Documente Academic

Documente Profesional

Documente Cultură

Cebex Cable Grout

Încărcat de

Mohamed SalamaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cebex Cable Grout

Încărcat de

Mohamed SalamaDrepturi de autor:

Formate disponibile

Cebex Cable Grout* constructive solutions

Pre-bagged, non-shrink cementitious grout admixture for

post tensioned cables

Uses Specification

For pumped or free flow grouting, it can be used in a wide Performance specification

range of applications:

All grouting, where shown on the drawing, must be carried

! Post tensioned bridge deck ducts out with a specialised grout admixture which is iron-free

and chloride-free. It shall be mixed with clean water and

! Prestressed structural element cables ducts

cement to the required consistency. The plastic grout must

! Slip form silo tendon ducts not bleed or segregate.

A positive volumetric expansion of up to 4% shall occur.

Advantages

The compressive strength of the grout must exceed 50 N/mm2

! Expansion system compensates for shrinkage and

at 7 days.

settlement in the plastic state

! Develops high early strength without the use of chlorides The storage, handling and placement of the grout must be in

strict accordance with the manufacturer's instructions.

! High ultimate strength and low permeability ensure the

durability of the hardened grout Supplier specification

! Compatible with ordinary Portland Cements complying All grouting where shown on the drawing must be carried out

to BS 12 and ASTM C150 using Cebex Cable Grout manufactured by Fosroc and used

in accordance with the manufacturer’s current data sheet.

Standards compliance

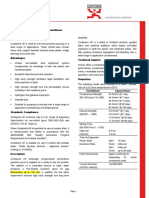

Cebex Cable Grout complies to BS8110 Part1: 1985 Sec. 8. Properties

The following properties were achieved using OPC cement

Description at a 0.36 w/c ratio.

Cebex Cable Grout is supplied as a dry powder requiring Compressive strength : 25 N/mm2 @ 1 day

only the addition of a controlled amount of clean water and BS 1881 part 116 40 N/mm2 @ 3 days

cement to produce a free flowing non-shrink grout. (flowable consistency) 50 N/mm2 @ 7 days

60 N/mm2 @ 28 days

Cebex Cable Grout is an all fines admixture containing Fresh wet density : Approximately 2000 kg/m3

expansive cement which impart controlled expansion in the depending on actual

plastic state whilst minimising water demand. The material consistency used.

is designed to allow uniform mixing, and eliminates Chloride content : Nil to BS5075

unwanted segregation and bleeding. Expansion : A positive expansion of

characteristics up to 4%

Note : It is recommended that trials be conducted prior

to use, to ascertain the best source of OPC for the

application.

Cebex Cable Grout

Cebex Cable Grout*

Instructions for use Cleaning

Preparation Cebex Cable Grout should be removed from tools and

equipment with clean water immediately after use. Cured

Several hours prior to grouting, the area should be flooded

material can be removed mechanically, or with Fosroc Acid

with fresh water. Immediately before grouting takes place any

Etch*†.

free water should be removed.

Sampling procedure

All cable ducts must be thoroughly cleaned. Those ducts

formed without metal sheaths should be flushed with water All sampling procedures for Cebex Cable Grout are to be

after which all surplus water must be removed. Cable conducted within the confines of a temperature controlled

anchorages should be sealed before the duct grouting is laboratory. The reactive agents within Cebex Cable Grout do

carried out. not permit site sampling and transport. The procedure for

sampling is to be as follows:

Mixing and placing - Application

1) A full and unopened bag of Cebex Cable Grout to be

Mixing

selected from the batch allocated for site use and

For best results a mechanically powered grout mixer should despatched to the testing laboratory.

be used. Do not use a colloidal impeller mixer if sands/

2) The Cebex Cable Grout shall be mixed in the laboratory

aggregates are being used.

following the instructions listed on the product data sheet.

To enable the grouting operation to be carried out continuously,

3) All sampling shall be conducted using 50 mm cube

it is essential that sufficient mixing capacity and labour are

moulds, any other size is not permissible.

available. The use of a grout holding tank with provision to

gently agitate the grout may be required. 4) When mixed, the Cebex Cable Grout shall be poured into

50 mm cube moulds, treated with release agent, in two

64 to 84 litres of clean water (depending on nature of cement)

lifts of 25 mm each with a 60 second interval between

and 200 kg of cement are required to be added per 12 kg bag

pours. The Cebex Cable Grout shall not be tamped, but

to achieve the correct consistency.

gentle tapping of the cube mould is permitted to promote

The water should be accurately measured into the mixer. The the release of air.

total contents of the Cebex Cable Grout bag should be slowly

5) Fill three 50 mm cube moulds with the Cebex Cable Grout

added with the cement and continuous mixing should take

for each curing time interval specified. Mould filling should

place for 5 minutes. This will ensure that the grout has a

be completed within 15 minutes of the end of the mixing

smooth even consistency.

cycle. The filled moulds should be stacked three high on

Placing top of each other to provide conditions of restraint. The top

mould should be restrained either with a weighted metal

Place the grout within 20 minutes of mixing.

plate or an empty cube mould.

Cebex Cable Grout can be placed in annular gaps of up to

6) The cubes should be stored at a 20°C+ 2°C temperature

60mm in thickness.

for 24 hours in the laboratory. After 24 hours the cubes are

Pumping should be from a single point to eliminate any air or to be demoulded and placed in a water curing tank

entrapment of water used for presoaking. maintained at a 20°C+ 2°C temperature. The cubes are

then to be cured in accordance with BS1881.

A heavy duty diaphragm pump is recommended for pumping.

Screw feed and piston pumps may also be suitable. 7) Cubes are to be crushed in calibrated compression testing

apparatus with a rate of loading not exceeding 180KN per

Curing

minute. Types of cube fracture are to be recorded. Three

Any exposed areas should be thoroughly cured. This should cubes are to be crushed for each curing time interval

be done by the use of Concure*† curing membrane. specified. Results are to be calculated and issued as an

average.

Cebex Cable Grout - Page 2 of 4

Cebex Cable Grout*

Limitations Estimating

Low temperature working Supply

Cebex Cable Grout : 12 kg bags

For ambient temperatures below 10°C the formwork should

be kept in place for at least 36 hours. Yield

When the air or contact surface temperatures are 5°C or below Cebex Cable Grout : approx. 136 litres when mixed

on a falling thermometer, warm water (30-40°C) is with 200 kg cement and 68

recommended to accelerate strength development. litres of water

Normal precautions for winter working with cementitious Note: Allowance should be made for wastage when

materials should then be adopted. estimating quantities required.

High temperature working Storage

It is suggested that, for temperatures above 35°C, the following Cebex Cable Grout has a shelf life of 12 months if kept in a dry

guidelines are adopted as good working practice: store in sealed bags. If stored in high temperature and high

(i) Store unmixed material in a cool (preferably temperature humidity locations the shelf life will be reduced.

controlled) environment, avoiding exposure to direct

sunlight. Precautions

(ii) Keep equipment cool, arranging shade protection if Health and safety

necessary. It is especially important to keep cool those Cebex Cable Grout is alkaline and should not come into contact

surfaces of the equipment which will come into direct with skin and eyes. Avoid inhalation of dust during mixing.

contact with the material itself. Gloves, goggles and dust mask should be worn. If contact

(iii) Try to eliminate application during the hottest times of the with skin occurs, wash with water. Splashes to eyes should

day. be washed immediately with plenty of clean water and medical

advice sought.

(iv) Make sufficient material, plant and labour available to

ensure that application is a continuous process. Fire

(v) Water (below 20°C) should be used for mixing the grout Cebex Cable Grout is non-flammable.

prior to placement.

Technical support

Fosroc offers a comprehensive technical support service to

specifiers, end users and contractors. It is also able to offer

on-site technical assistance, an AutoCAD facility and dedicated

specification assistance in locations all over the world.

Cebex Cable Grout - Page 3 of 4

Cebex Cable Grout*

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

! waterproofing membranes & waterstops

! joint sealants & filler boards

! cementitious & epoxy grouts

! specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosroc’s ‘Systematic

Approach’ to concrete repair features the following :

! hand-placed repair mortars

! spray grade repair mortars

! fluid micro-concretes

! chemically resistant epoxy mortars

! anti-carbonation/anti-chloride protective coatings

! chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s

responsibility to obtain the recent version. Refer to www.fosroc.com.

Head Office

Al Gurg Fosroc telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

LLC Regional offices

Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Post Box 657, Dubai Bahrain, YBA Kanoo telephone: 17735454 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

www.fosroc.com

Qatar, Tadmur telephone: 4500607 fax: 4500543 email: qatar@fosroc.com

UAE/0357/07/H

S-ar putea să vă placă și

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- 5 NDT Method For ConcreteDocument1 pagină5 NDT Method For ConcreteRamzi BEN AHMEDÎncă nu există evaluări

- Pile Caping Head Treatment PDFDocument2 paginiPile Caping Head Treatment PDFLimbert Rodriguez Pinto100% (1)

- Condensate SystemDocument35 paginiCondensate SystemSam100% (6)

- Moran, Michael J., INTRODUCTION TO THERMAL SYSTEMS ENGINEERING: Thermodynamics, Fluid Mechanics, and Heat Transfer 3rd EditionDocument1.113 paginiMoran, Michael J., INTRODUCTION TO THERMAL SYSTEMS ENGINEERING: Thermodynamics, Fluid Mechanics, and Heat Transfer 3rd EditionArif Zain90% (10)

- B23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Document4 paginiB23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Fanir ZÎncă nu există evaluări

- Point-Fixed Glass Wall Fitting Typical Product Catalog160PDocument155 paginiPoint-Fixed Glass Wall Fitting Typical Product Catalog160PNajib Kiwan100% (1)

- Drillability IndexDocument10 paginiDrillability Indexeduardoenrique08289100% (1)

- Fire and Smoke Fire - and - Smoke - Tight - Sliding - Doorstight Sliding Doors Mutli Purpose Doors 86038 enDocument32 paginiFire and Smoke Fire - and - Smoke - Tight - Sliding - Doorstight Sliding Doors Mutli Purpose Doors 86038 enAna GainaÎncă nu există evaluări

- LPG Check ListDocument39 paginiLPG Check ListARUL SANKARANÎncă nu există evaluări

- Cebex Cable Grout-1Document4 paginiCebex Cable Grout-1depi_rachmanÎncă nu există evaluări

- Cebex Cable Grout PlusDocument13 paginiCebex Cable Grout PlustalatzahoorÎncă nu există evaluări

- Fosroc Cebex Cable Grout Plus: Constructive SolutionsDocument4 paginiFosroc Cebex Cable Grout Plus: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Fosroc Cebex Cable Grout: Constructive SolutionsDocument4 paginiFosroc Cebex Cable Grout: Constructive SolutionsVan Chuong VoÎncă nu există evaluări

- Fosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesDocument3 paginiFosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesKRISHNA PRASATH SÎncă nu există evaluări

- Conbextra Cable GroutDocument4 paginiConbextra Cable Groutm.elsanee.cubicÎncă nu există evaluări

- Cebex Cable Grout - FosrocDocument4 paginiCebex Cable Grout - FosrocIrshadYasinÎncă nu există evaluări

- Conbextra PDocument4 paginiConbextra Pm.elsanee.cubicÎncă nu există evaluări

- Cebex 200Document2 paginiCebex 200Anonymous XVEucVMsEÎncă nu există evaluări

- TDS Cebex 200 India2 PDFDocument2 paginiTDS Cebex 200 India2 PDFKamal KumarÎncă nu există evaluări

- Concrete Repair MaterialDocument4 paginiConcrete Repair MaterialJeikor J128Încă nu există evaluări

- Cebex 200Document2 paginiCebex 200reshmitapallaÎncă nu există evaluări

- Fosroc Conbextra P: Constructive SolutionsDocument4 paginiFosroc Conbextra P: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Non-shrink underwater groutDocument4 paginiNon-shrink underwater grouttin aungtunÎncă nu există evaluări

- Non-shrink cement grout admixtureDocument2 paginiNon-shrink cement grout admixturetalatzahoorÎncă nu există evaluări

- Conbextra STDDocument2 paginiConbextra STDPritha DasÎncă nu există evaluări

- Fosroc Conbextra Cable Grout: Constructive SolutionsDocument4 paginiFosroc Conbextra Cable Grout: Constructive SolutionsVincent JavateÎncă nu există evaluări

- HK Cebex 100Document4 paginiHK Cebex 100batman12hkÎncă nu există evaluări

- Non-shrink precision groutDocument4 paginiNon-shrink precision groutEngr.Mohammed KhaledÎncă nu există evaluări

- Conbextra STDDocument2 paginiConbextra STDm.elsanee.cubicÎncă nu există evaluări

- Fosroc Supercast EPTDocument2 paginiFosroc Supercast EPTArun KumarÎncă nu există evaluări

- TDS Cebex 100 India PDFDocument3 paginiTDS Cebex 100 India PDFAnonymous XVEucVMsEÎncă nu există evaluări

- TDS Cebex 100 India3Document3 paginiTDS Cebex 100 India3Kishore Nayak kÎncă nu există evaluări

- Cebex 100 PDFDocument4 paginiCebex 100 PDFAnonymous IwqK1NlÎncă nu există evaluări

- Conbextra HESEDocument4 paginiConbextra HESEm.elsanee.cubicÎncă nu există evaluări

- Conbextra HFDocument4 paginiConbextra HFm.elsanee.cubicÎncă nu există evaluări

- Fosroc Cebex 100: Constructive SolutionsDocument2 paginiFosroc Cebex 100: Constructive SolutionsGcek AparichitÎncă nu există evaluări

- Fosroc Cebex 100: Constructive SolutionsDocument2 paginiFosroc Cebex 100: Constructive SolutionsShruti ShahÎncă nu există evaluări

- Fosroc Cebex 100: Constructive SolutionsDocument2 paginiFosroc Cebex 100: Constructive SolutionsbhupendraÎncă nu există evaluări

- Cebex 100 grout expands and strengthens construction jointsDocument2 paginiCebex 100 grout expands and strengthens construction jointsmathi vijayÎncă nu există evaluări

- TDS Cebex100 Saudi ArabiaDocument2 paginiTDS Cebex100 Saudi ArabiaSabyasachi BangalÎncă nu există evaluări

- Conbextra Ep40Document3 paginiConbextra Ep40talatzahoorÎncă nu există evaluări

- Cebex 100 BFLDocument3 paginiCebex 100 BFLpeashÎncă nu există evaluări

- Epoxy resin free flow grout for heavy duty applicationsDocument4 paginiEpoxy resin free flow grout for heavy duty applicationsFeri Oktara IrawanÎncă nu există evaluări

- Conbextra Cable GroutDocument4 paginiConbextra Cable GroutAnonymous uNhWGqNzÎncă nu există evaluări

- High Strength Epoxy Grout for Heavy LoadsDocument2 paginiHigh Strength Epoxy Grout for Heavy LoadsAcho SupraholicÎncă nu există evaluări

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 paginiFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateÎncă nu există evaluări

- Conbextra EP40 UAEDocument2 paginiConbextra EP40 UAEjasonÎncă nu există evaluări

- Fosroc Conbextra HF precision groutDocument4 paginiFosroc Conbextra HF precision groutThrtThrthÎncă nu există evaluări

- Datasheet File Conbextra - HFDocument4 paginiDatasheet File Conbextra - HFandikaÎncă nu există evaluări

- Expanse Al 600Document4 paginiExpanse Al 600raza102Încă nu există evaluări

- Fosroc Cebex 100 0811 PDFDocument2 paginiFosroc Cebex 100 0811 PDFghaghra bridgeÎncă nu există evaluări

- CONBEXTRA GP - JordanDocument4 paginiCONBEXTRA GP - JordanShabbir HussainÎncă nu există evaluări

- Conbextra EP10Document2 paginiConbextra EP10m.elsanee.cubicÎncă nu există evaluări

- Conbextra UW: Constructive SolutionsDocument4 paginiConbextra UW: Constructive SolutionstalatzahoorÎncă nu există evaluări

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocument3 paginiNitobond EP: Epoxy Resin Concrete Bonding AgentDinesh HastakÎncă nu există evaluări

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument1 paginăConbextra EP10 : High Strength, Epoxy Resin GroutminedataÎncă nu există evaluări

- 10 Conbextra EP10Document2 pagini10 Conbextra EP10ahmad wildaanÎncă nu există evaluări

- Low viscosity epoxy for crack injectionDocument3 paginiLow viscosity epoxy for crack injectionmohammad khabibÎncă nu există evaluări

- Conbextra UWDocument2 paginiConbextra UWm.elsanee.cubicÎncă nu există evaluări

- Supercast EPT UAEDocument2 paginiSupercast EPT UAEsriatul2006Încă nu există evaluări

- Nitobond EP 0608Document2 paginiNitobond EP 0608James PittsÎncă nu există evaluări

- X-Mix CableGrout AdditiveDocument2 paginiX-Mix CableGrout AdditiveKRISHNA PRASATH SÎncă nu există evaluări

- Cebex 100Document2 paginiCebex 100manil_5Încă nu există evaluări

- TDS-Conbextra-EP10-IndiaDocument3 paginiTDS-Conbextra-EP10-IndiaBabla SÎncă nu există evaluări

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 paginiConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajÎncă nu există evaluări

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 paginiFosroc Conbextra EP10: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Erection Material List JGS320Document2 paginiErection Material List JGS320Rashid Mahmood JaatÎncă nu există evaluări

- BARRIERTA GTE 403 EN enDocument2 paginiBARRIERTA GTE 403 EN enSiska JozefÎncă nu există evaluări

- Parkes-Series-Brochure ALTS Screen FA PDFDocument16 paginiParkes-Series-Brochure ALTS Screen FA PDFgio36Încă nu există evaluări

- Wood-Based Composite PDFDocument28 paginiWood-Based Composite PDFJayant Kumar JhaÎncă nu există evaluări

- Study of Building Drawing. Roll No.181001.Document19 paginiStudy of Building Drawing. Roll No.181001.Prafful BahiramÎncă nu există evaluări

- S MB Bearing CatalogueDocument104 paginiS MB Bearing Cataloguefog900Încă nu există evaluări

- OSI piston seal dimensions and specificationsDocument90 paginiOSI piston seal dimensions and specificationsChin Hui ChanÎncă nu există evaluări

- GulfSea AB Cooloil SeriesDocument2 paginiGulfSea AB Cooloil SeriesObydur RahmanÎncă nu există evaluări

- Technical DocumentationDocument84 paginiTechnical Documentationpotolok7767100% (2)

- PAC Chillers With Screw CompressorsDocument2 paginiPAC Chillers With Screw CompressorsMahmoud MohamedÎncă nu există evaluări

- Operating Instructions Indesit BAN 12 NF SDocument12 paginiOperating Instructions Indesit BAN 12 NF Scinefil70Încă nu există evaluări

- Galambos Ravindra 1976Document103 paginiGalambos Ravindra 1976Eric NolascoÎncă nu există evaluări

- 1 s2.0 S0925838823019904 MainDocument22 pagini1 s2.0 S0925838823019904 Mainlethao2011Încă nu există evaluări

- Method of Statement Repair HoneycombDocument12 paginiMethod of Statement Repair HoneycombSiti Rohani IsdrisÎncă nu există evaluări

- R 4360c 36 Series Gas Valve Cross Reference en 5239824Document28 paginiR 4360c 36 Series Gas Valve Cross Reference en 5239824pandahiuÎncă nu există evaluări

- Roof Layout: General Notes For BuildersDocument4 paginiRoof Layout: General Notes For Buildersivanstankovic4Încă nu există evaluări

- Hyperdesmo - ADY-E: One-Component, Semi-Glossy, Aliphatic, Elastic Polyurethane Top CoatDocument3 paginiHyperdesmo - ADY-E: One-Component, Semi-Glossy, Aliphatic, Elastic Polyurethane Top Coatmeena nachiyarÎncă nu există evaluări

- Microstructures and Mechanical Properties of Cold Rolled Mg-8Li andDocument5 paginiMicrostructures and Mechanical Properties of Cold Rolled Mg-8Li andVidya me20d015Încă nu există evaluări

- Bridge Works - MiscellaneousDocument26 paginiBridge Works - MiscellaneousamitjustamitÎncă nu există evaluări

- Bioact EC-7 Defluxer: Technical Data SheetDocument4 paginiBioact EC-7 Defluxer: Technical Data Sheetmadiahmad84Încă nu există evaluări

- 3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor ManualDocument12 pagini3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor Manualabbas dehghanÎncă nu există evaluări

- 2007 Russian Aluminum Alloys For Ultra Deep Water EngDocument8 pagini2007 Russian Aluminum Alloys For Ultra Deep Water EngHossam Ali RaghebÎncă nu există evaluări