Energy in A BPA Process Webinar - V2 - FINALDocument35 paginiMinimize Energy in A BPA Process Webinar - V2 - FINALrizanda93Încă nu există evaluări

- Environmental AuditDocument29 paginiEnvironmental AuditAnkit ShahÎncă nu există evaluări

- HSS COSH Day 5 - HODocument96 paginiHSS COSH Day 5 - HONicole SalemÎncă nu există evaluări

- Lead Exposure Control PlanDocument3 paginiLead Exposure Control PlanShahzeb HassanÎncă nu există evaluări

- Aashto T 250Document13 paginiAashto T 250Alejandra Vélez Mesa100% (3)

- Safety Engineering: Applied Science & Computing 2008Document46 paginiSafety Engineering: Applied Science & Computing 2008falkirk10bÎncă nu există evaluări

- Self Compacting Concrete m30 PDFDocument5 paginiSelf Compacting Concrete m30 PDFmalaya tripathyÎncă nu există evaluări

- IRMT Electronic RecsDocument195 paginiIRMT Electronic Recs4dev22100% (1)

- IAF MD 21 Migrationto ISO 45001 2018Document12 paginiIAF MD 21 Migrationto ISO 45001 2018pastelos100% (2)

- 00.list of ENV SOPDocument6 pagini00.list of ENV SOPPaddyÎncă nu există evaluări

- Amendment No. 3 February 2021 TO Is 10500: 2012 Drinking Water - SpecificationDocument3 paginiAmendment No. 3 February 2021 TO Is 10500: 2012 Drinking Water - SpecificationSharad JoshiÎncă nu există evaluări

- Rebar Impalement Hazards TBT FINAL July 2017Document2 paginiRebar Impalement Hazards TBT FINAL July 2017amizanÎncă nu există evaluări

- Fire Risk Assessment FormDocument19 paginiFire Risk Assessment FormGopinath SekarÎncă nu există evaluări

- Guidelines and Space Standards For Physically Disabled: Submitted byDocument32 paginiGuidelines and Space Standards For Physically Disabled: Submitted byrenuÎncă nu există evaluări

- Ims ManualDocument27 paginiIms ManualpjosesmÎncă nu există evaluări

- S-MatrixDocument8 paginiS-MatrixkhktvnÎncă nu există evaluări

- Material Safety Data Sheet For DieselDocument2 paginiMaterial Safety Data Sheet For DieselSadkatul BariÎncă nu există evaluări

- RISK Mba 17Document22 paginiRISK Mba 17Cecily Sandra100% (1)

- Quality Control Key Steps - ConstructionDocument26 paginiQuality Control Key Steps - ConstructionDarwin MarceloÎncă nu există evaluări

- Iso 14001 English PDFDocument5 paginiIso 14001 English PDFkemalÎncă nu există evaluări

- Environmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Document50 paginiEnvironmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Geroldo 'Rollie' L. QuerijeroÎncă nu există evaluări

- Progress Up To 05-Des-2013Document1 paginăProgress Up To 05-Des-2013Asep MAkmurÎncă nu există evaluări

- Full Time SHEQ Rep DutiesDocument1 paginăFull Time SHEQ Rep DutiesMoses MuchakaviriÎncă nu există evaluări

- Life Cycle AssessmentDocument8 paginiLife Cycle AssessmentDaman Huri WibowoÎncă nu există evaluări

- Environmental Management System: SANS/ISO 14001:2015Document6 paginiEnvironmental Management System: SANS/ISO 14001:2015Kevin RamanÎncă nu există evaluări

- Tender - Organics Processing FacilityDocument20 paginiTender - Organics Processing FacilitySimon McCarthyÎncă nu există evaluări

- 3 - Operational Risk Management - 1Document39 pagini3 - Operational Risk Management - 1MikealayÎncă nu există evaluări

- Procedure For Solid Waste MagtDocument3 paginiProcedure For Solid Waste MagtAkimBiÎncă nu există evaluări

- Application of Industrial and Agricultural Waste For Sustainable Construction PDFDocument9 paginiApplication of Industrial and Agricultural Waste For Sustainable Construction PDFJayesh MagarÎncă nu există evaluări

- Environmental Conservation Rules, 1997 (ECR'97)Document2 paginiEnvironmental Conservation Rules, 1997 (ECR'97)নরকেররাজপুত্রÎncă nu există evaluări

- Fall Protection PPT v-03!01!17Document31 paginiFall Protection PPT v-03!01!17Mustafa AdelÎncă nu există evaluări

- Chapter - 5 Implementation of 6S ConceptDocument27 paginiChapter - 5 Implementation of 6S Conceptdevesh vermaÎncă nu există evaluări

- Siemens' Motor HandbookDocument20 paginiSiemens' Motor HandbookJerome BaesÎncă nu există evaluări

- Effective Communication Course NotesDocument61 paginiEffective Communication Course NotesIonescu GeorgeÎncă nu există evaluări

- Environmental Aspect / Impact Registration and Evaluation SheetDocument3 paginiEnvironmental Aspect / Impact Registration and Evaluation SheetrewrtegamingÎncă nu există evaluări

- Process Matrix TemplateDocument2 paginiProcess Matrix TemplateJayant Kumar JhaÎncă nu există evaluări

- Incident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsDocument4 paginiIncident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsMobin Thomas AbrahamÎncă nu există evaluări

- NCR RepairDocument4 paginiNCR RepairPanruti S SathiyavendhanÎncă nu există evaluări

- Equipment Monthly Inspection ChecklistDocument1 paginăEquipment Monthly Inspection ChecklistNoufal PattambiÎncă nu există evaluări

- Package II Part I.1 Civil BOQ For Transit House BuildingDocument29 paginiPackage II Part I.1 Civil BOQ For Transit House Buildingdox4useÎncă nu există evaluări

- Public Consultation A Complete Guide - 2020 EditionDe la EverandPublic Consultation A Complete Guide - 2020 EditionÎncă nu există evaluări

- GCC MUTCD - Final - 20140929Document301 paginiGCC MUTCD - Final - 20140929Abu Majd100% (1)

- 72831Document2 pagini72831demetroÎncă nu există evaluări

- 9700 w04 ErDocument17 pagini9700 w04 ErwegdanÎncă nu există evaluări

- ME 2010 04 Vehicle Front-End Active AerodynamicsDocument6 paginiME 2010 04 Vehicle Front-End Active AerodynamicsAsha DashÎncă nu există evaluări

- A. Navigation Rules For MarinersDocument225 paginiA. Navigation Rules For MarinersnavyeyeÎncă nu există evaluări

- Prathmesh PPT NewDocument16 paginiPrathmesh PPT NewPrathamesh GawliÎncă nu există evaluări

- Consumer Behavior and Effect of Marketing Strategy On Atul Autofinal-1Document58 paginiConsumer Behavior and Effect of Marketing Strategy On Atul Autofinal-1rutvik080808Încă nu există evaluări

- Effective Date: 26 Mar 2020Document3 paginiEffective Date: 26 Mar 2020Piyush MankaniÎncă nu există evaluări

- Europe Beverage Dispensers Sales Market Report 2021Document7 paginiEurope Beverage Dispensers Sales Market Report 2021Hellina MartinsÎncă nu există evaluări

- CH 7Document36 paginiCH 7Oscar Sacases PlanasÎncă nu există evaluări

- Ad 2.12 Runway Physical Characteristics: AD 2-FAHG-5 AIP South AfricaDocument2 paginiAd 2.12 Runway Physical Characteristics: AD 2-FAHG-5 AIP South AfricaKHUSHAL BANSALÎncă nu există evaluări

- TRANSLINK - Company Profile PDFDocument39 paginiTRANSLINK - Company Profile PDFKaran DaveÎncă nu există evaluări

- Mohad Sharef Mohad-CholaDocument2 paginiMohad Sharef Mohad-CholaVara PrasadÎncă nu există evaluări

- Abstract Sheet 23-09-2022Document16 paginiAbstract Sheet 23-09-2022Rajesh Bhat - Estimation Dept. KBP CivilÎncă nu există evaluări

- Chikhaoui - Chafik - Cover - Letter CANADA SHIPOWNERS ASSOCIATIONDocument1 paginăChikhaoui - Chafik - Cover - Letter CANADA SHIPOWNERS ASSOCIATIONChikhaoui ChafikÎncă nu există evaluări

- Hypercoaster - Spec - Sheet (1) ZNDDocument2 paginiHypercoaster - Spec - Sheet (1) ZNDa “a” aÎncă nu există evaluări

- Tivyside Classified 031115Document5 paginiTivyside Classified 031115Digital MediaÎncă nu există evaluări

- GSYuasa LIM30H 8ADocument2 paginiGSYuasa LIM30H 8Abrome2014Încă nu există evaluări

- Itinerary - G236VWDocument3 paginiItinerary - G236VWKits SolayaoÎncă nu există evaluări

- A Study On Passenger S Satisfaction Towards Railway Services in Erode JunctionDocument6 paginiA Study On Passenger S Satisfaction Towards Railway Services in Erode JunctionEBIN JOHNÎncă nu există evaluări

- News WritingDocument67 paginiNews WritingneoclintÎncă nu există evaluări

- UIC Codex 779 9eDocument68 paginiUIC Codex 779 9eMiguel ParÎncă nu există evaluări

- Wheel Alignment Theory Operation PDFDocument5 paginiWheel Alignment Theory Operation PDFOskars ŠtālsÎncă nu există evaluări

- Caterpillar's Supply Chain Strategy and Results: Ron KruseDocument20 paginiCaterpillar's Supply Chain Strategy and Results: Ron KruseAgus Soy Yo0% (1)