Documente Academic

Documente Profesional

Documente Cultură

Consumption norms for cement, sand and aggregates

Încărcat de

schaktenDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Consumption norms for cement, sand and aggregates

Încărcat de

schaktenDrepturi de autor:

Formate disponibile

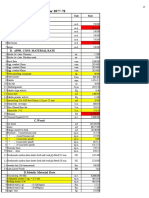

Consumption norms

Date:-8.6.05

Co-efficient of consumption of basic raw materials in cement consumption items for Estimation

Note :- No allowances has been made for bulking, handling & unavoidable wastage.

Sr.no. Description of works

A Concrete conventional mix Unit Cement Sand M-I M - II Admixer W /c

Bags / m3 Cft Cft Cft Milliliters Ratio

1 P.C.C.concrete mix 1:6:12 m3 2.19 16.42 16.42 16.42

2 P.C.C.concrete mix 1:5:10 m3 2.58 16.11 16.11 16.11

3 M10 ( 1: 4: 8 ) m3 3.39 16.95 16.95 16.95

4 M10 ( 1: 3: 6 ) m3 4.41 16.55 16.55 16.55

5 P.C.C.concrete mix 1:2.5:5 m3 5.30 16.55 16.55 16.55

6 P.C.C.concrete mix 1:3:4 m3 5.37 20.13 13.42 13.42

7 M15 ( 1: 2 : 4) m3 6.21 15.54 15.54 15.54

8 P.C.C.concrete mix 1:5/3:10/3 m3 7.42 15.45 15.45 15.45

9 M20 ( 1: 11/2 : 3) m3 8.02 15.03 15.03 15.03

10 M25 ( 1: 1 : 2 ) m3 11.19 13.99 13.99 13.99

B Cement sand grouting unit Cement G.sand

1 Cement sand grout mix 1:1 m3 20.48 25.60

2 Cement sand grout mix 1:1.5 m3 16.95 31.78

3 Cement sand grout mix 1:2 m3 13.59 33.99

4 Cement sand grout mix 1:3 m3 10.24 38.40

C Concrete ( Design mix ) Unit cement Sand M-I M - II Admixer W /c

Bags / m3 Liters Liters Liters Milliliters Ratio

Constituets for 1 bag cement

1 M10 ( 1: 4: 8 ) m3 3.18 120.00 60.00 65.00 0.00 0.70

2 M10 ( 1: 3: 6 ) m3 4.23 115.00 55.00 60.00 0.00 0.65

3 M15 ( design mix ) m3 6.00 110.00 50.00 55.00 250.00 0.60

4 M20 ( design mix ) m3 7.00 95.00 38.00 50.00 250.00 0.50

5 M25 ( design mix ) m3 7.32 90.00 35.00 45.00 300.00 0.45

6 M30 ( design mix ) m3 8.57 67.00 34.00 41.00 300.00 0.39

7 M35 ( design mix ) m3 9.15 60.00 34.00 41.00 400.00 0.37

8 M40 ( design mix ) m3 9.60 60.00 34.00 35.00 400.00 0.36

D Concrete with fly ash Unit Cement Sand M-I M - II Fly ash Admixer W /c

( Design mix ) Bags / m3 Liters Liters Liters Kg. Milliliters Ratio

Constituets for 1 bag cement

1 M10 ( 1: 4: 8 ) m3 2.54 151.20 75.60 81.90 13.00 0.00 0.70

2 M10 ( 1: 3: 6 ) m3 3.39 144.90 69.30 75.60 13.00 0.00 0.65

3 M15 ( design mix ) m3 5.25 107.34 47.22 71.83 22.00 250.00 0.35

4 M20 ( design mix ) m3 5.39 104.52 45.83 69.72 20.00 250.00 0.36

5 M25 ( design mix ) m3 5.66 100.00 50.00 59.86 17.00 300.00 0.37

6 M30 ( design mix ) m3 6.40 90.00 45.00 55.00 17.00 300.00 0.33

7 M35 ( design mix ) m3 6.70 80.00 45.00 55.00 17.00 400.00 0.31

8 M40 ( design mix ) m3 7.56 75.00 35.00 45.00 13.00 400.00 0.30

9 M50 ( design mix ) m3 9.00 54.00 34.00 40.00 13.00 570.00 0.30

Prepared by vinod 14/04/2006 Page 1

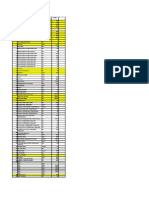

Consumption norms

Ordinry

E Masonry works Ratio Unit Cement Sand bricks Fly ash

4" brick masonry Bags M3 Nos. kg.

100 mm thk. Brick masonry

1 10mm thk. Joints 1:4 M2 0.12 0.02 55.00 (223x100x68)

100 mm thk. Brick masonry

2 10mm thk. Joints 1:5 M2 0.10 0.02 55.00

100 mm thk. Brick masonry

3 10mm thk. Joints 1:6 M2 0.08 0.02 55.00

100 mm thk. Brick masonry

4 12mm thk. Joints 1:4 M2 0.13 0.02 54.00

100 mm thk. Brick masonry

5 12mm thk. Joints 1:5 M2 0.11 0.02 54.00

100 mm thk. Brick masonry

6 12mm thk. Joints 1:6 M2 0.09 0.02 54.00

100 mm thk. Brick masonry 40% fly

6a 12mm thk. Joints 1:6 M2 0.054 0.02 54.00 1.80 ash by

100 mm thk. Brick masonry

7 15mm thk. Joints 1:4 M2 0.16 0.02 51.00

100 mm thk. Brick masonry

8 15mm thk. Joints 1:5 M2 0.13 0.02 51.00

100 mm thk. Brick masonry

9 15mm thk. Joints 1:6 M2 0.11 0.02 51.00

Ordinry

Ratio Unit Cement Sand bricks Fly ash

6" brick masonry Bags M3 Nos. kg.

150 mm thk. Brick Masonry

1 10mm thk. Joints 1:4 M2 0.13 0.02 42.00 (228x135x90)

150 mm thk. Brick Masonry

2 10mm thk. Joints. 1:5 M2 0.11 0.02 42.00

150 mm thk. Brick Masonry

3 10mm thk. Joints 1:6 M2 0.09 0.02 42.00

150 mm thk. Brick Masonry

4 12mm thk. Joints. 1:4 M2 0.15 0.02 41.00

150 mm thk. Brick Masonry

5 12mm thk. Joints. 1:5 M2 0.13 0.02 41.00

150 mm thk. Brick Masonry

6 12mm thk. Joints. 1:6 M2 0.11 0.02 41.00

150 mm thk. Brick Masonry 40% fly

6a 12mm thk. Joints. 1:6 M2 0.066 0.02 41.00 2.20 ash by

150 mm thk. Brick Masonry

7 15mm thk. Joints 1:4 M2 0.18 0.03 39.00

150 mm thk. Brick Masonry

8 15mm thk. Joints. 1:5 M2 0.15 0.03 39.00

150 mm thk. Brick Masonry

9 15mm thk. Joints 1:6 M2 0.13 0.03 39.00

10 230 mm thk. Brick masonry 1:5 M2 0.30 0.07 104.00

40% fly

10a 230 mm thk. Brick masonry 1:5 M2 0.18 0.07 104.00 6.00 ash by

General brick masonry (

11 230mm thk or above) 1:5 M3 1.76 0.39 529.00

General brick masonry ( 40% fly

11a 230mm thk or above) 1:5 M3 1.056 0.39 529.00 35.20 ash by

Prepared by vinod 14/04/2006 Page 2

Consumption norms

F Solid concrete block masonry Ratio Unit Cement Sand C. Blocks Fly ash

Bags M3 Nos. kg.

1 100mm concrete block masonry 1:4 M2 0.12 0.01 12.00

40% fly

1a 100mm concrete block masonry 1:4 M2 0.072 0.01 12.00 2.40 ash by

2 125mm concrete block masonry 1:4 M2 0.16 0.02 12.00

3 150mm concrete block masonry 1:4 M2 0.19 0.02 12.00

40% fly

ash by

3a 150mm concrete block masonry 1:4 M2 0.114 0.02 12.00 3.80 weight

Hollow concrete block H.c.

G masonry Ratio Unit Cement Sand blocks

Bags M3 Nos.

100mm thk. Hollow concrete

1 block masonry 1:4 M2 0.11 0.02 12.00

125mm thk. Hollow concrete

2 block masonry 1:4 M2 0.11 0.02 12.00

H Rubble masonry Ratio Units Cement Sand Rubbles Fly ash

Bags M3 M3 kg.

1 Coursed rubble masonry 1:5 M3 1.90 0.34 1.25

40% fly

1a Coursed rubble masonry 1:5 M3 1.14 0.34 1.25 38.00 ash by

2 Uncoursed rubble masonry 1:5 M3 1.80 0.43 1.30

40% fly

2a Uncoursed rubble masonry 1:5 M3 1.08 0.43 1.30 36.00 ash by

3 Ashlar masonry 1:6 M3 1.50 0.22 1.25

40% fly

3a Ashlar masonry 1:6 M3 0.90 0.22 1.25 30.00 ash by

Prepared by vinod 14/04/2006 Page 3

Consumption norms

Plaster

I Plaster works Thk. Ratio Unit Cement Sand neeru Fly ash

Bags M3 kg. kg.

1 Plaster 12mm 1:3 M2 0.14 0.02 1.90

15% fly

ash by

1a Plaster 12mm 1:3 M2 0.119 0.02 1.90 1.05 weight

2 Plaster 18mm 1:4 M2 0.18 0.02 1.90

15% fly

ash by

2a Plaster 18mm 1:4 M2 0.153 0.02 1.90 1.35 weight

3 Plaster 25mm 1:4 M2 0.23 0.03 1.90

15% fly

ash by

3a Plaster 25mm 1:4 M2 0.195 0.03 1.90 1.725 weight

Water

proofing

J Two coat sand face plaster Thk. Ratio Unit Cement Sand Fly ash compoun

Bags M3 kg.

1 1st coat 12mm 1:4 M2 0.12 0.02

15% fly

ash by

1a 1st coat 12mm 1:4 M2 0.102 0.02 0.90 weight

2 2nd coat 10mm 1:3 M2 0.13 0.01 1kg/bag

15% fly

ash by

2a 2nd coat 10mm 1:3 M2 0.11 0.01 0.97 weight

K Cement finished plaster 12mm 1:4 M2 0.32 0.02

( u.g.t.,o.h.t.,lift pit w.p. )

L Rough cast plaster Thk. Ratio Unit Cement Sand Pebbles

Bags M3

Backing coat 12mm 1:4 M2 0.15 0.01

Rough cast 1:3 0.17 0.00 0.01

.63m3 dry

mortar/

M Cement pointing Thk. Ratio Unit Cement Sand 100 m2

Bags M3

1 On 100 mm thk. Bk work 12mm 1:4 M2 0.036 0.005

2 On stone masonry 12mm 1:4 M2 0.046 0.007

3 On Block masonry 12mm 1:4 M2 0.027 0.004

Prepared by vinod 14/04/2006 Page 4

Consumption norms

White

N Flooring Ratio Unit Cement Sand cement Fly ash p.o.p.

Bags M3 Kg. kg. kg.

Bedding course+cement slurry avg bed

+cementation of joints. thk 2"

1 Mosaic , chequrred tiles 1:6 M2 0.264 0.055

50%fly

ash by

weight for

1a Mosaic , chequrred tiles 1:6 M2 0.182 0.055 4.10 bedding

2 Kotah 1:6 M2 0.264 0.055

50%fly

ash by

weight for

2a Kotah 1:6 M2 0.182 0.055 4.10 bedding

0.3 or

.011kg/rmt

3 Marble in grey cement 1:6 M2 0.264 0.055 jt.

50%fly

ash by

weight for

3a Marble in grey cement 1:6 M2 0.182 0.055 0.30 4.10 bedding

4 Marble in white cement 1:6 M2 0.164 0.055 5.30

50%fly

ash by

weight for

4a Marble in white cement 1:6 M2 0.082 0.055 5.30 4.10 bedding

5 Granite 1:6 M2 0.264 0.055

50%fly

ash by

weight for

5a Granite 1:6 M2 0.182 0.055 4.10 bedding

6 Ceramic , glazed, vitrified 1:6 M2 0.264 0.055 0.30

50%fly

ash by

weight for

6a Ceramic , glazed, vitrified 1:6 M2 0.182 0.055 0.30 4.10 bedding

7 p.o.p. for protection M2 2.10

White

O Skirting Ratio Unit Cement cement

C.paste Bags Kg.

1 4" h sktg fixing & grouting Rmt. 0.05 0.16

White

P Dado / clading works Ratio Unit Cement cement

C.paste Bags Kg.

1 On sand face plastered surface 6mmthk M2 0.22 0.54

2 Directly on bare surface M2 0.60 0.54

White Crazy

Q Crazy paving Ratio Unit Cement Sand cement paving

Bags M3 Kg. Kg.

1:4 M2 0.38 0.06 0.55 19.50

White China

R China mosaic Ratio Unit Cement Sand cement mosaic

Bags M3 Kg. Kg.

1:4 M2 0.38 0.06 0.55 13.50

Prepared by vinod 14/04/2006 Page 5

Consumption norms

S Brick bat water proofing

Ratio Unit Cement Sand Brick bats Or 4" bks

Bags M3 M3 Nos.

Cleaning ,grouting & applying

1 base coat 12mm thk. 1:4 M2 0.32 0.021 0.000 0.00

2 Brick bats 8" sunk (200mm) 1:4 M2 0.44 0.066 0.140 88.00

3 Brick bats 1' 6" sunk (450mm) 1:4 M2 1.00 0.140 0.315 197.00

4 Brick bats 1' 8" sunk (500mm) 1:4 M2 1.11 0.160 0.350 219.00

5 Brick bats 2' sunk (600mm) 1:4 M2 1.34 0.190 0.420 262.00

6 Finishing coat of b.b. (12mm) 1:3 M2 0.14 0.015 0.00 0.00

Terrace waterproofing

T ( average 125 mm thk.)

Ratio Unit Cement Sand Brick bats Or 4" bks

Bags M3 M3 Nos.

1 Cleaning& cement grouting M2 0.11 0.000 0.000 0.00

2 Brick bats 1:4 M2 0.30 0.033 0.088 55.00

3 Finishing coat of b.b. (12mm) 1:3 M2 0.14 0.02 0.00 0.00

U Box type water proofing Ratio Unit Cement Sand Metal

Floor Bags M3

1 Cleaning & cement grouting Slurry M2 0.11 0.00 0.00

Beddingcourse,cement slurry

fixing tiles & cementation of

2 joints 1:4 M2 0.30 0.050 0.00

3 Indian Patent Stone 50mm 1:2:4 M2 0.31 0.023 0.05

Wall

Backing coat

1 (on masonry surface) 1:4 M2 0.22 0.021 0.00

Cement

Fixing Stone & Cement slurry&

2 Grouting &Cementation of joints paste M2 0.35 0.00 0.00

3 Final cement finished plaster. 1:4 M2 0.32 0.021 0.00

Wastage considered for

Resources Estimation

purpose % wastage

1 cement 3

2 steel 5

3 Bricks 15

4 Metal 1 & 2 5

5 Sand 10

6 Rubble 10

7 Ceramic,vitrified tiles 7

8 Marble,cuddapa, granite 5

9 Italian Marble 12

Prepared by vinod 14/04/2006 Page 6

S-ar putea să vă placă și

- Material Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/MDocument5 paginiMaterial Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/Mjmarkunongo_69397286Încă nu există evaluări

- Aci 212.4R-93Document10 paginiAci 212.4R-93farhadamÎncă nu există evaluări

- Rate AnalysisDocument6 paginiRate AnalysisRaj BharathÎncă nu există evaluări

- Material Calculations Cement CalculationDocument6 paginiMaterial Calculations Cement CalculationKarthick KumaravelÎncă nu există evaluări

- Rate AnalysisDocument19 paginiRate AnalysisNikhil63% (8)

- Rate Analysis FormatDocument2 paginiRate Analysis FormatBheemm Bomjan Professional TrainerÎncă nu există evaluări

- Conversion FactorsDocument10 paginiConversion FactorsJohn MofireÎncă nu există evaluări

- Appendix G - Soldier Pile and Lagging Wall DesignDocument10 paginiAppendix G - Soldier Pile and Lagging Wall Designbusta299Încă nu există evaluări

- Analysis of Rates For C.C. Block M-30 Size 450x300x150m Minimum Cement 360 Kg. Per CumDocument13 paginiAnalysis of Rates For C.C. Block M-30 Size 450x300x150m Minimum Cement 360 Kg. Per Cumajay kunduÎncă nu există evaluări

- Rates For Diff ItemsDocument29 paginiRates For Diff ItemsMohanaÎncă nu există evaluări

- Thumb Rule To Calculate The Concrete Volume With Respect To AreaDocument4 paginiThumb Rule To Calculate The Concrete Volume With Respect To AreaGaurav ReddyÎncă nu există evaluări

- RATES For 2073-74: A. Approved Labour RateDocument40 paginiRATES For 2073-74: A. Approved Labour Rateक्षितिज चौलागाईंÎncă nu există evaluări

- Rate AnalyisDocument24 paginiRate Analyiskrishnashankar9_3743Încă nu există evaluări

- Cement Constant Latest - 2011Document7 paginiCement Constant Latest - 2011keshav1980100% (1)

- Cement Consumption Requirements for Construction ProjectsDocument4 paginiCement Consumption Requirements for Construction ProjectsAnonymous Qm0zbNkÎncă nu există evaluări

- Power Generation Installation GuideDocument30 paginiPower Generation Installation GuideAnonymous MDkp0hnb3l100% (8)

- Thumb Rules in Civil ConstructionDocument9 paginiThumb Rules in Civil ConstructionAnish Chandran100% (1)

- Material norms civil worksDocument5 paginiMaterial norms civil worksMANIKANDAN SelvamÎncă nu există evaluări

- Rates Analysis for Building WorksDocument8 paginiRates Analysis for Building WorksyogeshÎncă nu există evaluări

- Unit Price For Labor & Man PowerDocument4 paginiUnit Price For Labor & Man PowerARSEÎncă nu există evaluări

- Analysis of Rate S. No. Code Description Unit Quantity Rate Amount 1Document3 paginiAnalysis of Rate S. No. Code Description Unit Quantity Rate Amount 1Shashank Shekhar MishraÎncă nu există evaluări

- Rate Analysis: SL. No Labour/Material/Others Day Quatity/10m3 Rate Per Amount in RsDocument9 paginiRate Analysis: SL. No Labour/Material/Others Day Quatity/10m3 Rate Per Amount in Rsmuralidhar munireddyÎncă nu există evaluări

- Civil engineering guide for important pointsDocument21 paginiCivil engineering guide for important pointsVijay M100% (2)

- Labour EstimateDocument1 paginăLabour EstimateManasÎncă nu există evaluări

- MATERIAL QUANTITIES FOR CONCRETE, RENDERING, ROOFING, AND WALLSDocument5 paginiMATERIAL QUANTITIES FOR CONCRETE, RENDERING, ROOFING, AND WALLSjmarkunongo_69397286Încă nu există evaluări

- Rate AnalysisDocument21 paginiRate AnalysisMugahed Abdo Al-gahdariÎncă nu există evaluări

- Notes For Consumption For Varoius Civil Works: SL - NO. Unit Cement Consumption KG CUM BagsDocument3 paginiNotes For Consumption For Varoius Civil Works: SL - NO. Unit Cement Consumption KG CUM BagsSachidananda SahuÎncă nu există evaluări

- Sheet ValueDocument25 paginiSheet ValuesenthilÎncă nu există evaluări

- GP Build Karlapalem 01.03.17Document63 paginiGP Build Karlapalem 01.03.17Thota RevanthÎncă nu există evaluări

- Productivity CoefficientsDocument2 paginiProductivity CoefficientsApoorvaÎncă nu există evaluări

- IGBC Green Factory Building Rating SystemDocument82 paginiIGBC Green Factory Building Rating SystemRavish PatidarÎncă nu există evaluări

- Rate 2077-2078Document63 paginiRate 2077-2078क्षितिज चौलागाईंÎncă nu există evaluări

- Thumb Rules For Civil EngineersDocument12 paginiThumb Rules For Civil EngineersAvdhesh ChandraÎncă nu există evaluări

- The Revolutionary Bridges of Robert MaillartDocument8 paginiThe Revolutionary Bridges of Robert MaillartHamilton Reporter100% (1)

- Cement Consumption Norms for Construction ProjectsDocument4 paginiCement Consumption Norms for Construction ProjectsSyed Nizam ElahiÎncă nu există evaluări

- Deflection & Crack Width Check For Long Span BeamsDocument4 paginiDeflection & Crack Width Check For Long Span BeamsPrakash Singh RawalÎncă nu există evaluări

- Std. Civil DatasDocument316 paginiStd. Civil DatassujisonuÎncă nu există evaluări

- Manpower & Material Requirements of Civil Works.Document20 paginiManpower & Material Requirements of Civil Works.Bhavanishankar ShettyÎncă nu există evaluări

- Important Thumb Rules Used in Construction by Civil EngineersDocument5 paginiImportant Thumb Rules Used in Construction by Civil Engineersramesh_hinukaleÎncă nu există evaluări

- Abstract Estimate for Building Construction ItemsDocument3 paginiAbstract Estimate for Building Construction ItemsSravyaSreeÎncă nu există evaluări

- Rate Analysis - Finshing ItemsDocument52 paginiRate Analysis - Finshing ItemsRaghav Bhardwaj100% (1)

- Rate AnalysisDocument61 paginiRate Analysisvinoth100% (1)

- Material ListDocument36 paginiMaterial ListSachin PawarÎncă nu există evaluări

- Cement Sand and Aggregate For Nominal Mix Concrete GradesDocument7 paginiCement Sand and Aggregate For Nominal Mix Concrete GradesZakir Ali100% (5)

- S.N. Description Unit Current Rate Current Rate (Metric) A Civil MaterialDocument51 paginiS.N. Description Unit Current Rate Current Rate (Metric) A Civil MaterialNishan GajurelÎncă nu există evaluări

- Rate AnalysisDocument64 paginiRate Analysissachin_mate60% (5)

- Labour Output ConstantDocument14 paginiLabour Output ConstantJanesha100% (1)

- Labour Output ConstantDocument14 paginiLabour Output ConstantJanesha100% (1)

- ConsumptionDocument3 paginiConsumptionmilindk35100% (1)

- Useful Notes For Civil EngineerDocument8 paginiUseful Notes For Civil EngineerSathish KumarÎncă nu există evaluări

- Sreevatsa Real Estate cement adequacy guideDocument2 paginiSreevatsa Real Estate cement adequacy guidesivabuvanaÎncă nu există evaluări

- Rate Analysis Notes 3Document15 paginiRate Analysis Notes 3MADHU SUDAN H.N C-EÎncă nu există evaluări

- Building SSR 2019-20Document333 paginiBuilding SSR 2019-20NagabhushanamÎncă nu există evaluări

- The Capacity of Doing Work by An Artisan or Skilled Labour in The Form of Quantity of Work Per Day Is Known As The Task Work or Out Turn of The LabourDocument6 paginiThe Capacity of Doing Work by An Artisan or Skilled Labour in The Form of Quantity of Work Per Day Is Known As The Task Work or Out Turn of The LabourAyaaz KhanÎncă nu există evaluări

- Cement ConsuptionDocument1 paginăCement Consuptionjkg197350% (2)

- Design of Double Hull Tankers-GL Presentation May 2005Document42 paginiDesign of Double Hull Tankers-GL Presentation May 2005Mahdi100% (1)

- How To Use Rate Analysis of Brick Work Calculator Rate Analysis of Brick WorkDocument7 paginiHow To Use Rate Analysis of Brick Work Calculator Rate Analysis of Brick WorkM iqbalÎncă nu există evaluări

- Construction Method StatementDocument28 paginiConstruction Method Statementchu_viax100% (2)

- Chapter 4Document23 paginiChapter 4aileen eustaquioÎncă nu există evaluări

- Basic Formula and Unit CovertionDocument15 paginiBasic Formula and Unit CovertionBENÎncă nu există evaluări

- Bitumen Macadam Rate Analysis for MIHAN Warehouse ProjectDocument6 paginiBitumen Macadam Rate Analysis for MIHAN Warehouse Projectparth088Încă nu există evaluări

- Thumb Rules in Civil EngineeringDocument6 paginiThumb Rules in Civil EngineeringAdil ImtiazÎncă nu există evaluări

- Main Analysis of RatesDocument38 paginiMain Analysis of RatesSanjivKumarÎncă nu există evaluări

- Is Code 1200 - 11 Paving, Floor Finishing, Dado, SkirtingDocument11 paginiIs Code 1200 - 11 Paving, Floor Finishing, Dado, Skirtingamitkukna67% (3)

- Rate Analsis Chapter No 12 Wood WorkDocument329 paginiRate Analsis Chapter No 12 Wood WorkSarin100% (1)

- 12 Important Points For Civil Site Engineers - Civil StudentsDocument40 pagini12 Important Points For Civil Site Engineers - Civil Studentsvignesh kumar100% (1)

- RateAnalysis 22ndjanDocument412 paginiRateAnalysis 22ndjanYusuf You Can0% (1)

- House Estimation Excel SheetDocument17 paginiHouse Estimation Excel SheetKota Rajesh Reddy100% (1)

- Arulmigu Bavani Amman Thirukoil Periyapalayam EstimatessDocument158 paginiArulmigu Bavani Amman Thirukoil Periyapalayam EstimatessVignesh MÎncă nu există evaluări

- Manuali - 2, Tirane - 2015 (Draft1)Document326 paginiManuali - 2, Tirane - 2015 (Draft1)Alket DhamiÎncă nu există evaluări

- Grade of ConcreteDocument3 paginiGrade of ConcretesahaÎncă nu există evaluări

- All About ConcreteDocument5 paginiAll About ConcreteVikas GuptaÎncă nu există evaluări

- DrawingDocument9 paginiDrawingschaktenÎncă nu există evaluări

- DrawingDocument1 paginăDrawingschaktenÎncă nu există evaluări

- Indian Standards 1172.1993Document18 paginiIndian Standards 1172.1993Misama NedianÎncă nu există evaluări

- Provisional Fire NOC CertificateDocument2 paginiProvisional Fire NOC CertificateschaktenÎncă nu există evaluări

- 6x6 Sudoku Easy 5Document2 pagini6x6 Sudoku Easy 5LEE XIAO LING MoeÎncă nu există evaluări

- Nexus Project Solutions Private Limited Daily Progress ReportDocument1 paginăNexus Project Solutions Private Limited Daily Progress ReportschaktenÎncă nu există evaluări

- GST Council Extends Concessional 8% Rate to Affordable Housing ProjectsDocument3 paginiGST Council Extends Concessional 8% Rate to Affordable Housing ProjectsschaktenÎncă nu există evaluări

- PFD FileDocument4 paginiPFD FileschaktenÎncă nu există evaluări

- BusBar LiteratureDocument4 paginiBusBar LiteratureschaktenÎncă nu există evaluări

- 6x6 Sudoku Easy 5Document2 pagini6x6 Sudoku Easy 5LEE XIAO LING MoeÎncă nu există evaluări

- Inspection Report Book 14.04.12Document1 paginăInspection Report Book 14.04.12schaktenÎncă nu există evaluări

- GST Rates On Construction ServicesDocument3 paginiGST Rates On Construction ServicesschaktenÎncă nu există evaluări

- DL Is 814 Covered Electrodes For Manual Metal Arc WeldingDocument1 paginăDL Is 814 Covered Electrodes For Manual Metal Arc Weldingturbosri_mechÎncă nu există evaluări

- CED New IS16700 03012018Document2 paginiCED New IS16700 03012018schaktenÎncă nu există evaluări

- Pest PDFDocument2 paginiPest PDFschaktenÎncă nu există evaluări

- Microsoft Project For ConstructionDocument2 paginiMicrosoft Project For ConstructionschaktenÎncă nu există evaluări

- Indian Standard: Code of Practice For Prestressed ConcreteDocument64 paginiIndian Standard: Code of Practice For Prestressed ConcreteSupriyo PodderÎncă nu există evaluări

- Concretevibrators-Immersiontype - / ' Generalrequirements: Indian StandardDocument8 paginiConcretevibrators-Immersiontype - / ' Generalrequirements: Indian StandardschaktenÎncă nu există evaluări

- Hia Pestel PDFDocument11 paginiHia Pestel PDFschaktenÎncă nu există evaluări

- Pestle AnalysisDocument12 paginiPestle AnalysisTushar Kumar AgarwalÎncă nu există evaluări

- Indian Standard: Method of Measurement of Building and Civil Engineering WorksDocument8 paginiIndian Standard: Method of Measurement of Building and Civil Engineering Worksashwani053Încă nu există evaluări

- Cost Management Services IndiaDocument1 paginăCost Management Services IndiaschaktenÎncă nu există evaluări

- Is 269 2013Document13 paginiIs 269 2013schaktenÎncă nu există evaluări

- Building Load SheetDocument1 paginăBuilding Load SheetschaktenÎncă nu există evaluări

- Properties of Structural Materials: Chapter-2Document13 paginiProperties of Structural Materials: Chapter-2Kreepa TimsinaÎncă nu există evaluări

- Labor Rates PDFDocument1 paginăLabor Rates PDFfluret0% (1)

- Design of Rectangular Footing Col at Edge - 3Document27 paginiDesign of Rectangular Footing Col at Edge - 3Glenn SarneÎncă nu există evaluări

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 paginiEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiÎncă nu există evaluări

- Feasibility Study On Application of Ready Mix Concrete in Construction Projects in NepalDocument8 paginiFeasibility Study On Application of Ready Mix Concrete in Construction Projects in NepalAtul JaiswalÎncă nu există evaluări

- Bond Stress-Slip Response of Reinforcing Bars Embedded in FRC Matrices Under Monotonic and Cyclic LoadingDocument12 paginiBond Stress-Slip Response of Reinforcing Bars Embedded in FRC Matrices Under Monotonic and Cyclic LoadingpicottÎncă nu există evaluări

- 02DHIET - ARC 313 - Option - Advanced Structural Systems & Building Tech I - Lecture 1-2 PDFDocument10 pagini02DHIET - ARC 313 - Option - Advanced Structural Systems & Building Tech I - Lecture 1-2 PDFOmerta SpiritÎncă nu există evaluări

- Chapter 3 - Design of Tension and Compression Members PDFDocument84 paginiChapter 3 - Design of Tension and Compression Members PDFNiyibizi PromesseÎncă nu există evaluări

- Multi-Purpose Building Construction Project Backup ComputationDocument7 paginiMulti-Purpose Building Construction Project Backup ComputationMarc Dared CagaoanÎncă nu există evaluări

- Method of Statment For Internal Plaster Works t1Document7 paginiMethod of Statment For Internal Plaster Works t1Hytham El-NoubyÎncă nu există evaluări

- Cengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 1Document9 paginiCengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 1Benjamin EngelÎncă nu există evaluări

- Eqsv Unit 1Document61 paginiEqsv Unit 1SaikiranÎncă nu există evaluări

- Taguiling - Randell22@gmail - Com 2022-05-23 15-21-29 Refresher Masangkay StructuralDocument6 paginiTaguiling - Randell22@gmail - Com 2022-05-23 15-21-29 Refresher Masangkay StructuraldellcyberÎncă nu există evaluări

- Floor and Flat Based Puzzle Questions For IBPS RRB PO Prelims ExamDocument20 paginiFloor and Flat Based Puzzle Questions For IBPS RRB PO Prelims Exammilan mehta92% (12)

- Structural Analysis - WikipediaDocument10 paginiStructural Analysis - WikipediaEn Iyisi İnşaat MühendisiÎncă nu există evaluări

- Wallbond Crack Stitching PDFDocument2 paginiWallbond Crack Stitching PDFKevin BallÎncă nu există evaluări

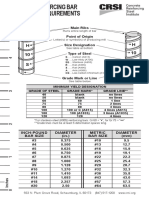

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Document2 paginiAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiÎncă nu există evaluări

- BOQ Sample For BOQ Magic ToolDocument38 paginiBOQ Sample For BOQ Magic Toolstimayo010809Încă nu există evaluări

- Dss - AssignmentDocument4 paginiDss - Assignmentapi-306484475Încă nu există evaluări

- Pile Foundation Basement: Main Types of PilesDocument1 paginăPile Foundation Basement: Main Types of PilesPranavÎncă nu există evaluări

- Block of 4 Flats Calculation Report 2Document152 paginiBlock of 4 Flats Calculation Report 2Isaac JosephÎncă nu există evaluări

- Structure II Model QuestionDocument51 paginiStructure II Model QuestionVictor Deb RoyÎncă nu există evaluări

- Baseline-Narrative ReportDocument15 paginiBaseline-Narrative ReportlightsonsÎncă nu există evaluări