Documente Academic

Documente Profesional

Documente Cultură

Test Performed During Inspection: Color: Qty (MTRS) Qty (Nos)

Încărcat de

Pritam SinghTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Test Performed During Inspection: Color: Qty (MTRS) Qty (Nos)

Încărcat de

Pritam SinghDrepturi de autor:

Formate disponibile

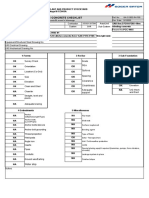

WORK IN PROGRESS INSPECTION REPORT STAGE WIRING & MOUNTING DOC NO.

QLTY:YT/0413/10

Date: 21.12.2013 Drg.No –PN1-PN9

Client: M/S T.P.S.C. (India) Pvt. Ltd

Project: 6X25KW MECHUKA MHP, A.P.

S.No. Wiring Inspection Quality Remarks Mounting Inspection Quality

1 Type of Wiring-Channel/Bunch OK/Not OK/NA Mounting OK/Not OK/NA

Power Wire Size as per OK/Not OK/NA Box Size In mm

2 Components Drawing

Spiral Pipe(Mounting Plate to OK/Not OK/NA Height = 1950

3 Door)

4 Power Lugs-Pull Test OK/Not OK/NA Width = 750

5 Control Lugs-Pull Test OK/Not OK/NA Depth = 750

6 Lugs –Type & Size OK/Not OK/NA

7 Mounting Door Legends OK/Not OK/NA

8 Internal Legends OK/Not OK/NA

9 Bus Bars Holes (As per Lug Size) OK/Not OK/NA

Wire Phase Neutral Negative Control

Color: Blue Blue -

Qty Qty

Item (Mtrs) (Nos)

Remarks

Control Wire

Control Wire Size 1 (1.5mm) 300

Control Wire Size 2 (2.5mm) 1200

Total No. of Control Wires: 1500

Power Wire

Power Wire Size 1 (10.0 mm) 600

Total No. Of Wires 600

Test Performed during Inspection

Yes No Remarks

1. ELC Load Transfer test OK/Not OK/NA

2. Synchronising Circuit OK/Not OK/NA

3. Freq. Matching OK/Not OK/NA

4. THD % Test OK/Not OK/NA

Name of QA Engineer: Mr. Ranjeet Mookerjee FOR YTEK CONTROLS

Remarks of QA Engineer: Inspection Found Satisfactory

(QA/QC) AUTHORISED SIGNATORY

Date: 21.12.2013

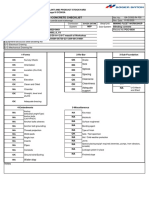

WORK IN PROGRESS INSPECTION REPORT STAGE FABRICATION & PAINT DOC NO. QLTY:YT/0413/11

Date:21.12.2013 Drg. No.PN1-PN9

Client: M/S T.P.S.C. (India) Pvt. Ltd

Project: 6X25KW MECHUKA MHP, A.P.

S.No Fabrication Inspection Value/Remarks Remarks Paint Inspection Quality

.

1 Box Length (Left to Right) 750

A) POWDER COAT

2 Box Length (Top to Bottom) 1950

3 Box Length (Front to Back) 750

Diagonal Front (Top Left to Bottom Powder Coating Inspected all over

4 Right)

2033 OK/Not OK/NA

Panel

Diagonal Front (Top Right to

5 Bottom Left)

2034

Diagonal Back (Top Left to Bottom Remarks:-

6 Right)

2022

Diagonal Back (Top Right to

7 Bottom Left)

2024

Diagonal Left (Top Left to Bottom

8 Right)

2022

Diagonal Left (Top Right to Bottom

9 Left)

2020

Diagonal Right (Top Left to Bottom

10 Right)

2024

11 Diagonal Right (Top Right to

2024

Bottom Left)

12 Diagonal Top (Top Left to Bottom B) PAINT

1067

Right)

Diagonal Top (Top Right to Bottom I) Body :- Quality

13 Left)

1067 OK/

Diagonal Bottom (Top Left to Not OK Colour : RAL 7032

14 Bottom Right)

1067

Diagonal Bottom (Top Right to Primer Application-Coat 1/2 OK/Not OK/NA

15 Bottom Left)

1067

16 Meters / Lights / Cutouts OK/Not OK/NA Primer Application-Coat 1/2

17 Louver Cutouts (Nos.):- OK/Not OK/NA I) Mounting Plate :- Quality

18 Lifting Hook (Nos.):- OK/Not OK/NA Colour : RAL 7032

19 Cable Alley/Fixing Channel OK/Not OK/NA Primer Application-Coat 1/2 OK/Not OK/NA

20 Bus Bar Support Channel Mounting OK/Not OK/NA Primer Application-Coat 1/2

21 Gland Plate Cutout (Done/NA) OK/Not OK/NA Remarks:-

22 Hinge & Lock Cutouts , Hinge

Type

OK/Not OK/NA

23 Door Bending & Joint Quality OK/Not OK/NA

24 All Door to Door Gap (Parallel &

Right Angle)

OK/Not OK/NA

25 All items in Right Angle to Each

Other

OK/Not OK/NA

26 All items in Right Angle to Each

Other

OK/Not OK/NA

27 All Joints Filled in(Will not be seen

After PC /Painting

OK/Not OK/NA

Name of QA Engineer: Mr. Ranjeet Mookhrjee FOR YTEK CONTROLS

Remarks of QA Engineer: Inspection Found Satisfactory

(QA/QC) AUTHORISED SIGNATORY

Date: 21.12.2013

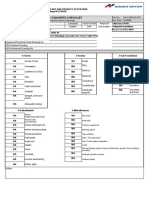

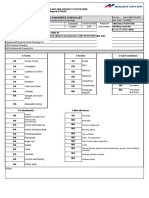

WORK IN PROGRESS INSPECTION REPORT STAGE FABRICATION & PAINT DOC NO. QLTY:01 (R001)

Date: 21.12.2013 Drg. No. PN1-PN9

Client: M/S TPSC India Pvt. Ltd.Noida

Project:

S.No. Normal Standard Test Remarks Value Quality

1. BOM Check OK / NOT OK

2. Power Wire Loose Termination OK / NOT OK

3. Control Wire Loose Termination OK / NOT OK

4. Tag No. As per Drawings OK / NOT OK

5. Interlock Test OK / NOT OK

6. Finish & Box Size OK / NOT OK

7. Paper Slide Test At 3 Places OK / NOT OK

Megger/ Insulation Test OK / NOT OK

1. R- Phase to Y- Phase <100MΩ

2. R- Phase to B- Phase <100MΩ

3. Y- Phase to B- Phase <100MΩ

4. R- Phase to N- Phase <100MΩ

5. Y- Phase to N- Phase <100MΩ OK / NOT OK

6. B- Phase to N- Phase <100MΩ

7. R- Phase to E- Phase <100MΩ

8. Y- Phase to E- Phase <100MΩ

9. B- Phase to E- Phase <100MΩ

High Voltage Test

1. R- Phase to Y- Phase 2.5V/30 Sec

2. R- Phase to B- Phase 2.5V/30 Sec

3. Y- Phase to B- Phase 2.5V/30 Sec

4. R- Phase to N- Phase 2.5V/30 Sec

5. Y- Phase to N- Phase 2.5V/30 Sec OK / NOT OK

6. B- Phase to N- Phase 2.5V/30 Sec

7. R- Phase to E- Phase 2.5V/30 Sec

8. Y- Phase to E- Phase 2.5V/30 Sec

9. B- Phase to E- Phase 2.5V/30 Sec

Name of QA Engineer: Mr. Ranjeet Mookhrjee FOR YTEK CONTROLS

Remarks of QA Engineer: Inspection Found Satisfactory

(QA/QC) AUTHORISED SIGNATORY

Date: 21.12.2013

Testing Instrument List:

S. No. Instrument Name Type Make Management No.

1. Insulation Tester NO157-4-8 Logic YT/ELI/2012

2. Digital Multi Meter MAS830L Mastech YT/ELI/2012

3. Techo Hitester Lutron YT/ELI/2012

4. Infra Red Hitester YT/ELI/2012

5. Digital Storage Oscilloscope PDS6062S(60MHZ) Owen YT/ELI/2012

6. Digital Oscilloscope DS5032E(30MHZ) Owen YT/ELI/2013

7. CT Testing Kit(Variac) PE-1 Dimmer Tech YT/ELI/2012

S-ar putea să vă placă și

- Abb Reb650 Busbar High ImpDocument6 paginiAbb Reb650 Busbar High Imphizbi7Încă nu există evaluări

- Dish End Inspection Report: 66 MM MaxDocument2 paginiDish End Inspection Report: 66 MM MaxGlenn DcruzÎncă nu există evaluări

- Commissioning Service Department Commissioning Standard Test FormatsDocument6 paginiCommissioning Service Department Commissioning Standard Test Formatsm khÎncă nu există evaluări

- Utility PDB PanelDocument20 paginiUtility PDB PanelTILAK RAJ KambojÎncă nu există evaluări

- SACEP - RTCC - Delivery #0971542-11Document16 paginiSACEP - RTCC - Delivery #0971542-11Ryan condeÎncă nu există evaluări

- Internal Inspection Report - H Vax - 300cfm - DC - 01 - SSDocument4 paginiInternal Inspection Report - H Vax - 300cfm - DC - 01 - SSsantosh yadavÎncă nu există evaluări

- SACEP - RTCC - Delivery #0971558-12Document16 paginiSACEP - RTCC - Delivery #0971558-12Ryan condeÎncă nu există evaluări

- CW2099436 Q006 0001 - R1Document27 paginiCW2099436 Q006 0001 - R1D S Sagar TripuramalluÎncă nu există evaluări

- Inspection Check ListDocument6 paginiInspection Check ListNagesh RaoÎncă nu există evaluări

- Door FrameDocument1 paginăDoor FramegiridharreddyÎncă nu există evaluări

- SACEP - RTCC - Delivery #0971407-05Document12 paginiSACEP - RTCC - Delivery #0971407-05Ryan condeÎncă nu există evaluări

- LF SapatDocument5 paginiLF SapatAchmad ArromanÎncă nu există evaluări

- Page 1 of 13: Exc K oDocument13 paginiPage 1 of 13: Exc K oSARAVANAN AÎncă nu există evaluări

- Pipeline Survey Questionnaire: Tuboscope Job NumberDocument3 paginiPipeline Survey Questionnaire: Tuboscope Job NumberAnonymous bQsPAALIR6Încă nu există evaluări

- Check List Int DiaDocument2 paginiCheck List Int DiaCrazzy RamÎncă nu există evaluări

- End To End Test 7008 Circuit 7041 Mbci01Document3 paginiEnd To End Test 7008 Circuit 7041 Mbci01abonada.hqÎncă nu există evaluări

- Ae-318-043-Pr 2013-SKDocument1 paginăAe-318-043-Pr 2013-SKUmer IlliasÎncă nu există evaluări

- PQT Report For Heat No.: 6-52055, ZJ2689 & 6-52056 HN: 6-52055 HN: ZJ2689 HN: 6-52056Document2 paginiPQT Report For Heat No.: 6-52055, ZJ2689 & 6-52056 HN: 6-52055 HN: ZJ2689 HN: 6-52056GomathyselviÎncă nu există evaluări

- Abb Rec670 Acse Relay TestDocument10 paginiAbb Rec670 Acse Relay Testm khÎncă nu există evaluări

- Vis 08394 001Document1 paginăVis 08394 001Kerron DhorayÎncă nu există evaluări

- Sony SDM-S51Document33 paginiSony SDM-S51wiliamklÎncă nu există evaluări

- SACEP - RTCC - Delivery #0971291-01Document9 paginiSACEP - RTCC - Delivery #0971291-01Ryan condeÎncă nu există evaluări

- Ds-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.b)Document3 paginiDs-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.b)Panisa BanimaÎncă nu există evaluări

- Workshop 18Document2 paginiWorkshop 18N KingÎncă nu există evaluări

- Strucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKDocument1 paginăStrucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKSteelcraft engineeringÎncă nu există evaluări

- General Format For Girder Fabrication Check ListDocument4 paginiGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryÎncă nu există evaluări

- Ds-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.0)Document3 paginiDs-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.0)Panisa BanimaÎncă nu există evaluări

- Apqp B5B15102Document4 paginiApqp B5B15102quality.rudrapurÎncă nu există evaluări

- Daily Activities Report 12-11-2017Document1 paginăDaily Activities Report 12-11-2017pstechnical_43312697Încă nu există evaluări

- Ilovepdf MergedDocument13 paginiIlovepdf MergedRajesh Bhat - Estimation Dept. KBP CivilÎncă nu există evaluări

- Abb Rec670 Cap Bank ProtnDocument11 paginiAbb Rec670 Cap Bank ProtnRatheesh KumarÎncă nu există evaluări

- Bottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionDocument1 paginăBottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionSubodh MurkewarÎncă nu există evaluări

- REPORT - Oct. 2024Document6 paginiREPORT - Oct. 2024Tilan LeonardÎncă nu există evaluări

- Valve Chamber Construction ReportDocument2 paginiValve Chamber Construction ReportArvind SahaniÎncă nu există evaluări

- WPQDocument10 paginiWPQayoki100% (3)

- Daily Activities Report 13-11-2017Document1 paginăDaily Activities Report 13-11-2017pstechnical_43312697Încă nu există evaluări

- Damper DS - 1196DPR-430Document2 paginiDamper DS - 1196DPR-430harishcsharmaÎncă nu există evaluări

- Jamal MiaDocument1 paginăJamal MiaJHUN SUAREZÎncă nu există evaluări

- 2005 S003 NBPG Rfi 04957 - R00Document1 pagină2005 S003 NBPG Rfi 04957 - R00RPDeshÎncă nu există evaluări

- Abb Rec670 Busbar High ImpDocument4 paginiAbb Rec670 Busbar High Impm khÎncă nu există evaluări

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 paginiForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoÎncă nu există evaluări

- Daily Spot Check ListDocument2 paginiDaily Spot Check ListAnilkumar G NairÎncă nu există evaluări

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document2 paginiTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaÎncă nu există evaluări

- Process Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VDocument6 paginiProcess Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VadjiÎncă nu există evaluări

- Pressure Test ReportDocument9 paginiPressure Test Reportjaysonquitelgonzales06Încă nu există evaluări

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 paginiForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoÎncă nu există evaluări

- Service Manual: Multi Sync Ea294WmiDocument134 paginiService Manual: Multi Sync Ea294WmiHans LütherÎncă nu există evaluări

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 paginiForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoÎncă nu există evaluări

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 paginiForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoÎncă nu există evaluări

- AccsDocument8 paginiAccsm kh100% (1)

- Data Collection For Shrinkage2Document97 paginiData Collection For Shrinkage2SagarÎncă nu există evaluări

- AVE MOD V2.2 Build GuideDocument16 paginiAVE MOD V2.2 Build GuideCristobalzqÎncă nu există evaluări

- Quality Check List FormatDocument28 paginiQuality Check List Formatjagadeesh_kumar_20100% (1)

- 7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDDocument8 pagini7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDAnonymous dH3DIEtzÎncă nu există evaluări

- Machine InspectionDocument18 paginiMachine InspectionFERCHIU CRISTIANÎncă nu există evaluări

- 4TB & 8TB Moment ConnectionDocument13 pagini4TB & 8TB Moment ConnectionShamik Ghosh0% (1)

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 paginiForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoÎncă nu există evaluări

- 2857 Edmonson - DB2Document1 pagină2857 Edmonson - DB2Juan Carlos OlivasÎncă nu există evaluări

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 paginiForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoÎncă nu există evaluări

- Enquiry For Manufacture, Testing & Supply of Generator Power and Auxiliary Transformers For Our Ongoing Three Projects in NepalDocument7 paginiEnquiry For Manufacture, Testing & Supply of Generator Power and Auxiliary Transformers For Our Ongoing Three Projects in NepalPritam SinghÎncă nu există evaluări

- Comparison For CTS and PtsDocument6 paginiComparison For CTS and PtsPritam SinghÎncă nu există evaluări

- Item Description Unit Qty 1 Turbine & AuxiliariesDocument4 paginiItem Description Unit Qty 1 Turbine & AuxiliariesPritam SinghÎncă nu există evaluări

- General Specification For Ring Main Unit Switchgear, From 3.3 To 13.8 KVDocument9 paginiGeneral Specification For Ring Main Unit Switchgear, From 3.3 To 13.8 KVPritam SinghÎncă nu există evaluări

- Sr. No. Item Description MakeDocument10 paginiSr. No. Item Description MakePritam SinghÎncă nu există evaluări

- SNO Project ItemDocument9 paginiSNO Project ItemPritam SinghÎncă nu există evaluări

- Generation Voltage 6.6 KV Generator Capacity 2500 KW Genrator Current 257.2938 AMP at 95% Voltage 270.8355Document1 paginăGeneration Voltage 6.6 KV Generator Capacity 2500 KW Genrator Current 257.2938 AMP at 95% Voltage 270.8355Pritam SinghÎncă nu există evaluări

- IndexDocument1 paginăIndexPritam SinghÎncă nu există evaluări

- Hydro Power Synchronous GeneratorsDocument8 paginiHydro Power Synchronous GeneratorsPritam SinghÎncă nu există evaluări

- LBSDocument5 paginiLBSPritam SinghÎncă nu există evaluări

- Control Panel Layoutgc - Copy (2) ModelDocument9 paginiControl Panel Layoutgc - Copy (2) ModelPritam SinghÎncă nu există evaluări

- DS - Calatogue PDFDocument8 paginiDS - Calatogue PDFPritam SinghÎncă nu există evaluări

- Kirloskar SLDDocument1 paginăKirloskar SLDPritam SinghÎncă nu există evaluări

- Control Panel Manual1X25Document12 paginiControl Panel Manual1X25Pritam SinghÎncă nu există evaluări

- MHP Panel BOMDocument6 paginiMHP Panel BOMPritam SinghÎncă nu există evaluări

- GPS Spoofing (2002-2003)Document8 paginiGPS Spoofing (2002-2003)Roger JohnstonÎncă nu există evaluări

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDocument1.092 paginiSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaÎncă nu există evaluări

- LetrasDocument9 paginiLetrasMaricielo Angeline Vilca QuispeÎncă nu există evaluări

- Career Essay 1Document2 paginiCareer Essay 1api-572592063Încă nu există evaluări

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 paginiUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcÎncă nu există evaluări

- Agco Serie 800 PDFDocument24 paginiAgco Serie 800 PDFJohnny VargasÎncă nu există evaluări

- Essay Rough Draft 19Document9 paginiEssay Rough Draft 19api-549246767Încă nu există evaluări

- Project Scheduling and TrackingDocument47 paginiProject Scheduling and TrackingArun VinodhÎncă nu există evaluări

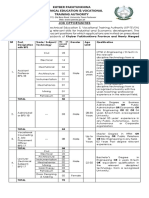

- KP Tevta Advertisement 16-09-2019Document4 paginiKP Tevta Advertisement 16-09-2019Ishaq AminÎncă nu există evaluări

- Presentation 11Document14 paginiPresentation 11stellabrown535Încă nu există evaluări

- Nama: Yossi Tiara Pratiwi Kelas: X Mis 1 Mata Pelajaran: Bahasa InggrisDocument2 paginiNama: Yossi Tiara Pratiwi Kelas: X Mis 1 Mata Pelajaran: Bahasa InggrisOrionj jrÎncă nu există evaluări

- Android Developer PDFDocument2 paginiAndroid Developer PDFDarshan ChakrasaliÎncă nu există evaluări

- Hamstring - WikipediaDocument21 paginiHamstring - WikipediaOmar MarwanÎncă nu există evaluări

- Rule 113 114Document7 paginiRule 113 114Shaila GonzalesÎncă nu există evaluări

- Corrosion Fatigue Phenomena Learned From Failure AnalysisDocument10 paginiCorrosion Fatigue Phenomena Learned From Failure AnalysisDavid Jose Velandia MunozÎncă nu există evaluări

- Stearns 87700 Series Parts ListDocument4 paginiStearns 87700 Series Parts ListYorkistÎncă nu există evaluări

- RSA - Brand - Guidelines - 2019 2Document79 paginiRSA - Brand - Guidelines - 2019 2Gigi's DelightÎncă nu există evaluări

- Modulo EminicDocument13 paginiModulo EminicAndreaÎncă nu există evaluări

- Chapter 3 - Organization Structure & CultureDocument63 paginiChapter 3 - Organization Structure & CultureDr. Shuva GhoshÎncă nu există evaluări

- 2SB817 - 2SD1047 PDFDocument4 pagini2SB817 - 2SD1047 PDFisaiasvaÎncă nu există evaluări

- Law of EvidenceDocument14 paginiLaw of EvidenceIsha ChavanÎncă nu există evaluări

- Analysis of Electric Machinery Krause Manual Solution PDFDocument2 paginiAnalysis of Electric Machinery Krause Manual Solution PDFKuldeep25% (8)

- 7400 IC SeriesDocument16 pagini7400 IC SeriesRaj ZalariaÎncă nu există evaluări

- Ob NotesDocument8 paginiOb NotesRahul RajputÎncă nu există evaluări

- AntibioticsDocument36 paginiAntibioticsBen Paolo Cecilia RabaraÎncă nu există evaluări

- Business Plan 3.3Document2 paginiBusiness Plan 3.3Rojin TingabngabÎncă nu există evaluări

- Assessment of Students' Oral Communication in English ClassDocument10 paginiAssessment of Students' Oral Communication in English ClassKeebeek S ArbasÎncă nu există evaluări

- 05 x05 Standard Costing & Variance AnalysisDocument27 pagini05 x05 Standard Costing & Variance AnalysisMary April MasbangÎncă nu există evaluări

- 8.ZXSDR B8200 (L200) Principle and Hardware Structure Training Manual-45Document45 pagini8.ZXSDR B8200 (L200) Principle and Hardware Structure Training Manual-45mehdi_mehdiÎncă nu există evaluări

- Agnes de MilleDocument3 paginiAgnes de MilleMarie-Maxence De RouckÎncă nu există evaluări