Documente Academic

Documente Profesional

Documente Cultură

Ama-Grease Brochure 17.9

Încărcat de

luvfearDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ama-Grease Brochure 17.9

Încărcat de

luvfearDrepturi de autor:

Formate disponibile

KSB Customized Grease Separator System Solutions

NS 4/7/10/15/20/25/30

Advantages: Other sizes available upon request. Ama-Grease

1. Ama-Grease separator compartment made of 4.5mm thick

SS304L (default) / SS316L stainless steel plate. Customizable 2-compartment

Stainless Steel 304L / 316L

2. More durable and better fire resistance than materials like

Sludge & Grease Separator

Fibreglass and Polyethylene. Grease

Chamber

3. 2-compartment chamber design with slope bottom. Grease & Sludge

sludge holding capacity not affected by “The 25% Rule”. Chamber Comply with BS EN 1825-1 Standard

2-compartment

Unlike those single-compartment grease separator. effluent quality is

always better than Approved for used in Singapore by PUB

4. Free standing type comes with air-tight SS304L (default) / 1-compartment

SS316L 600x600mm square cover. Suitable for Free Standing and Grease/Sludge

5. Underground type comes with SS304L (default) / SS316L

Underground installation Positive Displacement Customizable System

Disposal Pump

600x600mm extension collar. EN 124 Standard 600x600mm

air tight manhole covers by others.

Grease Layer Sensors PLC Master & Remote

(Can be connected to BMS)

6. (Optional) Fully automatic, program-controlled Control Panels

(Can be connected to BMS)

sludge/grease disposal pump system with IP55 master and

remote control panel.

7. (Optional) Fully automatic Ø4”/100mm disposal pipe flushing

system to minimize pipe clogging.

8. Odour-free disposal. Air vent pipe is required.

Ama-Grease KSB Customized Disposal Pipe (4")

9. (Optional) Bigger sludge holding capacity available upon 2-compartment

Grease Separator Flushing Feature

request (Standard is NS x 100 in Litres). Separator Only

System Solutions

10. (Optional) Bigger Inlet & Outlet sizes and different

orientation available upon request.

11. 10-year warranty for Ama-Grease stainless steel SS304L

(default) / SS316L body.

12. (Optional) Grease layer monitoring devices designed to

KSB Solutions cater to the Needs of every Project while keeping to the Constraints of the Site.

comply EN 1825 and DIN 4040 norms.

17.9 vers. Page 1

Minimum Minimum

H (mm) ● Detailed design and

*Nominal Inlet & Air Vent Sludge Grease Inlet Outlet

Total Wet For Free value engineering

Ama-Grease

Size Outlet Pipe Pipe DN Chamber Storage L (mm) W (mm) Invert H Invert H Fall (mm) advice.

Volume Standing

(NS) DN (mm) (mm) Volume Capacity (mm) (mm)

Type

(NS x 100) (NS x 40) ● Hydraulic calculations

4 150 150 400 L 160 L 1580 L 2500 800 1440 1040 970 70 for peak flow rate and

sludge/grease disposal

7 150 150 700 L 280 L 2525 L 2700 1100 1500 1100 1030 70 pump.

10 150 150 1000 L 400 L 3829 L 3100 1300 1600 1200 1130 70

● Technical and

15 200 200 1500 L 600 L 5731 L 3560 1533 1700 1300 1230 70 installation advice.

20 200 200 2000 L 800 L 8575 L 4700 1533 1775 1440 1370 70

25 200 200 2500 L 1000 L 10603 L 4950 1800 1775 1440 1370 70 Contact KSB

Building Services Team

30 200 200 3000 L 1200 L 12733 L 5350 2000 1775 1440 1370 70

*Other NS sizes available upon request.

*NS = Qpeakflow x Density factor x Temp. factor x Detergent factor

"The 25% RULE" does not apply on

2-compartment grease separator.

Partition Wall

Sludge Grease

Grease Layer Sensor

Chamber Chamber

Partition Wall

Sludge Grease

Chamber Chamber

Copyright

The contents of this brochure and its layout are the property of KSB and are

copyright protected. Any copying of the brochure or its individual contents is

prohibited without the express permission of the owner and is subject to

prosecution or civil judgements. All rights reserved.

●Above Typical Free Standing installation.

●Underground installation comes with SS extension collar. Rights reserved for technical changes.

(Not shown)

17.9 vers. Page 2

S-ar putea să vă placă și

- Individualized Education PlanDocument7 paginiIndividualized Education PlanElaine Aninang Hupeda100% (2)

- Dr. Berg's Favorite HEALTHY JUNK FOODS & Other AlternativesDocument23 paginiDr. Berg's Favorite HEALTHY JUNK FOODS & Other Alternativesprashant_padte100% (8)

- 432 HZ - Unearthing The Truth Behind Nature's FrequencyDocument6 pagini432 HZ - Unearthing The Truth Behind Nature's FrequencyShiv KeskarÎncă nu există evaluări

- Essential Rubber Formulary: Formulas for PractitionersDe la EverandEssential Rubber Formulary: Formulas for PractitionersEvaluare: 3 din 5 stele3/5 (1)

- Medical PhysicsDocument81 paginiMedical Physicsroni roniÎncă nu există evaluări

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsDe la EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsEvaluare: 4 din 5 stele4/5 (1)

- API 682 4th Edition Application GuideDocument31 paginiAPI 682 4th Edition Application Guidearunima04Încă nu există evaluări

- Performance and Mechanical Running Tests of Centrifugal CompressorsDocument5 paginiPerformance and Mechanical Running Tests of Centrifugal CompressorsVicky KumarÎncă nu există evaluări

- Bomag 40 PDFDocument20 paginiBomag 40 PDFIGNACIOÎncă nu există evaluări

- HBSE-Mock ExamDocument3 paginiHBSE-Mock ExamAnneÎncă nu există evaluări

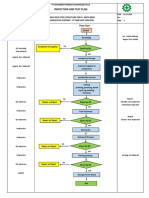

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 paginăInspection and Test Plan: Flow Chart Start IncomingSinden AyuÎncă nu există evaluări

- Diploma Pharmacy First Year - Hap - MCQSDocument13 paginiDiploma Pharmacy First Year - Hap - MCQSAnitha Mary Dambale91% (33)

- D Formation Damage StimCADE FDADocument30 paginiD Formation Damage StimCADE FDAEmmanuel EkwohÎncă nu există evaluări

- Halton DSH Datasheet 2020Document14 paginiHalton DSH Datasheet 2020Reno MeatShopÎncă nu există evaluări

- Models 3180/3185Document40 paginiModels 3180/3185Israel ColinaÎncă nu există evaluări

- Abanaki Oil Grabber Model MBDocument4 paginiAbanaki Oil Grabber Model MBSepti fitriyaÎncă nu există evaluări

- Filter 169-460-...Document1 paginăFilter 169-460-...AÎncă nu există evaluări

- GP - AF - Low 1Document8 paginiGP - AF - Low 1maguilar20Încă nu există evaluări

- LIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBDocument1 paginăLIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBHicham BenÎncă nu există evaluări

- Marine Dual Remote Filtration System Order Online atDocument2 paginiMarine Dual Remote Filtration System Order Online atBruce WappmanÎncă nu există evaluări

- Shell Paper Machine Oil S3 M 220Document3 paginiShell Paper Machine Oil S3 M 220DENNY BAYUAJIÎncă nu există evaluări

- Multi-Channel Open Impeller: Submersible PumpsDocument12 paginiMulti-Channel Open Impeller: Submersible PumpsXuan Khanh maÎncă nu există evaluări

- Solutions For Industrial Applications: Chemineer™ Small MixerDocument6 paginiSolutions For Industrial Applications: Chemineer™ Small MixerSandeep K TiwariÎncă nu există evaluări

- Textar BRO BrakeDisc ENG WEBDocument8 paginiTextar BRO BrakeDisc ENG WEBhoussem houssemÎncă nu există evaluări

- PTG Facet Marine CatalogDocument79 paginiPTG Facet Marine CatalogEdmund LimÎncă nu există evaluări

- Begg Cousland Envirotec - Oil & Gas - 2017Document8 paginiBegg Cousland Envirotec - Oil & Gas - 2017Wili Nur RahmanÎncă nu există evaluări

- Burckhardt Plate Valve™: The Long Running Valve - Best in O ApplicationsDocument4 paginiBurckhardt Plate Valve™: The Long Running Valve - Best in O ApplicationsgemagdyÎncă nu există evaluări

- PDS Top Tec 6300 0W-20Document1 paginăPDS Top Tec 6300 0W-20Akbar SaputroÎncă nu există evaluări

- P000290 Formula Super 20W 50 41 en - GBDocument1 paginăP000290 Formula Super 20W 50 41 en - GBOmer IkhlasÎncă nu există evaluări

- Ficha Tecnica Castrol Optigear BM RangeDocument3 paginiFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezÎncă nu există evaluări

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 paginiSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosÎncă nu există evaluări

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 paginiDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- Atlas Copco: Small Portable Air CompressorsDocument2 paginiAtlas Copco: Small Portable Air CompressorsAsad AijazÎncă nu există evaluări

- AMSOIL Oil Filters: Superior Oil Filtration For Cars and Light TrucksDocument2 paginiAMSOIL Oil Filters: Superior Oil Filtration For Cars and Light TrucksbassamÎncă nu există evaluări

- AmsoilSyntheticOilProductInfo SheetsDocument2 paginiAmsoilSyntheticOilProductInfo Sheetsapi-19921780Încă nu există evaluări

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 paginăP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaÎncă nu există evaluări

- 5 ImpactsDocument60 pagini5 ImpactsfaisalnadimÎncă nu există evaluări

- Coalescer SeparatorDocument1 paginăCoalescer Separatoramol shindeÎncă nu există evaluări

- 187 - GB - 200809 CL 3... C 9Document8 pagini187 - GB - 200809 CL 3... C 9Ghufran KhanÎncă nu există evaluări

- EfekDocument2 paginiEfekGasa RafliÎncă nu există evaluări

- P004547 Top Tec 6300 0W 20 11 en - GBDocument1 paginăP004547 Top Tec 6300 0W 20 11 en - GBHaja_01Încă nu există evaluări

- Suzuki Marine Gear Oil 90 en FR MotulDocument1 paginăSuzuki Marine Gear Oil 90 en FR MotulAbu Abdou SiyahyaÎncă nu există evaluări

- SCOOTER POWER 4T 10W-30 MB en FR Motul 20210310Document2 paginiSCOOTER POWER 4T 10W-30 MB en FR Motul 20210310Sarathy S SachinÎncă nu există evaluări

- Product Information: Special Tec AA 10W-30 BenzinDocument1 paginăProduct Information: Special Tec AA 10W-30 BenzinMuhÎncă nu există evaluări

- Catalog May Bom Tsurumi Serie KTZ (E)Document6 paginiCatalog May Bom Tsurumi Serie KTZ (E)phamtungiq102Încă nu există evaluări

- Generador de Aerosoles TopasDocument2 paginiGenerador de Aerosoles TopasFerenc SzekeresÎncă nu există evaluări

- SKF Filament Wound BushingsDocument8 paginiSKF Filament Wound BushingsWes VendrigÎncă nu există evaluări

- P004087 Leichtlauf Energy 0W 40 17 en - GBDocument1 paginăP004087 Leichtlauf Energy 0W 40 17 en - GBHalil Marcelo SejkicÎncă nu există evaluări

- A600Document2 paginiA600Sasi KumarÎncă nu există evaluări

- Grease Ep 2 Data Sheet tcsl0003Document1 paginăGrease Ep 2 Data Sheet tcsl0003Abdulwahed alsafanyÎncă nu există evaluări

- Hynds Oil and Grit Interceptor SW6Document4 paginiHynds Oil and Grit Interceptor SW6EmolNZÎncă nu există evaluări

- P000335 Special Tec AA 5W 20 61 en - GBDocument2 paginiP000335 Special Tec AA 5W 20 61 en - GBAXIS LUBRIFICANTESÎncă nu există evaluări

- 8100 X-Power 10W60 (EN)Document1 pagină8100 X-Power 10W60 (EN)Márton MolnárÎncă nu există evaluări

- Shell Turbo Oil T 68 Technical Data SheetDocument2 paginiShell Turbo Oil T 68 Technical Data SheetMuhammad SaputraÎncă nu există evaluări

- Shell Turbo Oil T 68 Technical Data SheetDocument2 paginiShell Turbo Oil T 68 Technical Data SheetAntonio CardosoÎncă nu există evaluări

- TDS Shell Mysella S6 N 40Document2 paginiTDS Shell Mysella S6 N 40MUHAMMAD LUTHFIÎncă nu există evaluări

- Edx10 11Document8 paginiEdx10 11Fernando NapitupuluÎncă nu există evaluări

- Gadus S2 V 100 3Document2 paginiGadus S2 V 100 3Anonymous ABPUPbKÎncă nu există evaluări

- TDS Total Ceran-Xm-220 4KF 201607 en UsaDocument2 paginiTDS Total Ceran-Xm-220 4KF 201607 en Usathe anhÎncă nu există evaluări

- Shell Morlina s2 BL 10 France TdsDocument2 paginiShell Morlina s2 BL 10 France TdsRolando GuijarroÎncă nu există evaluări

- SB43-II TS-P: SB Series Breaker SB Series Breaker SB Series Breaker SB Series BreakerDocument1 paginăSB43-II TS-P: SB Series Breaker SB Series Breaker SB Series Breaker SB Series BreakerjoseivanmuÎncă nu există evaluări

- Tin Mill Products, Black Plate, Double Reduced: Standard Specification ForDocument2 paginiTin Mill Products, Black Plate, Double Reduced: Standard Specification Forist93993Încă nu există evaluări

- Petronas Disrol 50: Premium Quality 6 TBN Marine Diesel Engine OilsDocument1 paginăPetronas Disrol 50: Premium Quality 6 TBN Marine Diesel Engine OilsHazrulnizam HassanÎncă nu există evaluări

- Phenoline 187 Primer and FinishDocument2 paginiPhenoline 187 Primer and Finish이선엽Încă nu există evaluări

- 3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Document2 pagini3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Sebastian SalazarÎncă nu există evaluări

- Admix Datasheet Boston ShearmillDocument2 paginiAdmix Datasheet Boston ShearmillVishal SalveÎncă nu există evaluări

- Fleetlife Moisture Master BrochureDocument6 paginiFleetlife Moisture Master BrochureFL Paul BÎncă nu există evaluări

- Sandtrap Louver DetailedDocument10 paginiSandtrap Louver Detailedzahee007Încă nu există evaluări

- Shell Mysella S7 N Ultra 40: Performance, Features & BenefitsDocument2 paginiShell Mysella S7 N Ultra 40: Performance, Features & BenefitsMudabbir Shan AhmedÎncă nu există evaluări

- You'll Retire Before It Does.: So DurableDocument2 paginiYou'll Retire Before It Does.: So DurableluvfearÎncă nu există evaluări

- TZ-400 Techincal SpecificationDocument2 paginiTZ-400 Techincal SpecificationluvfearÎncă nu există evaluări

- MacroAir - AirVolution PDFDocument2 paginiMacroAir - AirVolution PDFluvfearÎncă nu există evaluări

- SynergyDocument39 paginiSynergyluvfearÎncă nu există evaluări

- Navisworks Appearance Profiler PDFDocument3 paginiNavisworks Appearance Profiler PDFluvfearÎncă nu există evaluări

- HVLS - Eurus II AHE PDFDocument2 paginiHVLS - Eurus II AHE PDFluvfearÎncă nu există evaluări

- Guideline on Boundary Noise Limits for AC and Ventilation SystemsDocument11 paginiGuideline on Boundary Noise Limits for AC and Ventilation SystemsluvfearÎncă nu există evaluări

- Mallia Express Yourself Like Never BeforeDocument26 paginiMallia Express Yourself Like Never BeforeluvfearÎncă nu există evaluări

- Arteor B2B PDFDocument162 paginiArteor B2B PDFluvfearÎncă nu există evaluări

- My Interior LandscapesDocument19 paginiMy Interior LandscapesluvfearÎncă nu există evaluări

- PLEXO Catalogue 01 PDFDocument12 paginiPLEXO Catalogue 01 PDFluvfearÎncă nu există evaluări

- Arteor Leaflet 2011 PDFDocument32 paginiArteor Leaflet 2011 PDFluvfearÎncă nu există evaluări

- Arteor B2CDocument56 paginiArteor B2CluvfearÎncă nu există evaluări

- Imple Reasons To Switch: BelankoDocument24 paginiImple Reasons To Switch: BelankoluvfearÎncă nu există evaluări

- Wiring Devices/Home Automation Systems: ArteorDocument62 paginiWiring Devices/Home Automation Systems: ArteorluvfearÎncă nu există evaluări

- Load Rate: Test ReportDocument1 paginăLoad Rate: Test ReportluvfearÎncă nu există evaluări

- Arteor Leaflet 2011 PDFDocument32 paginiArteor Leaflet 2011 PDFluvfearÎncă nu există evaluări

- VivaceDocument6 paginiVivaceluvfearÎncă nu există evaluări

- Guide To Sewage Development ControlDocument13 paginiGuide To Sewage Development ControlluvfearÎncă nu există evaluări

- SE BrochureDocument28 paginiSE BrochureluvfearÎncă nu există evaluări

- Progress As A Tradition: Fresh Ideas For Your HomeDocument15 paginiProgress As A Tradition: Fresh Ideas For Your HomeluvfearÎncă nu există evaluări

- Fee 2010Document22 paginiFee 2010gohviccÎncă nu există evaluări

- Fee 2016Document42 paginiFee 2016Manoj GuptaÎncă nu există evaluări

- SWV Series SNOW trPVC pipes soil waste vent systemsDocument1 paginăSWV Series SNOW trPVC pipes soil waste vent systemsluvfearÎncă nu există evaluări

- DF-0414 01Document2 paginiDF-0414 01luvfearÎncă nu există evaluări

- Excavation Safe Work ProcedureDocument2 paginiExcavation Safe Work ProcedureluvfearÎncă nu există evaluări

- Fee 2010Document22 paginiFee 2010gohviccÎncă nu există evaluări

- Section4 PDFDocument3 paginiSection4 PDFluvfearÎncă nu există evaluări

- Fee 2016Document42 paginiFee 2016Manoj GuptaÎncă nu există evaluări

- SK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Document30 paginiSK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Viktor RégerÎncă nu există evaluări

- Treating Thyroid Emergencies: Myxedema Coma and Thyroid StormDocument17 paginiTreating Thyroid Emergencies: Myxedema Coma and Thyroid StormMarlon UlloaÎncă nu există evaluări

- ZP Series Silicon Rectifier: Standard Recovery DiodesDocument1 paginăZP Series Silicon Rectifier: Standard Recovery DiodesJocemar ParizziÎncă nu există evaluări

- Airborne Life Support Systems In-House Infant Transport Sys 185A Infant Incubator - Manufacturer SpecificationsDocument2 paginiAirborne Life Support Systems In-House Infant Transport Sys 185A Infant Incubator - Manufacturer SpecificationsAsistir Biomedica SASÎncă nu există evaluări

- Soil properties problemsDocument2 paginiSoil properties problemsAldrin LampareroÎncă nu există evaluări

- Temporomandibular Joint SyndromeDocument11 paginiTemporomandibular Joint SyndromeRahma RahmaÎncă nu există evaluări

- Separation/Termination of Employment Policy SampleDocument4 paginiSeparation/Termination of Employment Policy SampleferÎncă nu există evaluări

- Eu Donor Atlas PDFDocument2 paginiEu Donor Atlas PDFBrentÎncă nu există evaluări

- Genset Ops Manual 69ug15 PDFDocument51 paginiGenset Ops Manual 69ug15 PDFAnonymous NYymdHgy100% (1)

- Ulcus Decubitus PDFDocument9 paginiUlcus Decubitus PDFIrvan FathurohmanÎncă nu există evaluări

- Amaryllidaceae Family Guide with Endemic Philippine SpeciesDocument28 paginiAmaryllidaceae Family Guide with Endemic Philippine SpeciesMa-anJaneDiamos100% (1)

- PR Cuisine vs US CuisineDocument2 paginiPR Cuisine vs US CuisineJannette HernandezÎncă nu există evaluări

- Acute Coronary Syndrome Guidelines 2020Document79 paginiAcute Coronary Syndrome Guidelines 2020Γιώργος ΕλευθεριάδηςÎncă nu există evaluări

- Impact of Dairy Subsidies in NepalDocument123 paginiImpact of Dairy Subsidies in NepalGaurav PradhanÎncă nu există evaluări

- Solucionario. Advanced Level.Document68 paginiSolucionario. Advanced Level.Christian Delgado RamosÎncă nu există evaluări

- Edna Adan University ThesisDocument29 paginiEdna Adan University ThesisAbdi KhadarÎncă nu există evaluări

- CSK - W - My - Mother - at - Sixty - Six 2Document2 paginiCSK - W - My - Mother - at - Sixty - Six 2Aaron JoshiÎncă nu există evaluări

- The Congressional Committee and Philippine Policymaking: The Case of The Anti-Rape Law - Myrna LavidesDocument29 paginiThe Congressional Committee and Philippine Policymaking: The Case of The Anti-Rape Law - Myrna LavidesmarielkuaÎncă nu există evaluări

- Rundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967Document15 paginiRundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967nixyingboÎncă nu există evaluări

- Plant Cell Culture: Genetic Information and Cellular MachineryDocument18 paginiPlant Cell Culture: Genetic Information and Cellular MachineryYudikaÎncă nu există evaluări

- Steps of Repertorization - 5e097dab9ad98Document18 paginiSteps of Repertorization - 5e097dab9ad98Sowjanya JyothsnaÎncă nu există evaluări