Documente Academic

Documente Profesional

Documente Cultură

Nfpa 70B - 2013175

Încărcat de

AbdulMajidYousoffTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nfpa 70B - 2013175

Încărcat de

AbdulMajidYousoffDrepturi de autor:

Formate disponibile

p p

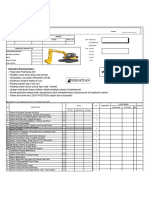

70B–172 ELECTRICAL EQUIPMENT MAINTENANCE

ENGINE GENERATOR INSPECTION

SHEET NO. OF

CUSTOMER DATE PROJECT NO.

ADDRESS AIR TEMP. REL. HUMIDITY

OWNER/USER DATE LAST INSPECTION

ADDRESS LAST INSPECTION REPORT

EQUIPMENT LOCATION

CIRCUIT IDENTIFICATION

ENGINE TYPE: GASOLINE DIESEL GAS TURBINE

MAKE MODEL SERIAL NO. KS #

KVA KW VOLTAGE F.L.A.

RPM HZ HP TECH. BULL. #

1. Change oil and lube oil filters.

2. Remove unused oil from premises.

3. Change fuel oil elements.

4. Service crankcase breather.

5. Inspect air cleaner element, clean if required. If replacement is required, element(s) will be

billed separately. Price of element(s) not included in contract price.

6. Check coolant level and maintain safe degree of protection. Engine mounted radiators only. (Remote

radiators, cooling towers & heat exchangers serviced at user’s request on a time and material basis.)

7. Check manifolds, brackets, mountings and flex connections.

8. Inspect fan belts, adjust if required.

9. Check pulley hub, bearings, lubricate if required.

10. Check operation of auxiliary water pump or fan motor.

11. Check operation of automatic louvers.

12. Repair minor fuel, coolant and lube oil leaks.

13. Check operation of jacket water heater(s).

14. Inspect generator, perform any routine maintenance as required.

Megger

15. Inspect governor/actuator linkage.

16. Check battery electrolyte level and maintain to include:

Temperature Specific Gravity Voltage

17. Check operation of charger and/or alternator.

18. Inspect fuel supply system for leaks or low level, inform owner of any discrepancies.

19. Drain condensation from day tank and check for any contamination. ONLY if day tank

is equipped with a drain valve.

20. Check operation of transfer pump.

21. Check for correct generator output voltage & frequency, adjust if required.

22. Simulate & check operation of each safety shutdown and alarm device, relay type control panels only.

23. Check operation of generator control instrumentation; volts, amps, etc.

24. Test fault lamps & replace bulbs as required, panels with lamp test only.

25. Tank crankcase oil sample, owner to be notified of any discrepancies.

26. Submit report to owner

27. Auto start test.

REMARKS

SUBMITTED BY EQUIPMENT USED

Courtesy of Northeast Electrical Testing NFPA 70B

FIGURE H.22 Typical Engine Generator Set Inspection Checklist.

2013 Edition

S-ar putea să vă placă și

- Guidelines For Inspection and Preventive Maintenance of MCCBDocument41 paginiGuidelines For Inspection and Preventive Maintenance of MCCBvhgiaoÎncă nu există evaluări

- Tajweed Chart A4 ColourDocument3 paginiTajweed Chart A4 ColourAbdulMajidYousoff100% (4)

- Nfpa 70BDocument32 paginiNfpa 70BShafi Marwat100% (3)

- Panel Board ShortCircuit RatingsDocument2 paginiPanel Board ShortCircuit RatingsuddinnadeemÎncă nu există evaluări

- DMTCL - GIS Project Drawing / Document Control ListDocument2 paginiDMTCL - GIS Project Drawing / Document Control ListRsp SrinivasÎncă nu există evaluări

- NT-Series UPS Installation and Commissioning Check ListDocument20 paginiNT-Series UPS Installation and Commissioning Check ListWalter AchayaÎncă nu există evaluări

- Tajweed Chart A3 Colour White BackgroundDocument3 paginiTajweed Chart A3 Colour White BackgroundAbdulMajidYousoffÎncă nu există evaluări

- Battery Room Ventilation GuidelinesDocument5 paginiBattery Room Ventilation GuidelinesARC Electrical Safety ConsultingÎncă nu există evaluări

- RB Data Center Power System Sequence of OperationDocument7 paginiRB Data Center Power System Sequence of Operationakheel201Încă nu există evaluări

- Ieee 1106-2005Document39 paginiIeee 1106-2005Hector Valencia100% (2)

- Technical Specification Rmu Frtu Rev 01Document55 paginiTechnical Specification Rmu Frtu Rev 01Ramesh Ananthanarayanan100% (1)

- Electrical Room Heat Dissipation Calculation PDFDocument1 paginăElectrical Room Heat Dissipation Calculation PDFmadhivananspÎncă nu există evaluări

- Vol.1 (CH 00 - CH 31)Document605 paginiVol.1 (CH 00 - CH 31)versineÎncă nu există evaluări

- Jacobbs Ele Installations SpecsDocument33 paginiJacobbs Ele Installations Specssureshn829Încă nu există evaluări

- Guidance For Candidates - The Iam Certificate: Edition 2 - January 2013Document14 paginiGuidance For Candidates - The Iam Certificate: Edition 2 - January 2013gosalhs9395Încă nu există evaluări

- Technical Submittal - 3 WAY & 4 WAY - RMUDocument149 paginiTechnical Submittal - 3 WAY & 4 WAY - RMUفارس معتوقÎncă nu există evaluări

- Safety and Hygiene in The KitchenDocument3 paginiSafety and Hygiene in The Kitchenzoltan2014100% (1)

- BMS T&C Manual PDFDocument25 paginiBMS T&C Manual PDFSultan SikandarÎncă nu există evaluări

- Onenote 2016 Quick Start Guide PDFDocument4 paginiOnenote 2016 Quick Start Guide PDFMarcelo Pillajo Mera100% (1)

- Electrical Preventive Maintenance (EPM) Program Standards - The Hanover Insurance GroupDocument13 paginiElectrical Preventive Maintenance (EPM) Program Standards - The Hanover Insurance Groupatmoko2100% (1)

- Digital Transformation in Airport Ground Operations: ReviewDocument25 paginiDigital Transformation in Airport Ground Operations: ReviewOannaÎncă nu există evaluări

- Checklist ElectricalDocument34 paginiChecklist ElectricalDhirendra Singh100% (1)

- Nfpa110 Gen StandardDocument4 paginiNfpa110 Gen StandardMd ShÎncă nu există evaluări

- IEEEStd 30067 - 2013presentationDocument42 paginiIEEEStd 30067 - 2013presentationbudi hermawanÎncă nu există evaluări

- BHEL HRSG Electrical Controls Instrumentation GuideDocument79 paginiBHEL HRSG Electrical Controls Instrumentation GuideSatyanneshi ERÎncă nu există evaluări

- Commissioning New Substation EquipmentDocument13 paginiCommissioning New Substation Equipmentbrockwell496Încă nu există evaluări

- Fire Pump Field Acceptance TestDocument23 paginiFire Pump Field Acceptance Testwalitedison100% (1)

- Project: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoDocument24 paginiProject: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoNay Win MaungÎncă nu există evaluări

- LV Switchboard and Generator Specification for English Heritage OfficeDocument46 paginiLV Switchboard and Generator Specification for English Heritage OfficeTukaram PawarÎncă nu există evaluări

- 1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Document21 pagini1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Muhammad Ibad AlamÎncă nu există evaluări

- Comprehensive Facility Operation & Maintenance Manual - WBDG Whole Building Design GuideDocument6 paginiComprehensive Facility Operation & Maintenance Manual - WBDG Whole Building Design GuideDũng Tây NinhÎncă nu există evaluări

- Supervision Guide For Electrical Engineering Works (30 Jan 2012)Document37 paginiSupervision Guide For Electrical Engineering Works (30 Jan 2012)Zhu Qi Wang100% (1)

- BS8519 2010 PDFDocument12 paginiBS8519 2010 PDFwaytobhushan100% (1)

- Electrical Work SpecsDocument33 paginiElectrical Work SpecsusmanaliÎncă nu există evaluări

- LANDSNET KKS HANDBOOK EDITION 09Document122 paginiLANDSNET KKS HANDBOOK EDITION 09Idhata100% (1)

- RTU FAT Test Book for Lucy RMUDocument15 paginiRTU FAT Test Book for Lucy RMUMallampati RamakrishnaÎncă nu există evaluări

- IEEE 1187 Recommended Practice For Installation Design and Installation of Valve-RegulatedDocument46 paginiIEEE 1187 Recommended Practice For Installation Design and Installation of Valve-RegulatedMarco Antonio Esquivel BarretoÎncă nu există evaluări

- Fire Pump specialities-NFPA20Document23 paginiFire Pump specialities-NFPA20WHITE LOTUS VOICE-OVERÎncă nu există evaluări

- Emergi-Lite Emergency Lighting Design GuideDocument84 paginiEmergi-Lite Emergency Lighting Design Guideangeltandingan100% (1)

- Bms SystemDocument58 paginiBms SystemAnandu AshokanÎncă nu există evaluări

- ComissioningDocument254 paginiComissioningsyedahmedsabir100% (2)

- List of Essential Books For Civil EngineeringDocument1 paginăList of Essential Books For Civil Engineeringraju_420034520100% (1)

- Compliance Sheet: SL No Specific Comments Reply Mechanical: AANDocument1 paginăCompliance Sheet: SL No Specific Comments Reply Mechanical: AANJaren SobremisanaÎncă nu există evaluări

- 695 Power To The Pump-MHDocument4 pagini695 Power To The Pump-MHJOSE LUIS FALCON CHAVEZÎncă nu există evaluări

- Clean Agent Enclosure Design For NFPA 2001 Retrotec Version PDFDocument8 paginiClean Agent Enclosure Design For NFPA 2001 Retrotec Version PDFNa2_tuÎncă nu există evaluări

- Digital Meters - Newtek Electricals, Multifunction Energy Meters, VAF Meter, Smart MeterDocument18 paginiDigital Meters - Newtek Electricals, Multifunction Energy Meters, VAF Meter, Smart MeterNewtek ElectricalsÎncă nu există evaluări

- Central OnLite System ZumtobelDocument64 paginiCentral OnLite System ZumtobelRejhan KaramanÎncă nu există evaluări

- Nema A, B, C and D DesignDocument3 paginiNema A, B, C and D Designsteve_y100% (1)

- Part B - Section 1 General RequirementsDocument24 paginiPart B - Section 1 General RequirementsGino GeorgeÎncă nu există evaluări

- En Tn008-Nfpa110 PDFDocument5 paginiEn Tn008-Nfpa110 PDFHedi Ben MohamedÎncă nu există evaluări

- UL325 Presentation Rev5 PDFDocument25 paginiUL325 Presentation Rev5 PDFHJÎncă nu există evaluări

- Annex 4 - Tier Certification of Operational Sustainability - PresentationDocument12 paginiAnnex 4 - Tier Certification of Operational Sustainability - PresentationKamran SiddiquiÎncă nu există evaluări

- What Is Commissioning and Related Terms Rev 01Document1 paginăWhat Is Commissioning and Related Terms Rev 01sunil601Încă nu există evaluări

- Epp 1718 10 - 09Document6 paginiEpp 1718 10 - 09Yilber Briceño Carrero100% (2)

- KM Flushing and Sterilization GuideDocument8 paginiKM Flushing and Sterilization GuideLuwalhati TomilasÎncă nu există evaluări

- Atmospheric Foam TankDocument5 paginiAtmospheric Foam TankAndro SidhomÎncă nu există evaluări

- Tanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Document2 paginiTanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Paulo MaresÎncă nu există evaluări

- Low Current ItpDocument5 paginiLow Current ItpMohamedÎncă nu există evaluări

- GS690 Installation Manual Rev ADocument63 paginiGS690 Installation Manual Rev Acasmadi casmadi100% (1)

- Table - 14 Typical Diversity Factors For Large BldgsDocument1 paginăTable - 14 Typical Diversity Factors For Large Bldgskiran raghukiranÎncă nu există evaluări

- Motor Protection Voltage UnbalanceDocument7 paginiMotor Protection Voltage UnbalancehaamadhÎncă nu există evaluări

- Cleaning Agitator SOPDocument3 paginiCleaning Agitator SOPJamaila GanozaÎncă nu există evaluări

- I/O List For Hvac System: Sensitivity: LNT Construction Internal UseDocument3 paginiI/O List For Hvac System: Sensitivity: LNT Construction Internal UseAlla Naveen Kumar100% (1)

- SRMU Training at META Co. RiyadhDocument46 paginiSRMU Training at META Co. RiyadhTanveer Ahmad100% (1)

- Engine Generator Set Inspection Checklist: Section A - Customer DataDocument2 paginiEngine Generator Set Inspection Checklist: Section A - Customer Datasri_lntÎncă nu există evaluări

- Jadwal Weekly MaintanaceDocument8 paginiJadwal Weekly Maintanaceardy ansyahÎncă nu există evaluări

- National irrigation standby generator checklistDocument4 paginiNational irrigation standby generator checklistMartie ClustersÎncă nu există evaluări

- 10 Questions Save LifeDocument1 pagină10 Questions Save LifeAbdulMajidYousoffÎncă nu există evaluări

- Be An Active Listener and ObserverDocument17 paginiBe An Active Listener and ObserverAbdulMajidYousoffÎncă nu există evaluări

- Floor CleaningDocument1 paginăFloor CleaningPaul WoworÎncă nu există evaluări

- Subtitle Edit Tutorial: 1. InstallationDocument11 paginiSubtitle Edit Tutorial: 1. Installationhans_lbsÎncă nu există evaluări

- La Germania Stove Parts Diagram Part 6 Parts List Goes With Diagrams PDFDocument3 paginiLa Germania Stove Parts Diagram Part 6 Parts List Goes With Diagrams PDFAbdulMajidYousoffÎncă nu există evaluări

- Engineering Glossary of TermsDocument53 paginiEngineering Glossary of TermsAbdulMajidYousoffÎncă nu există evaluări

- Vozni Red AutobusaDocument4 paginiVozni Red AutobusamiskoscribdÎncă nu există evaluări

- SC Subtitle Filter 0.5 Guide – Programmer's OverviewDocument6 paginiSC Subtitle Filter 0.5 Guide – Programmer's OverviewAbdulMajidYousoffÎncă nu există evaluări

- Complex Machine Performance Testing: Business JustificationDocument2 paginiComplex Machine Performance Testing: Business JustificationMAFS0504Încă nu există evaluări

- Engineering Problem Solving and ExcelDocument43 paginiEngineering Problem Solving and ExcelGhayas Ud-din DarÎncă nu există evaluări

- AssetReliability Wireman - ppt2Document16 paginiAssetReliability Wireman - ppt2AbdulMajidYousoffÎncă nu există evaluări

- RespirationDocument18 paginiRespirationapi-362922893Încă nu există evaluări

- Flare PDFDocument2 paginiFlare PDFAbdulMajidYousoffÎncă nu există evaluări

- QFI Infographic Mouth Final PrintDocument1 paginăQFI Infographic Mouth Final PrintAbdulMajidYousoffÎncă nu există evaluări

- Think Like An Engineer: Conceive, Design, Implement, Operate A MOOCDocument24 paginiThink Like An Engineer: Conceive, Design, Implement, Operate A MOOCAbdulMajidYousoffÎncă nu există evaluări

- Engineer Thingking PP-SimanDocument19 paginiEngineer Thingking PP-SimanAbdulMajidYousoffÎncă nu există evaluări

- Engineering Problem Solving and ExcelDocument43 paginiEngineering Problem Solving and ExcelGhayas Ud-din DarÎncă nu există evaluări

- Wps PDFDocument2 paginiWps PDFAbdulMajidYousoffÎncă nu există evaluări

- TP Safe PDFDocument10 paginiTP Safe PDFAbdulMajidYousoffÎncă nu există evaluări

- Think Like An Engineer: Conceive, Design, Implement, Operate A MOOCDocument24 paginiThink Like An Engineer: Conceive, Design, Implement, Operate A MOOCAbdulMajidYousoffÎncă nu există evaluări

- Petrosync - API 510 Pressure Vessel Inspector Course 2019Document6 paginiPetrosync - API 510 Pressure Vessel Inspector Course 2019AbdulMajidYousoffÎncă nu există evaluări

- MATE 662 - 462 Winter 2008 An Example of Assessing Welded Pipeline SteelsDocument9 paginiMATE 662 - 462 Winter 2008 An Example of Assessing Welded Pipeline SteelsAbdulMajidYousoffÎncă nu există evaluări

- Qualification of Welding Procedures and Performance According To Asme Section IxDocument3 paginiQualification of Welding Procedures and Performance According To Asme Section IxAbdulMajidYousoffÎncă nu există evaluări

- Flare System Design - What Is Important?: John Zink CompanyDocument7 paginiFlare System Design - What Is Important?: John Zink CompanyAbdulMajidYousoffÎncă nu există evaluări

- Sticker Monthly PDFDocument2 paginiSticker Monthly PDFAbdulMajidYousoffÎncă nu există evaluări

- Do's and DontDocument3 paginiDo's and DontsivachandranÎncă nu există evaluări

- Barudan TESDocument42 paginiBarudan TESMartinandKimberly RayÎncă nu există evaluări

- Cisco Unified Communications Solutions for Call Processing and MobilityDocument16 paginiCisco Unified Communications Solutions for Call Processing and MobilityMuhammad Ameer SabriÎncă nu există evaluări

- 3900 Series Base Station Cables (04) (PDF) - enDocument787 pagini3900 Series Base Station Cables (04) (PDF) - enAndrei Ghitiu100% (1)

- Script FontDocument76 paginiScript FontJulio Gomez SilvermanÎncă nu există evaluări

- Yaqoob Et Al. - 2016 - Big Data From Beginning To FutureDocument19 paginiYaqoob Et Al. - 2016 - Big Data From Beginning To FutureBruno OliveiraÎncă nu există evaluări

- TAD941GEDocument2 paginiTAD941GEjesus silvaÎncă nu există evaluări

- Flat-Eight Engine: Design Use in Automobiles Use in Aircraft Use in Marine Vessels See Also ReferencesDocument5 paginiFlat-Eight Engine: Design Use in Automobiles Use in Aircraft Use in Marine Vessels See Also ReferencesAve FenixÎncă nu există evaluări

- Service Bulletin: Honda Connect HFT - System InformationDocument3 paginiService Bulletin: Honda Connect HFT - System InformationIsidora PopescuÎncă nu există evaluări

- The Keyword Golden RatioDocument6 paginiThe Keyword Golden RatioUmar GondalÎncă nu există evaluări

- Paranoia XP Character Sheet: Action SkillsDocument2 paginiParanoia XP Character Sheet: Action SkillsChristopherÎncă nu există evaluări

- Page 1Document6 paginiPage 1langbotÎncă nu există evaluări

- Kent Bulldozer TY320Document1 paginăKent Bulldozer TY320MOZAMBiCARÎncă nu există evaluări

- Not for Reproduction: en - English ar-es - Español et - Eesti keel fr - Français ru - Pусский sw - KiswahiliDocument52 paginiNot for Reproduction: en - English ar-es - Español et - Eesti keel fr - Français ru - Pусский sw - KiswahilifosterÎncă nu există evaluări

- VIIIDocument6 paginiVIIIKumarÎncă nu există evaluări

- Sophos Email PDFDocument322 paginiSophos Email PDFDaniel PereiraÎncă nu există evaluări

- Envirotainer Releyer RLP Container Tech SpecsDocument3 paginiEnvirotainer Releyer RLP Container Tech Specstsboy89Încă nu există evaluări

- UT Austin Texas PGP AIML Brochure 3Document17 paginiUT Austin Texas PGP AIML Brochure 3Hasna ChouikhÎncă nu există evaluări

- Design and simulation of a 2x2 MIMO antenna system for IEEE 802.11a applicationsDocument7 paginiDesign and simulation of a 2x2 MIMO antenna system for IEEE 802.11a applicationsValery ShevchenkoÎncă nu există evaluări

- BE46-122-03 J52 SwitchesDocument2 paginiBE46-122-03 J52 SwitchesMichaelÎncă nu există evaluări

- Securing SC Series Storage Best Practices Dell 2016 (BP1082)Document17 paginiSecuring SC Series Storage Best Practices Dell 2016 (BP1082)Le Ngoc ThanhÎncă nu există evaluări

- X-Force 2021 Download - Civil MDCDocument12 paginiX-Force 2021 Download - Civil MDCmichal hana100% (1)

- Python Modes and OperatorsDocument27 paginiPython Modes and OperatorsTejas BhagitÎncă nu există evaluări

- Types of InnovationDocument3 paginiTypes of InnovationEsmyriadeÎncă nu există evaluări

- A Miniaturized Dielectric-Resonator - Ieee - ConfDocument4 paginiA Miniaturized Dielectric-Resonator - Ieee - ConfSaikat Ch BakshiÎncă nu există evaluări

- Exercise SatelliteDocument2 paginiExercise SatelliteVimala ElumalaiÎncă nu există evaluări

- To RC MBS 1Document5 paginiTo RC MBS 1hitosnapÎncă nu există evaluări

- Low-Profile Wideband Four-Corner-Fed Square Patch Antenna For 5G MIMO Mobile Antenna ApplicationDocument5 paginiLow-Profile Wideband Four-Corner-Fed Square Patch Antenna For 5G MIMO Mobile Antenna Applicationrajesh yadavÎncă nu există evaluări