Documente Academic

Documente Profesional

Documente Cultură

Temp Airflow

Încărcat de

anon_551879060Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Temp Airflow

Încărcat de

anon_551879060Drepturi de autor:

Formate disponibile

Temperature Split

Airflow Check Procedure

Adapted from Carrier, Adapted from CheckMe!™

Contrary to “common Procedures, Adapted from California Title 24.

knowledge” the temperature Criteria

split should not universally be If the temperature split is more than 3ºF above the target,

between 18ºF and 20ºF. See the low airflow is low.

the table below for the target If the temperature split is more than 3ºF below the target,

the air conditioner probably has low capacity due to some

temperature split for fault other than airflow.

differing indoor conditions. If the temperature split falls within 3ºF of the target, the air

The temperature split test is flow is probably OK. Another possibility is that the airflow is

low and so is the capacity.

a fast and easy indication of

The proper amount of refrigerant depends on the airflow.

airflow and capacity. It is a Whenever airflow is changed, the refrigerant charge test

useful screening tool, but not needs to be repeated to ensure proper refrigerant charge.

Since the temperature split test is dependent on capacity,

an adequate replacement for changes in refrigerant charge mandate a new temperature

direct airflow measurement. split test.

Instrumentation Specifications

Digital Thermometer. Digital thermometer

must have thermocouple compatibility and

Calibration Fahrenheit readout with:

Thermometers with their /temperature sensors shall

• Accuracy: ± (0.1% of reading + 1.3º F)

be calibrated monthly to ensure that they are reading

accurate temperatures. • Resolution: 0.2º F to 1.0º F

The following procedure shall be used to check

Thermocouples. Measurements require three

thermometer/temperature sensor calibration:

(3) beaded low-mass wire thermocouples and

1. Fill an insulated cup (foam) with crushed ice. The one (1) cotton wick for measuring web-bulb

ice shall completely fill the cup. Add water to fill the temperatures.

cup. Title 24 specifies distilled water; Proctor’s

laboratory tests show no measurable difference

between distilled water and tap water. Even saturated

salt water showed less than a 0.2ºF difference.

2. Insert two sensors into the center of the ice bath

and attach them to the digital thermometer.

3. Let the temperatures stabilize. The temperatures

shall be 32°F (plus or minus 1°F). If the temperature

is off by more than 1°F make corrections according to

the manufacturer’s instructions. Any sensors that are

off by more than 2°F shall be replaced.

4. Switch the sensors and ensure that the

temperatures read on both channels are still within

plus or minus 1°F of 32°F.

5. Repeat the process for all sensors.

Calculations Measurement

The following steps describe the The following procedure shall be used to obtain

calculations. measurements

1. Calculate the Actual 1. Turn system on and let it run for 15 minutes to

Temperature Split as the return air stabilize temperatures and pressures before taking

dry-bulb temperature minus the

supply air dry-bulb temperature.

any measurements. While system is stabilizing,

Actual Temperature Split = Treturn, proceed with setting up the temperature

db - Tsupply, db measurements.

2. Determine the Target 2. Place wet-bulb thermocouple in water to ensure it

Temperature Split from the table is saturated when needed. Do not get the dry-bulb

below using the return air wet-bulb thermocouples wet.

temperature (Treturn, wb) and

return air dry-bulb temperature 3. Insert the dry-bulb thermocouple in the supply

(Treturn, db). plenum at the center of the airflow.

3. Calculate the difference between 4. At 12 minutes, insert a dry-bulb thermocouple and

target and actual temperature split

a wet-bulb thermocouple into the return plenum at

(Actual Temperature Split-Target

Temperature Split and compare it to the center of the airflow.

the criteria listed at the top of this 5. At 15 minutes when the return plenum

sheet. (± 3°F probably OK, outside temperatures have stabilized measure and record the

that range not OK)

return (evaporator entering) air dry-bulb temperature

(Treturn, db) and the return (evaporator entering) air

wet-bulb temperature (Treturn, wb).

6. Measure and record the supply (evaporator leaving)

air dry-bulb temperature (Tsupply, db).

Return Air Wet-Bulb (ºF) (T return, wb)

50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76

70 20.9 20.7 20.6 20.4 20.1 19.9 19.5 19.1 18.7 18.2 17.7 17.2 16.5 15.9 15.2 14.4 13.7 12.8

71 21.4 21.3 21.1 20.9 20.7 20.4 20.1 19.7 19.3 18.8 18.3 17.7 17.1 16.4 15.7 15.0 14.2 13.4 12.5

72 21.9 21.8 21.7 21.5 21.2 20.9 20.6 20.2 19.8 19.3 18.8 18.2 17.6 17.0 16.3 15.5 14.7 13.9 13.0 12.1

73 22.5 22.4 22.2 22.0 21.8 21.5 21.2 20.8 20.3 19.9 19.4 18.8 18.2 17.5 16.8 16.1 15.3 14.4 13.6 12.6 11.7

Return Air Dry–Bulb (ºF) (T return, db)

74 23.0 22.9 22.8 22.6 22.3 22.0 21.7 21.3 20.9 20.4 19.9 19.3 18.7 18.1 17.4 16.6 15.8 15.0 14.1 13.2 12.2 11.2

75 23.6 23.5 23.3 23.1 22.9 22.6 22.2 21.9 21.4 21.0 20.4 19.9 19.3 18.6 17.9 17.2 16.4 15.5 14.7 13.7 12.7 11.7 10.7

76 24.1 24.0 23.9 23.7 23.4 23.1 22.8 22.4 22.0 21.5 21.0 20.4 19.8 19.2 18.5 17.7 16.9 16.1 15.2 14.3 13.3 12.3 11.2 10.1

77 - 24.6 24.4 24.2 24.0 23.7 23.3 22.9 22.5 22.0 21.5 21.0 20.4 19.7 19.0 18.3 17.5 16.6 15.7 14.8 13.8 12.8 11.7 10.6 9.5

78 - - - 24.7 24.5 24.2 23.9 23.5 23.1 22.6 22.1 21.5 20.9 20.2 19.5 18.8 18.0 17.2 16.3 15.4 14.4 13.4 12.3 11.2 10.0 8.8

79 - - - - - 24.8 24.4 24.0 23.6 23.1 22.6 22.1 21.4 20.8 20.1 19.3 18.5 17.7 16.8 15.9 14.9 13.9 12.8 11.7 10.6 9.4 8.1

80 - - - - - - 25.0 24.6 24.2 23.7 23.2 22.6 22.0 21.3 20.6 19.9 19.1 18.3 17.4 16.4 15.5 14.4 13.4 12.3 11.1 9.9 8.7

81 - - - - - - - 25.1 24.7 24.2 23.7 23.1 22.5 21.9 21.2 20.4 19.6 18.8 17.9 17.0 16.0 15.0 13.9 12.8 11.7 10.4 9.2

82 - - - - - - - - 25.2 24.8 24.2 23.7 23.1 22.4 21.7 21.0 20.2 19.3 18.5 17.5 16.6 15.5 14.5 13.4 12.2 11.0 9.7

83 - - - - - - - - - 25.3 24.8 24.2 23.6 23.0 22.3 21.5 20.7 19.9 19.0 18.1 17.1 16.1 15.0 13.9 12.7 11.5 10.3

84 - - - - - - - - - 25.9 25.3 24.8 24.2 23.5 22.8 22.1 21.3 20.4 19.5 18.6 17.6 16.6 15.6 14.4 13.3 12.1 10.8

S-ar putea să vă placă și

- Vapor Compression Refrigeration Test Rig Computerised Lab ManualDocument12 paginiVapor Compression Refrigeration Test Rig Computerised Lab ManualAshish Verma50% (2)

- Design Guide Fire ProtectionDocument36 paginiDesign Guide Fire ProtectionElan Bakar84% (19)

- HVAC BasicsDocument25 paginiHVAC BasicsMohazfa100% (2)

- Duct Velocity AshraeDocument1 paginăDuct Velocity Ashraekdpmansi100% (5)

- Basic Engineering ThermodynamicsDocument95 paginiBasic Engineering Thermodynamicspapaye371275% (4)

- Vapor Compression Refrigeration Test Rig Lab Manual LatestDocument12 paginiVapor Compression Refrigeration Test Rig Lab Manual LatestAshish VermaÎncă nu există evaluări

- Cold and Hot Water Demand Calculation AlfouzanDocument22 paginiCold and Hot Water Demand Calculation Alfouzananon_551879060100% (1)

- Lab Sheet Air CondDocument8 paginiLab Sheet Air CondAhmad AbaÎncă nu există evaluări

- ACMVDocument155 paginiACMVKHA120096 StudentÎncă nu există evaluări

- Hvac Formulas PDFDocument25 paginiHvac Formulas PDFSaraswatapalit0% (1)

- Thermodynamics Lab ManualDocument9 paginiThermodynamics Lab ManualEr Shankar Singh Dhami100% (2)

- Experiment 8 Cooling and De-Humidification of Air: 1. ObjectiveDocument6 paginiExperiment 8 Cooling and De-Humidification of Air: 1. ObjectiveShakyamuni Gautam Kumar100% (1)

- Marcet Boiler Lab ReportDocument15 paginiMarcet Boiler Lab ReportAnna Kay100% (7)

- Lecture - 4 - BSE2201 - Air Conditioning Processes & CyclesDocument74 paginiLecture - 4 - BSE2201 - Air Conditioning Processes & CyclesBrian LiÎncă nu există evaluări

- Cooling Tower Performance and Sensors For Thermal-Fluid SystemsDocument11 paginiCooling Tower Performance and Sensors For Thermal-Fluid Systemshozipek5599Încă nu există evaluări

- Fire Engineering Calculations Examples FsecalculationsDocument27 paginiFire Engineering Calculations Examples Fsecalculationscypal54100% (3)

- Che Thermodynamics: Dimensions and UnitsDocument31 paginiChe Thermodynamics: Dimensions and UnitsRugi Vicente RubiÎncă nu există evaluări

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 paginiBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilÎncă nu există evaluări

- BME-Module 2Document23 paginiBME-Module 2Ajith KumarÎncă nu există evaluări

- Mechanical Heat PumpDocument8 paginiMechanical Heat PumpClara SariÎncă nu există evaluări

- Vapour Compression Refrigeration PDFDocument5 paginiVapour Compression Refrigeration PDFjose100% (1)

- Refrigeration Lab Report: Ali Rida Bachir SID 8104461Document4 paginiRefrigeration Lab Report: Ali Rida Bachir SID 8104461NARE EDMUNDÎncă nu există evaluări

- AC Exp2Document8 paginiAC Exp2sososivar55Încă nu există evaluări

- Experiment 1 Testing of A Vapor Compression Refrigeration System 1Document12 paginiExperiment 1 Testing of A Vapor Compression Refrigeration System 1Ashley Justine RowanÎncă nu există evaluări

- Power Knot Measuring Enthalpy To Calculate EfficiencyDocument7 paginiPower Knot Measuring Enthalpy To Calculate EfficiencySarath PurushothamanÎncă nu există evaluări

- Knowledge Troubleshooting AC SystemDocument13 paginiKnowledge Troubleshooting AC SystemRupak KumarÎncă nu există evaluări

- Lab 5 - Film Boiling Condensation - ProcedureDocument3 paginiLab 5 - Film Boiling Condensation - ProcedureMohd HaafizÎncă nu există evaluări

- (CARNOT CYCLE) Lab Report On Cooling and Heating Effects in An Air Conditioning SystemDocument12 pagini(CARNOT CYCLE) Lab Report On Cooling and Heating Effects in An Air Conditioning SystemUmer Qureshi0% (1)

- Experiment 1: TheoryDocument2 paginiExperiment 1: TheoryMUSKAN PRNÎncă nu există evaluări

- 2.1 Dry Bulb (DB) TemperatureDocument6 pagini2.1 Dry Bulb (DB) TemperaturePrashanth SaiÎncă nu există evaluări

- CTI ATC-105-2000 Preview - Acceptance Test Code For Water Cooling Towers - 9Document1 paginăCTI ATC-105-2000 Preview - Acceptance Test Code For Water Cooling Towers - 9YapKJÎncă nu există evaluări

- Im 120Document8 paginiIm 120DASAIS ServiProyeÎncă nu există evaluări

- Thermo CalibrationDocument10 paginiThermo CalibrationAngelo De AsisÎncă nu există evaluări

- RH P P P T Note:t: Air Conditioning and Ventilation SystemsDocument5 paginiRH P P P T Note:t: Air Conditioning and Ventilation SystemsDharen OlaÎncă nu există evaluări

- 2Document1 pagină2Eric PaderÎncă nu există evaluări

- Boiling Heat Transfer ModuleDocument10 paginiBoiling Heat Transfer ModuleD7ooM_612Încă nu există evaluări

- Experiment #1 - Testing of A Vapor-Compression Refrigeration SystemDocument8 paginiExperiment #1 - Testing of A Vapor-Compression Refrigeration SystemIvanÎncă nu există evaluări

- RefrigeratorDocument6 paginiRefrigeratorChooi San LaiÎncă nu există evaluări

- Mid Term Exam - Alya 安佩妮 (4B016024)Document4 paginiMid Term Exam - Alya 安佩妮 (4B016024)Alya penta agharidÎncă nu există evaluări

- 5 200 PDFDocument12 pagini5 200 PDFDee RajaÎncă nu există evaluări

- Dew PointDocument4 paginiDew Pointسالي سامي ابو النُّونÎncă nu există evaluări

- Lab 5 Refrigeration-1Document9 paginiLab 5 Refrigeration-1Ahmed MaqsoodÎncă nu există evaluări

- Unit VDocument12 paginiUnit VYuvaperiyasamy MayilsamyÎncă nu există evaluări

- Air Conditioning Lab Final1Document20 paginiAir Conditioning Lab Final1haziqÎncă nu există evaluări

- Refrigration and Air Conditioning MDTDocument10 paginiRefrigration and Air Conditioning MDTSudhir KoliÎncă nu există evaluări

- Air-Conditioning Process 1Document21 paginiAir-Conditioning Process 1Hazali Othman100% (1)

- R & AC Lab ManualDocument30 paginiR & AC Lab ManualShashankÎncă nu există evaluări

- Refrigeration and Air Conditioning (2161908) : A Laboratory Manual ForDocument62 paginiRefrigeration and Air Conditioning (2161908) : A Laboratory Manual ForAbhishek RaiÎncă nu există evaluări

- Thermo ManualDocument24 paginiThermo ManualRajakhalidÎncă nu există evaluări

- Film Boiling Condensation ManualDocument3 paginiFilm Boiling Condensation ManualSyafIq AimanÎncă nu există evaluări

- Temperature FundamentalsDocument39 paginiTemperature Fundamentalsartup3l0nÎncă nu există evaluări

- TR 017 PDFDocument2 paginiTR 017 PDFAzar DeenÎncă nu există evaluări

- Relative Humidity PDFDocument3 paginiRelative Humidity PDFMariel CondesaÎncă nu există evaluări

- Chemical Engg Thermodynamics Lab ManualDocument32 paginiChemical Engg Thermodynamics Lab ManualGee DevilleÎncă nu există evaluări

- FME Notes Unit3Document7 paginiFME Notes Unit3vishal shuklaÎncă nu există evaluări

- Experiment #3 - Demonstration and Analysis of Psychrometric ProcessesDocument11 paginiExperiment #3 - Demonstration and Analysis of Psychrometric ProcessesIvanÎncă nu există evaluări

- Experiment No. 04Document3 paginiExperiment No. 04madhavkhandelwal848Încă nu există evaluări

- Cooling Tower Performance: Thermal ScienceDocument2 paginiCooling Tower Performance: Thermal ScienceXmean NegativeÎncă nu există evaluări

- TR 017Document2 paginiTR 017Mohaned Hossam100% (1)

- ME 115 Experiment 1 Analysis of A Hilton Air Conditioning Laboratory UnitDocument5 paginiME 115 Experiment 1 Analysis of A Hilton Air Conditioning Laboratory UnitCoby IlasÎncă nu există evaluări

- Lecture 8Document17 paginiLecture 8Umar ShahidÎncă nu există evaluări

- 1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFDocument116 pagini1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFPankaj KumarÎncă nu există evaluări

- Refrigeration and Air Conditioning: Lecture # 3Document38 paginiRefrigeration and Air Conditioning: Lecture # 3Owais AzharÎncă nu există evaluări

- SBS5225 1718 Lab AC ProcessesDocument8 paginiSBS5225 1718 Lab AC ProcessesSam C M HuiÎncă nu există evaluări

- Weather Studies: The Commonwealth and International Library: Rural and Environmental Studies DivisionDe la EverandWeather Studies: The Commonwealth and International Library: Rural and Environmental Studies DivisionÎncă nu există evaluări

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDe la EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesÎncă nu există evaluări

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemDe la EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemÎncă nu există evaluări

- Engineering ThermodynamicsDocument116 paginiEngineering Thermodynamicsanon_551879060Încă nu există evaluări

- Cleaning and Flushing of HvacDocument5 paginiCleaning and Flushing of HvacMudassir PashaÎncă nu există evaluări

- Q4: How Use of Building Energy Code in Building Envelope Can Save Energy? ........................................... 21 What Are Energy Codes?Document24 paginiQ4: How Use of Building Energy Code in Building Envelope Can Save Energy? ........................................... 21 What Are Energy Codes?anon_551879060Încă nu există evaluări

- Typical Detail FCUDocument1 paginăTypical Detail FCUanon_551879060Încă nu există evaluări

- Typical Detail ChillerDocument1 paginăTypical Detail Chilleranon_551879060Încă nu există evaluări

- SHR ReportDocument42 paginiSHR Reportanon_551879060Încă nu există evaluări

- Typical Detail PumpDocument1 paginăTypical Detail Pumpanon_551879060Încă nu există evaluări

- Hyundai - Parts - Aftermarket - Product List (HASI) PDFDocument6 paginiHyundai - Parts - Aftermarket - Product List (HASI) PDFSprinter Transit VanÎncă nu există evaluări

- Heat Transfer Lab AssignmentDocument5 paginiHeat Transfer Lab AssignmentChristyÎncă nu există evaluări

- Individual Tasks SuciDocument3 paginiIndividual Tasks SuciSuciana SafadinaÎncă nu există evaluări

- 2.5 (A) Enthalpy: Chapter 2. The First LawDocument71 pagini2.5 (A) Enthalpy: Chapter 2. The First Lawnabila OktavianiÎncă nu există evaluări

- Tugas Rutin II (Worksheet of Heat and Temperature)Document2 paginiTugas Rutin II (Worksheet of Heat and Temperature)Lyly IndahÎncă nu există evaluări

- HVAC DataDocument49 paginiHVAC DataআসিফহাসানখানÎncă nu există evaluări

- Revision Notes On Chemical ThermodynamicsDocument6 paginiRevision Notes On Chemical ThermodynamicsManish SainiÎncă nu există evaluări

- Air ConditioningDocument3 paginiAir ConditioningBoJassim100% (1)

- Assignment 2Document2 paginiAssignment 2Lovish ChopraÎncă nu există evaluări

- Technological Institute of The Philippines: Determination of COP of A Refrigeration SystemDocument15 paginiTechnological Institute of The Philippines: Determination of COP of A Refrigeration SystemDessa GuditoÎncă nu există evaluări

- Russian Literature, 44 (4), 409-432 (1998) .Document24 paginiRussian Literature, 44 (4), 409-432 (1998) .Юрий СеменовÎncă nu există evaluări

- Specific Heat Capacities of Air TableDocument1 paginăSpecific Heat Capacities of Air TableJo Aaron TalvoÎncă nu există evaluări

- Lab 4 Calorimetry LabDocument6 paginiLab 4 Calorimetry Labapi-458764744Încă nu există evaluări

- Gcse Physics: Heat TransferDocument25 paginiGcse Physics: Heat TransferYasin GüneriÎncă nu există evaluări

- Calibration of Thermometers: de La Salle UniversityDocument14 paginiCalibration of Thermometers: de La Salle UniversityNazario Emil LintagÎncă nu există evaluări

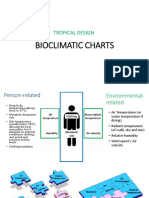

- Bioclimatic ChartsDocument29 paginiBioclimatic ChartsPatricia Franchette AmoraÎncă nu există evaluări

- Thermoregulation PDFDocument1 paginăThermoregulation PDFCarina JLÎncă nu există evaluări

- Thermodynamics ImpDocument7 paginiThermodynamics Impashoku24007Încă nu există evaluări

- Thermodynamics ProblemsDocument1 paginăThermodynamics ProblemsTots HolaresÎncă nu există evaluări

- Heat Concept Map ColorDocument1 paginăHeat Concept Map Colorrebbieg100% (2)

- Me Lab 10Document16 paginiMe Lab 10BensoyÎncă nu există evaluări

- Green, Don W & Perry, Robert H. Perry's Chemical Engineers' Handbook. Eighth Edition. 2008Document3 paginiGreen, Don W & Perry, Robert H. Perry's Chemical Engineers' Handbook. Eighth Edition. 2008Anderson BermudezÎncă nu există evaluări

- Problems On Vapour Compression CycleDocument6 paginiProblems On Vapour Compression CycleTECHNICAL STARÎncă nu există evaluări

- Cooling Strategies, Summer Comfort and Energy Performance of A Rehabilitated Passive Standard Office Building PDFDocument9 paginiCooling Strategies, Summer Comfort and Energy Performance of A Rehabilitated Passive Standard Office Building PDFIkutegbe CharlesÎncă nu există evaluări