Documente Academic

Documente Profesional

Documente Cultură

I in NV VA AC CO O2 2 I in NT Te Er RN Na at Ti Io

Încărcat de

sssTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

I in NV VA AC CO O2 2 I in NT Te Er RN Na at Ti Io

Încărcat de

sssDrepturi de autor:

Formate disponibile

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/266457309

I IN NV VA AC CO O2 2: : I In nt te er rn na at ti io on na al l S Se em mi in na

ar r, I IN NN NO OV VA AT TI IO ON N & & V VA AL LO OR RI IZ ZA AT TI IO ON

N I IN N C CI IV VI IL...

Article

CITATIONS READS

0 65

4 authors, including:

Jamal M Khatib Belkacem Menadi

University of Wolverhampton Saad Dahlab Blida 1 University, Algeria

201 PUBLICATIONS 2,771 CITATIONS 16 PUBLICATIONS 77 CITATIONS

SEE PROFILE SEE PROFILE

S. Kenai

Saad Dahlab University

101 PUBLICATIONS 1,751 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Characteristics of Shock waves and its effect on structural elements View project

Producing innovative chemical admixtures based on waste View project

All content following this page was uploaded by S. Kenai on 09 February 2015.

The user has requested enhancement of the downloaded file.

INVACO2: International Seminar, INNOVATION & VALORIZATION IN CIVIL ENGINEERING & CONSTRUCTION MATERIALS

N° : 1O-339 KHATIB J M,University of Wolverhampton, England, United Kingdom

Water Absorption by Capillary Action of Self-Compacting Concrete containing Fly Ash

J M Khatib*,

School of Technology, University of Wolverhampton, Wulfruna Street, Wolverhampton, WV1 1LY, UK,

Email:

A Y Shaaban,

Senior Engineer, Al-Waha Oil Company, PO Box 395, Tripoli, Libya

B Menadi, S Kenai,

Geomaterials Laboratory, Civil Engineering Department, University of Blida, Algeria

Abstract

The influence of including fly ash (FA) on the capillary water absorption and other properties of

self-compacting concrete (SCC) is investigated. Portland cement (PC) was partially replaced by

0-80% FA (in increments of 20). The water to binder ratio was maintained at 0.36 for all mixes.

The studied properties include workability, capillary water absorption, compressive strength and

ultrasonic pulse velocity. The results indicate that there is reduction in compressive strength as

the percentage of fly ash is a partial replacement of cement increases. This is also the case for

ultrasonic pulse velocity data. However acceptable strength with the inclusion of fly ash is

achieved at 7 days of curing. The total water absorption increases with the increase of fly ash.

However, this inclusion up to 40% replacement level did not show greater difference in capillary

water absorption compared to the control mix. This suggests that using fly ash in self-compacting

concrete is beneficial. However at a replacement level of 80%, the rate of water absorption is

higher than the other mixes.

Keywords: Absorption, capillary water absorption, fly ash, self-compacting concrete, strength,

ultrasonic pulse velocity.

1. INTRODUCTION

There has been an increasing interest in the use of self-compacting concrete (SCC) in recent

years as it can offer various advantages. These include the pumping of concrete to a great height,

the flow through congested reinforcing bars under the concrete self-weight, a reduction in

construction time, labour cost and noise level on the construction site. In addition SCC can allow

the construction of more slender building elements [1] (Holton, 2004). The use of chemical

admixtures in the production of SCC is necessary in order to increase the workability and reduce

segregation. Also the content of fine aggregate (i.e. sand) is higher than those of normal concrete.

In addition to the larger content of sand, there are normally larger amounts of fine particles in

SCC such as, blast furnace slag, fly ash and lime powder in order to avoid gravity segregation of

larger particles [2-4] (Nagamato and Ozava 1997, Okamura and Onchi 1999, Goodier 2003).

It is well established that the use of fly ash (FA) in concrete increases the workability and contributes

towards long-term strength. The incorporation of FA reduces the need of SP necessary to obtain a similar

slump flow compared with the concrete containing only cement as binder [5] (Sonebi and Batros 2002).

The strength and shrinkage of SCC containing high volume FA were found to be similar to that of normal

concrete. Also the shrinkage was not noticeably different from that of traditional concrete. The results

were based at varying water to binder ratios [6] (Persson 2001).

Some of the mechanical properties of SCC containing fly ash have been reported in a previous

investigation [7] (Khatib, 2008). The focus of the current investigation is on the water absorption

coefficient of SCC containing FA at constant water to binder (PC+FA) ratio of 0.36. Also workability,

density, compressive strength, absorption and ultrasonic pulse velocity were determined.

---------------------------------------

* Khatib, J.M: email: j.m.khatib@wlv.ac.uk

Morocco – Rabat / November 23-25, 2011 1

INVACO2: International Seminar, INNOVATION & VALORIZATION IN CIVIL ENGINEERING & CONSTRUCTION MATERIALS

N° : 1O-339 KHATIB J M,University of Wolverhampton, England, United Kingdom

2. EXPERIMENTAL

2.1. Materials

The constituents of mixes were Portland cement (PC), fly ash (FA), water, fine aggregate (i.e. sand) and

coarse aggregate. The PC and FA complied with EN 197-1 and EN 450 respectively. The fine aggregate

conformed to class M of BS 882: 1992, and 10 mm nominal size crushed and washed was used as coarse

aggregate. The admixture (AD) used to produce self-compacting concrete was a liquid based on a

modified synthetic carboxylated polymer. The AD conformed to Types A and F Admixtures of BS 5075

Parts 1 & 3 and EN 934-2:2000 with a relative density of 1.08. Composition of PC and FA is given in

Table 1.

2.2. Mix Proportions

Total of 8 mixes were made to investigate the properties of self-compacting concrete (SCC) with and

without fly ash (FA). Properties investigated were, workability using the flow table, density, compressive

strength, absorption, ultrasonic pulse velocity and shrinkage (length change). The control mixes M1-M3

had a proportion of 1 (PC): 1.75 (fine aggregate): 1.75 (coarse aggregate) without the inclusion of FA.

Three different dosages of admixtures (AD) were used for these control mixes. The dosages of AD were

0.6, 0.7 and 1.0% (by mass of PC) for mixes M1, M2 and M3 respectively. In mixes M4-M7, PC was

partially replaced with 20, 40, 60 and 80% FA (% by mass of binder), respectively. The binder (b)

consists of PC and FA. The dosage of AD for these mixes was 0.7% (by mass of binder). The water to

binder (w/b) ratio for all mixes was maintained constant at 0.36 and no adjustment to the water content

was made for mixes containing FA.

2.3. Casting, Curing and Testing

Cubes of 100mm in size were used for the determination of density, compressive strength,

absorption, ultrasonic pulse velocity (V) and length change. For each mix, 18 cubes and 2 prisms

were cast. Workability test using the flow table was conducted as per BS 1881, Part 105: 1984.

The table had dimensions of 700mm x 700mm and these are the minimum recommended

dimensions [8, 9] (Domone 1996, EFNARC 2002). Specimens (cubes and prisms) were then cast

in steel moulds and were not subjected to any compaction other than their own self-weights. The

specimens were kept covered in a controlled chamber at 20±2oC for 24 hours until demoulding.

Thereafter, cubes were placed in water at 20oC. The prisms, however, were left to air cure in a

controlled chamber at 20oC and 60% RH. Testing included density, compressive strength, total

absorption, absorption by capillary and ultrasonic pulse velocity (V). All specimens were cured

for 7days.

Table 1: Chemical Composition of Portland cement and Fly Ash in (%)

SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O SSB

(m2/kg)

Portland 20.2 4.2 2 63.9 2.1 3 0.14 0.68 368

cement

Fly Ash 50.5 24.7 7.4 2.6 1.5 0.8 0.8 3.0 356

After the required curing period, each cube was cut into two slices. The area of each half section

is 100mmx100mm and the thickness is approximately 50mm. After the sampling procedure,

samples (i.e. slices) were dried in an oven at 80±5°C for 72 hours. The specimens were then

cooled in an airtight container at 20±1°C prior to testing. For the determination of water

absorption (WA) by total immersion, the dry mass (Md) for each sample was recorded and then

totally immersed (shallow immersion) in water at 20°C until they achieved a constant mass (Ms).

Morocco – Rabat / November 23-25, 2011 2

INVACO2: International Seminar, INNOVATION & VALORIZATION IN CIVIL ENGINEERING & CONSTRUCTION MATERIALS

N° : 1O-339 KHATIB J M,University of Wolverhampton, England, United Kingdom

Ms was taken as the saturated mass. This took up to 72 hours. The water absorption (WA) was

then calculated by the following formula:

Ms −Md

WA (%) = 100 × (Eq. 1)

Md

The capillary rise test was conducted at 20±2°C and 60±5% RH. Dried slices were placed on supports in a

shallow tray and water was added slowly until the water level was about 1.5mm above the base of the

sample in contact with water. The increase in sample mass was measured at regular intervals. The mass of

water absorbed per unit area was plotted against the square root of time. The initial slope of the line is

taken as the water absorption coefficient (WAC). Further details about the test are reported elsewhere [10]

(Khatib and Clay 2004). For each of the absorption tests (WA and WAC), two slices were tested at each

age and the average was taken to represent the absorption value. The absorption values were within ± 5%

of the average. The method for determining the density, compressive strength, ultrasonic pulse velocity

was according to BS1881, Part 114:1983, Part 116: 1983 and Part 217: 1983 respectively.

3. RESULTS AND DISCUSSION

3.1. Workability

All mixes exhibited high workability, in that the flow spread (i.e. diameter) for all mixes was in excess of

700mm. These values are higher than those indicating elsewhere [5] (Sonebi 2004]. Slump flow of

650±50mm is required for SCC [9] (EFNARC 2002), and all the mixes under investigation fall in this

category. Visual examination of mixes containing FA suggest that there was further increase in

workability, as demonstrated by the ease of flow in the moulds, compared with the control mixture. It is

well established that the use of FA in concrete reduces the water demand for a given workability.

Therefore, concrete containing FA will cause an increase in workability at constant water to binder ratio.

3.2. Density

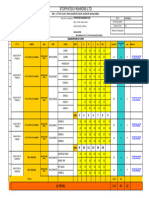

Density values for all mixes at 7 days curing are shown in Figure 1. Each density value represents the

average density of 3 specimens. The incorporation of increasing amounts of FA in concrete causes a

systematic reduction in density, mainly resulting from the lower density of FA compared with PC.

Although the mix proportions of SCC are different than those of traditional concrete, it is worth noting

that the density values of SCC are similar or slightly lower than those of traditional vibrated concrete [11]

(Khatib 2005), indicating the good compaction of SCC.

3.3. Absorption

The influence of varying amount of fly ash on total water absorption at 7 days of curing and at

different immersion times is shown in Figure 2. There is systematic increase in absorption with

increasing FA content. At 30 min immersion, all concretes (except the 80% fly ash mix, had

absorption of less than 4%, which is considered to be a medium water absorption [12] (Concrete

Society 1988). Only the 80% fly ash mix show large absorption values compared with the other

mixes. Generally, the absorption values for all mixes are lower than those reported in another

investigation [10] (Khatib and Clay 2004). The water absorbed by capillary action during the first

60 minutes for the various concrete mixes is shown in Figures 3. The amount of water absorbed

is generally higher when mixes contain increasing amounts of fly ash up to 80% partial

replacement of cement. Also the rate of water absorption, as described by the slope of the initial

part of the curve, increases as the fly ash in the mix increases. This slope is referred to as the

capillary water coefficient and further information about its determination is given elsewhere

[13] (Mangat and Khatib 1995). The water absorption coefficient is related to the open pore and

the diameters of such pores. This increase in water absorption coefficient with the increase in fly

ash content is clearly demonstrated in Figure 3. However, it must be noticed that this increase is

not clearly apparent when up to 40% of cement is replaced with fly ash. In other words replacing

up to 40% of cement with fly ash does not cause a noticeable increase in water absorption

coefficient. The largest increase in water absorption coefficient occurs at 80% fly ash content.

Morocco – Rabat / November 23-25, 2011 3

INVACO2: International Seminar, INNOVATION & VALORIZATION IN CIVIL ENGINEERING & CONSTRUCTION MATERIALS

N° : 1O-339 KHATIB J M,University of Wolverhampton, England, United Kingdom

2400

7 days

2350

Density (Kg/m )

3

2300

2250

2200

0 20 40 60 80

Fly Ash (%)

Figure 1: Density of concrete containing varying amounts of Fly Ash at 7 days of curing

7

7 days

6

Absorption (% by dry mass)

2 0%FA (Control)

20% FA

40% FA

1 60% FA

80% FA

0

0 25 50 75 100 125 150

Time (min)

Figure 2: Water absorbed for concrete containing varying amounts of FA at 7 days of curing

60

7 days 0% FA (Control)

20% FA

50 40% FA

Massgainedper unit area (g/mm)

60% FA

2

80% FA

40

30

20

10

0

0 1 2 3 4 5 6 7 8

Sqrt (time-minutes)

Figure 3: Water absorbed per unit area for concrete with FA at 7 days of curing

3.4. Compressive strength

Figure 4 shows the effect of incorporating fly ash on the compressive strength of concrete at 7

days of curing. There is systematic decrease in strength with the increase in fly ash content. The

trend is largely similar to that reported elsewhere [7] (Khatib 2008), except the 40% fly ash mix.

Khatib (2008) showed that a slight increase in strength at 40% fly compared to that at 20%. This

does not seem to occur in the present investigation and no sound justification can be made. At

40% the strength is nearly half of that of the control. These low strength values with fly ash is

expected at this early age of curing where there is not sufficient calcium hydroxide for the fly

ash particles to hydrate. As for compressive strength, the ultrasonic pulse velocity (Figure 5)

decreases as the fly ash content in the mix increases. However the rate of decrease is not quite

similar to those of compressive strength, in that the decrease in ultrasonic pulse velocity at 20%

fly ash is slightly lower than that of the control. Comparing Figures 4 and 5, there seems to be a

positive correlation between compressive strength and ultrasonic pulse velocity in that, an

Morocco – Rabat / November 23-25, 2011 4

INVACO2: International Seminar, INNOVATION & VALORIZATION IN CIVIL ENGINEERING & CONSTRUCTION MATERIALS

N° : 1O-339 KHATIB J M,University of Wolverhampton, England, United Kingdom

increase in ultrasonic pulse velocity is associated with an increase in compressive strength. Also

comparing other figures shows that a decrease in compressive is associated with an increase in

water absorption and water absorption coefficient.

40

7 days

35

Compressivestrength(N/mm)

2

30

25

20

15

10

0

0 20 40 60 80

Fly Ash (%)

Figure 4: Compressive strength of concrete with varying amounts of FA at 7 days of curing

2400

7 days

Ultrasonic Pulse Velocity (m/s)

2350

2300

2250

2200

0 20 40 60 80

Fly Ash (%)

Figure 5: Ultrasonic pulse velocity of concrete with varying amounts of FA at 7 days of curing

4. CONCLUSIONS

The following conclusions are based on the results of the present investigation:

• High percentage of FA can be used to produce SCC with an adequate strength. Using of up to 60%

FA as PC replacement can produce SCC with a strength above 20% at 7 days of curing.

• Although the absorption increases with increasing FA content, the absorption values of SCC

containing high volume (up to 60%) of FA is below 4% at 7 days of curing.

• There is an increase in water absorption coefficient as the replacement of cement with fly ash

increases.

Acknowledgements

The authors would like to thank the technical staff in the School of Technology at the University

of Wolverhampton, Mr G Cooper and Mr M Lloyd for their assistance.

References

[1] Holton, I (2004), Self-compacting concrete, BRE information Paper, Report IP 3/04, British Research

Establishment, Watford, UK.

[2] Nagamoto N, Ozava K (1997), Mixture properties of self-compacting concrete, Proc. of 3rd CANMET/ACI Int.

Conf. on Design and Materials and Recent Advances in Concrete Technology, ACI SP 172, Kuala Lumpur,

American Concrete Institute, Farmington Hills, MI, USA, pp 623-637.

[3] Okamura, H, Onchi, M (1999), Self-compacting concrete: development, present use and future, Proc. 1st Intern.

Conf. on Self-Compacting Concrete, Stockholm, Sweeden, 3-14.

[4] Goodier, CI (2003) Development of self-compacting concrete, Proceedings of the Institution of Civil Engineers,

Structures & Buildings 156, Issue SB4, pp 405-414.

Morocco – Rabat / November 23-25, 2011 5

INVACO2: International Seminar, INNOVATION & VALORIZATION IN CIVIL ENGINEERING & CONSTRUCTION MATERIALS

N° : 1O-339 KHATIB J M,University of Wolverhampton, England, United Kingdom

[5] Sonebi, M (2004), Medium strength self-compacting concrete containing fly ash: Modelling using factorial

experimental plans, Cement and Concrete Research, Vol 34, 1199-1208.

[6] Persson, B (2001) A comparison between mechanical properties of self-compacting concrete and the

corresponding properties of normal concrete, Cement and Concrete Research, Vol. 31, pp. 193-198.

[7] Khatib, J (2008), Performance of Self-Compacting Concrete Containing Fly Ash”, Construction and Building

Materials Journal, September, 22(9), 1963-1971.

[8] Domone, PL and Chai, HW (1996), Design and testing of SCC: Production methods and workability of

concrete, Proceedings of an International RILEM Conference, E & F N Spon, London, ISBN 419 22070 4.

[9] European Federation of Producers and Contractors of Specialist Products for Structures (EFNARC), 2002.

Specifications and guidelines for self-compacting concrete, Surrey, 32p.

[10] Khatib, JM and Clay, RJ (2004), Absorption characteristics of metakaolin concrete, Cement and Concrete

Research, 34, 19-29.

[11] Khatib, JM (2005), Properties of concrete containing fine recycled aggregates, Cement and Concrete Research,

35, 763-769.

[12] Concrete Society (1988), Permeability testing of site concrete - a review of methods and experience, Concrete

Society Technical Report No. 31.

[13] Khatib, JM and Mangat, PS (1995) “Absorption Characteristics of Concrete as a Function of Location Relative

to the Casting Position”, Cement and Concrete Research Journal, 25(5), 999-1010.

Morocco – Rabat / November 23-25, 2011 6

View publication stats

S-ar putea să vă placă și

- Corrosion: Corrosion ControlDe la EverandCorrosion: Corrosion ControlL L ShreirEvaluare: 5 din 5 stele5/5 (1)

- Formation of Tio Nano Fibers On A Micro-Channeled Al O - Zro /tio Porous Composite Membrane For Photocatalytic FiltrationDocument7 paginiFormation of Tio Nano Fibers On A Micro-Channeled Al O - Zro /tio Porous Composite Membrane For Photocatalytic FiltrationSIDDHARTH BHASNEYÎncă nu există evaluări

- Rao CBM 96 (2015) 508-517Document11 paginiRao CBM 96 (2015) 508-517Ali AliievÎncă nu există evaluări

- OTIENO 2016 - Corrosion Rate Prediction Models PART IDocument13 paginiOTIENO 2016 - Corrosion Rate Prediction Models PART IVinícius RamosÎncă nu există evaluări

- Workability, Strength, and Shrinkage of Ultra-Highperformance Seawater, Sea Sand Concrete WithDocument23 paginiWorkability, Strength, and Shrinkage of Ultra-Highperformance Seawater, Sea Sand Concrete WithGerad ValdezÎncă nu există evaluări

- Mechanical Behavior and Durability of Fibre Reinforced Mortar in An Aggressive EnvironmentDocument9 paginiMechanical Behavior and Durability of Fibre Reinforced Mortar in An Aggressive EnvironmentAnonymous LEVNDh4Încă nu există evaluări

- Study on Preventing Rebar Corrosion with Sacrificial AnodesDocument8 paginiStudy on Preventing Rebar Corrosion with Sacrificial AnodesNew NSskinÎncă nu există evaluări

- Effect of Water-Based Nanolubricant Containing nano-TiO2 On FrictDocument28 paginiEffect of Water-Based Nanolubricant Containing nano-TiO2 On FrictFrancois BornmanÎncă nu există evaluări

- Geopolymer ConcreteDocument13 paginiGeopolymer ConcreteBramantyo WijayaÎncă nu există evaluări

- Experimental Study On Mechanical PropertDocument6 paginiExperimental Study On Mechanical Propertsamreenzeba444Încă nu există evaluări

- Optimizing Study of Some Factors That Influence The PerformanceDocument11 paginiOptimizing Study of Some Factors That Influence The PerformanceJoel OkohÎncă nu există evaluări

- Termkhajornkit2009 Study of Self Healing Ability of Flyash Cement SystemsDocument9 paginiTermkhajornkit2009 Study of Self Healing Ability of Flyash Cement SystemsDEEBA S 20PHD1159Încă nu există evaluări

- Corrosion Behavior of Reinforcing Steel Embedded in Fly Ash ConcreteDocument7 paginiCorrosion Behavior of Reinforcing Steel Embedded in Fly Ash ConcreteAlmas XamiÎncă nu există evaluări

- Properties of Concrete Incorporating Nano-SilicaDocument7 paginiProperties of Concrete Incorporating Nano-SilicaChan NovÎncă nu există evaluări

- The Influence of Chloride Contents in Sands On Reinforcement CorrosionDocument8 paginiThe Influence of Chloride Contents in Sands On Reinforcement CorrosionPrashant DevdaÎncă nu există evaluări

- Anticorrosive Effect of Electrochemical Manganese Dioxide By-Products in Reinforced ConcreteDocument13 paginiAnticorrosive Effect of Electrochemical Manganese Dioxide By-Products in Reinforced Concreteselvi1056Încă nu există evaluări

- Surface Tolerant Coatings NW NACE2004 PDFDocument9 paginiSurface Tolerant Coatings NW NACE2004 PDFpaola100% (1)

- Experimental design for copper cementationDocument5 paginiExperimental design for copper cementationYashika ca20m007Încă nu există evaluări

- Effect of Calcium Nitrate and Sodium Nitrite On The Rebar Corrosion of Medium Carbon Steel in Seawater and Cassava FluidDocument7 paginiEffect of Calcium Nitrate and Sodium Nitrite On The Rebar Corrosion of Medium Carbon Steel in Seawater and Cassava FluidMohammed AdamuÎncă nu există evaluări

- The Use of Blast Furnace Slag As A Supplementary CDocument13 paginiThe Use of Blast Furnace Slag As A Supplementary CCivil manÎncă nu există evaluări

- Early Age Properties of Self-Compacting Concrete - Effects of Fine Aggregate and Limestone Filler - ThesisDocument206 paginiEarly Age Properties of Self-Compacting Concrete - Effects of Fine Aggregate and Limestone Filler - ThesisyoussefÎncă nu există evaluări

- Corrosion of Steel Rebar Embedded in Ternary Blended Concrete Exposed To High Humidity EnvironmentDocument7 paginiCorrosion of Steel Rebar Embedded in Ternary Blended Concrete Exposed To High Humidity EnvironmentAlmas XamiÎncă nu există evaluări

- Effect of expanded perlite on thermal properties of clay bricksDocument9 paginiEffect of expanded perlite on thermal properties of clay bricksvaleriacostacivilÎncă nu există evaluări

- Full Paper A.sprince DundeeDocument12 paginiFull Paper A.sprince DundeeFreddy HutaurukÎncă nu există evaluări

- Geopolymer Cements and Their Properties A ReviewDocument17 paginiGeopolymer Cements and Their Properties A ReviewSergioAndresEspinozaSilvaÎncă nu există evaluări

- Afzalinaniz 2018Document49 paginiAfzalinaniz 2018Moncea AndreeaÎncă nu există evaluări

- Translucent Concrete Mechanical Properties EvaluationDocument8 paginiTranslucent Concrete Mechanical Properties EvaluationsehunÎncă nu există evaluări

- Bio Concrete Review: Bacteria Types and Effects on Concrete PropertiesDocument13 paginiBio Concrete Review: Bacteria Types and Effects on Concrete PropertiesABHIJEET DHOBALEÎncă nu există evaluări

- 2016 SEMCHol AliDocument5 pagini2016 SEMCHol AliCalvin TehÎncă nu există evaluări

- A Review of The Possible Applications of Nanotechnology in Refractory ConcreteDocument9 paginiA Review of The Possible Applications of Nanotechnology in Refractory ConcreteamnajamÎncă nu există evaluări

- A.M. Said Et Al. (2012)Document7 paginiA.M. Said Et Al. (2012)arorathevipulÎncă nu există evaluări

- Construction and Building Materials: I. Feurgard, C. Lors, R. Gagné, D. DamidotDocument8 paginiConstruction and Building Materials: I. Feurgard, C. Lors, R. Gagné, D. DamidotEdgar Enrique Vilca RomeroÎncă nu există evaluări

- A Review Paper On The Effect of Sulphate Attack On Concrete DurabilityDocument7 paginiA Review Paper On The Effect of Sulphate Attack On Concrete DurabilityIJRASETPublicationsÎncă nu există evaluări

- Nano SilicaDocument11 paginiNano Silicacibif40663Încă nu există evaluări

- European Polymer Journal: Beibei Li, Xiaoyan Liu, Xinying Zhang, Wenbo ChaiDocument6 paginiEuropean Polymer Journal: Beibei Li, Xiaoyan Liu, Xinying Zhang, Wenbo ChaiDhurgham QuasimÎncă nu există evaluări

- Accelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesDocument9 paginiAccelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesAlmas XamiÎncă nu există evaluări

- Major Project A4Document22 paginiMajor Project A4Vamshi ChinthalaÎncă nu există evaluări

- VanDeventer Provis DuxsonBrice WasteBiomassValorization Vol1no1 2010 pp145-155Document12 paginiVanDeventer Provis DuxsonBrice WasteBiomassValorization Vol1no1 2010 pp145-155زھرة ٱلبيلسآنÎncă nu există evaluări

- Bernal 2011Document8 paginiBernal 2011Jamman Shahid ShiblyÎncă nu există evaluări

- Utilisation of Foundry Sand in Concrete ProductionDocument9 paginiUtilisation of Foundry Sand in Concrete ProductionDhiraj YelmateÎncă nu există evaluări

- Effect of Using Wastewater On The Properties of High Strength ConcreteDocument8 paginiEffect of Using Wastewater On The Properties of High Strength ConcreteMarcial Sandy ChoqueÎncă nu există evaluări

- A Rafa 722015 Js RR 16824Document9 paginiA Rafa 722015 Js RR 16824Benharzallah KrobbaÎncă nu există evaluări

- Kamath2021 Chapter ReviewOfLowToHighStrengthAlkalDocument9 paginiKamath2021 Chapter ReviewOfLowToHighStrengthAlkalMuralidhar KamathÎncă nu există evaluări

- Cube TestDocument10 paginiCube Testridhuanzainal100% (1)

- Some Aspects of The Effect of Porosity On Moisture Transfer in ConcreteDocument6 paginiSome Aspects of The Effect of Porosity On Moisture Transfer in ConcreteResearch ParkÎncă nu există evaluări

- Numerical Study of Two-Phase Flow in Centrifugal Dust CollectorsDocument6 paginiNumerical Study of Two-Phase Flow in Centrifugal Dust CollectorsResearch ParkÎncă nu există evaluări

- Civil Engineering JournalDocument9 paginiCivil Engineering JournalharshitÎncă nu există evaluări

- The Permeability at Ions Chlorinates As Indicator of Durability of ConcretesDocument4 paginiThe Permeability at Ions Chlorinates As Indicator of Durability of ConcretesInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Performance of Slag Concrete in Marine Environment: Aci Materials Journal Technical PaperDocument7 paginiPerformance of Slag Concrete in Marine Environment: Aci Materials Journal Technical PaperangthiankongÎncă nu există evaluări

- An Experimental Study On The Internal Corrosion of A Subsea Multiphase PipelineDocument7 paginiAn Experimental Study On The Internal Corrosion of A Subsea Multiphase PipelineYogaÎncă nu există evaluări

- Evaluation of Methods Used To Quantify The Durability of Coal-Biomass BriquettesDocument11 paginiEvaluation of Methods Used To Quantify The Durability of Coal-Biomass BriquettesChanaÎncă nu există evaluări

- Influence of Graphene Nanoplatelet and Silver Nanoparticle On The Rheological Properties of Water-Based MudDocument13 paginiInfluence of Graphene Nanoplatelet and Silver Nanoparticle On The Rheological Properties of Water-Based MudAsif Abdur RehmanÎncă nu există evaluări

- Effect of Nanobubbles On The Flotation of Different Sizes of Coal ParticlesDocument6 paginiEffect of Nanobubbles On The Flotation of Different Sizes of Coal ParticlesronypassÎncă nu există evaluări

- Nanocoatings: Randa Abdel-KarimDocument37 paginiNanocoatings: Randa Abdel-KarimEnrique FrancoÎncă nu există evaluări

- Long-Term Testing of The Chloride-Penetration Resistance of Concrete Containing High-Reactivity MetakaolinDocument7 paginiLong-Term Testing of The Chloride-Penetration Resistance of Concrete Containing High-Reactivity MetakaolinAboalmaail AlaminÎncă nu există evaluări

- Ijresm V5 I9 1Document4 paginiIjresm V5 I9 1MS GeorgeÎncă nu există evaluări

- 2 Properties of Ultra Highperformancefiberconcreteuhpfcunderdifferentcuringregimes PDFDocument10 pagini2 Properties of Ultra Highperformancefiberconcreteuhpfcunderdifferentcuringregimes PDFLawend KoramarkiÎncă nu există evaluări

- A Study On The Use of Foundry Sand As A Sustainable Construction Material A ReviewDocument10 paginiA Study On The Use of Foundry Sand As A Sustainable Construction Material A ReviewIJRASETPublicationsÎncă nu există evaluări

- Ordered Porous Solids: Recent Advances and ProspectsDe la EverandOrdered Porous Solids: Recent Advances and ProspectsValentin ValtchevÎncă nu există evaluări

- 1-Kromatografi Kolom Dan Lapis TipisDocument9 pagini1-Kromatografi Kolom Dan Lapis TipisSelvia VeronikaÎncă nu există evaluări

- RoClean L403Document1 paginăRoClean L403eduardoÎncă nu există evaluări

- (Shima and Afshan, 3C) BMS Water-Proofing Market Survey (Group 4)Document17 pagini(Shima and Afshan, 3C) BMS Water-Proofing Market Survey (Group 4)Shima SharafÎncă nu există evaluări

- 10.1007@978 981 15 3669 4Document388 pagini10.1007@978 981 15 3669 4Muhammad Abdur RashidÎncă nu există evaluări

- A Study On The Initial Corrosion Behavior of Carbon Steel Exposed To Outdoor Wet-Dry Cyclic ConditionDocument12 paginiA Study On The Initial Corrosion Behavior of Carbon Steel Exposed To Outdoor Wet-Dry Cyclic ConditionHa Linh VuÎncă nu există evaluări

- Paint defects guide: causes and remediesDocument13 paginiPaint defects guide: causes and remediesMohamed NouzerÎncă nu există evaluări

- Wooden Boat Building Sheets Translation DraftDocument68 paginiWooden Boat Building Sheets Translation DraftJoao Calinho100% (1)

- General Specs and Steel and Aluminium WorksDocument10 paginiGeneral Specs and Steel and Aluminium WorksPoojaÎncă nu există evaluări

- Delta-Protekt® KL 105: Article Number: 08405488Document5 paginiDelta-Protekt® KL 105: Article Number: 08405488Mustafa AydemirÎncă nu există evaluări

- Conceptualized Transmutation Reactor To Mass-Produce Helium-3 and Precious MetalsDocument28 paginiConceptualized Transmutation Reactor To Mass-Produce Helium-3 and Precious MetalsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- WMM Moisture Correction SheetDocument34 paginiWMM Moisture Correction SheetQuality JamÎncă nu există evaluări

- Care Label Booking Buyer-Enorsia Date-04.08.23Document1 paginăCare Label Booking Buyer-Enorsia Date-04.08.23itmukul24Încă nu există evaluări

- RW Ti Pds Prorox WM 960 Astm IndiaDocument1 paginăRW Ti Pds Prorox WM 960 Astm IndiaLee Kok RoyÎncă nu există evaluări

- Floor hardener for heavy traffic areasDocument2 paginiFloor hardener for heavy traffic areasMahmoudÎncă nu există evaluări

- Designation Codes for Harmonized CablesDocument7 paginiDesignation Codes for Harmonized Cablesvinayak.khorate2707Încă nu există evaluări

- Lec 10 Week (7) (Water Distribution System)Document27 paginiLec 10 Week (7) (Water Distribution System)Ahmad RazaÎncă nu există evaluări

- Steps in Making Denture BaseDocument4 paginiSteps in Making Denture BaseRosette Go100% (1)

- Problems in The Cement Industry PDFDocument35 paginiProblems in The Cement Industry PDFAnujKumarVermaÎncă nu există evaluări

- Mapua Chm143L Organic Chemistry 2 Lab ReportDocument7 paginiMapua Chm143L Organic Chemistry 2 Lab ReportMaiSakurajimaÎncă nu există evaluări

- Htfine SitemapDocument5 paginiHtfine SitemapQin HuinaÎncă nu există evaluări

- Práctica 3, Equipo 5 - TermodinámicaDocument5 paginiPráctica 3, Equipo 5 - TermodinámicaCristian JiménezÎncă nu există evaluări

- Fr4tg135 UkDocument1 paginăFr4tg135 UkAnonymous zBSE9MÎncă nu există evaluări

- Know All About Jewelry Maki NG Jewelry Desi Gni NG and Metal Worki NG PDFDocument116 paginiKnow All About Jewelry Maki NG Jewelry Desi Gni NG and Metal Worki NG PDFhung garul100% (2)

- Title: Project Report On Polyester Webbing: Subject: Project Management in EngineeringDocument6 paginiTitle: Project Report On Polyester Webbing: Subject: Project Management in EngineeringShahbaz ahmad100% (1)

- Topic 1 StudentDocument34 paginiTopic 1 Studentnayana wanasingheÎncă nu există evaluări

- Lubricants 05 00044Document17 paginiLubricants 05 00044Jesus OcampoÎncă nu există evaluări

- Anleitung Lesezeichen Utl KWenDocument2 paginiAnleitung Lesezeichen Utl KWenfaomosgirlÎncă nu există evaluări

- 3-1 Fuels LabDocument33 pagini3-1 Fuels LabP.v RaoÎncă nu există evaluări

- Permalok Steel Casing Pipe For Microtunneling and Other Jacking ApplicationsDocument36 paginiPermalok Steel Casing Pipe For Microtunneling and Other Jacking Applicationsvmi_dude100% (2)

- Evaluating Cu-W Composite Powder Metallurgy ProcessesDocument24 paginiEvaluating Cu-W Composite Powder Metallurgy Processesmuthu kumarÎncă nu există evaluări