Documente Academic

Documente Profesional

Documente Cultură

Quality Control Sampling of Sand and Rootzone Mixture Stockpiles

Încărcat de

yamanta_rajTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Quality Control Sampling of Sand and Rootzone Mixture Stockpiles

Încărcat de

yamanta_rajDrepturi de autor:

Formate disponibile

Quality Control Sampling Of Sand

And Rootzone Mixture Stockpiles

O ne of the most important aspects of putting green

construction is the rootzone. Whether the rootzone

is composed of straight sand or a mixture of sand and

Amendments may also vary slightly from bag to bag or lot

to lot. And, when materials are blended, some variability

is introduced through the operation of the blending

amendments, quality control testing is recommended equipment. Good suppliers of sand, amendments, and

to ensure the rootzone material remains as consistent blending services can keep these variables to a minimum.

as possible. This is accomplished by removing samples

There is another major source of variability that

from the stockpile and submitting those samples to an

can cause significant discrepancies in the quality control

accredited physical soil-testing laboratory for analysis.

testing efforts. Improper and/or inconsistent sample

The goal of the sampling and testing procedure collection procedures will introduce unwarranted errors

is to monitor changes in the rootzone material as it is in the test results. Poor sampling procedures can result in

produced. It is important to realize that some change test results that make a good rootzone material appear to

is inevitable. As sand is mined from a pit or from a body be inconsistent and therefore of poor quality.

of water, the physical make-up of the sand changes.

When To Sample

There are two levels of sampling and testing that are almost certain to vary. The initial testing procedure

should be carried out. The first level should take place at should be used only to identify materials that fall within

the source where the sand and amendments are produced. the project guidelines.

Samples should be collected and sent to an accredited

The second level of sampling should occur

laboratory for analysis. The test results are then provided

throughout the actual production of the rootzone

to the person responsible for approval of the materials.

materials so that mistakes due to handling the material

Sampling and testing several candidate materials during mixing and transportation are detected. Collect a

is the best means to identify the most appropriate and sample from the first 200 tons produced and submit to

cost-effective products. The laboratory will determine if the laboratory for complete analysis. If the lab determines

the sand meets the green construction criteria selected the sample meets the requirements of the project (e.g.

for the project. For example, if the USGA’s Method of USGA Guidelines), the test results become the target

Putting Green Construction is to be followed, the lab will for all subsequent quality control testing. The goal of all

analyze the sand according to those criteria. Typically, the future rootzone material production is to match as closely

lab also will add amendments to the sand in varying ratios as possible the material in the first 200-ton pile. After

to identify the best mixture possible for the project. It is the initial 200 tons, collect a sample for every 1000 tons

important to realize that such amendments are added by of rootzone mix produced. If less material is being used

hand in the lab, often from small stocks they keep on hand. (for example, building only one green) or if the material

Later, when the rootzone mixture is produced in bulk, is inconsistent in its composition as indicated by testing,

blending will be accomplished by machinery. As a result, sample every 500 tons or less.

when samples are collected from the blended stockpiles

and compared to the preliminary testing, the numbers

©2015 by United States Golf Association, All rights reserved.

Please see Policies for the Reuse of USGA Green Section

Publications. Subscribe to the USGA Green Section Record. Page 1

How To Sample

Field sampling errors are almost certain to cause confidence. The greater the number of voters interviewed,

significant variability in laboratory test results and can the greater the level of confidence there will be in the

cause confusion, delay, and unnecessary expense. It is poll. Similarly, the more samples that are removed from

imperative therefore, that stockpiles be sampled in a a stockpile, the more accurately the test results will

manner such that the composite sample removed from reflect the actual make-up of the pile. This document

each pile represents the average properties of the entire recommends that at least 8 samples be collected from

pile. To do this, a sufficient volume of material should be each 1000-ton stockpile to achieve good results.

taken with each sampling unit (a sampling unit is a core or

Field sampling procedures should be standardized

auger of a given dimension) and all sampling units should

for the duration of the quality control testing program.

be collected to make a composite sample (combining of

ASTM D 75-97, Standard Practice for Sampling Aggregate,

sampling units) that are of equal volumes.

offers some guidance regarding the best method of

To better illustrate the importance of removing sampling putting green rootzone mixture stockpiles.

enough sampling units, consider the science of polling The standard states, “If circumstances make it necessary

during an election. If a pollster queried only a few to obtain samples from a stockpile of coarse aggregate

voters, there would not be a large enough sample of the or a stockpile of combined coarse and fine aggregate,

population to reasonably predict the outcome. While the design a sampling plan that will give confidence in results

most accurate method would be to ask every single voter therefrom that is agreed upon by all parties concerned

how he or she voted, this is not feasible or cost-effective. to be acceptable for this particular situation.” There are

The pollsters utilize statistical analysis to determine how two very important statements in this quote from the

large a group of voters must be interviewed to determine standard. First, a sampling plan must be established.

the likely outcome of the election to a certain level of Secondly, all parties should agree to the plan.

The standard does not state exactly how the sampling procedure

should be designed. To meet this need, the USGA utilized the expertise

of university, industry and laboratory professionals to develop the

following procedure. All samples should be collected as detailed in

the following step-by-step procedure.

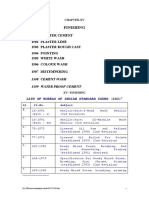

Produce a stockpile of approximately 1000 tons. The individual in

the photo is standing in front of a recently produced, 1000-ton pile

of rootzone sand. Assemble the necessary tools for sampling the

stockpile. These include a:

• clean, 5-gallon bucket

• rubber hammer

• shovel

• permanent marker

• 1-gallon zip lock plastic bags

©2015 by United States Golf Association, All rights reserved.

Please see Policies for the Reuse of USGA Green Section

Publications. Subscribe to the USGA Green Section Record. Page 2

• mailing labels and

• a large, non-permeable plastic tarp

The sampling tool is made from a 4-foot long piece of 2-inch PVC pipe. To make sampling easier, one end of the pipe can

be cut at a 45-degree angle. A PVC “T” can be placed on the other end to make it easier to push the pipe into the sand.

Duct tape can be used to mark the 2-foot sampling depth.

Step By Step Procedure For Sampling A Stockpile

Collect a minimum of 8 samples to ensure an accurate representation

of the pile. Take samples at four equidistant points around the pile, at

⅓ and ⅔ up the face of the pile, for a total of at least eight samples.

Dig a hole into the face of the pile to prevent collection of any of the

sand from the surface of the pile. Expose an undisturbed face of the

pile into which the collection tube can be inserted. When you first dig

into the pile, material from above will usually flow down the face into

the area you are clearing. Keep digging until the hole becomes stable.

The shovel also works very well to expose an undisturbed face. Make a

vertical cut down into the face just above the sampling point.

Insert the collection tube into the undisturbed face to a depth of two

feet. The tube should be inserted at a slightly upward angle to prevent

the sample from falling out when the pipe is removed. Mark the

collection tube to ensure uniform depth insertion. The “T” fitting on

the end of the two-inch, PVC pipe makes it easier to push the pipe into

the pile. In most cases, the pipe can be pushed in by hand to the proper

depth. In “tight” sand, a rubber hammer may be needed to drive the

pipe to the 2-foot depth.

©2015 by United States Golf Association, All rights reserved.

Please see Policies for the Reuse of USGA Green Section

Publications. Subscribe to the USGA Green Section Record. Page 3

Carefully remove the collection tube from the face of the pile.

Empty the sample from the tube into a clean, 5-gallon bucket.

Improper sample collection procedures will result in problems. This

sample is being collected incorrectly from the surface of the pile rather

than from within the pile. When this sample is tested, the results will

not represent the overall make-up of the stockpile. Samples collected

in this manner will be highly inconsistent from test to test since the

surface of the stockpile changes rapidly.

Samples collected from the surface of this pile can vary widely from

those collected from within the pile. Notice how the surface of the

pile has segregated due to wind and rain. As the finer materials erode,

the coarser materials accumulate on the pile surface. Test results of a

sample removed from this area would indicate a higher percentage of

coarse materials than actually exists in the pile.

©2015 by United States Golf Association, All rights reserved.

Please see Policies for the Reuse of USGA Green Section

Publications. Subscribe to the USGA Green Section Record. Page 4

After the eight samples are collected from the 1000-ton pile, the

5-gallon bucket should be about ½ to ⅔ full. (If a stockpile larger

than 1000 tons is sampled, the number of samples collected should

be increased proportionately. Thus, at least 16 samples should be

collected from a 20w00-ton pile.)

Empty the bucket onto a clean, non-permeable surface. Thoroughly

mix the samples together by hand. The combined sample should now

be reduced to approximately 1 gallon to be sent into the laboratory.

This is accomplished by splitting the sample. The sample should be

shaped into a square so that it can be divided into quarters.

Divide the sample into equal quarters. Opposite quarters will be

removed from the sample and discarded. For example, if quarters 1 and

4 are removed and discarded, quarters 2 and 3 will be recombined and

mixed again. Another square is then formed. The process is repeated

until the sample is reduced to approximately 1 gallon

Place the 1-gallon sample into a plastic, zip-lock bag. Label the outside

of the bag using a permanent marker. Record the pile number and

date of collection. Print the same information on a mailing label and

place the label on the outside of the bag. Place the sealed and labeled

bag into another plastic bag and seal it with duct tape. This labeling

and double-bagging procedure is important to ensure the lab receives

the sample intact.

©2015 by United States Golf Association, All rights reserved.

Please see Policies for the Reuse of USGA Green Section

Publications. Subscribe to the USGA Green Section Record. Page 5

With assistance from university and labortory scientists, the USGA Green Section has identified the maximum

amount of variation that should be tolerated for key test parameters measured during quality control testing. The

following table details a variability percentage for each parameter. This variability percentage is more accurately

referred to as the confidence interval and is used to establish plus or minus values for each measured parameter. For

example, assume the laboratory test indicates a value for fine sand to be 10%. Using the confidence interval percentage

for fine sand of 15%, the acceptable variance is 10% plus or minus 1.5% for an acceptable range for quality control

testing of 8.5 to 11.5%.

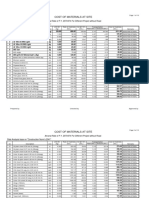

Table 1—USGA Confidence Intervals For Quality Control Testing

Test Parameter USGA Confidence Intervals

Fine Gravel 50%

Very Coarse Sand 50%

Coarse Sand 10%

Medium Sand 10%

Fine Sand 15%

Very Fine Sand 30%

Silt 25%

Clay 25%

Total Porosity 10%

Air-filled Porosity 10%

Capillary Porosity 10%

Saturated Conductivity 20%

Percent Organic Matter of Mix 0.2*

* The confidence interval for percent organic matter is not represented as a percentage. Thus, a reported value of 0.7% organic matter could

range from 0.5 - 0.9%.

©2015 by United States Golf Association, All rights reserved.

Please see Policies for the Reuse of USGA Green Section

Publications. Subscribe to the USGA Green Section Record. Page 6

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Lab Design Guide ChecklistDocument9 paginiLab Design Guide ChecklistWaleed El-azabÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Integra 400s Operartion Sop PDFDocument11 paginiIntegra 400s Operartion Sop PDFBasheer AlmetwakelÎncă nu există evaluări

- Lab Statistics Fun and Easy Fifth EditionDocument204 paginiLab Statistics Fun and Easy Fifth EditionJosé González CamposÎncă nu există evaluări

- Master's Handbook For Construction ManagementDocument15 paginiMaster's Handbook For Construction Managementyamanta_rajÎncă nu există evaluări

- BOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITDocument3 paginiBOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITyamanta_rajÎncă nu există evaluări

- Annex 5: Bill of Quantities (Boqs) : Unicef Jco - RFPDocument8 paginiAnnex 5: Bill of Quantities (Boqs) : Unicef Jco - RFPyamanta_rajÎncă nu există evaluări

- Bill of Quantity:: Tiger Circle - ManipalDocument8 paginiBill of Quantity:: Tiger Circle - Manipalyamanta_rajÎncă nu există evaluări

- BOQ RCC Septic Tank For AFOH Offices PDFDocument7 paginiBOQ RCC Septic Tank For AFOH Offices PDFxalid AbdulrahmanÎncă nu există evaluări

- Unprised PSF BoQsDocument6 paginiUnprised PSF BoQsyamanta_rajÎncă nu există evaluări

- BoQ - Lologo PTC Fence, Gate House, Guard House + BoreholeDocument4 paginiBoQ - Lologo PTC Fence, Gate House, Guard House + BoreholeHaymanAHMED100% (2)

- Proposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at KiamwathiDocument49 paginiProposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at Kiamwathiyamanta_rajÎncă nu există evaluări

- PRINCE2 Detailed Process Map v4Document1 paginăPRINCE2 Detailed Process Map v4yamanta_rajÎncă nu există evaluări

- Institute For Empirical Research in Economics University of ZurichDocument23 paginiInstitute For Empirical Research in Economics University of Zurichyamanta_rajÎncă nu există evaluări

- Practice File - 01Document12 paginiPractice File - 01yamanta_rajÎncă nu există evaluări

- 2nd - PPM E-CourseDocument12 pagini2nd - PPM E-Courseyamanta_rajÎncă nu există evaluări

- Contract Manager: A New Project Team Member?Document5 paginiContract Manager: A New Project Team Member?yamanta_rajÎncă nu există evaluări

- Project Management OfficeDocument10 paginiProject Management Officeyamanta_rajÎncă nu există evaluări

- Project Management Approaches For Dynamic EnvironmentsDocument31 paginiProject Management Approaches For Dynamic Environmentsyamanta_rajÎncă nu există evaluări

- Assessment of Hire Rate Analysis of Heavy Equipment in NepalDocument13 paginiAssessment of Hire Rate Analysis of Heavy Equipment in Nepalyamanta_raj100% (1)

- Specification (GRP Tank)Document7 paginiSpecification (GRP Tank)yamanta_rajÎncă nu există evaluări

- 2764Document102 pagini2764yamanta_rajÎncă nu există evaluări

- (1B) District Transport Master Plan: Presentation For LRN TrainingDocument36 pagini(1B) District Transport Master Plan: Presentation For LRN Trainingyamanta_rajÎncă nu există evaluări

- Metal Fencing SpecificationsDocument6 paginiMetal Fencing Specificationsyamanta_rajÎncă nu există evaluări

- Civil General 6th I & IIDocument7 paginiCivil General 6th I & IIyamanta_rajÎncă nu există evaluări

- Rate Analysis of Different Item 21 DecDocument34 paginiRate Analysis of Different Item 21 Decyamanta_rajÎncă nu există evaluări

- Norms DUDBC PDFDocument60 paginiNorms DUDBC PDFDebendra Dev Khanal84% (19)

- Norms For Consumption of Materials For Building WorksDocument1 paginăNorms For Consumption of Materials For Building WorksVishal TiwariÎncă nu există evaluări

- PKG - 1 TEKU Dovan Area BoQ - FinalDocument48 paginiPKG - 1 TEKU Dovan Area BoQ - Finalyamanta_raj0% (1)

- Rate Analysis-Norms 1Document10 paginiRate Analysis-Norms 1yamanta_rajÎncă nu există evaluări

- Rate Analysis-NormsDocument7 paginiRate Analysis-NormsGajendra Joshi0% (1)

- SP15Document38 paginiSP15yamanta_rajÎncă nu există evaluări

- Guide Specification For The Construction of Interlocking Concrete PavementDocument6 paginiGuide Specification For The Construction of Interlocking Concrete PavementGaneshÎncă nu există evaluări

- Specification For Road ReinstatementDocument10 paginiSpecification For Road Reinstatementyamanta_rajÎncă nu există evaluări

- Safety ContractDocument3 paginiSafety ContractDestre TashjianÎncă nu există evaluări

- SyllabusDocument26 paginiSyllabusmasoodmuhidÎncă nu există evaluări

- Self Assessment Report NewDocument36 paginiSelf Assessment Report NewsmrutiranjandashÎncă nu există evaluări

- Workshop 1 (GROUP 1) : Profile of Laboratory Objectives of Laboratory Action Plan List of Non-CompliancesDocument32 paginiWorkshop 1 (GROUP 1) : Profile of Laboratory Objectives of Laboratory Action Plan List of Non-CompliancesGretchel PontilarÎncă nu există evaluări

- Manual Basic LAboratoryDocument245 paginiManual Basic LAboratoryAngelo Palaming100% (2)

- Waw FormDocument9 paginiWaw FormBryan MadssÎncă nu există evaluări

- SARS CoV 2 Airborne Detection White PaperDocument6 paginiSARS CoV 2 Airborne Detection White PaperagcpzdeqpyeaeypxifÎncă nu există evaluări

- 2019-20 Handbook CatalogDocument254 pagini2019-20 Handbook CatalogGH PractitionerÎncă nu există evaluări

- Mangesh and Mansi Quality Assurance UnitDocument27 paginiMangesh and Mansi Quality Assurance UnitSumant SainiÎncă nu există evaluări

- JSS 0256-01Document149 paginiJSS 0256-01jagadi582895100% (3)

- Daftar Bahan Kimia Chemical Register GuidelinesDocument3 paginiDaftar Bahan Kimia Chemical Register GuidelinesDzuraineyBtAbuBakar100% (1)

- Riya Gupta.Document2 paginiRiya Gupta.Drishti MalhotraÎncă nu există evaluări

- Course OutlineDocument25 paginiCourse OutlinewilliamsdevanelÎncă nu există evaluări

- CBSE Maths Projects Manual - Class 9-10 - Module 1Document37 paginiCBSE Maths Projects Manual - Class 9-10 - Module 1msujoyÎncă nu există evaluări

- Em1 3Document8 paginiEm1 3Keith D. PatchÎncă nu există evaluări

- UT Dallas Syllabus For Ee1102.104.09f Taught by Nathan Dodge (Dodge)Document6 paginiUT Dallas Syllabus For Ee1102.104.09f Taught by Nathan Dodge (Dodge)UT Dallas Provost's Technology GroupÎncă nu există evaluări

- Computer Lab TechnicianDocument2 paginiComputer Lab TechnicianrezhabloÎncă nu există evaluări

- NORSOK STANDARD M-650 Edition 4 Qualification of Manufacturers of Special MaterialsDocument19 paginiNORSOK STANDARD M-650 Edition 4 Qualification of Manufacturers of Special MaterialsGiovanni LupoliBVÎncă nu există evaluări

- 09.16.2020 CMS Testing Requirements For LTCFsDocument1 pagină09.16.2020 CMS Testing Requirements For LTCFsMichael HowellÎncă nu există evaluări

- Imran Khan CVDocument3 paginiImran Khan CVHafiz Abdul HaseebÎncă nu există evaluări

- CourseGuide ES085Document5 paginiCourseGuide ES085Loraine CastilloÎncă nu există evaluări

- Name: - T - / 58 ClassDocument5 paginiName: - T - / 58 ClassNovita SariÎncă nu există evaluări

- Saic Q 1005Document3 paginiSaic Q 1005Tayyab AchakzaiÎncă nu există evaluări

- Fyp Logbook - Syafiqah (Kh17033)Document6 paginiFyp Logbook - Syafiqah (Kh17033)anis amiraÎncă nu există evaluări

- CIVE 306 - Syllabus v5Document3 paginiCIVE 306 - Syllabus v5jean paulÎncă nu există evaluări

- NELSON MANDELA UNIVERSITY'S Dream Medical SchoolDocument11 paginiNELSON MANDELA UNIVERSITY'S Dream Medical SchoolDispatchLIVEÎncă nu există evaluări

- Cepietso PCP 20151Document4 paginiCepietso PCP 20151EusoofÎncă nu există evaluări