Documente Academic

Documente Profesional

Documente Cultură

Catalog

Încărcat de

ravi474Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Catalog

Încărcat de

ravi474Drepturi de autor:

Formate disponibile

About Tokyo Rope Innovative HTLS Transmission Conductor With ® Core

Tokyo Rope was established in 1887

and has been the leader in Japan's wire

rope industry. Our global operations

are expanding. Our main products are

Steel Wire Rope, Fiber Rope, Steel Cord

for tire, and CFCC.

ALUMINUM CONDUCTOR FIBER REINFORCED

Low Loss

China

● Shanghai office

● Hong Kong office

Russia

●Moscow Office

High

Capacity

USA

● Detroit Office

Japan Head Office ● Michigan CFCC Plant

●

●

Gamagori CFCC Plant

Tsuchiura Plant

●Kitakami Plant

Low Sag

●Kitakami Works

●Sakai Plant

●Tokyo Seiko Rope

●Ako Rope

Kazakhstan

●

Astana City Office Vietnam Brazil

●

Almaty Plant ●Binh Duong Plant ●Rio de Janeiro Office

Thailand

● Bangkok Office

Click here

TOKYO ROPE MFG. CO., LTD.

NIHONBASHI FRONT BLDG. 6-2 NIHONBASHI 3-CHOME CHUO-KU TOKYO 103-8306 JAPAN

Tel.: + 81 3 6366 7731, Fax: +81 3 3278 6870

http://www.tokyorope.co.jp/english/product/acfr/index.html

E-mail: inquiry_cfcc@tokyorope.co.jp

TOKYO ROPE MFG. CO., LTD.

17-03-SA

Today's Overhead Conductor's market

Current Status Challenge

Transmission Owners are facing

ACSR is a conventional type

the following requirements:

of conductor which has

● Huge Electric Demand

three drawbacks as follows:

● Environmental Concern(CO2)

● Heavy steel core ● Sag Violations

● Large Thermal Expansion ● Right of Way Issue

● Corrosion

● Construction Cost & Period

● Lower Life Cycle Cost

Solution

Next generation conductor

cable=

● Low Transmission Loss

● High Transmission Capacity

● Low Sag

● Longevity

● Easy Handling

ACFR Structure

ACFR stands for Aluminum Conductor Fiber Reinforced

Core Light Weight and Small Thermal Expansion

Trapezoidal Aluminum Wire Large Cross Sectional Area

Core

Annealed Aluminum Wire

(or TAL / Hard Drawn Wire)

Trapezoidal Shape

ALUMINUM CONDUCTOR FIBER REINFORCED

ALUMINUM CONDUCTOR FIBER REINFORCED

Case Study Accessories (Dead End Clamp and Mid Span Joint)

Performance Example compared to ACSR Basic Design is the same as those for the conventional ACSR conductor,

Design Concept Transmission Loss Transmission Capaicty Sag except for using an aluminum buffer which grabs the CFCC core securely.

Low Loss 27% Less Same Same

High Capacity More 120% More Same

Low Sag-Low Loss 9% Less Same 12% Less

*This figure depends on design

Low Sag-High Capacity More 103% More 10% Less and operating conditions.

ACSR

Low 27% Less

Loss

100A 90A 100A 93A

Dead End Clamp Mid Span Joint

*These pictures are for example purposes. Actual design to be decided by the customer's requirements.

ACSR

High Supply Scheme

Capacity 100A 200A

Tokyo Rope provides CFCC to local conductor producer which will make ACFR.

100A

Twice capacity using Reference

exsiting tower

Advisor: ACFR Design

Longer span Lower tower’s height Accessories Local

development

Low Reduction of total construction cost includig land,

foundation and tower.

Deduction of tower structual cost Conductor

Producer

Sag ACSR TOKYO ROPE Contractor

Transmission

Owner

Accessories

Producer

ACSR

Advisor: Accessories Installation Training

Conductor Stringing Training

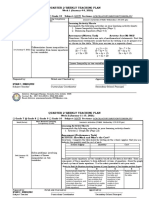

Standard ACFR Design Example

The following is standard ACFR Design Example. Final design should be agreed with the conductor's manufacturer.

Equivalent conventional ACSR Hawk Drake Curlew Bison Zebra

Type of design Low Loss Low Sag Low Loss Low Sag Low Loss Low Sag Low Loss Low Sag Low Loss Low Sag

Size 310/40 290/55 520/55 470/95 660/70 570/140 490/45 430/95 540/55 440/140

8/TW(4.44) 10/TW(3.97) 8/TW(4.82) 12/TW(3.90) 8/TW(4.13) 8/TW(4.38)

10/TW(3.88) 10/TW(5.01) 10/TW(4.75) 12/TW(4.46)

Aluminum No./mm

12/TW(4.43) 14/TW(3.98) 12/TW(4.83) 16/TW(3.90) 12/TW(4.14) 12/TW(4.38)

Stranding *1 14/TW(3.90) 14/TW(5.02) 14/TW(4.77) 16/TW(4.47)

18/TW(3.98) 16/TW(4.83) 20/TW(3.90) 16/TW(4.16) 16/TW(4.38)

Core No./mm 7/2.6 7/3.2 7/3.2 7/4.2 7/3.6 7/5.1 7/2.9 7/4.2 7/3.2 7/5.1

Rated Tensile Strength kN 95.15 135.47 147.44 228.03 186.39 331.05 126.63 225.66 148.48 324.22

Conductor mm 21.79 21.79 28.14 28.14 31.62 31.62 27.00 27.00 28.62 28.62

Diameter

Core mm 7.80 9.60 9.60 12.50 10.80 15.20 8.80 12.50 9.60 15.20

Conductor mm2 309 285 522 474 659 573 486 427 542 439

Cross Sectional Area Core mm2 37.2 56.3 56.3 95.4 71.3 141 47.3 95.4 56.3 141

Total mm2 346 342 578 570 730 714 533 523 599 580

Weight kg/km 917.3 884.6 1540.2 1461.0 1938.4 1811.0 1425.1 1331.1 1597.1 1437.1

DC Resistance at 20°C Ω/km 0.0910 0.0985 0.0539 0.0593 0.0426 0.0490 0.0578 0.0658 0.0518 0.0641

*2

at 75°C A 678 652 932 890 1074 1006 892 838 954 861

Current Carrying Capacity

at 175°C A 1250 1202 1748 1668 2032 1900 1668 1565 1791 1614

Conductor GPa 74.7 79.0 74.5 77.2 73.7 79.6 73.6 78.0 74.3 82.4

Modulus of Elasticity

Core GPa 130 135 135 123 126 127 131 123 135 127

Conductor ×10-6/ °C 18.9 16.8 19.1 17.1 19.3 16.1 19.5 16.7 19.2 14.7

Coefficient of Thermal Expansion

Core ×10-6/ °C 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Notes *1: TW(X.XX) stands for Trapezoidal Shaped Wires for which the equivalent outside diameter is X.XX mm.

*2: Current Carrying Capacity is solved using the Cigre Method.

Calculation Conditons: Ambient temperature: 35°C, Wind: 0.9 m/s, Wind direction: 45°, Solar radiation: 0.1 W/cm2,

Absorptivity and Emmisivity of conductor surface: 0.5, Frequency: 50 Hz, Sea level: 0m

CFCC Development History CFCC Advantage

CFCC core's development was started in the 1980s. Initially, CFCC was used for civil engineering CFCC core is uniquely stranded CFRP and has eight advantages:

applications. In 2002, Tokyo Rope supplied CFCC core to conductor partners which produce ACFR,

and since then, more than 10 years have passed with satisfactory operations. Non-magnetic No Iron Loss

Lightweight 1/5 of Steel

High Flexibility Can be wound to the small Drum

1980s Started development of CFCC

High Corrosion resistance Against acid, alkali, water and UV

1986 Supplied for PC Bridge project in Japan

High Tensile Fatigue Able to withstand wind vibration

2001 Supplied for PC Bridge project in Michigan/USA.

Small Thermal Expansion 1/10 of Steel (CFCC: 1.0×10-6; Steel : 11.5×10-6)

2002 Supplied for ACFR project in Japan High Modulus Superior to other FRP

2002 ACFR presentation in CIGRE* session 2002 Low Creep Similar to Steel

2007 Supplied for ACFR project in Korea

2011 Established Gamagori CFCC Plant in Japan

(First full-scale integrated CFCC factory.) Standard Characteristics

2012

Supplied for ACFR project in China Properties Item 1×7 7.8φ HT Type

2015 Tensile strength (kN/mm2) *1 2.14

Supplied for ACFR project in Indonesia General mechanical Tensile elastic modulus (kN/mm2) *1 130

2016

properties Elongation at break (%) 1.70

Established Michigan CFCC Plant in USA

(First overseas CFCC production facility.) Specific gravity 1.60

Relaxation (%) *2 1.3

*CIGRE is international council on Large Electric System Creep strain *3 0.07×10-3

Static properties Coefficient of linear expansion (×10-6/℃) *4 Less than 1

Specific resistance (µΩcm) 3,000

Creep failure load ratio *5 0.85

Fatigue capacity(Stress range) (N/mm2) *6 780

Bending stiffness (kN・cm2) 56.9

Others 175℃(Operating)

Heat resistance (℃)

200℃(Emergency)

Acid resistance Superior to steel

Alkaline resistance Almost the same as steel

*1: Calculated by nominal cross sectional area

*2: 0.7pu, 1000hrs(20±2℃), according to JSCE-E534.

*3: 0.6pu, 1000hrs(20±2℃)

*4: 20℃~200℃, according to JSCE-E536.

*5: Tests of CFCC 1×12.5φ according to JSCE-E533 “Test Method for Creep Failure of Continuous Fiber Reinforcing

Materials” gave a load ratio of 0.85 at 1 million hours.

Tendons of the prestressed concrete pier *6: Average load is 75% of breaking load. The number of cycles is 2×106, according to JSCE-E535.

(Partly used) pu: breaking load

“Excellent construction resistances”

Standard Specification of CFCC

Designation Nominal cross Breaking Nominal mass Tensile elastic

Diameter

(Configuration diameter) sectional area load density* modulus*

(mm) (mm2) (kN) (g/m) (kN/mm2)

U 5.0φ 5.0 19.6 41.9 30 135

1×7 6.8φ 6.8 28.2 60.3 45 122

1×7 7.8φ 7.8 37.2 79.5 61 130

Gamagori CFCC Plant Michigan CFCC Plant in USA 1×7 8.3φ 8.3 42.1 90.0 69 131

1×7 9.6φ 9.6 56.3 121 93 135

1×7 10.8φ 10.8 71.3 153 111 126

1×7 12.5φ 12.5 95.4 204 146 123

1×7 15.2φ 15.2 141 302 221 127

1×7 20.9φ 20.9 267 571 412 129

*Reference value

®

CARBON FIBER COMPOSITE CABLE

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Example Substation Insulation Coordination Study by ArresterWorksDocument21 paginiExample Substation Insulation Coordination Study by ArresterWorksqais652002100% (3)

- Gothic ArchitectureDocument6 paginiGothic ArchitectureleeÎncă nu există evaluări

- Transpowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-StrandedDocument18 paginiTranspowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-Strandedravi474Încă nu există evaluări

- RELATION AND FUNCTION - ModuleDocument5 paginiRELATION AND FUNCTION - ModuleAna Marie ValenzuelaÎncă nu există evaluări

- TL - Vol. IV - Tower ErectionDocument155 paginiTL - Vol. IV - Tower Erectionobayapalli100% (8)

- Data Structures and Algorithms SyllabusDocument9 paginiData Structures and Algorithms SyllabusBongbong GalloÎncă nu există evaluări

- Power Traction Transformers BrochureDocument12 paginiPower Traction Transformers BrochureDave Chaudhury100% (1)

- IEEE Lightning Protection For Switch YardDocument50 paginiIEEE Lightning Protection For Switch Yardelayaraja100% (19)

- Performance Evaluation Report For Practicum TraineesDocument2 paginiPerformance Evaluation Report For Practicum TraineesJ.S100% (3)

- (BS IEC - IEEE 62271-37-013) - High-Voltage Switchgear and Controlgear. Part 37-013. Alternating Current Generator Circuit-BreakersDocument215 pagini(BS IEC - IEEE 62271-37-013) - High-Voltage Switchgear and Controlgear. Part 37-013. Alternating Current Generator Circuit-Breakersravi474100% (2)

- Little: PrinceDocument18 paginiLittle: PrinceNara Serrano94% (18)

- Example Small Power Plant Lightning StudyDocument15 paginiExample Small Power Plant Lightning StudyyaoÎncă nu există evaluări

- Final Integrated Technical and ESIA TORs 050219 - 0Document22 paginiFinal Integrated Technical and ESIA TORs 050219 - 0ravi474Încă nu există evaluări

- Expansion Planning of Electricity Generating System Using The VALORAGUA and WASP-IV Models in NepalDocument7 paginiExpansion Planning of Electricity Generating System Using The VALORAGUA and WASP-IV Models in Nepalravi474Încă nu există evaluări

- 150Document4 pagini150RAFAEL CALVOÎncă nu există evaluări

- Campbell 2006Document7 paginiCampbell 2006ravi474Încă nu există evaluări

- Dcs 2076Document192 paginiDcs 2076ravi474100% (1)

- Transient Stability Events and ActionsDocument8 paginiTransient Stability Events and ActionsAnonymous xBi2FsBxÎncă nu există evaluări

- PD Detection by Uhf Method PDFDocument5 paginiPD Detection by Uhf Method PDFravi474Încă nu există evaluări

- Annex 1 66 KV Single Line DiagramDocument1 paginăAnnex 1 66 KV Single Line Diagramravi474Încă nu există evaluări

- Reactive Power FundamDocument24 paginiReactive Power FundamNaveedÎncă nu există evaluări

- Setting Up An Electrical Testing Laboratory PDFDocument36 paginiSetting Up An Electrical Testing Laboratory PDFravi474Încă nu există evaluări

- PEFA - Transient Stability - TransientStabilitymanual - 3-21 PDFDocument138 paginiPEFA - Transient Stability - TransientStabilitymanual - 3-21 PDFravi474Încă nu există evaluări

- Is 3070 3 1993 PDFDocument40 paginiIs 3070 3 1993 PDFAmey GudigarÎncă nu există evaluări

- PEFA - Transient Stability - TransientStabilitymanual - 3-21Document138 paginiPEFA - Transient Stability - TransientStabilitymanual - 3-21ravi474Încă nu există evaluări

- Switching Shunt Reactors 27 Jan 2011 PDFDocument6 paginiSwitching Shunt Reactors 27 Jan 2011 PDFJuan Rogger Llacza PorrasÎncă nu există evaluări

- CYME 82 PowerFlow EN V1-0 PDFDocument57 paginiCYME 82 PowerFlow EN V1-0 PDFravi474Încă nu există evaluări

- Switching Over Voltages (SOV) : TrainingDocument31 paginiSwitching Over Voltages (SOV) : TrainingVigneswaran KÎncă nu există evaluări

- 2.Mr. Sommai PDFDocument51 pagini2.Mr. Sommai PDFravi474Încă nu există evaluări

- Unplanned - Flows - in - The - CEE - Region - V4Study 01-2013Document41 paginiUnplanned - Flows - in - The - CEE - Region - V4Study 01-2013ravi474Încă nu există evaluări

- Techtopics44rev1 PDFDocument4 paginiTechtopics44rev1 PDFjoseÎncă nu există evaluări

- Temprecord International Ltd. IP Rating Information Sheet PDFDocument4 paginiTemprecord International Ltd. IP Rating Information Sheet PDFvineets058Încă nu există evaluări

- Sustainability 08 01333 PDFDocument9 paginiSustainability 08 01333 PDFravi474Încă nu există evaluări

- KumarsinhJhala2015 PDFDocument67 paginiKumarsinhJhala2015 PDFravi474Încă nu există evaluări

- OFWF Cooling SystemDocument6 paginiOFWF Cooling SystemashutoshÎncă nu există evaluări

- Mang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Document52 paginiMang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Anh Quân TrầnÎncă nu există evaluări

- Template Remarks For IIDocument18 paginiTemplate Remarks For IIjasleeneceÎncă nu există evaluări

- Sample Valuation ReportDocument15 paginiSample Valuation Reportayush singlaÎncă nu există evaluări

- EC105Document14 paginiEC105api-3853441Încă nu există evaluări

- UK Tabloids and Broadsheet NewspapersDocument14 paginiUK Tabloids and Broadsheet NewspapersBianca KissÎncă nu există evaluări

- Npad PGP2017-19Document3 paginiNpad PGP2017-19Nikhil BhattÎncă nu există evaluări

- GSM Radio ConceptsDocument3 paginiGSM Radio ConceptsMD SahidÎncă nu există evaluări

- Ccu 3900alDocument3 paginiCcu 3900alTourchianÎncă nu există evaluări

- Teaching Plan - Math 8 Week 1-8 PDFDocument8 paginiTeaching Plan - Math 8 Week 1-8 PDFRYAN C. ENRIQUEZÎncă nu există evaluări

- Ch04Exp PDFDocument17 paginiCh04Exp PDFConstantin PopescuÎncă nu există evaluări

- Online Shopping MallDocument17 paginiOnline Shopping MallMerin LawranceÎncă nu există evaluări

- EPSS 627: DescriptionDocument2 paginiEPSS 627: DescriptionudayakumartÎncă nu există evaluări

- Gummy Bear Story RubricDocument1 paginăGummy Bear Story Rubricapi-365008921Încă nu există evaluări

- Present Perfect Tense ExerciseDocument13 paginiPresent Perfect Tense Exercise39. Nguyễn Đăng QuangÎncă nu există evaluări

- Thesis Topics in Medicine in Delhi UniversityDocument8 paginiThesis Topics in Medicine in Delhi UniversityBecky Goins100% (2)

- Journal Articles: Types of JournalsDocument4 paginiJournal Articles: Types of JournalsOtieno SteveÎncă nu există evaluări

- Matokeo CBDocument4 paginiMatokeo CBHubert MubofuÎncă nu există evaluări

- Hot Rolled Coils Plates & SheetsDocument40 paginiHot Rolled Coils Plates & Sheetssreekanth6959646Încă nu există evaluări

- Bofa Turkish Banks-Back On The RadarDocument15 paginiBofa Turkish Banks-Back On The RadarexperhtmÎncă nu există evaluări

- Hansen Aise Im Ch12Document66 paginiHansen Aise Im Ch12Rizki19maretÎncă nu există evaluări

- 762id - Development of Cluster-7 Marginal Field Paper To PetrotechDocument2 pagini762id - Development of Cluster-7 Marginal Field Paper To PetrotechSATRIOÎncă nu există evaluări

- Operation of A CRT MonitorDocument8 paginiOperation of A CRT MonitorHarry W. HadelichÎncă nu există evaluări

- Modular ResumeDocument1 paginăModular ResumeedisontÎncă nu există evaluări

- Discover It For StudentsDocument1 paginăDiscover It For StudentsVinod ChintalapudiÎncă nu există evaluări

- Geography NotesDocument2 paginiGeography NotesMinethegroundÎncă nu există evaluări