Documente Academic

Documente Profesional

Documente Cultură

Insulation System Installation

Încărcat de

FsDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Insulation System Installation

Încărcat de

FsDrepturi de autor:

Formate disponibile

INSULATION SYSTEM INSTALLATION

Verify all inspection and acceptance testing of the piping as required by the specification has been

completed and that the piping is ready for installation of insulation (e.g., leak/pressure tests).

■ Verify all surfaces are clean, dry and free from dirt, scale, moisture, oil, grease and any required

coatings are applied.

■ Verify there is adequate clearance to install the mineral fiber pipe insulation in accordance with

project drawings, operation performance parameters of the specification, such as access to controls,

valves and for maintenance and repair.

■ Install pipe insulation per Figure 2.1.

■ Verify all pipe hangers, supports and anchors are installed in accordance with the project

specification per Figures 2.11 through 2.13.

■ All pipe insulation longitudinal and circumferential joints must be sealed using the self-seal lap and

butt strips. All self seal-laps and butt strips must be firmly rubbed with a sealing tool such as a

squeegee to assure proper adhesion. The butt strip must be centered on the circumferential joint and

the end of the strip should overlap itself by a minimum of 1” (25.4mm). See Figures 2.1 and 2.2.

■ Stapling of the ASJ jacket or self-sealing joints is not recommended. If staples are used they must be

outward clinching staples that must then be sealed with a vapor retarder mastic or covered with an

approved ASJ tape.

■ The outermost ASJ vapor retarder must have a continuous, unbroken vapor seal. Hangers, supports,

anchors, etc., that are secured directly to cold surfaces must be adequately insulated and vapor sealed

to prevent condensation.

■ The butt end of every fourth pipe insulation section, and the ends or raw edges of insulation

terminations at equipment connections, fittings and fire stop systems shall be sealed with vapor

retarder mastic.

■ When a vapor retarder mastic is required, a maximum water vapor permeance of 0.02 per ASTM E-

96 Procedure B must be achieved. Follow the mastic manufacturer’s recommendations for application

to achieve the 0.02 perm rating. Preformed mineral pipe insulation with factory applied ASJ jacket

Butt strip tape, end of strip overlaps itself by a minimum of 1” (25.4mm) Factory applied self-seal tape

joint Self seal lap and factory supplied butt strips must be firmly rubbed with sealing tool such as a

plastic squeegee

Installation Tips

When the specification calls for a double layer insulation system, follow the same installation protocol

as a single layer system. NAIMA recommends removing the facing on the inner layer of the pipe

insulation before installing the second layer. Secure the inner layer with wire or tape. In multiple layer

applications, it is recommended that joints be staggered to minimize thermal shorts at through joints.

S-ar putea să vă placă și

- S Form - Ing Form: Simple Form Past Tense Form Past Participle Form RegularDocument1 paginăS Form - Ing Form: Simple Form Past Tense Form Past Participle Form RegularFsÎncă nu există evaluări

- Nipolet PDFDocument1 paginăNipolet PDFFsÎncă nu există evaluări

- Sandblasting ProcedureDocument3 paginiSandblasting ProcedureFs100% (2)

- Duct Systems DesignDocument4 paginiDuct Systems DesignFsÎncă nu există evaluări

- Fig.1. Flat Position T-Butt Weld Vs Overhead Fillet WeldDocument2 paginiFig.1. Flat Position T-Butt Weld Vs Overhead Fillet WeldFsÎncă nu există evaluări

- Butt JointsDocument3 paginiButt JointsFsÎncă nu există evaluări

- Definition and Details of Flanges Torque TighteningDocument4 paginiDefinition and Details of Flanges Torque TighteningFsÎncă nu există evaluări

- SWEEPOLETDocument1 paginăSWEEPOLETFsÎncă nu există evaluări

- La TroletDocument1 paginăLa TroletFsÎncă nu există evaluări

- Requirements For Duct Leakage TestingDocument1 paginăRequirements For Duct Leakage TestingFsÎncă nu există evaluări

- Codes and Standards in NDT IndustryDocument8 paginiCodes and Standards in NDT IndustryFsÎncă nu există evaluări

- NIPOLETDocument1 paginăNIPOLETFsÎncă nu există evaluări

- Branch Connection FittingsDocument1 paginăBranch Connection FittingsFsÎncă nu există evaluări

- Socko LetDocument1 paginăSocko LetFsÎncă nu există evaluări

- American Society of Mechanical Engineers (ASME) Codes: Code DescriptionDocument1 paginăAmerican Society of Mechanical Engineers (ASME) Codes: Code DescriptionFsÎncă nu există evaluări

- Australian Standards For WeldingDocument1 paginăAustralian Standards For WeldingFsÎncă nu există evaluări

- Codes and StandardsDocument2 paginiCodes and StandardsFsÎncă nu există evaluări

- Threadolet and Threadolet DimensionsDocument7 paginiThreadolet and Threadolet DimensionsFsÎncă nu există evaluări

- Welding SteelDocument3 paginiWelding SteelFsÎncă nu există evaluări

- American Welding SocietyDocument4 paginiAmerican Welding SocietyFs100% (1)

- New Pipe Insulation ThicknessesDocument3 paginiNew Pipe Insulation ThicknessesFsÎncă nu există evaluări

- British Standards For WeldingDocument1 paginăBritish Standards For WeldingFsÎncă nu există evaluări

- Standard Specification For Mineral Fiber Pipe InsulationsDocument2 paginiStandard Specification For Mineral Fiber Pipe InsulationsFsÎncă nu există evaluări

- Chilled Water Piping Distribution Systems Ashrae 3-12-14Document78 paginiChilled Water Piping Distribution Systems Ashrae 3-12-14haseebamerÎncă nu există evaluări

- General Specifications For HVACDocument53 paginiGeneral Specifications For HVACEhab Shawky100% (1)

- New Pipe Insulation ThicknessesDocument3 paginiNew Pipe Insulation ThicknessesFsÎncă nu există evaluări

- PDFDocument12 paginiPDFMustafa ElfatihÎncă nu există evaluări

- MVAC Testing & Commissioning Procedure - 2007Document245 paginiMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- IMDL 40, 60, 90 Ducted Fan Coil Units Installation & MaintenanceDocument4 paginiIMDL 40, 60, 90 Ducted Fan Coil Units Installation & MaintenanceFsÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Marine Upholstery SpecsDocument1 paginăMarine Upholstery SpecsRezza KurniawanÎncă nu există evaluări

- Tillotson HD & HR Service ManualDocument11 paginiTillotson HD & HR Service ManualBeckyÎncă nu există evaluări

- Chapter 11Document10 paginiChapter 11NungkiwidyasÎncă nu există evaluări

- External Otitis (OE)Document24 paginiExternal Otitis (OE)Hannah BLissÎncă nu există evaluări

- Experiments: Mouthpiece, Which Is A Short Tube of Length About Equal To The Radius of The Orifice That Projects Into TheDocument4 paginiExperiments: Mouthpiece, Which Is A Short Tube of Length About Equal To The Radius of The Orifice That Projects Into Thefrancis dimakilingÎncă nu există evaluări

- Bock09 - Video Compression SystemsDocument300 paginiBock09 - Video Compression SystemsWong_Ngee_SengÎncă nu există evaluări

- Job Hazard Analysis Form: Section A: Task InformationDocument3 paginiJob Hazard Analysis Form: Section A: Task InformationHasnei NÎncă nu există evaluări

- 1965 Elio R. Freni - Electrolytic Lead Refining in SardiniaDocument9 pagini1965 Elio R. Freni - Electrolytic Lead Refining in SardiniaGeorgettaÎncă nu există evaluări

- Baño - Griferia - KOHLER - K-74013M+0.50GPMDocument3 paginiBaño - Griferia - KOHLER - K-74013M+0.50GPMGiordano Tuanama YapoÎncă nu există evaluări

- Role of BisoprololDocument43 paginiRole of BisoprololFidel Martua Marpaung67% (3)

- MIXDECK - FAQ and Troubleshooting 01Document8 paginiMIXDECK - FAQ and Troubleshooting 01F>F>Încă nu există evaluări

- GOLDEN DAWN 1 10 The Banishing Ritual of HexagramDocument4 paginiGOLDEN DAWN 1 10 The Banishing Ritual of HexagramF_RC86% (7)

- Worktips 01 Priming of PavementsDocument2 paginiWorktips 01 Priming of PavementsDilhara WickramaarachchiÎncă nu există evaluări

- PC-FT 403: Lecture (1) byDocument21 paginiPC-FT 403: Lecture (1) byFT 19 Suparno DasÎncă nu există evaluări

- SBB Product NoteDocument3 paginiSBB Product NoteFilipe MartinsÎncă nu există evaluări

- Assignment Oumh2103 English For Science Technical PurposesDocument12 paginiAssignment Oumh2103 English For Science Technical PurposesKhairul AnuarÎncă nu există evaluări

- Ffu 0000034 01Document8 paginiFfu 0000034 01Karunia LestariÎncă nu există evaluări

- Nokia 6131 NFCDocument5 paginiNokia 6131 NFCvetvetÎncă nu există evaluări

- ESL Discussion Questions To Practise IdiomsDocument5 paginiESL Discussion Questions To Practise IdiomsElaine Mc AuliffeÎncă nu există evaluări

- SMAW Health Hazards of g12 Students During Laboratory ActivitiesDocument25 paginiSMAW Health Hazards of g12 Students During Laboratory ActivitiesPaul Patrick Guanzon100% (1)

- Coronary Stents: Current StatusDocument42 paginiCoronary Stents: Current StatusMANSI SALUNKEÎncă nu există evaluări

- B2 First For Schools 4, Test 4 Answer Key, Reading and Use of EnglishDocument7 paginiB2 First For Schools 4, Test 4 Answer Key, Reading and Use of EnglishAlejandro Iglesias Peón0% (1)

- Safety Data Sheet: 1. IdentificationDocument7 paginiSafety Data Sheet: 1. IdentificationKhobeb MuslimÎncă nu există evaluări

- Manual DessertDocument32 paginiManual DessertDANIEL F. HERNANDEZ100% (1)

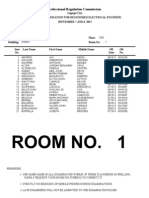

- REE0913ra LegazpiDocument6 paginiREE0913ra LegazpiScoopBoyÎncă nu există evaluări

- Designing Hopping Animal PDFDocument3 paginiDesigning Hopping Animal PDFAntonio Francisco Muñoz100% (1)

- Introduction To Mass Transfer - Part 1Document39 paginiIntroduction To Mass Transfer - Part 1Biniyam haile100% (1)

- Traina 250Wp PDFDocument2 paginiTraina 250Wp PDFSherifImamÎncă nu există evaluări

- Biochemistry - Syllabus Marks EtcDocument8 paginiBiochemistry - Syllabus Marks EtcshahzebÎncă nu există evaluări

- 12abmb2 Group4 Chapter1Document20 pagini12abmb2 Group4 Chapter1Kenneth Del RosarioÎncă nu există evaluări