Documente Academic

Documente Profesional

Documente Cultură

Unico Componet Layout - 0

Încărcat de

Kyaw San OoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Unico Componet Layout - 0

Încărcat de

Kyaw San OoDrepturi de autor:

Formate disponibile

Bulletin 40-30 / May 2007

Component Layout

GENERAL the modular units (M2430, M3642, and M4860) can be

installed in the vertical downflow configuration. The

This manual, when used in conjunction with Bulletin 40-40,

installation possibilities are:

System Sizing and Layout should provide the necessary

information to determine the UNICO SYSTEM sizing, layout A. Horizontal Units:

and job material list. The many specification and installation 1. Attic installation supported on a platform or

instructions for the UNICO SYSTEM equipment should be suspended from attic rafters.

studied so the system designer understands the equipment 2. Basement installation suspended from the floor

thoroughly before proceeding with the system design and joists.

layout. 3. Furred down installation in hallways, closets or

utility rooms.

SYSTEM SIZING B. Vertical Upflow Units:

1. Closet or utility room installation on a cabinet

Before the proper equipment can be selected for a UNICO

base or wall brackets.

SYSTEM installation, it is imperative that the heat gain and/or 2. Basement installation on a cabinet base or

heat loss be calculated for the structure that is to be comfort platform.

conditioned. To assure a proper layout and a well-balanced

C. Vertical Downflow Units:

system, room by room heat gain and/or heat losses should 1. First floor closet or utility room installation

be calculated using generally recognized methods, such as over a crawl space or slab (requires special

ACCA Manual J or the ASHRAE Cooling and Heating Load

consideration for the distribution system –

Calculation Manual. The extra time spent designing a Bulletin 30-05, Air Distribution Systems)

proper system will be repaid many times and result in: 2. Second story closet or utility room installation

1. Correctly sized equipment feeding into plenum between floors.

2. Properly balanced system

3. Less call backs OUTDOOR EQUIPMENT

4. Satisfied customers

The UNICO SYSTEM air handling units can be matched with

5. More profit

any compatible outdoor condensing unit or outdoor heat

Note: It is permissible to use shorter and quicker

pump section from any ARI listed manufacturer; however,

procedures for job estimating purposes. These are covered

the matchups are the responsibility of the installer since

in a separate instruction. However, it is important to

different outdoor units have different operating

remember that such procedures are for the initial cost

characteristics. Bulletin 30-20, ‘M’ Series Modular Air

estimates and are no substitute for the more detailed longer

Handling Units Installation Manual provides for the

procedures as outlined above.

recommended charging procedures for cooling systems and

Bulletin 30-24, Heat Pump Installation for heat pump

EQUIPMENT SELECTION systems. Using chilled water and hot water coils, multiples

Unico, Inc. air handlers are available in three (3) basic of units can be matched to individual or larger capacity

models in the ‘M’ series. The M1218 provides a small chillers and boilers. If desired the chilled water coil can be

compact unit in one package for 1 and 1-1/2 ton cooling used with both chilled and hot water.

systems. The M series modular air handling units are

available in 3 sizes, the M2430 for 2 and 2-1/2 ton cooling INSTALLATION INSTRUCTIONS

systems, the M3642 for 3 and 3-1/2 ton cooling systems,

Detailed installation instructions are available for the

and the M4860 for 4-5 ton cooling systems. All air handlers

various system components and should be consulted for the

are available as cooling only (either DX or chilled water),

applicable equipment before beginning the system layout.

heat pump with auxiliary electric heating and hot water coil

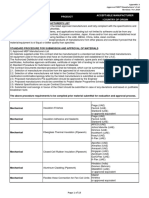

The following installation instructions are available:

heating.

Bulletin 30-05, Air Distribution Systems

EQUIPMENT LOCATION Bulletin 30-10, M1218 Fan Coil

Bulletin 30-20, M Series Modular Air Handler Units

All UNICO SYSTEM air handlers can be installed in the

Bulletin 30-24, M Series Modular Heat Pump Systems

horizontal and vertical upflow configurations. Additionally, Bulletin 30-30, Hot Water Coils

© Copyright 2007 Unico, Inc.

Bulletin 40-30 — Page 2

Bulletin 30-34, Electric Duct Heaters it is then necessary to build a suitable filter box or frame at

Except for Bulletin 30-05, a copy of each instruction is

shipped with each piece of equipment. For air distribution

system components there are many individual specifications

which include installation instructions. Check for the

instruction upon unpacking the equipment.

DISTRIBUTION SYSTEM AND ACCESSORIES

Figure 1. Optional Air Handler Placement

The key distribution system components are depicted on

Bulletin 20-15, System Component Specifications. The many the air handler.

accessory items shown on this specification sheet facilitate

installation in a variety of situations. For basement or crawl space applications it can be handled

as follows:

Any system installed where water leakage from condensate

or a hot water coil MUST HAVE A SECONDARY 1. Install a filter-grille low in the sidewall.

DRAIN PAN installed. These are available as UPC-94 for 2. Pan the basement or crawl space joists back to the

the M1218, UPC-20B and –20C for the M2430 models air handler.

when 2 or 3 modules are used and UPC-24B or –24C for the 3. Connect the flexible return air duct to the panning:

M3642 models for 2 or 3 modules or for the M4860 for 2 A. By using the return air filter box normally

modules. The UPC-24D is used for the M4860 for 3 supplied and fasten it to panning.

modules.

Where a vertical installation is planned the Vertical

Conversion Kits, UPC-63A for the M2430 and UPC-64A

for the M3642 and M4860, are required. The M1218 is a

multi-purpose unit and does not require any kits or

modifications for vertical upflow applications.

RETURN AIR COMPONENTS

Unico, Inc. provides components for a complete return air

system, including filters, which are particularly useful for

attic type installations where one central ceiling return can

be used. Different components are required for each size of

air handler, which are detailed in Table 1.

Table 1. Return Air Box Components

Models Return Grille Return Air Duct Return Cap

1218 UPC-01-1218 UPC-04-1218 UPC-104-1218

Figure 2. Optional Grille Placement

UPC-59B-2430

2430 UPC-01-2430 UPC-04-2430

(UPC-104-2430)*

B. Fabricate or obtain a sheet metal collar to which

UPC-59B-3642

3642 UPC-01-3642 UPC-04-3642

(UPC-104-3642)* flexible return duct can be fastened and connect

to the panning. See Figure 2.

UPC-59B-4860

4860 UPC-01-4860 UPC-04-4860

(UPC-104-4860)* When desired or necessary due to space limitations, a

*used to connect directly to the heating module fabricated return duct system can be used. This would

usually be done when multiple return ducts are required.

The return air duct, UPC-04-1218/2430/3642/4860, has a Fabricated duct board or metal duct with acoustical lining

sound attenuating core; flexible duct with a solid plastic may be used. The return duct including filter should be

lining which should not be used as it will be noisy. designed for a maximum static pressure drop of 0.15 IWC

The standard return air components can be adapted to other (37 Pa). A 90! bend or elbow should always be used for

than ceiling installation. The filter-grille can be installed in proper acoustical performance.

the sidewall (see Figure 1). However, if a filter-grille can

not be used in the sidewall then other grilles can be used, Duct Layout

such as a standard wall grille, a baseboard grille or an out-

To provide optimum system performance several important

of-the wall baseboard grille. The filter-grille is more

guidelines must be followed in doing the duct layout. The

desirable because when other standard type grilles are used,

static pressure of the system determines the airflow for good

system performance. The system operates most effectively

© Copyright 2007 Unico, Inc.

Bulletin 40-30 — Page 3

in the range of 1.0 to 1.5 IWC of total static pressure it imposes a much higher-pressure drop. Suggested

reflecting both the return air system and the supply side or layouts using tees are shown in Figure 3. It is best to

distribution system. install the tee or elbow 48-inches from the unit

although 24-inches is acceptable in tight places.

Plenum Layout

4. Tee Airflow Splits: When using a tee, split the flow

For the Unico System the installer has a choice of 2 different as close to 50/50 as possible—no more than 60/40.

types of plenum systems: square fiberglass duct board (6- Use a turning vane for the M4860; it is not

1/2 x 6-1/2, 8-1/2 x 8-1/2, and 9-1/2 x 9-1/2-inches I.D.) and necessary for the smaller models. For the M4860

field insulated round sheet metal (7, 9 and 10-inch I.D). In unit it is preferable to us 10-inch insulated round

certain cases with space limitations, such as dropped sheet metal up to the tee, then a 10x9x9-inch tee

ceilings, it is possible to use plenum that is flatter, such as (Unico Part No. UPC-19(V)-100909) providing 9-

rectangular fiberglass ductboard or sheet metal. In these inch branch runs in both directions. In this case a

cases the dimensions should provide a flow area at least 70/30 split in airflow is possible.

equal to or greater than the factory supplied plenum, e.g. 4 x

11-inch I.D. or 5 x 9-inch I.D. 5. Shotgun Systems: Where a shotgun system (see

Figure 3) provides a better layout for the M4860

The following guidelines should be followed for the plenum unit, use 10-inch insulated metal or fiberglass duct

system: for the first 40% of the airflow, then reduce to 9-

inch for the remaining 60%, if desired. For smaller

1. More Plenum, Less 2-inch run length: The

units, 9-inch may be run the entire length.

plenum has less pressure drop than the 2-inch duct

runs so the plenum system should be designed to 6. Horseshoe / Perimeter Patterns: Where horseshoe

keep the 2-inch duct runs to a shorter length (12-ft. or “H” systems are used, consider closing the

or less, if possible). This may require using more horseshoe or end of the “H” into a perimeter loop

plenum and plenum fittings and consideration of (see Figure 4).

layouts that are not always the most obvious.

2. Minimize Restriction: The UNICO SYSTEM supplied 40% Min.

plenum fittings are designed to minimize restriction

of the plenum system. They include full flow tees 9 inch

with turning vanes (where helpful) and full flow

elbows. If locally supplied components, such as 60%

sheet metal fittings, are to be used be sure they are

of full flow design. 7 inch

Shotgun System

3. First Fitting—Tee: Every effort should be made to

use a tee as the first fitting off the air handler, Figure 4. Typical Shotgun System Layout

particularly with the M4860. When an elbow is used

Figure 3. Typical System Layouts

© Copyright 2007 Unico, Inc.

Bulletin 40-30 — Page 4

30%Max.

Side Branch System

Figure 6. Typical Side-Branch System Layout

7. Side Branch: For a side branch, turn the tee 90! and

never use a turning vane. Take no more than 30% of

the airflow from the side branch (see Figure 5).

8. Minimum Distance to Fittings: Always use a

straight duct prior to any fitting such as elbow, tee,

plenum takeoff, or electric heater. It is best to have Figure 7. Typical Plenum Horizontal Layout

48 inches before each fitting although 24-inches is

REMEMBER THAT ANY TIME THE DISTRIBUTION

acceptable in most applications. Avoid elbows

SYSTEM CAN BE LOCATED IN THE CONDITIONED

SPACE THERE IS NO DUCT LOSSES AND ENERGY

WILL BE SAVED.

OUTLETS AND SUPPLY DUCT LAYOUT

The following guidelines apply to the outlets and 2-inch

duct runs:

1. Minimize Length, Minimize Restriction: Keep

the 2-inch supply duct length as close to 12-feet as

possible and never less than 6-feet. Use the fewest

number of bends as possible. Maximize the radius of

any bends making sure the bend in the sound

attenuating tubing near the outlet is at least 6-inches

Figure 5. Typical Plenum Vertical

Layout

directly off units, which is the worst design possible.

9. Space Takeoffs Evenly: Maintain the distance

between takeoffs as evenly as possible. Space the

takeoffs at least 6-inches apart and 12-inches from

the end cap.

6"

10. Plenum for Multiple Stories: The plenum is

normally in the attic or basement. In some two story

or split-level home it is advantageous to go from

one level to another with the plenum. Boxing in the Figure 8. Typical Supply Tubing Bend

plenum (see Figure 6) or routing it through a closet

usually accomplishes this. (see Figure 8).

11. Plenum in Living Area: In some homes where attic 2. 6 Outlets Per Ton Minimum: Provide a

space is not available, the plenum can be enclosed minimum of 6 full outlets per ton of cooling (200

by boxing it in (see Figure 7) or running it above CFM/ton minimum). For the M4860 unit on a 5-ton

dropped ceilings. In areas with cathedral ceilings, system and any heat pump system use 6-1/2 full

this can be done along with boxing in the supply outlets per cooling ton. For hot water heating, use

tubing next to an exposed beam. Remember that 40 CFM per full outlet and refer to hot water coil

once the system is boxed in it is difficult to gain performance charts to get the required total. A full

access for changes so it is imperative that the system outlet is 10-feet of supply duct without any

be properly designed and checked out for airflow balancing orifices. Add more outlets for those less

before final boxing is done.

© Copyright 2007 Unico, Inc.

Bulletin 40-30 — Page 5

than full. For example, two runs 10-feet long with

50% balancing orifices are equal to one full outlet.

3. 10% Rule: For supply ducts longer than 10-feet,

the air is reduced in that run by 10% for every 5-feet

over 10-feet. The curves provided in Bulletin 40-40,

System Sizing and Layout Procedure takes this into

account when doing the detailed layout for room

outlet selection.

4. Consider Traffic Pattern: Place outlets out of

Figure 11. Incorrect Placement of Tubing

stud wall (usually 3-1/2-inches wide) for horizontal

discharge with the sound attenuating tubing in the

wall with a 90! turn. This application is not

acceptable because of the short radius in the tubing.

The air noise would not be acceptable (see Figure

11). For stud wall applications use the slotted outlet.

7. Proper Installation for Noise: In planning the

length of duct runs be sure to provide sufficient

length that gives as generous a radius as possible in

the sound attenuating tubing at the outlet. Minimum

Figure 9. Typical Kitchen Soffit Layout

radius must be 6-inches as indicated but the greater

the radius of any bend at the outlet the quieter the

run will be. Be sure to include a minimum of 3-feet

of sound attenuating tubing (UPC-26C) at the end of

each run. For runs up to 12-feet all sound

attenuating tubing may be used. For greater lengths,

use the aluminum core supply tubing (UPC-25) with

a 3-foot attenuator at the end.

Also, adding a few extra outlets can reduce sound

levels further. The round outlet is designed for 20 to

40 cfm. The slotted outlet is designed for 20 to 35

cfm. As a general rule the more outlets, the lower

the cfm per outlet and the lower the sound level will

be. For applications where all the surfaces (floor,

wall, and ceiling) are hard it is best to design the

Figure 10. Typical Cabinet Layout

number of outlets to achieve approximately 30 cfm.

traffic pattern. A corner, 5-inches from each wall, is Also, sound is additive so that if you have a small

a good location, or along walls or blowing space with lots of outlets it is best to design for 30

horizontally. Two excellent spots for horizontal cfm.

discharge are in the soffit above kitchen cabinets

(see Figure 9) and in the top portion of closets (see Sound is subjective meaning what is acceptable for

Figure 10). Consider floor outlets (with screens) for some is not for others. Therefore, when in doubt add

units located in the basement. a few extra outlets. Rest assured, though, that the

noise level for any outlet within its allowable range

5. Allow for aspiration: Locate outlets so the air will be quieter than most conventional duct systems,

stream does not impinge on any objects or people – provided the outlets are properly installed.

at least 3-feet away. Use outlet deflectors and outlet

balancing orifices sparingly as they disrupt the

aspiration.

6. No Terminators in Stud Walls: Do not attempt

to install the terminators in a standard 2 x 4-inch

© Copyright 2007 Unico, Inc.

Bulletin 40-30 — Page 6

story. The first floor tubing is run from the plenum

in the attic down through the second story to ceiling

outlets on the first floor (see Figure 13).

SINGLE STORY APPLICATION LAYOUT The supply tubing is small enough to go in stud

This application is normally the quickest and simplest spaces but this is often difficult in older homes

application to make. Figure 12 is a typical layout for this type because of hidden obstructions in the walls. It is

of structure.

Figure 15. Placement of Supply tubing

usually easier to run the supply tubing from the attic

down through second story closets to first story

termination (see Figure 14).

Another common practice is to run supply

tubing from the attic down into corners of the

Figure 12. Typical System Placement and Layout second story rooms to first story outlets. Supply

tubing in the corners of the second story rooms

Two Story Application Layout

The two-story residence is usually handled in one of two

manners:

1. One UNICO SYSTEM in the attic with supply tubing

run in the attic to ceiling outlets for the second

Figure 13. Placement of Supply Tubing

between Floors

can then be boxed in and are hardly noticeable

since the overall diameter of tubing is only 3-

1/2-inches (see Figure 15).

Figure 14. Two-Story Home with One Unico System

© Copyright 2007 Unico, Inc.

Bulletin 40-30 — Page 7

2. The second most common way to handle the older

two-story home is to install two separate systems.

One is placed in the attic to handle the second story

Figure 16. Placement of Supply Tubing between Floors

with ceiling terminators and return air. The other

system is placed in the basement utilizing floor

terminators with the duct system suspended in the

basement area (see Figure 16).

With two systems, it often takes less time on the job and

gives the homeowner a truly zoned system where the

comfort conditions of the two areas can be

independently controlled.

Split Level Applications

The UNICO SYSTEM distribution system on cooling only

installations where the duct system is in the non-

conditioned areas, such as attics, should be blocked off

during the winter season. Winter shutoff caps are

shipped with the installation kits. For the return air grille

a sheet metal plate can be fabricated to fit in front of the

filter.

If a residence has proper or more than adequate humidity

during the heating season, it is possible for this air to

travel throughout the distribution system. When this

occurs, moisture from the humidified air can condense

on the inside of the plenum and the supply tubing. An

excess quantity of moisture collected in the distribution

system may result in wet ducts and water dripping from

the terminators.

Be sure the Homeowner is given the winter shutoff

caps and return air grille block off and understands

the importance of their use during the heating

season.

© Copyright 2007 Unico, Inc.

S-ar putea să vă placă și

- Training Manual Air Handling UnitDocument201 paginiTraining Manual Air Handling UnitNikhil TbÎncă nu există evaluări

- Variable Air Volume SystemDocument28 paginiVariable Air Volume SystemNishanth N NairÎncă nu există evaluări

- IOM EcoZonePlus Refrigeration Racks AnDocument16 paginiIOM EcoZonePlus Refrigeration Racks AnVaso RoknicÎncă nu există evaluări

- Wall Mount: Installation, OperationDocument7 paginiWall Mount: Installation, OperationTradutor TécnicoÎncă nu există evaluări

- 12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkDocument367 pagini12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkJhoÎncă nu există evaluări

- Carrier 38ANDocument30 paginiCarrier 38ANeeooaaiiÎncă nu există evaluări

- IOMDocument61 paginiIOMTugrul TanÎncă nu există evaluări

- Internship Report HvacDocument23 paginiInternship Report HvacIhsanul HaqÎncă nu există evaluări

- Fan Coil Unit (Fcu) : Including Horizontal (Ceiling Mounted) or Vertical (Floor Mounted)Document10 paginiFan Coil Unit (Fcu) : Including Horizontal (Ceiling Mounted) or Vertical (Floor Mounted)bandhuarushiÎncă nu există evaluări

- TEC3000 Series On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers With Dehumidification CapabilityDocument48 paginiTEC3000 Series On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers With Dehumidification CapabilityIvar Denicia DelgadilloÎncă nu există evaluări

- Installation & Man Ual: OperationDocument108 paginiInstallation & Man Ual: Operationosvald97Încă nu există evaluări

- Instrument Air SystemDocument16 paginiInstrument Air SystemDony RamdhaniÎncă nu există evaluări

- Chapter12 Water and DX SystemDocument32 paginiChapter12 Water and DX SystemNurhidayat NurhidayatÎncă nu există evaluări

- Product Data: 38AUQ07 - 12 Heat Pump Outdoor Unit Split System With Puronr Refrigerant 60 HZDocument24 paginiProduct Data: 38AUQ07 - 12 Heat Pump Outdoor Unit Split System With Puronr Refrigerant 60 HZMarco Antonio Camacho Tezanos-PintoÎncă nu există evaluări

- INNCOM Integrated Room Automated System Specifications 25510Document17 paginiINNCOM Integrated Room Automated System Specifications 25510er.bhagwanÎncă nu există evaluări

- Carrier Multi Split Inverter 38-40gxm-1pdDocument16 paginiCarrier Multi Split Inverter 38-40gxm-1pdasdthuÎncă nu există evaluări

- York D3CG 090, 120 & 150 50Hz TGDocument20 paginiYork D3CG 090, 120 & 150 50Hz TGCarlos Eduardo RivasÎncă nu există evaluări

- Product Data: 40QNC / 38HDF 40QNQ / 38QRF High - Wall Duct Free Split System Sizes 018 To 036Document34 paginiProduct Data: 40QNC / 38HDF 40QNQ / 38QRF High - Wall Duct Free Split System Sizes 018 To 036din_thorpe3248Încă nu există evaluări

- Compu Mate Brochure v2Document11 paginiCompu Mate Brochure v2pabloabelgilsotoÎncă nu există evaluări

- Installing PACU and CRE ComponentsDocument42 paginiInstalling PACU and CRE ComponentsBeth AusteÎncă nu există evaluări

- Modular AHU ManualDocument17 paginiModular AHU ManualwolfzemunÎncă nu există evaluări

- York TS CondenserDocument16 paginiYork TS Condenserrbooth80Încă nu există evaluări

- HVAC Course PDFDocument273 paginiHVAC Course PDFliliÎncă nu există evaluări

- Overview Matrix PDFDocument42 paginiOverview Matrix PDFcarmaÎncă nu există evaluări

- Identification Matrix: 69NT20-531-300 Series, 69NT40-489-100 Series 69NT40-511, 521 & 531 SeriesDocument45 paginiIdentification Matrix: 69NT20-531-300 Series, 69NT40-489-100 Series 69NT40-511, 521 & 531 SeriesSerhiiÎncă nu există evaluări

- HVAC Handbook CARRIER New Edition Part 12 Water and DX System PDFDocument23 paginiHVAC Handbook CARRIER New Edition Part 12 Water and DX System PDFalejandro100% (1)

- Ferroli Hot Oil HTR (GB)Document30 paginiFerroli Hot Oil HTR (GB)RodÎncă nu există evaluări

- AHU ManualDocument17 paginiAHU ManualwolfzemunÎncă nu există evaluări

- Models 69NT40-489-100 Series 69NT40-511,521& 531Document40 paginiModels 69NT40-489-100 Series 69NT40-511,521& 531cloviskrelling100% (1)

- Krueger Fan Coil EngineeringDocument15 paginiKrueger Fan Coil EngineeringYutt WattÎncă nu există evaluări

- Variable Refrigerant FlowDocument15 paginiVariable Refrigerant FlowHoward RoarkÎncă nu există evaluări

- Service and Technical Guide: Ductless Split SystemDocument24 paginiService and Technical Guide: Ductless Split SystemNatnael GirmaÎncă nu există evaluări

- 15836Document18 pagini15836JhoÎncă nu există evaluări

- Package UnitDocument60 paginiPackage Unitintequab100% (2)

- VRF-SLB005-EN 10 2lowDocument48 paginiVRF-SLB005-EN 10 2lowarqu1ch100% (1)

- MD T, D, E-Iom enDocument48 paginiMD T, D, E-Iom enMihai ConstantinescuÎncă nu există evaluări

- Lecture No.5 (Air Handling Unit)Document9 paginiLecture No.5 (Air Handling Unit)Mohsen HassanÎncă nu există evaluări

- Sequence of Operations For Hvac ControlsDocument4 paginiSequence of Operations For Hvac Controlsmacanipharoldf6220Încă nu există evaluări

- Product Data: 38AUQ07 - 25 Heat Pump Outdoor Unit Split System With Puronr Refrigerant 60 HZDocument38 paginiProduct Data: 38AUQ07 - 25 Heat Pump Outdoor Unit Split System With Puronr Refrigerant 60 HZsuhasÎncă nu există evaluări

- Installation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersDocument2 paginiInstallation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersJed DavidÎncă nu există evaluări

- 1646 - Generator Operating ManualDocument52 pagini1646 - Generator Operating ManualmaronnamÎncă nu există evaluări

- SUNLINE 2000-: Single Package Gas / Electric Units and Single Package Air ConditionersDocument16 paginiSUNLINE 2000-: Single Package Gas / Electric Units and Single Package Air ConditionersBernardo RodriguezÎncă nu există evaluări

- CarrierDSB10 0007Document1 paginăCarrierDSB10 0007drocklÎncă nu există evaluări

- APC Application Note #69: Air Distribution Unit ApplicationDocument4 paginiAPC Application Note #69: Air Distribution Unit ApplicationdexiÎncă nu există evaluări

- APC Application Note #69: Air Distribution Unit ApplicationDocument4 paginiAPC Application Note #69: Air Distribution Unit ApplicationdexiÎncă nu există evaluări

- Fcu (Free Cooling Unit)Document5 paginiFcu (Free Cooling Unit)fhsn84Încă nu există evaluări

- Tec JhonsonDocument42 paginiTec JhonsonNahuelÎncă nu există evaluări

- Guide Specifications - 48Lc 14-26Document14 paginiGuide Specifications - 48Lc 14-26Selyun E OnnajÎncă nu există evaluări

- Liebert HCR Y HBRDocument56 paginiLiebert HCR Y HBRNelson SantiagoÎncă nu există evaluări

- Weatherexpert Ultra High Efficiency Gas Heat/Electric Cooling Packaged Variable Air Volume (Vav) RooftopDocument14 paginiWeatherexpert Ultra High Efficiency Gas Heat/Electric Cooling Packaged Variable Air Volume (Vav) RooftopSelyun E OnnajÎncă nu există evaluări

- WGS RXS - FTXS15 24lvjuDocument6 paginiWGS RXS - FTXS15 24lvjuRicky ViadorÎncă nu există evaluări

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneDe la EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneÎncă nu există evaluări

- Networked Control System: Fundamentals and ApplicationsDe la EverandNetworked Control System: Fundamentals and ApplicationsÎncă nu există evaluări

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDe la EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideEvaluare: 4 din 5 stele4/5 (8)

- Instrument Technology: Telemetering and Automatic ControlDe la EverandInstrument Technology: Telemetering and Automatic ControlÎncă nu există evaluări

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsDe la EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsÎncă nu există evaluări

- 2019 Multi V EU CatalogDocument1 pagină2019 Multi V EU CatalogKyaw San OoÎncă nu există evaluări

- MULTI V Catalog (2way Ceiling Cassette)Document1 paginăMULTI V Catalog (2way Ceiling Cassette)Kyaw San OoÎncă nu există evaluări

- LG Multi V 5 2017Document146 paginiLG Multi V 5 2017Kyaw San OoÎncă nu există evaluări

- Multi V S (Side Discharge) CatalogDocument1 paginăMulti V S (Side Discharge) CatalogKyaw San Oo100% (1)

- Industrial Ventilators (Mitshubishi)Document20 paginiIndustrial Ventilators (Mitshubishi)Kyaw San OoÎncă nu există evaluări

- 2019 Eu Multi V CatalogDocument118 pagini2019 Eu Multi V CatalogAlberto Bravo SánchezÎncă nu există evaluări

- Low Static: Accessories AccessoriesDocument1 paginăLow Static: Accessories AccessoriesKyaw San OoÎncă nu există evaluări

- Wiring DiagramsDocument4 paginiWiring DiagramsAli Shaikh Abdul50% (2)

- Duct Chart $$$$$$$$$$$$$Document2 paginiDuct Chart $$$$$$$$$$$$$Kyaw San OoÎncă nu există evaluări

- Elctronic ComponentsDocument17 paginiElctronic ComponentsganpatsuÎncă nu există evaluări

- Mobile Phone's Hardware Repairing MethodsDocument196 paginiMobile Phone's Hardware Repairing Methodshtaw soe100% (1)

- Elctronic ComponentsDocument17 paginiElctronic ComponentsganpatsuÎncă nu există evaluări

- 1 1 3 5Document15 pagini1 1 3 5Vlad AdrianÎncă nu există evaluări

- Android Root Guide For HTC, Sony Erisson, LG, LenovoDocument358 paginiAndroid Root Guide For HTC, Sony Erisson, LG, Lenovohtaw soeÎncă nu există evaluări

- Induction Motor Design PDFDocument46 paginiInduction Motor Design PDFdiptiÎncă nu există evaluări

- Motor Rewinding PDFDocument343 paginiMotor Rewinding PDFsailolla3086% (87)

- (2PRD-003A) Refrigerant ComparisonDocument31 pagini(2PRD-003A) Refrigerant ComparisonKyaw San OoÎncă nu există evaluări

- ALL TABLE FAN WINDING DATA - With Connection Coil Loaction - PDFDocument20 paginiALL TABLE FAN WINDING DATA - With Connection Coil Loaction - PDFKyaw San Oo95% (58)

- ABB - Electrical Installation Handbook - IDocument168 paginiABB - Electrical Installation Handbook - Iapi-3806201100% (10)

- (2PRD-002A) Refrigeration CycleDocument57 pagini(2PRD-002A) Refrigeration CycleKyaw San Oo100% (1)

- Effect of Repair Rewinding On Motor Efficiency - OptimisedDocument82 paginiEffect of Repair Rewinding On Motor Efficiency - OptimisedAkmal Radiansyah100% (1)

- ABB - Electrical Installation Handbook - IIDocument137 paginiABB - Electrical Installation Handbook - IIBahador Saghatchian89% (9)

- PVI3000 DiagramaDocument4 paginiPVI3000 DiagramaGuillermo Maldonado Pájaro100% (4)

- Service Manual: HCD-V808Document86 paginiService Manual: HCD-V808Kyaw San OoÎncă nu există evaluări

- ABB - Electrical Installation Handbook - IDocument168 paginiABB - Electrical Installation Handbook - Iapi-3806201100% (10)

- ABB - Electrical Installation Handbook - IIDocument137 paginiABB - Electrical Installation Handbook - IIBahador Saghatchian89% (9)

- Everyday Electronics 1973 05Document60 paginiEveryday Electronics 1973 05Kyaw San Oo100% (1)

- Power Quality Measurement DevicesDocument32 paginiPower Quality Measurement DevicesKyaw San OoÎncă nu există evaluări

- Service Manual: KEH-1032 KEH-2031Document50 paginiService Manual: KEH-1032 KEH-2031Kyaw San OoÎncă nu există evaluări

- Calibrating A Thermometer: To Calibrate A Thermometer, The Ice Point of Water Is Usually Taken To BeDocument4 paginiCalibrating A Thermometer: To Calibrate A Thermometer, The Ice Point of Water Is Usually Taken To BeMuhammad UbaidÎncă nu există evaluări

- 3 - Cooling, Freezing, Refrigeration Systems in Baking IndustryDocument21 pagini3 - Cooling, Freezing, Refrigeration Systems in Baking IndustryshahidÎncă nu există evaluări

- Rac MCQDocument20 paginiRac MCQAbhijit BiswasÎncă nu există evaluări

- Instruction Manual - Digital Drybath - ENDocument19 paginiInstruction Manual - Digital Drybath - ENAlain ManceraÎncă nu există evaluări

- Template ElectricalDocument24 paginiTemplate ElectricalSEDFREY DELA CRUZÎncă nu există evaluări

- Pcs0911a Skyair Nu Series Co PDFDocument24 paginiPcs0911a Skyair Nu Series Co PDFVietHienÎncă nu există evaluări

- Assignment 16 The Ideal GasDocument8 paginiAssignment 16 The Ideal Gasbob jizzleÎncă nu există evaluări

- Thermal Transmittance Measurement With The Hot BoxDocument9 paginiThermal Transmittance Measurement With The Hot BoxLuca Scarsella100% (1)

- Properties of Natural GasDocument83 paginiProperties of Natural GasJose Daniel QuinteroÎncă nu există evaluări

- Lennox-Vrf Submittal Vep210n432k StandardDocument2 paginiLennox-Vrf Submittal Vep210n432k StandardEduardo LegorretaÎncă nu există evaluări

- Ahu RF 27Document3 paginiAhu RF 27Mohammed HamedÎncă nu există evaluări

- Heat Air Guide PDFDocument51 paginiHeat Air Guide PDFSharon LambertÎncă nu există evaluări

- DeLand Frost GuardDocument7 paginiDeLand Frost GuardAlexandru IsacÎncă nu există evaluări

- CERN-Superconductivity For AcceleratorsDocument600 paginiCERN-Superconductivity For Acceleratorskaizhang0222Încă nu există evaluări

- CM 310 Final Exam Study GuideDocument7 paginiCM 310 Final Exam Study GuideChad FaccioloÎncă nu există evaluări

- BS Iso TR 05925-2-1997 (1999)Document16 paginiBS Iso TR 05925-2-1997 (1999)Олег СоловьевÎncă nu există evaluări

- Properties of MI CableDocument2 paginiProperties of MI CablekmiqdÎncă nu există evaluări

- 1796 Books Doubtnut Question BankDocument16 pagini1796 Books Doubtnut Question BankMohit BhatiÎncă nu există evaluări

- NCERT Science 9 PDFDocument228 paginiNCERT Science 9 PDFPrateek JainÎncă nu există evaluări

- Shahjalal University of Science and Technology Dept. of Chemical Engineering and Polymer ScienceDocument7 paginiShahjalal University of Science and Technology Dept. of Chemical Engineering and Polymer ScienceSourav SutradharÎncă nu există evaluări

- MEP Manufacturer's List (Rev. NOV.2020)Document18 paginiMEP Manufacturer's List (Rev. NOV.2020)Mohammed AzharÎncă nu există evaluări

- Atomic Emission Spectroscopy - University NotesDocument22 paginiAtomic Emission Spectroscopy - University NotesLilac44100% (1)

- Huizhou Fudi Electrical Appliances Limited Company Air To Air Thermoelectric Cooler - FD-100WDocument3 paginiHuizhou Fudi Electrical Appliances Limited Company Air To Air Thermoelectric Cooler - FD-100WLio LiverhÎncă nu există evaluări

- Dump CondenserDocument6 paginiDump CondensersakalidhasavasanÎncă nu există evaluări

- Simple Comfort ThermostatDocument20 paginiSimple Comfort Thermostattalonscorer100% (1)

- BF Simulation User Guide 1.00Document18 paginiBF Simulation User Guide 1.00eneskilincÎncă nu există evaluări

- Enhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsDocument27 paginiEnhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsAleš NagodeÎncă nu există evaluări

- Ashrae Library 1 PDFDocument16 paginiAshrae Library 1 PDFosama alabsiÎncă nu există evaluări

- New Developments in Gas Cooling: TTTTTDocument4 paginiNew Developments in Gas Cooling: TTTTTlcsmesquitaÎncă nu există evaluări