Documente Academic

Documente Profesional

Documente Cultură

Welder's Qualification Test - Template

Încărcat de

Diosdado Mingi Jr.100%(3)100% au considerat acest document util (3 voturi)

4K vizualizări2 paginiWelder's Qualification Test - Template

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLSX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWelder's Qualification Test - Template

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

100%(3)100% au considerat acest document util (3 voturi)

4K vizualizări2 paginiWelder's Qualification Test - Template

Încărcat de

Diosdado Mingi Jr.Welder's Qualification Test - Template

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

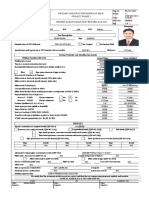

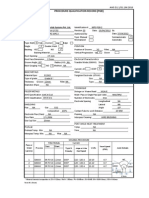

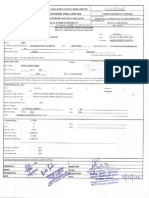

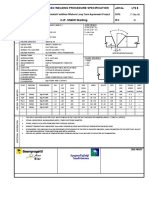

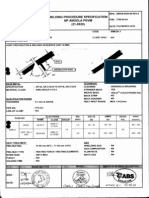

WELDER QUALIFICATION TEST

Company Logo

AS PER ASME IX

company

> Welder's Name :

> Welder's Identification :

> Date of Qualification :

> Identification of WPS followed : WELDER'S PHOTO

> Type : Test Coupon X Production Weld

> Specification of base Metal (s) : S275JR+N / SA-36

> Thickness : 20mm

TESTING CONDITIONS & QUALIFICATION LIMITS WHEN USING SEMI-AUTOMATIC WELDING

WELDING VARIABLE (QW-350) ACTUAL VALUES RANGE QUALIFIED

Welding Process (es) FCAW FCAW

Type of Welding (Manual, Semi-Auto) used SEMI-AUTO SEMI-AUTO

Backing (Metal, Weld Metal, Double-Welded,Etc.) WITH BACKING WITH BACKING

Groove plate and pipe 2 7/8" OD & over

Plate / Pipe ( Enter dia. If Pipe ) PLATE

Fillet: Plate and pipe - All Dia.

Metal P-Number to P-Number P1 TO P1 P1 TO P1

Metal or Electrode Specification ((S) (SFA) info, Only) SFA - A5.20 SFA - A5.20

Metal or Electrode Specification ((S) info, Only) E71T-1C E71T-1C

Metal F-Number(s) 6 6

Groove: Maximum to be welded

Deposit Thickness 15 MM Fillet: All base material

thicknesses, fillet sizes &

diameters

Plate / Pipe over 24" F,V

Position Qualified 3G Pipe 2 7/8 " ≤ 24" F

Fillet F,H,V

Weld progression (Uphill/Downhill) UPHILL UPHILL

Welding Current Type / Polarity DCEP DCEP

TEST RESULTS

Applicable Test Type of Tests Results

Weld Visual : VISUAL EXAMINATION Acceptable

Non-Destructive Test: RT-10 / Dated: RADIOGRAPHY TEST Acceptable

Conducted by:

Mechanical Test: _______ / Dated: Cross Weld Tensile - ASME IX:2017 Acceptable

Conducted by: Bend Test - ASME IX:2017 Acceptable

Specimen Evaluation:

EVALUATION Acceptable

Evaluated by: Bureau Veritas

Weld fracture Test: Length & percent of defect N/A

Macro Examination N/A

Fillet Leg size: N/A

Concavity / Convexity: N/A

Lab. Test: N/A

We certify that the statements in this record are correct and that the test coupon were prepared, welded & tested in

accordance with the requirements of Section IX of ASME Code

PGCC REPRESENTATIVE TPI CLIENT

SIGN & STAMP

NAME

DATE

S-ar putea să vă placă și

- WPQ Sample PrintoutDocument1 paginăWPQ Sample PrintoutKannan VelÎncă nu există evaluări

- Welder Qualification Form for Rana Pratap ChouhanDocument1 paginăWelder Qualification Form for Rana Pratap ChouhanMahendra singhÎncă nu există evaluări

- Welder Qualification Test Certificate for Mohan ReddyDocument2 paginiWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- WQTDocument1 paginăWQTRamkunwar YadavÎncă nu există evaluări

- Val Caraig WPQTDocument1 paginăVal Caraig WPQTMark Jason M. BrualÎncă nu există evaluări

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 paginiWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberÎncă nu există evaluări

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 paginiAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehÎncă nu există evaluări

- Wps Is 2062 GR B Butt-OkDocument2 paginiWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Aws d1.1 WPS, PQR & WQTDocument4 paginiAws d1.1 WPS, PQR & WQTWeld Bro SandeepÎncă nu există evaluări

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 paginiWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Fcaw 16 THKDocument5 paginiFcaw 16 THKparesh2387Încă nu există evaluări

- List of Qualified WeldersDocument3 paginiList of Qualified WeldersdavÎncă nu există evaluări

- 03 WPS PQR For FCAWDocument3 pagini03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WQT Record for Pipeline Welder QualificationDocument99 paginiWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- WELDER QUAL TEST REPORTDocument1 paginăWELDER QUAL TEST REPORTtantri.hellyanti100% (1)

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument4 paginiPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepÎncă nu există evaluări

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDocument11 paginiIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 paginăWelder Qualification Test Certificate: Weld Test Details Range of ApprovalPeter Johnston100% (3)

- Wps Gmaw SawDocument2 paginiWps Gmaw Sawupedro26Încă nu există evaluări

- WPS - 024Document4 paginiWPS - 024MAT-LIONÎncă nu există evaluări

- WPS PQR Smaw + Fcaw D1.1Document8 paginiWPS PQR Smaw + Fcaw D1.1Yhuto W. Putra100% (3)

- 19403955-WPS M.S. Is 2062Document10 pagini19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pagini(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 paginiMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajÎncă nu există evaluări

- Welding Visual Inspection FormatDocument2 paginiWelding Visual Inspection Formatgst ajah100% (3)

- EQT ChecklistDocument5 paginiEQT Checklistvijayachidu100% (1)

- Fit Up Report Format-1Document1 paginăFit Up Report Format-1BalkishanDyavanapellyÎncă nu există evaluări

- Sample API 1104 WpsDocument6 paginiSample API 1104 Wpsjacquesmayol100% (2)

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDocument1 paginăASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliÎncă nu există evaluări

- Sample API 1104 WpsDocument3 paginiSample API 1104 WpsMuhammadShabbir0% (1)

- Wps SawDocument2 paginiWps Sawdevendrasingh2021100% (6)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 paginiWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielÎncă nu există evaluări

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 paginiWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniÎncă nu există evaluări

- GMAW WQTDocument1 paginăGMAW WQTKeneth Del Carmen100% (2)

- Fit Up ReportDocument5 paginiFit Up ReportAkash Singh Tomar100% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 paginăWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 paginiWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanÎncă nu există evaluări

- WPS PQR A36.20Document5 paginiWPS PQR A36.20gchaves504100% (2)

- PQR Gmaw3gDocument4 paginiPQR Gmaw3gdevendrasingh2021100% (3)

- WPS SampleDocument6 paginiWPS SampleAshishÎncă nu există evaluări

- WPS MigDocument3 paginiWPS MigAJOJOY00960% (5)

- WPQR Welding Procedure Qualification RecordsDocument3 paginiWPQR Welding Procedure Qualification Recordsramesh rajaÎncă nu există evaluări

- WPS & PQRDocument46 paginiWPS & PQRJohn Candidate CIns88% (8)

- WPS and PQRDocument4 paginiWPS and PQRdandiar1Încă nu există evaluări

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 paginiAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- PQR FormatDocument2 paginiPQR Formatravi0009880% (5)

- Plate Inspection ReportDocument1 paginăPlate Inspection ReportlalitaliÎncă nu există evaluări

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangÎncă nu există evaluări

- Welding Procedure Specification - TemplateDocument2 paginiWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- GMAW welding parameters for SS400 pipeDocument2 paginiGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- WPS PQR-09Document11 paginiWPS PQR-09Ranjan KumarÎncă nu există evaluări

- WPS 6G CS Pipe CorrectDocument4 paginiWPS 6G CS Pipe CorrectAla ReguiiÎncă nu există evaluări

- Reports - QAQC - R0Document10 paginiReports - QAQC - R0talupurumÎncă nu există evaluări

- Wps SmawDocument1 paginăWps SmawFedericoC67% (3)

- 6GR WPS PQRDocument15 pagini6GR WPS PQRKiukStaks100% (6)

- WPQ WeldCanada PDFDocument1 paginăWPQ WeldCanada PDFAhmad DanielÎncă nu există evaluări

- Pipe-to-Plate Welding Qualification Test RecordDocument1 paginăPipe-to-Plate Welding Qualification Test RecordErick GoyesÎncă nu există evaluări

- WPQR Record for Welder Jaun Velez FCAW ProcessDocument1 paginăWPQR Record for Welder Jaun Velez FCAW ProcessJBStringerÎncă nu există evaluări

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 paginăWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 paginiWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamedÎncă nu există evaluări

- Painting cost calculation and summary for molasses tankDocument2 paginiPainting cost calculation and summary for molasses tankDiosdado Mingi Jr.Încă nu există evaluări

- Paint Calculation - TankDocument1 paginăPaint Calculation - TankDiosdado Mingi Jr.Încă nu există evaluări

- Boq - Paint CalculationDocument8 paginiBoq - Paint CalculationDiosdado Mingi Jr.Încă nu există evaluări

- MBBR Tank Painting Cost EstimationDocument2 paginiMBBR Tank Painting Cost EstimationDiosdado Mingi Jr.Încă nu există evaluări

- Ladder Calculation 9april2018Document2 paginiLadder Calculation 9april2018Diosdado Mingi Jr.Încă nu există evaluări

- Welding Procedure Specification - TemplateDocument2 paginiWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- MBBR Tank Painting Cost EstimationDocument2 paginiMBBR Tank Painting Cost EstimationDiosdado Mingi Jr.Încă nu există evaluări

- Lifting Lug Calculation 4april2018Document2 paginiLifting Lug Calculation 4april2018Diosdado Mingi Jr.Încă nu există evaluări

- Thermit Welding Process Breif Manufacturing CatalogDocument4 paginiThermit Welding Process Breif Manufacturing CatalogMaulik ShahÎncă nu există evaluări

- JMP Doe GuideDocument162 paginiJMP Doe GuideAru Manikam100% (1)

- Fiat Kobelco E40sr E45sr Evolution Workshop ManualDocument20 paginiFiat Kobelco E40sr E45sr Evolution Workshop Manualkristen98% (46)

- C57.12.28-2005 Pad-Mounted Equipment-Enclosure IntegrityDocument28 paginiC57.12.28-2005 Pad-Mounted Equipment-Enclosure IntegrityPedro Luis YanezÎncă nu există evaluări

- Project On Pressure VesselDocument72 paginiProject On Pressure Vesselfanus100% (2)

- Formwork System: CatalogueDocument83 paginiFormwork System: CatalogueashenafiiÎncă nu există evaluări

- Matrusri Engineering College lesson plan on utilization of electrical energyDocument9 paginiMatrusri Engineering College lesson plan on utilization of electrical energysrinureddy2014Încă nu există evaluări

- WpsDocument4 paginiWpsMahfudRido'iRonggomaniaÎncă nu există evaluări

- Delta 500 EngDocument9 paginiDelta 500 EngPurushothaman JayabalanÎncă nu există evaluări

- DNV CP 0246Document20 paginiDNV CP 0246Eren HürcanÎncă nu există evaluări

- Tes-W-109.01-R0-General Welding CriteriaDocument23 paginiTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇÎncă nu există evaluări

- CCTV Annual Maintenance Contract Proposal SampleDocument441 paginiCCTV Annual Maintenance Contract Proposal Sampleakshat brahmbhattÎncă nu există evaluări

- TALRUT LeafletDocument2 paginiTALRUT LeafletCarlos DuenasÎncă nu există evaluări

- CIP CIL Interstage Screening SolutionsDocument4 paginiCIP CIL Interstage Screening SolutionsevalenciaÎncă nu există evaluări

- Mil STD 1246cDocument36 paginiMil STD 1246cmariobasile5063Încă nu există evaluări

- Dissimilar Base Metal ThicknessDocument5 paginiDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- EFR EU27 Steel Scrap SpecificationDocument12 paginiEFR EU27 Steel Scrap SpecificationAnonymous dIK4xERPÎncă nu există evaluări

- PR-1272 Standard Welding PQRs For On-Plot PipingDocument10 paginiPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002Încă nu există evaluări

- Gas Metal Arc Welding: Product and Procedure SelectionDocument96 paginiGas Metal Arc Welding: Product and Procedure SelectionSubhash SharmaÎncă nu există evaluări

- Welding A Cra-Lined Pipeline: Two "Bugs" Simultaneously Weld JointDocument9 paginiWelding A Cra-Lined Pipeline: Two "Bugs" Simultaneously Weld JointYan FerizalÎncă nu există evaluări

- Lincoln Electric's Unique Management SystemDocument5 paginiLincoln Electric's Unique Management SystemPriyeshÎncă nu există evaluări

- Government of Andhra Pradesh Basic RatesDocument54 paginiGovernment of Andhra Pradesh Basic RatesseshukvsÎncă nu există evaluări

- Low - Alloy-Tool - Steel 90sDocument10 paginiLow - Alloy-Tool - Steel 90smarcos crisostoÎncă nu există evaluări

- Clause 6. Inspection AWS D1.1/D1.1M:2015: Part FDocument1 paginăClause 6. Inspection AWS D1.1/D1.1M:2015: Part FMd. Sahabul IslamÎncă nu există evaluări

- Asme Pressure Vessel Joint EfficiencyDocument4 paginiAsme Pressure Vessel Joint EfficiencynasrpkÎncă nu există evaluări

- AWS c7.4mDocument7 paginiAWS c7.4mromanosky11Încă nu există evaluări

- 02 Samss 005Document15 pagini02 Samss 005Cherukunnon JubuÎncă nu există evaluări

- Specifications ThermitDocument34 paginiSpecifications Thermit100offeerÎncă nu există evaluări

- 00 SP 83701-Protective Paint & CoatingsDocument27 pagini00 SP 83701-Protective Paint & Coatingskhyle093009100% (1)

- List of PracticalsDocument5 paginiList of PracticalsSakil K SÎncă nu există evaluări