Documente Academic

Documente Profesional

Documente Cultură

Skewed Box Culverts PDF

Încărcat de

iñakiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Skewed Box Culverts PDF

Încărcat de

iñakiDrepturi de autor:

Formate disponibile

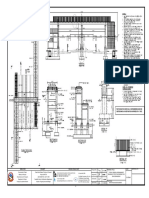

LEFT END RIGHT END GENERAL NOTES:

90 90

WINGWALL WINGWALL

135 45 45 135 LIVE LOAD: HL-93.

Direction of Stationing

Valid Skew

(SW) (SW) CONSTRUCTION LOADING: It is the construction Contractor’s responsibility to provide for

Angle Range Valid Skew

supporting construction loads that exceed AASHTO HL-93, and any construction load

Angle Range

applied prior to 2 feet of compacted fill placed above the top slab.

SURFACE FINISH: All concrete surfaces shall receive a general surface finish.

225 225

SKEWED CONSTRUCTION JOINTS: Construction joints in barrels of culverts with skewed

-50 -50 wingwalls may be placed parallel to the headwalls and the reinforcing steel, and the slabs

may be cut provided that the cut reinforcing steel extends beyond the construction joint

enough for splices to be made in accordance with Table 1 on this sheet. The cost of

»¿ Cu

construction joints and additional reinforcing shall be at the expense of the Contractor.

Ri

ghtHeadwal

l

Left Headwall Val

id Skew Angl

e

CULVERT EXTENSIONS: For cut backs and ties into existing concrete box culverts see

Val

id Skew Angl

e Ranges (SR)

Sheet 6 of 7.

Ranges (SL)

+50 +50

REINFORCING STEEL: See the "Box Culvert Data Tables" in the Contract Plans for grade

225 225 and bar spacing. See the Reinforcing Bar List in the Contract Plans for bar sizes and

bar bending details.

Valid Skew

Angle Range Valid Skew

(SW) (SW)

Angle Range

Culvert Skew f

o

135 45 45 135 (

Negati

ve Skew) n

io g

t in

90 SCHEMATIC "A" - PLAN VIEW 90 c

LEFT BEGIN RIGHT BEGIN For Headwal

lSkew e on

ir i

t

WINGWALL HEADWALL & WINGWALL ALIGNMENT WINGWALL and Wi

ngwal

lSkews, D

ta

S

See Schemati

c"A" 90

NOTE: All headwall and culvert skew angles are measured in degrees from

dgn

a line perpendicular to the centerline of culvert (counter-clockwise

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-1of8.

positive), see Schematic "B".

»¿ Cu

For Headwal

lSkew

th

and Wi

ngwal

lSkews,

nd

ng

See Schemati

c"A"

E

le

ft

l

al

Le

SCHEMATIC "B" - PLAN VIEW

gw

CULVERT ALIGNMENT

in

Construct

ionJoi

nti

n

W

Footi

ngper NOTE: For Cul

vertSkewsee ContractPl

ans.

mi

tted

Exteri

or BarrelWal

l

TABLE 1 - MINIMUM BAR SPLICE LENGTHS

FOR LONGITUDINAL REINFORCING

Construction Joint

Limits of sloped

(See Detail "F", BAR SPLICE (CLASS B) BAR SPLICE (CLASS B)

Sheet 5) top surface (Lw) SIZE CLASS II CLASS IV SIZE CLASS II CLASS IV

W ingwall H eight

Front Tip

Construct

ionJoi

nti

n (3400 psi) (5500 psi) (3400 psi) (5500 psi)

Wi

ngwal

lrequi

red #3 1’-0" 1’-0" #8 3’-6" 2’-9"

H e)

H s)

#4 1’-4" 1’-4" #9 4’-5" 3’-6"

Front Tip

th

in

H eight (

#5 1’-8" 1’-8" #10 6’-7" 4’-5"

(

ng

eg

Front Tip

le

#6 1’-11" 1’-11" #11 7’-10" 6’-5"

B

l

ft

al

Exteri

or Barrel Wal

l #7 2’-8" 2’-3"

Le

gw

Front Tip Height

TABLE 1 NOTE: Splice lengths are based on an AASHTO

in

(He) (1’-6" Min.)

Class B tension lap splice for the Specification Section 346

W

C:

Construct

ionJoi

nti

n concrete class shown.

Footi

ngpermi

tted

Half Elevation showing Half Elevation showing

Parallel Wingwalls Tapered Wingwalls

rd960rh

PART PLAN SHOWING PARALLEL WINGWALLS END ELEVATION

AND LOCATION OF CONSTRUCTION JOINTS OF CULVERT

NOTE:

20 AM

Construction Joints in wingwalls and footings are located as follows:

40:

For non-skewed wingwalls they are located adjacent to the exterior

11:

»¿ face of the exterior barrel wall; when the of wingwall and

exterior barrel wall results in an acute angle see Left End Wingwall

above, and when the angle is obtuse see Left Begin Wingwall above

12/30/2011

and Detail C (Sheet 5).

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/11 FY 2012/2013 289 1

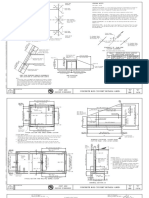

Bars 110 top mat (see Note 1)

Bars 111 bottom mat A

Tt

Half Bar

Bars 101

Space –

(Typ.)

Bars 412 W all to Box Dowel Bars,

Bars 105

exposed side

Bars 406 exposed side

)

Cover

Bars 102

Typ.

Bars 405

Bars 403

soil side

2" x 2" (See Note 3) Bars 401 soil side

exposed side

Chamfer (Typ.) (Tied to Bars 407)

Bars 113 each m at

Bars 114 each m at

Tw Tw

Bars 407 or

Wc

see Note 2)

see Note 2)

see Note 2)

soil side

Bars 408 (Dowels)

Hs

Typical Space

(when Req’d.)

Hc

Bars 108 Bars 108

See Note 3)

)

(

-6" M in.

(

(

Typical Space

Bars 404

Bars 402

)

Typ.

Cover

He

(Typ.)

4" (

1’

(See Note 3) Bars 407 (Dowels)

(

Bars 103

Bars 106

Rd

-0"

Half Bar

Space –

2’

Tb

Bars 104

(Typ.)

Construction Bars 109 top mat

Bars 411

Joint (Typ.) Bars 112 bottom mat (see Note 1)

Half Bar Bars 409 top mat Half Bar

TYPICAL SECTION THRU SINGLE BARREL CULVERT

Space – Bars 410 bottom mat Space –

CULVERT BARREL NOTES:

Lw

»¿ Constru

dgn

»¿1. Space Bars 110 and 112 with a bar in each corner, and at the of interior walls

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-2of8.

multiple barrel culverts only), and the remaining bars placed at equal spacing shown Joint (See Note 1)

A

in the Contract Plans. Adjust last bar spacing when required.

2. Place Bars 113 and 114 at spacing shown in the Contract Plans evenly between

WINGWALL ELEVATION - Variable Height

Bars 109 and 111.

(Left End shown - other corners similar)

3. Locate the first transverse bar from the ends of the culvert at one half the bar

spacing, but provide the minimum reinforcement cover and not greater than 4" clear.

)

3" M in.

)

Varies

3" M in.

Varies

2"x2"

Rw

Chamfer

(

Bars 110 top mat (see Note 1)

(

(Typ.) (Typ.)

Bars 111 bottom mat

Tt

Half Bar

Bars 101

Space –

(Typ.)

Bars 406 Bars 401

Bars 105

403 Varies)

405 Varies)

Bars 102

2" x 2"

d.

Chamfer

Bars 116, 117, if Req’

Right Exterior W all

Bars 113 each m at

Bars 115 each m at

Bars 114 each m at

for Interior W alls)

Left Exterior W all

(Typ.) WINGWALL NOTES:

Bars 107

Dowel Bars 412

1. Align construction joint perpendicular to wingwall.

see Note 2)

see Note 2)

Wc @ 8" spacing

Bars 402 (

Bars 404 (

2. In the vicinity of the construction joint, field bend

shown as ( )

reinforcement as necessary to maintain minimum

Hc

Tw Ti Bars 108 (Typ.)

reinforcement cover.

3. For constant height wingwalls, variable length Bars

403, 405 & 408 are not required, and as such

(

(

C:

Rt Rh the limits of Bars 401 & 407 extend the full length

Typ.

Cover

of the wingwall, and the limits of Bars 402 & 404

(Typ.)

)

Cover

Typ.

(

4" (

Bars 409 extend to the full height of the wingwall.

Bars 107

rd960rh

Bars 103

Bars 106

Rd

-0"

Half Bar

2’

Space –

Tb

21 AM

Construction Bars 104

(Typ.) Bars 407

Joint (Typ.) Bars 109 top mat Bars 410

40:

or Bars 408

11:

Bars 112 bottom mat (see Note 1) 1’-0"

TYPICAL SECTION THRU MULTIPLE BARREL CULVERT 312" 312"

Bars 411 each face

@ equal spacing

12/30/2011

WINGWALL SECTION A-A

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/07 FY 2012/2013 289 2

Left End Wingwall, Right End Wingwall,

R

(Reinforcing Bars 401-412) (Reinforcing Bars 601-612)

(T

h

y

p

»¿Lc (Length at of Cul

.)

R

w

R

SR,Ri

(T

Normal Bars 101 (Top mat of Top Slab), Bars 102 (Bottom mat of Top Slab) Normal ght

y

He

p

(T

ad

.)

Space Cul

ver Space w

y

tS (- al

p

ke sho l

.)

See Detail "D", w wn S

(

Se k

e An ) e

SW (Typ.) Wingwall Skew No w

SL, Left Headwall (Sheet 5) t g

e le

.)

Skew (- shown) 1) Bars 106 (Bottom corner of Barrel)

p

y

Bars 108 (Inside Face)

(T

End Culvert (See Note 1)

w

L

WP (See

Note 2) Bars 303 (Top mat, Right Skew)

Bottom m at)

Bottom m at)

Bars 203 (Top mat, Left Skew)

Bars 201 & 202 (Left Skew)

Top m at)

Top m at)

Bars 101 (Top mat) Bars 103 (Top mat)

Bars 301 & 302 (Right Skew) (Typ.) Bars 304 (Bottom mat, Right Skew)

Bars 102 (Bot. mat) Bars 104 (Bot. mat)

g

Bars 204 (Bottom mat, Left Skew)

in

n

o

ti

Brcw

ta

Bars 110 (

Bars 109 (

Bars 801 (Left Headwall)

S

Bars 111 (

Bars 112 (

f

Bars 804 (Right Headwall)

o

»¿ Cu

n

o

ti

c

B

Bars 303 & 304 (Right Skew)

e

lh

ir

w

Bars 203 & 204 (Left Skew) (Typ.)

D

Bars 201 (Top mat, Left Skew)

See Detail "E", Bars 301 (Top mat, Right Skew)

(Sheet 5) Bars 202 (Bottom mat, Left Skew)

Bars 302 (Bottom mat, Right Skew)

WP (See

Note 2) Bars 811 (Right Cutoff Wall)

Bars 808 (Left Cutoff Wall)

Begin Culvert

Bars 108 (Inside Face)

(See Note 1)

dgn

Bars 105 (Top corner of Barrel) SW (Typ.) Wingwall Skew

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-3of8.

Left Begin Right Begin Wingwall,

Wingwall, Bars 103 (Top mat of Bottom Slab (Reinforcing Bars 701-712)

(Reinforcing Bars 104 (Bottom mat of Bottom Slab)

Bars 501-512) Slab Reinforcing Steel within these Slab Reinforcing Steel within these

limits apply for the skewed portion Slab Reinforcing Steel within these limits apply for the nonskewed portion of slabs limits apply for the skewed portion

of culvert slabs when the left of culvert slab when the right

Headwall is skewed. Headwall is skewed.

PARTIAL PLAN TOP SLAB PARTIAL PLAN BOTTOM SLAB

(Left Side, Left Skew) SINGLE BARREL BOX CULVERT (Right Side, Right Skew)

NOTES: (Skewed Culvert With Parallel Wingwalls Shown)

1. See Contract Plans for Culvert location, Culvert

Skew Angle and Roadway Cross Section. Center of Traffic Lanes

2. WP = Working Point, used for wingwall layout and

location of construction joint. See Detail "C" (Sheet 5).

X

1 Side Slope 1:X

Depth of fill (do not use upper or

See Detail "J",

lower points in normal or superelevated

(Sheet 5)

roadway sections unless so directed by

Half Bar Space – the Structures Design Office.)

Bars 803 Bars 806

Bars 802 Bars 805

(Typ.) Bars 110 (Typ.)

Construction Joint

C:

Bars 108 ~ Interior Bars 111

Face (Exterior Wall) Bars 113 & 114 Exterior

Bars 107 ~ Each Face

Walls (Each Face)

Bars 105/Bars 106 ~ Exterior (Interior Wall - Multiple Barrels only)

Bars 115, 116... Interior Walls

rd960rh

Face (Exterior Wall) (Each Face, Multiple Barrels only)

Bars 109 4" (Typ.)

Construction Joint

Bars 112

Bars 809 Bars 812

22 AM

40:

Half Bar Space –

11:

Bars 808 See Detail "K" Bars 811

Partial Section showing Exterior Walls Partial Section showing Interior Walls (Multiple Barrels only)

(Typ.) (Sheet 5) (Typ.)

LONGITUDINAL SECTION THRU CULVERT

12/30/2011

(Transverse Top & Bottom Slab Reinforcing Not Shown For Clarity)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/07 FY 2012/2013 289 3

Culvert

Skew An SR

SL gle

ew (

Se e No Ri

gh

LeftSk te 1) tSkew

hown) (-sh (-sho

(+s own) wn)

»¿Lc (Length at of Cul

Bars 105 (Top corner of barrel) Bars 106 (Bottom corner of barrel)

Bars 108 (Inside Face) Bars 108 (Inside Face)

Slab Reinforcing Steel within these limits apply for the nonskewed portion of slabs Right End Wingwall

(Reinf. Bars 601-612)

Bars 101 (Top mat of Top Slab), Bars 102 (Bottom mat of Top Slab)

Bars 103 (Top mat of Bottom Slab), Bars 104 (Bottom mat of Bottom Slab)

Normal Normal

End Culvert (See Note 1)

Space Space

Left End Wingwall

(Reinf. Bars 401-412)

WP (See Note 2)

Bars 201 (Top mat, Left Skew) Bars 303 (Top mat, Right Skew)

Bars 301 (Top mat, Right Skew) Bars 203 (Top mat, Left Skew)

WP (See Note 2)

Bars 202 (Bottom mat, Left Skew) Bars 304 (Bottom mat, Right Skew)

)

Typ.

Wc

Bars 302 (Bottom mat, Right Skew) Bars 204 (Bottom mat, Left Skew)

Bottom m at)

Bottom m at)

(

Top m at)

g

Top m at)

Bars 201 & 202 (Left Skew)

nin

Bars 303 & 304 (Right Skew)

Bars 301 & 302 (Right Skew) (Typ.) Bars 203 & 204 (Left Skew) (Typ.)

tio

Sta

Bars 109 (

Ti

Bars 110 (

»¿ Cu

Bars 112 (

of

Bars 111 (

Bars 801 (Left Headwall)

ion

Bars 804 (Right Headwall) See Detail "G"

ect

Bars 101 (Top mat) Bars 103 (Top mat) (Sheet 5)

D ir

Bars 104 (Bottom mat)

dgn

Bars 102 (Bottom mat) Brcw

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-4of8.

hw

Bl

-6" Bars 812 (Right Cutoff Wall)

1’

See Detail "C",

Bars 809 (Left Cutoff Wall)

(Sheet 5) Wingwall WP (See Note 2)

to Box Connection

See Detail E (Sheet 5),

Chamfer Requirements

WP (See Note 2)

SW (Typ.)

Begin Culvert (See Note 1)

Left Begin Wingwall Wingwall Skew

Right Begin Wingwall

(Reinf. Bars 501-512)

Partial Plan Top Slab Partial Plan Bottom Slab (Reinf. Bars 701-712)

SW (Typ.)

Lw

Wingwall Skew )

p.

(T

Ty

(

yp

Rt

.)

PARTIAL PLAN TOP SLAB PARTIAL PLAN BOTTOM SLAB

)

p. )

(Left Side, Left Skew) (Right Side, Right Skew) Ty p.

( Ty

(

Rh

MULTIPLE BARREL BOX CULVERT Rw

(Skewed Culvert With Skewed Wingwalls Shown)

C:

rd960rh

NOTES:

1. See Contract Plans for Culvert Location,

23 AM

Culvert Skew Angle and Roadway Cross Section.

2. WP = Working Point, used for wingwall layout and

40:

location of construction joint. See Detail C (Sheet 5).

11:

12/30/2011

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/07 FY 2012/2013 289 4

NOTES:

Bars 412 (Left End Wingwall)

See Detail "G" See Detail "F" Coarse Aggregate 1. For small angles, the Contractor may elect to fill the area between the

Bars 712 (Right Begin Wingwall) (Typ.)

box and the wingwall footing with unreinforced concrete. For wingwall skew

Bars 512 (Left Begin Wingwall)

2’-0" (Typ.)

angles less then 90 degrees, field bend wingwall reinforcement as necessary

Bars 612 (Right End Wingwall) (Typ.)

1 while maintaining cover. No additional payment will be made for this work.

L ’

-0"

3" Weep Hole with -

a 0" Type D-3 Filter 2. Location of Construction Joint determined by WP at theoretical intersection of:

p

1’

continuous Underdrain

Fabric

H e and H s)

- Soil side face of Headwall and outside face of Box Exterior Wall, for SW=90;

W all H eight

(See Detail B)

1 - Outside face of Wingwall and outside face of Box Exterior Wall, for SW>90.

12 (Min.)

6"

3. Provide 6" chamfer when angle ’A’ is greater than 45. Maintain

1 Underdrain Pipe

minimum wall thickness. Field adjust reinforcing to maintain cover.

(See Index 286)

4. Wingwall Skew Angles (SW) are measured from the adjacent box

(

exterior wall to the wingwall.

2’-0" 5. Turn or extend Wingwall Cutoff Wall as necessary to meet Box Cutoff Wall.

6. Provide additional reinforcement in the top of the top slab below traffic

6" 1’-6" railings to ensure a minimum area of 0.80 sq. in./ft. transverse reinforcing.

1’-0" Min. Hlcw (Left) Provide additional 3" Weep

Slope of Holes @ 10’-0" spacing when

(Typ.) Hrcw (Right)

Backfill base of Wingwall is exposed

DETAIL "B"

Blhw

END ELEVATION UNDERDRAIN DETAIL

2" x 2"

(Showing Constant Height And (Similar to Type II ~ Index 286) Bars 801

Chamfer

(Bars 804)

Variable Height Wingwalls) (Typ.)

Traffic Railing Barrier

(32" F-Shape shown) Optional

Bars 803

(Bars 806) Construction

Headwall

Cutoff Wall Joint (Typ.)

H lhw

Align Exposed Face of

See Traffic Railing Index

Construction Joint Wingwall with Inside

for reinforcing details

Tt

(See Note 2) Face of Box Exterior Wall 6" x 6"

dgn

Chamfer

Construction Roadway Surface

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-5of8.

WP (SW=90)

(Typ.)

Wingwall Joint required

Cutoff Wall

»¿ Varies (4" Min. if optional

(See Note 5) Bars 802 (Bars 805) (Typ.)

Const. Joint provided)

Exterior Wall of Box

»¿˘" Cha

WP Optional DETAIL "J"

See Note 1 Construction Joint

Wingwall (SW>90) LEFT HEADWALL SECTION

(Right Headwall similar)

8" Min. TL-4 Traffic Railing

SW (See Note 4) Bars 803 (Bars 806)

10" Min. TL-5 Traffic Railing

Min. #5 bars @ 8" sp. End of Barrel &

Face of Headwall

Wingwall Footing Edge of

Provide supplemental top bars

(Min. 5’-0" long) (See Note 6) 1’-6" Chamfer

»¿˘"

DETAIL "C" - PLAN VIEW

DETAIL "I" Chamfer

WINGWALL TO BOX CONNECTION

TRAFFIC RAILING ATTACHMENT TO HEADWALL

(Left Begin Corner Shown, Other Corners Similar)

Tb

1 Optional Construction

2»¿" V-Groove a Bars 807

Joint (Typ.)

Construction Joint (Bars 810)

6"

in Vertical Face of

Cham fer

6"

6" Top

Wingwall Only

H lcw

C:

Ti Interior Wall Bars 809 (Bars 812)

6"

Bars 808 (Bars 811)

6"

See Note 1

rd960rh

H H

1/3 Ti

6"

6" Side 1/3 Ti

Angle ’A’

Chamfer Blcw

24 AM

(See Note 3)

40:

DETAIL "D" DETAIL "F" DETAIL "E" DETAIL "G" SECTION H-H DETAIL "K"

11:

LEFT CUTOFF WALL SECTION

CROSS REFERENCE:

(Right Cutoff Wall similar)

See Sheet 3 for locations of Details "D", "E", "J" & "K".

12/30/2011

See Sheet 4 for locations of Detail "C".

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/10 FY 2012/2013 289 5

Remove Wingwalls and Footings

Sufficient to Construct Length for

Length For

Culvert Extension Estimated Quantities

Estimated Quantities Longitudinal Reinforcing

C Steel to be Extended

Remove Headwall,

Longitudinal Reinforcing

into Culvert Extension

Wingwall & Footing

Steel to be Extended Culvert Extension (Lc, Culvert Extension (Lc,

(See Note 3)

to Construction Joint

into Culvert Extension Tabulated on Box Culvert Tabulated on Box Culvert

(See Note 3) Tie-In

C Data Tables for Standard Cut back Existing Tie-In Data Tables for Standard

Length Length

Box Section Extension) Walls, Top Slab & Box Section Extension)

Bottom Slab to

Exist. Box Box Culvert Beginning of Radius

Culvert Extension (2’-0" Min.)

Existing

A A Box Culvert B B Existing

2’-0" Box Culvert

Box Box Culvert

Extension Exist. Box Box

Extension

Culvert Extension

Culvert Culvert

Cut back Existing

Walls, Top Slab & C C

See Transition See Transition

Bottom Slab Exist. Construction Joint

Detail L Detail "L"

OUTSIDE WALLS OF BOXES SECTION A-A OUTSIDE WALLS OF BOXES

SECTION B-B

FLARED WINGWALL

STRAIGHT WINGWALL

Proposed Side Slope

2’-0" Straight 2’-0" Tapered Existing

Transition Transition NOTES:

Side Slope

(See Detail "M") 1. The Box Culvert Data Tables and Reinforcing Bar List do not include the additional

Existing Remove Portion of quantities needed for dowel connections or transitions from double walls of existing

Wingwall Wingwall less than 1’-0" concrete box culverts; the cost for additional reinforcement and the thickened

below Proposed Side Slope Surface concrete wall in the transitional area shall be included in the costs for concrete and

dgn

steel in the culvert extension.

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-6of8.

2. Cost for removal and disposal of material from existing headwalls, wingwalls and box,

and cost of cleaning, straightening and extending or doweling longitudinal

reinforcing steel shall be included in the cost for concrete and steel of the culvert

INTERIOR DOUBLE WALLS OF BOXES

SECTION C-C extension.

3. Remove existing concrete while avoiding damage to existing reinforcement. Clean

and straighten existing reinforcement, lap and tie onto extension reinforcement.

2’-0" Straight 2’-0" Tapered

4. Dowel in #4 Bars @ 1’-0" max. spacing into wall/slab when there is a single mat

Transition Transition

of existing reinforcing steel, otherwise splice 1’-6" as shown for inside

(See Detail "L")

reinforcement. Use an Adhesive Bonding Material System in accordance with

Specifications Section 416 & 937.

5. Provide additional transverse bars for top and bottom slab, parallel and full width

of any skewed joint connection when shown in the Plans.

6. See Box Culvert Data Table notes in Plans for Connection Types allowed.

INTERIOR SINGLE WALLS OF BOXES

Section of Existing Box Culvert to be removed Existing Headwall 2’-0" Transition

PLAN VIEWS

and replaced, for Type I Connection.

2’-0" Min. 2’-0" Tapered

Wrap Filter Fabric 2’-0" (See Note 3)

(See Note 3) Transition

Around Construction 1" Min. ~

Joint (2’-0" Min. Width) Face of Existing Headwall or Wingwall 3" Max.

1’-6" Min.

Field Bend Outside Face of Wall/Slab

3" Min. Cl.

(Splice Length)

C:

as Required

Existing

Existing

Slab or Wall

Walls Extension Wall

Thickness Extension Slab

rd960rh

or Wall Thickness

See Note 5 Inside Face of Wall/Slab

Longitudinal Reinforcing

See Note 4 Bend horizontal bars to lap with existing

1’-0" (Min. 1" Min. ~ 3" Max.

24 AM

inner wall reinforcement 1’-6" Min.

Embedment)

40:

DETAIL "L" - TRANSITION FOR EXTERIOR WALL/SLAB EXTENSION DETAIL "M" - TRANSITION FOR INTERIOR DOUBLE WALLS OF BOX CULVERTS

11:

(Interior Single Walls Similar)

12/30/2011

TYPE I CONNECTION DETAILS FOR CONCRETE BOX CULVERT EXTENSIONS

(CUT BACK EXISTING CONCRETE)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/12 FY 2012/2013 289 6

Remove Portions of Wingwalls

Length for

Sufficient to Construct Length for

Longitudinal Reinforcing Estimated Quantities

Culvert Extension Estimated Quantities

C Steel to be Extended

Remove Headwall

Cut back Concrete and into Culvert Extension

Culvert Extension (Lc, & Wingwall to

Reinforcing to Face of (See Note 3) Culvert Extension (Lc,

2’-0" Tie-In Length Tabulated On Box Culvert Construction Joint

Culvert (See Note 3) Tabulated on Box Culvert

For Type I Connection Data Tables for Standard Tie-In Data Tables for Standard

C

Box Section Extension) Cut back Existing Length Box Section Extension)

Walls, to Beginning

Exist. Box Box Culvert of Radius or Top

Culvert Extension Slab Chamfer

A A

Existing

Box Culvert B B Existing

Box Culvert

Box Exist. Box Box Culvert Box

Extension Extension

Culvert Culvert Extension Culvert

C C See Transition

See Transition

Exist. Construction Joint Detail "N"

Detail N

SECTION B-B

OUTSIDE WALLS OF BOXES SECTION A-A OUTSIDE WALLS OF BOXES

FLARED WINGWALL STRAIGHT WINGWALL

NOTES:

1. The Box Culvert Data Tables and Reinforcing Bar List do not include the additional

quantities needed for dowel connections or transitions from double walls of existing

Proposed Side Slope

2’-0" Tapered concrete box culverts; the cost for additional reinforcement and the thickened

Existing

2’-0" Straight Transition concrete wall in the transitional area shall be included in the costs for concrete and

Side Slope

Transition (See Detail M) steel in the culvert extension.

Existing Remove Portion of Wingwall 2. Cost for roughening and cleaning existing headwalls, wingwalls and box, and cost of

dgn

Wingwall doweling longitudinal reinforcing steel shall be included in the cost for oncrete

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-7of8.

and/or Headwalls less than 1’-0"

Face of Footing below Proposed Side Slope Surface and steel of the culvert extension.

Trim Wall Reinforcing

Cut off Wall 3. Remove existing concrete and reinforcing back to edge of any chamfers exceeding

to provide 2" Min.

(Location varies) 1". Roughen and clean existing or exposed surface and coat with a Type A epoxy

Existing Clearance

bonding compound in accordance with the manufacturer’s recommendations.

Box Culvert

INTERIOR DOUBLE WALLS OF BOXES 4. Dowel in #5 Bars @ 1’-0" max. spacing horizontally into center of wall/slab. Provide

Wall 1" Min. ~

SECTION C-C vertical dowels in footing to match size, alignment and spacing of outside vertical

3" Max. Cl.

wall reinforcing. Use an Adhesive Bonding Material System in accordance with

Box Culvert Extension

Specifications Section 416 & 937.

2’-0" Straight 2’-0" Tapered Wall Reinforcing

Length

Splice

5. Provide additional transverse bars for top and bottom slab, parallel and full width

-6"

Transition Transition

of any skewed joint connection when shown in the Plans.

1’

(See Detail "L")

6. Remove top of existing headwall when necessary to provide 1’-0" clearance below

Top of

finished grade. Saw cut full width and seal with Type F-2 epoxy compound to

Bottom Slab

protect exposed reinforcing.

Face of Footing 7. See Box Culvert Data Table notes in Plans for Connection Types allowed.

Cut off Wall Em bedm ent

See Note 4 Filter Fabric

6" M in.

2’-0" Straight 2’-0" Tapered Transition

See Note 3

INTERIOR SINGLE WALLS OF BOXES Existing Toe Slab Transition

Existing Toe Slab

and Cutoff Wall

PLAN VIEWS Existing Headwall Varies & Cutoff Wall

DETAIL "N"

Roughened face of Existing 2’-0" Min. ~ Walls 2’-0" Transition See Note 4

Headwall or Wingwall (See Note 3) Varies ~ Slabs

Wrap Filter Fabric around See Note 6

Construction Joint (2’-0" Min. Width)

C:

1’-6" Min.

Field Bend Outside Face of Wall/Slab Existing

3" Min. Cl. (Overlap) 1’-6" Min.

as Required

Walls Extension Wall

Existing (Splice Length)

Slab or Wall Extension Slab

rd960rh

Thickness or Wall Thickness

Bend horizontal bars to lap with dowelled

1’-0" Min. 1" Min. ~ 3" Max. wall reinforcement 1’-6" Min. (Non-contact

See Note 5 Inside Face of Wall/Slab

See Note 4 (Embedment) lap splice permitted)

25 AM

1’-0" (Min. 1" Min. ~ 3" Max.

40:

Embedment)

11:

DETAIL "L" - TRANSITION FOR EXTERIOR WALL/SLAB EXTENSION DETAIL "M" - TRANSITION FOR INTERIOR DOUBLE WALLS OF BOX CULVERTS

(Interior Single Walls Similar)

12/30/2011

TYPE II CONNECTION DETAILS FOR CONCRETE BOX CULVERT EXTENSIONS

(ADHESIVE DOWEL TO EXISTING CONCRETE)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/12 FY 2012/2013 289 7

Norm al slab

Norm al slab

2 ~ #7 Bars 2’-6" 4’-4"

Thickness

Thickness

2 ~ #7 Bars @

@ Each Corner

1 Slightly & Moderately Each Corner (Typ.)

(Typ.) 4" 2’-512" (Grate) 1

4"

1

2" 4’-3" (Grate) 1

2"

Aggressive Environment Slightly & Moderately Aggressive Environment

4"

Extremely Aggressive Extremely Aggressive Environment

Environment

5"

10"

12"

10"

12"

3" 3"

45 45

3 ~ #7 Bars @ 3" sp. 1’-0" Additional Concrete Haunch Additional Concrete Haunch

4" 3’-8" 4"

For Entire Width of Required Only When Normal Required Only When Normal

Culvert Slab (Typ.) Slab Thickness is Less Than 3 ~ #7 Bars @ 3" sp. 1’-0" Slab Thickness is Less Than

SECTION A-A

Minimum Shown For Entire Width of Minimum Shown

Use Extra Base When This

2’-6" Culvert Slab (Typ.) SECTION B-B

Dimension is Less Than 12"

10’-0"

3" 6" Unless Otherwise

3"

Shown in Plans »¿ Median

Bottom of Base

Culvert Wall Culvert Wall

Friable 2’-0"

Base Material

5"

1’-0"

A A

B B

Concrete Box

-3"

-1"

Culvert

2’

3’

The cost of furnishing and installing extra friable base

3 ~ #7 Bars material shall be included in the cost of the Box Culvert.

-8"

@ 3" Sp. (Typ.)

4’

FRIABLE BASE

5"

dgn

\d\projects\standards\structures\current\ready4release\2012book_draft\00289-8of8.

See Index No. 231

See Index No. 230

for Grate detail

for Grate detail 3 ~ #7 Bars Use Extra Base When This

@ 3" Sp. (Typ.)

Dimension is Less Than 12"

10’-0"

Bottom of Base

»¿ Median 2 ~ #7 Bars 3’-6" long @ 3" sp. 2’-0"

Coarse

Above Bottom Mat of Reinf. Across

PLAN Aggregate

Each Corner of Opening (Typ.)

Filter Fabric

1’-0" (both sides)

INLET TYPE A GRATE

NOTES: Concrete Box

PLAN

1. Cost of Steel Grating to be included in cost of Box Culvert. Culvert

2. All reinforcing shall be 2" clear for Slightly and Moderately Aggressive

Environments, and 3" clear for Extremely Aggressive Environments.

INLET TYPE B GRATE

Place coarse aggregate in 6 inch lifts and compact sufficiently as

to be firm and unyielding. Provide coarse aggregate gravel or stone

INLET IN TOP OF BOX CULVERT meeting the requirements of Specification Section 901-2 or 901-3

respectively. Meet the gradation requirements of Specification

Paint Recessed Section 901-6, Grades 4, 467, 5, 56 or 57 unless restricted in the

»¿ Bridge Cu Surfaces Black plans. Provide Type D-3 filter fabric (see Index No. 199). The cost

Location of Number

of furnishing and installing the coarse aggregate and filter fabric

45 45 shall be included in the cost of the Box Culvert.

C:

000000

8"

ASPHALTIC CONCRETE BASE

3

rd960rh

20’ or more NOTE: Extra base is required when cross box culverts are located

(Bridge Culvert) on facilities subject to high speed traffic ( >45 mph) or high

traffic volumes ( >1600 ADT) and the cover is within the

SECTION THRU RECESSED V-GROOVE range specified in the notation above.

26 AM

The number is to be placed in the center of TO FORM INSCRIBED FIGURES

the top surface of all bridge culvert headwalls.

40:

Black Plastic Figures 3" in height as approved by the Engineer

For Bridge Number see Plan-Profile sheet(s).

11:

3

may be used in lieu of numbers formed by 8" V-Grooves.

TOP VIEW OF HEADWALL V-Grooves shall be formed by preformed figures.

EXTRA BASE FOR BOX CULVERTS

12/30/2011

CROSSING UNDER FLEXIBLE PAVEMENT

BRIDGE CULVERT NUMBER LOCATION

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

CONCRETE BOX CULVERT DETAILS (LRFD)

01/01/07 FY 2012/2013 289 8

S-ar putea să vă placă și

- Drawings For Culvert at 293+538 PDFDocument3 paginiDrawings For Culvert at 293+538 PDFSurya GowthamÎncă nu există evaluări

- Analysis and Design of Well FoundationDocument40 paginiAnalysis and Design of Well Foundationdhanabal100% (1)

- Equivalent Udl For IRC Live LoadsDocument14 paginiEquivalent Udl For IRC Live LoadsHanamantrao Khasnis100% (1)

- RCC NP3 Pipe Bedding DesignDocument1 paginăRCC NP3 Pipe Bedding DesignSuseendar Ramadoss100% (2)

- Drain Cum Retaining WallDocument12 paginiDrain Cum Retaining WallvivekÎncă nu există evaluări

- Syphon Aqueduct DesignDocument7 paginiSyphon Aqueduct DesignSanjeev Mishra100% (2)

- Bridge Hydrology and Scour: Rajendra Raj Sharma Department of RoadsDocument40 paginiBridge Hydrology and Scour: Rajendra Raj Sharma Department of RoadsGaurabÎncă nu există evaluări

- Hydraulic DesignDocument27 paginiHydraulic DesignHrishikesh R50% (2)

- Design Data - T-Girder - Jan 11 - 2017 PDFDocument1 paginăDesign Data - T-Girder - Jan 11 - 2017 PDFYirga BezabehÎncă nu există evaluări

- Bridge BookDocument76 paginiBridge BookSunkara Hemanth KumarÎncă nu există evaluări

- Arch Bridge Code - RDSO, IRDocument8 paginiArch Bridge Code - RDSO, IRJogesh S SondhiÎncă nu există evaluări

- Irc 112Document24 paginiIrc 112Bharath Reddy ChinthiReddy100% (1)

- 1x1.2x1.2 BOX CULVERT REINFORCEMENT DETAILS-4-LANE PDFDocument1 pagină1x1.2x1.2 BOX CULVERT REINFORCEMENT DETAILS-4-LANE PDFbakhteyar shaikhÎncă nu există evaluări

- Design Report of Intz Type Water Tank-Bia-01.07.2015 PDFDocument56 paginiDesign Report of Intz Type Water Tank-Bia-01.07.2015 PDFGR Kanna100% (1)

- Compendium On Silting of Reservoirs in India - CWC (2015)Document219 paginiCompendium On Silting of Reservoirs in India - CWC (2015)saradhi26Încă nu există evaluări

- Culvert အကြောင်းသိကောင်းစရာများ (Saya Thet Lwin)Document91 paginiCulvert အကြောင်းသိကောင်းစရာများ (Saya Thet Lwin)Myanmar ZorroÎncă nu există evaluări

- Hydraulic Calculation For Box Type Minor Bridge Bridge at CH - 08+967Document17 paginiHydraulic Calculation For Box Type Minor Bridge Bridge at CH - 08+967Nilay Gandhi100% (3)

- Spayed Wing Wall BBS 155+586 RHSDocument1 paginăSpayed Wing Wall BBS 155+586 RHSHegdeVenugopal100% (1)

- Hume Pipe Culvert Drawing PDFDocument1 paginăHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- Breast Wall 2.5MDocument4 paginiBreast Wall 2.5MSharun ShajiÎncă nu există evaluări

- Design Note of Crash Barrier With Friction SlabDocument9 paginiDesign Note of Crash Barrier With Friction SlabRahul Kare100% (1)

- Hume Pipe Culvert Drawing PDFDocument1 paginăHume Pipe Culvert Drawing PDFVikramjit Singh100% (1)

- Design of Bridges1Document30 paginiDesign of Bridges1rahatul bashirÎncă nu există evaluări

- Culvert and Bridge Material.Document221 paginiCulvert and Bridge Material.Godana Tadicha100% (1)

- Environment and Hydrology Objective QuestionsDocument5 paginiEnvironment and Hydrology Objective QuestionsICE Group of Education BhopalÎncă nu există evaluări

- IRC-6-CNew Clause - 214.5-Approved by B2 in 19th MeetingDocument3 paginiIRC-6-CNew Clause - 214.5-Approved by B2 in 19th MeetingGobinder Singh VirdeeÎncă nu există evaluări

- GAD of Structure - A-13 - 2 PDFDocument30 paginiGAD of Structure - A-13 - 2 PDFmayank007aggarwal0% (1)

- RDSO Substructure Code PDFDocument71 paginiRDSO Substructure Code PDFTarun Sai100% (1)

- Box Culvert Without CushionDocument23 paginiBox Culvert Without CushionPrafulla Malla100% (1)

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Document4 paginiThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KafleÎncă nu există evaluări

- Road Estimate FormatDocument7 paginiRoad Estimate Formatalok jhaÎncă nu există evaluări

- GT Report Open Cutting at Ch. 34 KM MizoramDocument15 paginiGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarÎncă nu există evaluări

- Rdso Guide Lines FR BridgesDocument76 paginiRdso Guide Lines FR BridgesUtpal KantÎncă nu există evaluări

- PDF Power Grid On Well FoundationDocument150 paginiPDF Power Grid On Well FoundationLiton ShilÎncă nu există evaluări

- IRC Guidelines For Culvert DesignDocument90 paginiIRC Guidelines For Culvert DesignsrijanÎncă nu există evaluări

- Economic Design of RCC Box Culvert ThrouDocument7 paginiEconomic Design of RCC Box Culvert ThrouOscarKonzultÎncă nu există evaluări

- Crash Barrier Friction Slab Design Calculation URS 2017 PDFDocument187 paginiCrash Barrier Friction Slab Design Calculation URS 2017 PDFAnkush SharmaÎncă nu există evaluări

- Nawa Khola Vented Causeway EstimatesDocument8 paginiNawa Khola Vented Causeway Estimateshimal kafleÎncă nu există evaluări

- Design - PCC Toe WallDocument10 paginiDesign - PCC Toe Wallsiddharth yadavÎncă nu există evaluări

- Drawing Title: Employer Project Design Consultant: HouseDocument5 paginiDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalÎncă nu există evaluări

- Crackwidth Calculation Spreadsheet (Restricted Version)Document11 paginiCrackwidth Calculation Spreadsheet (Restricted Version)Nicholas ThompsonÎncă nu există evaluări

- Abutment: W Ing W AllDocument2 paginiAbutment: W Ing W AllRam Prasad AwasthiÎncă nu există evaluări

- Scour Depth & Stone Apron SizingDocument18 paginiScour Depth & Stone Apron SizingguildkeyÎncă nu există evaluări

- RCC Encasing Pipe CulvertDocument40 paginiRCC Encasing Pipe CulvertVM&CO VM&CO0% (1)

- Design of PSC Cross Girder As Per IRC 112Document2 paginiDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- Amendment To IRC 24 - 2010Document6 paginiAmendment To IRC 24 - 2010mrraee4729100% (1)

- IRC SP 18-1996 Bridges Maintenance Inspection PDFDocument24 paginiIRC SP 18-1996 Bridges Maintenance Inspection PDFakvosmÎncă nu există evaluări

- What Is A Culvert - Types of Culverts, Its Materials and LocationDocument4 paginiWhat Is A Culvert - Types of Culverts, Its Materials and LocationJustin MusopoleÎncă nu există evaluări

- Drainage Spout & Crash Barrier Detail PDFDocument1 paginăDrainage Spout & Crash Barrier Detail PDFshshank guptaÎncă nu există evaluări

- Slab Culvert DrawingDocument1 paginăSlab Culvert DrawingLokeshÎncă nu există evaluări

- Lecture 10 (A) - MR Alok Bhowmick On Chapter 8 & 9Document40 paginiLecture 10 (A) - MR Alok Bhowmick On Chapter 8 & 9Sulabh Gupta100% (1)

- East WallDocument8 paginiEast WallKumar Atray100% (1)

- SLRB 70Document1 paginăSLRB 70Anonymous oVmxT9Kzrb100% (1)

- Modified LVUP DrawingsDocument1 paginăModified LVUP DrawingsAldrinÎncă nu există evaluări

- Design Parameters Considered For Storm Water Drainage Design From CH 1311 940 To 1314 510 PDFDocument6 paginiDesign Parameters Considered For Storm Water Drainage Design From CH 1311 940 To 1314 510 PDFsagu27Încă nu există evaluări

- Design of Box CulvertDocument4 paginiDesign of Box CulvertPriodeep ChowdhuryÎncă nu există evaluări

- 00289Document8 pagini00289Alok vermaÎncă nu există evaluări

- G H N D: Fdot Design StandardsDocument8 paginiG H N D: Fdot Design Standardsharnishtanna212Încă nu există evaluări

- Culvert: D N G HDocument8 paginiCulvert: D N G HkingdbmÎncă nu există evaluări

- Culvert: D N G HDocument8 paginiCulvert: D N G Hvijay kumarÎncă nu există evaluări

- Review Rachna WasteDocument9 paginiReview Rachna WasteSanjeet DuhanÎncă nu există evaluări

- Yumemiru Danshi Wa Genjitsushugisha Volume 2Document213 paginiYumemiru Danshi Wa Genjitsushugisha Volume 2carldamb138Încă nu există evaluări

- Electronics 12 00811Document11 paginiElectronics 12 00811Amber MishraÎncă nu există evaluări

- Hunger Games Mini Socratic Seminar2012Document4 paginiHunger Games Mini Socratic Seminar2012Cary L. TylerÎncă nu există evaluări

- Analysis of Green Entrepreneurship Practices in IndiaDocument5 paginiAnalysis of Green Entrepreneurship Practices in IndiaK SrivarunÎncă nu există evaluări

- Placa 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Document39 paginiPlaca 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Sergio GalliÎncă nu există evaluări

- VPZ M BrochureDocument2 paginiVPZ M BrochuresundyaÎncă nu există evaluări

- 240-56062705 RTV Silicone Rubber Insulator Coating and Shed Extender Supplier StandardDocument10 pagini240-56062705 RTV Silicone Rubber Insulator Coating and Shed Extender Supplier StandardJane ChatsiriphatthanaÎncă nu există evaluări

- WAM ES Screw Conveyors Manual JECDocument43 paginiWAM ES Screw Conveyors Manual JECabbas tawbiÎncă nu există evaluări

- Focal Length of Convex LensDocument5 paginiFocal Length of Convex LensHey AnuragÎncă nu există evaluări

- ZH210LC 5BDocument24 paginiZH210LC 5BPHÁT NGUYỄN THẾ0% (1)

- U2 LO An Invitation To A Job Interview Reading - Pre-Intermediate A2 British CounciDocument6 paginiU2 LO An Invitation To A Job Interview Reading - Pre-Intermediate A2 British CounciELVIN MANUEL CONDOR CERVANTESÎncă nu există evaluări

- Mi Account ေက်ာ္နည္းDocument16 paginiMi Account ေက်ာ္နည္းamk91950% (2)

- Thesis StoryboardDocument5 paginiThesis StoryboardJill Brown100% (2)

- DC Motor: F Bli NewtonDocument35 paginiDC Motor: F Bli NewtonMuhammad TausiqueÎncă nu există evaluări

- SHAW Superdew 3 Specification SheetDocument3 paginiSHAW Superdew 3 Specification SheetGeetha ManoharÎncă nu există evaluări

- Gauss' Law: F A FADocument14 paginiGauss' Law: F A FAValentina DuarteÎncă nu există evaluări

- FmatterDocument12 paginiFmatterNabilAlshawish0% (2)

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDocument3 paginiTensile Strength of Ferro Cement With Respect To Specific SurfaceheminÎncă nu există evaluări

- EF3e Intplus Filetest 10aDocument4 paginiEF3e Intplus Filetest 10aLin Shufen100% (1)

- Slipform Construction TechniqueDocument6 paginiSlipform Construction TechniqueDivyansh NandwaniÎncă nu există evaluări

- Video Tutorial: Machine Learning 17CS73Document27 paginiVideo Tutorial: Machine Learning 17CS73Mohammed Danish100% (2)

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocument11 paginiEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavÎncă nu există evaluări

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocument1 paginăSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiÎncă nu există evaluări

- Demonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BeDocument4 paginiDemonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BePavan Sankar KÎncă nu există evaluări

- 13 SK Kader Pendamping PGSDocument61 pagini13 SK Kader Pendamping PGSrachman ramadhanaÎncă nu există evaluări

- Dimmable Bulbs SamplesDocument11 paginiDimmable Bulbs SamplesBOSS BalaÎncă nu există evaluări

- Teaching Mathematics Content Through Explicit TeachingDocument39 paginiTeaching Mathematics Content Through Explicit Teachingronna drio100% (1)

- Tourism PlanningDocument36 paginiTourism PlanningAvegael Tonido Rotugal100% (1)

- He Sas 23Document10 paginiHe Sas 23Hoorise NShineÎncă nu există evaluări