Documente Academic

Documente Profesional

Documente Cultură

Bucket Teeth For Excavator Buckets PDF

Încărcat de

Miguel Angel Ojeda OreTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bucket Teeth For Excavator Buckets PDF

Încărcat de

Miguel Angel Ojeda OreDrepturi de autor:

Formate disponibile

®

Cat

Bucket Teeth

Options & Replacement parts

for Excavator Buckets

Penetration & Protection

Choosing the right Ground Engaging Tool (GET) for your bucket In addition to choosing teeth with your initial bucket purchase,

is important to getting the highest return on your machine they can be changed or replaced during the life of your bucket.

investment. Bucket Teeth options protect the expensive parts Contact your Cat dealer to understand the many options and for

of your buckets and the resulting longer life reduces your technical assistance in selecting the bucket teeth you need for

maintenance costs. Bucket Teeth also play a big part in how well each specific job.

your machine performs in a specific application.

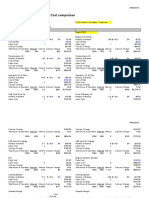

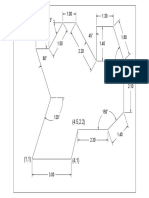

TEETH OPTIONS FOR 311-314; 390 CAT® EXCAVATORS

Long Heavy Duty Long

Use in most general applications. Use on larger machines in general

loading and excavation work. Has

longer wear life and greater strength.

Wide Short

Provides a clean floor. Increases Use in high-impact and pry-out work

capacity with less spillage. such as rock. Extremely strong.

Heavy Duty Abrasion Penetration

Use on larger machines when Use in densely-compacted material

working sand, gravel and shot rock. such as clay. Gives enhanced

penetration. Self-sharpening.

Penetration Plus Twin Sharp

Use in difficult to penetrate material Use for enhanced fracture capability.

with moderate-to-high impact Less penetration than sharp tip. More

conditions such as sedimentary rock, wear material than sharp tip.

cemented gravel or poorly shot rock.

Ground Engaging Tools (GET) for Excavator Buckets: Teeth

TEETH OPTIONS FOR 315–390 CAT® EXCAVATORS

Penetration Plus Penetration

Recommended for most excavator Recommended for harder-to-penetrate,

applications including high impact moderate impact, lower abrasive

trenching, excavation and loading. materials. Very good penetration, less

Good penetration. Stays sharp. wear material, stays sharp.

General Duty Heavy Abrasion

Recommended for general excavation Use on larger machines when

and loading in moderate impact working in sand, gravel and shot rock.

and abrasive conditions. Moderate Maximum wear material.

penetration, self-sharpening cavities.

Extra Duty Spike

Recommended for general excavation Recommended for maximum

and loading requiring more wear penetration, especially in cohesive

material in moderate impact materials. Excellent penetration, less

conditions. Moderate penetration. wear material, stays sharp. (Use

Double Spike in corners.)

Wide Double Spike

Recommended for easy-to-penetrate Recommended for harder-to-penetrate,

trenching applications where smooth fracturable materials. Very good

floors are required. penetration, stays sharp. Use in corner

positions with Spike centers.

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at GEHQ0067 (07-14)

www.cat.com

©2014 Caterpillar

All Rights Reserved

Materials and specifications are subject to change without notice. Featured machines in photos may include additional

equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, their

BUILTrespective

FOR IT, their

logos,

respective

“Caterpillar

logos,Yellow,”

“Caterpillar

and the

Yellow,”

POWERandEDGE

the POWER

trade dress,

EDGEastrade

welldress,

as as well as

corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

S-ar putea să vă placă și

- Analyzing The Caterpillar Production SystemDocument6 paginiAnalyzing The Caterpillar Production Systemmanasmhatre007100% (2)

- Caterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFDocument22 paginiCaterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFfkdmma0% (2)

- Mine DesDocument21 paginiMine DesGaluizu001Încă nu există evaluări

- 993K Specalog Aehq5922 PDFDocument32 pagini993K Specalog Aehq5922 PDFpercyÎncă nu există evaluări

- 5.1 Curva Vent. Aux.2 Howden - Alphair 66 PG 200 HPDocument1 pagină5.1 Curva Vent. Aux.2 Howden - Alphair 66 PG 200 HPNicolás Alberto RojasÎncă nu există evaluări

- MSODocument2 paginiMSOJoseph AnésÎncă nu există evaluări

- Technical Specification Boltec 235 9851 2129 01 tcm795-1532543 PDFDocument4 paginiTechnical Specification Boltec 235 9851 2129 01 tcm795-1532543 PDFyansenÎncă nu există evaluări

- EarthZyme Paving A New Way For Haul Road ConstructionDocument18 paginiEarthZyme Paving A New Way For Haul Road ConstructionEDÎncă nu există evaluări

- CAT Cross ReferenceDocument350 paginiCAT Cross ReferenceOzenildo Ferreira PondeÎncă nu există evaluări

- 2016 TMI TrainingDocument23 pagini2016 TMI TrainingJuan Carlos Gomez Valderrama0% (1)

- Parts Program: ExcellenceDocument61 paginiParts Program: ExcellenceIbrahim AwadÎncă nu există evaluări

- Scooptram St2D: Atlas Copco Underground LoadersDocument4 paginiScooptram St2D: Atlas Copco Underground LoadersMiguel Flores100% (1)

- Mine2-4d Tutorial2Document171 paginiMine2-4d Tutorial2edhy_03100% (1)

- D25KS D245S Blasthole Drill PDFDocument4 paginiD25KS D245S Blasthole Drill PDFlorenzo henerÎncă nu există evaluări

- Pc850-8e0 Cen00384-03 201506Document16 paginiPc850-8e0 Cen00384-03 201506Augusto OliveiraÎncă nu există evaluări

- 2012 Internal Business ReviewDocument29 pagini2012 Internal Business ReviewBiniyam12Încă nu există evaluări

- Jenis Alat BorDocument7 paginiJenis Alat BorIrmank Al-Basir100% (1)

- XH200 Spec Sheet USLETTER PrintDocument2 paginiXH200 Spec Sheet USLETTER PrintTiago HenriquesÎncă nu există evaluări

- Technical Report (Ni43-101) Preliminary Economic Assessment of The Woodlawn ProjectDocument292 paginiTechnical Report (Ni43-101) Preliminary Economic Assessment of The Woodlawn ProjectYojan Ccoa CcopaÎncă nu există evaluări

- Production of QuarriesDocument114 paginiProduction of QuarriesSarinÎncă nu există evaluări

- Optimized Open Pit Mine Planning and SchedulingDocument6 paginiOptimized Open Pit Mine Planning and SchedulingIoannis KapageridisÎncă nu există evaluări

- Plan Semanal 07 Al 13 de Junio 21 PerforaciónTronadura Rev2Document12 paginiPlan Semanal 07 Al 13 de Junio 21 PerforaciónTronadura Rev2Elías Bravo Cortés100% (1)

- Optimalisasi AlatDocument12 paginiOptimalisasi AlatPAMBUDIÎncă nu există evaluări

- Pre Conditioning Cadia East A Catalan G DunstanDocument15 paginiPre Conditioning Cadia East A Catalan G DunstanMatías Ignacio Fuentes Bustamante100% (1)

- JKSimBlast Installation in Windows 7Document2 paginiJKSimBlast Installation in Windows 7Julio SantosÎncă nu există evaluări

- Analisis Ekonomi Teknik PT. Koko Prima CoalDocument87 paginiAnalisis Ekonomi Teknik PT. Koko Prima Coalpelatihanminescape 1Încă nu există evaluări

- Konsep Washing Plant 250 TPHDocument16 paginiKonsep Washing Plant 250 TPHaswar_mhÎncă nu există evaluări

- Rocvent Catalogue PDFDocument48 paginiRocvent Catalogue PDFrudarÎncă nu există evaluări

- Presentasi DND KSBDocument50 paginiPresentasi DND KSBPengadilan Negeri BanjarmasinÎncă nu există evaluări

- Ds311 Specification Sheet EnglishDocument4 paginiDs311 Specification Sheet EnglishYonatan Tarazona HilarioÎncă nu există evaluări

- MC 100 Cargador de ExplosivosDocument8 paginiMC 100 Cargador de ExplosivosWiwa Hernandez Donoso100% (1)

- Aura Almas Gold Project Updated Feasibility Study Technical Report NI43 101Document459 paginiAura Almas Gold Project Updated Feasibility Study Technical Report NI43 101Bruno Henrique MacielÎncă nu există evaluări

- AC2 Specification SheetDocument4 paginiAC2 Specification SheetWiwa Hernandez DonosoÎncă nu există evaluări

- Design of The Second Block Cave at Northparkes E26 MineDocument12 paginiDesign of The Second Block Cave at Northparkes E26 MineYojan Ccoa CcopaÎncă nu există evaluări

- Comparison of Mine Ventilation Simulation SoftwareDocument5 paginiComparison of Mine Ventilation Simulation Softwarealexander ayalaÎncă nu există evaluări

- Performance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)Document24 paginiPerformance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)EVCY100% (1)

- The Optimization of Mining Method and EquipmentDocument6 paginiThe Optimization of Mining Method and EquipmentkullieÎncă nu există evaluări

- Big Vessel: Solution For Your ProductivityDocument4 paginiBig Vessel: Solution For Your ProductivityKreunik ArtÎncă nu există evaluări

- FD 280 DT 6x4Document2 paginiFD 280 DT 6x4ranowijayaÎncă nu există evaluări

- WIDIA 2017 Master Catalog MetricDocument1.815 paginiWIDIA 2017 Master Catalog Metricswami061009Încă nu există evaluări

- Th430 Specification Sheet EnglishDocument8 paginiTh430 Specification Sheet EnglishAmanda TaylorÎncă nu există evaluări

- 71R o RD3A-250 Raise Borer - Technical Specification SheetDocument4 pagini71R o RD3A-250 Raise Borer - Technical Specification SheetRoiÎncă nu există evaluări

- Working GeometryDocument1 paginăWorking Geometrydidi setiawanÎncă nu există evaluări

- Cortez SimulationDocument5 paginiCortez SimulationCarlos SantosÎncă nu există evaluări

- Schedule Roster Timbangan 2018 (NEW)Document19 paginiSchedule Roster Timbangan 2018 (NEW)yudiansyahÎncă nu există evaluări

- Model Mfc-160: General Information ConstructionDocument3 paginiModel Mfc-160: General Information Constructionyosuatogi panjaitan100% (1)

- Jumbo Ficha TecnicaDocument4 paginiJumbo Ficha TecnicaRodrigo FooÎncă nu există evaluări

- Loose Bulk Density and Swell Factor MeasurementDocument3 paginiLoose Bulk Density and Swell Factor MeasurementBrad OlsenÎncă nu există evaluări

- REV 1 Screen MediaDocument10 paginiREV 1 Screen MediaDyego GarciaÎncă nu există evaluări

- Orepro 3D: Blast Movement Modelling and Grade Control OptimiserDocument2 paginiOrepro 3D: Blast Movement Modelling and Grade Control OptimiserTchouleko judicael100% (1)

- DD310-26 6232sfDocument4 paginiDD310-26 6232sfRoger TrujilloÎncă nu există evaluări

- Analyst Visit Sadiola Hill and Yatela Gold Mines: 17 February 2004Document61 paginiAnalyst Visit Sadiola Hill and Yatela Gold Mines: 17 February 2004IvanÎncă nu există evaluări

- Fast Fill Fuel KitsDocument8 paginiFast Fill Fuel Kitsjgmanaure3105Încă nu există evaluări

- Costo de Mantenimiento Retroexcavadora CAT Vs John DeereDocument9 paginiCosto de Mantenimiento Retroexcavadora CAT Vs John DeereLuis Llanos Llanos Sanchez100% (1)

- MinePlan Release NotesDocument14 paginiMinePlan Release NotesJuanJo RoblesÎncă nu există evaluări

- Boomer XL3 D Face Drilling RigDocument5 paginiBoomer XL3 D Face Drilling RigElber Luis Chavez Barrios100% (1)

- 6-3 Drilling and Blasting Stopes Tm3Document7 pagini6-3 Drilling and Blasting Stopes Tm3johnson OlubiÎncă nu există evaluări

- DM901HDE: Diesel Driven & Electric DrillerDocument6 paginiDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenÎncă nu există evaluări

- Three-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata Solution PDFDocument16 paginiThree-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata Solution PDFDiego Ignacio VelizÎncă nu există evaluări

- Atlas Copco Rock Drilling Tools: SECOROC Product CatalogueDocument108 paginiAtlas Copco Rock Drilling Tools: SECOROC Product Catalogueleon li100% (1)

- 9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855Document20 pagini9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855marioxxyÎncă nu există evaluări

- Atlas Copco 072010Document2 paginiAtlas Copco 072010Frederic Salazar100% (1)

- BP Anbauwerkzeuge enGB PDFDocument40 paginiBP Anbauwerkzeuge enGB PDFRomanÎncă nu există evaluări

- "Think Different,,: Heavy Duty Equipment Ground Engaging Tools (G.E.T) Undercarriage Component & AccesoriesDocument11 pagini"Think Different,,: Heavy Duty Equipment Ground Engaging Tools (G.E.T) Undercarriage Component & Accesoriesoriental.bento2Încă nu există evaluări

- Excavators - PSK:GETDocument15 paginiExcavators - PSK:GETgulam husseinÎncă nu există evaluări

- PC1Document1 paginăPC1Miguel Angel Ojeda OreÎncă nu există evaluări

- Corani Ag-Au Project, Peru - Grade/Thickness Contour G (Equivalent Silver) X TDocument1 paginăCorani Ag-Au Project, Peru - Grade/Thickness Contour G (Equivalent Silver) X TMiguel Angel Ojeda OreÎncă nu există evaluări

- Bucket Teeth For Excavator BucketsDocument2 paginiBucket Teeth For Excavator BucketsMiguel Angel Ojeda OreÎncă nu există evaluări

- MINING LAW Latin America McCarthy Tetrault 2017Document60 paginiMINING LAW Latin America McCarthy Tetrault 2017Miguel Angel Ojeda OreÎncă nu există evaluări

- Tutorial 07 Finite Element Groundwater SeepageDocument19 paginiTutorial 07 Finite Element Groundwater SeepageMiguel Angel Ojeda OreÎncă nu există evaluări

- Tutorial 01 Quick Start PDFDocument19 paginiTutorial 01 Quick Start PDFCesar Koala Soria CanazaÎncă nu există evaluări

- Precipitation Module (TC-PRISMA) User GuideDocument55 paginiPrecipitation Module (TC-PRISMA) User GuideMiguel Angel Ojeda OreÎncă nu există evaluări

- MGHQ Exploratory Data Analysis 1st EdDocument41 paginiMGHQ Exploratory Data Analysis 1st EdMiguel Angel Ojeda OreÎncă nu există evaluări

- Thermodynamics Database For Use With The: Thermo Add-InDocument10 paginiThermodynamics Database For Use With The: Thermo Add-InMiguel Angel Ojeda OreÎncă nu există evaluări

- CoraniDocument13 paginiCoraniMiguel Angel Ojeda OreÎncă nu există evaluări

- Bieniawski - Engineering Rock Mass ClasificationDocument249 paginiBieniawski - Engineering Rock Mass ClasificationMiguel Angel Ojeda Ore100% (1)

- Palmstrom - RMiDocument215 paginiPalmstrom - RMiMiguel Angel Ojeda Ore100% (1)

- 11 Congreso ISRM Lisboa2007Document4 pagini11 Congreso ISRM Lisboa2007Miguel Cruzado ChávezÎncă nu există evaluări

- Atlas of Rock-Forming Minerals PDFDocument100 paginiAtlas of Rock-Forming Minerals PDFwafaÎncă nu există evaluări

- 834K Wheel Dozer LWY00001-UP (MACHINE) POWERED BY C18 Engine (SEBP5757 - 38) - Búsqueda Básica PDFDocument18 pagini834K Wheel Dozer LWY00001-UP (MACHINE) POWERED BY C18 Engine (SEBP5757 - 38) - Búsqueda Básica PDFmauricioÎncă nu există evaluări

- Shipping World & Shipbuilder, 2011 VALEMAX - Nickel Ore Cargo DangersDocument43 paginiShipping World & Shipbuilder, 2011 VALEMAX - Nickel Ore Cargo Dangersgnd100100% (1)

- Neumáticos Michelin 44-80r57Document4 paginiNeumáticos Michelin 44-80r57carlucido247970Încă nu există evaluări

- Caterpillar d5b Crawler Parts Manual SN 26x878 and UpDocument8 paginiCaterpillar d5b Crawler Parts Manual SN 26x878 and UpCarmen GarciaÎncă nu există evaluări

- TRAINING - BOOK - Customer TrakindoDocument16 paginiTRAINING - BOOK - Customer TrakindoSoffan TangerangÎncă nu există evaluări

- Esperience MocambiqueDocument2 paginiEsperience MocambiquesergiosarbÎncă nu există evaluări

- Calibration Engine C11Document9 paginiCalibration Engine C11Ibrahim AwadÎncă nu există evaluări

- Dump Truck 13 PDFDocument23 paginiDump Truck 13 PDFHaby Reski Quesi Yuda PratamaÎncă nu există evaluări

- Haul Truck Fuel Consumption - PublishedDocument6 paginiHaul Truck Fuel Consumption - PublishedAhmed IdiÎncă nu există evaluări

- Roc F7Cr & Roc F9Cr: Atlas Copco Surface Drill RigsDocument8 paginiRoc F7Cr & Roc F9Cr: Atlas Copco Surface Drill RigsVenerable DezzyÎncă nu există evaluări

- Cargador 990 II - Información Del Producto PDFDocument18 paginiCargador 990 II - Información Del Producto PDFLuis MÎncă nu există evaluări

- TTT - D9R - TEKQ0413 3408E Engine Update - SalesgramDocument2 paginiTTT - D9R - TEKQ0413 3408E Engine Update - SalesgramAngham SolimanÎncă nu există evaluări

- Warranty Statement For Industrial Engine and EPGDocument2 paginiWarranty Statement For Industrial Engine and EPGptd.sitedmp2023Încă nu există evaluări

- CTP EngineDocument5 paginiCTP Enginealfred100% (1)

- CAT 950 Oil SpecDocument8 paginiCAT 950 Oil SpecbarazamelÎncă nu există evaluări

- Filtros Aire CatDocument2 paginiFiltros Aire CatJuan Carlos López SalazarÎncă nu există evaluări

- International Mining January 2018Document80 paginiInternational Mining January 2018GordÎncă nu există evaluări

- Caterpillar Service Training 735 740 Articulated TrucksDocument7 paginiCaterpillar Service Training 735 740 Articulated TrucksKathryn96% (54)

- Caterpillar D6D Crawler Tractor Specs & Dimensions - RitchieSpecs PDFDocument4 paginiCaterpillar D6D Crawler Tractor Specs & Dimensions - RitchieSpecs PDFBox TVÎncă nu există evaluări

- Contact About Me: Equipment ManagementDocument2 paginiContact About Me: Equipment ManagementGRACIENÎncă nu există evaluări

- D R-Ii: Medium BulldozerDocument12 paginiD R-Ii: Medium BulldozerOctavio Lopez Cerpa100% (1)

- 3408-12 ToolsDocument27 pagini3408-12 ToolsAlbertoÎncă nu există evaluări

- Ficha Técnica 336GC CATDocument12 paginiFicha Técnica 336GC CATWilmer RoyÎncă nu există evaluări

- Unidades HeuiDocument50 paginiUnidades HeuiagnaldoÎncă nu există evaluări